High-strength ceramic substrate and preparation method and production line thereof

A ceramic substrate, high-strength technology, used in ceramic molding machines, ceramic molding workshops, manufacturing tools, etc., can solve problems such as low flexural strength, and achieve the effects of high flexural strength, uniform grains and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] High-strength ceramic substrate, made of ceramic powder, binder, dispersant, plasticizer and solvent, the weight ratio of the ceramic powder, binder, dispersant, plasticizer and solvent is 1:0.08 : 0.01: 0.03: 0.5; wherein the ceramic powder is composed of alumina powder and zirconia powder, and the content of zirconia powder in the ceramic powder is 3wt%.

[0034] The particle size of alumina in the ceramic powder is 0.5 μm, the particle size of zirconia is 0.1 μm, and the specific surface area of the ceramic powder is 5000 m 2 / kg; the solvent is composed of absolute ethanol and butanone, and the weight ratio of absolute ethanol and butanone is 1:1.

[0035] A method for preparing a high-strength ceramic substrate, comprising the following steps:

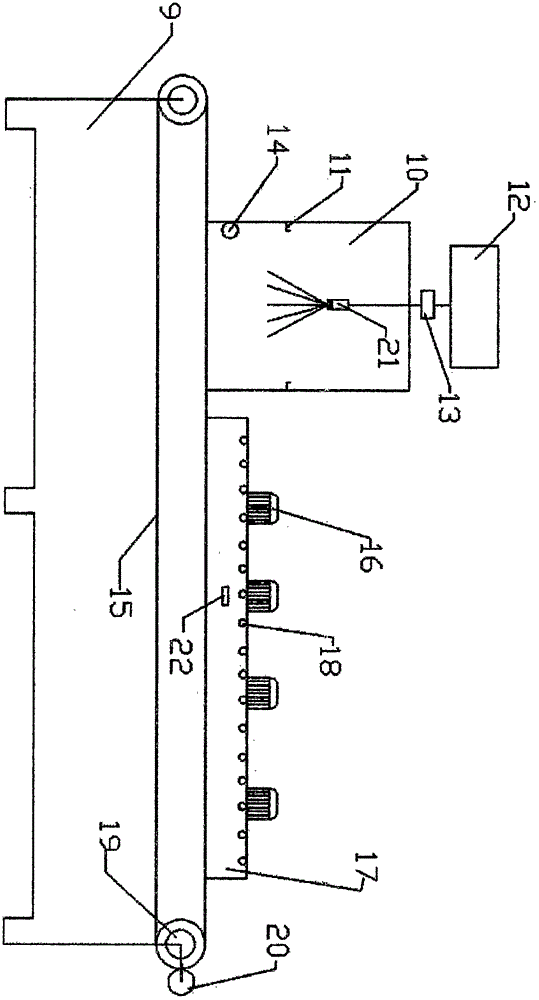

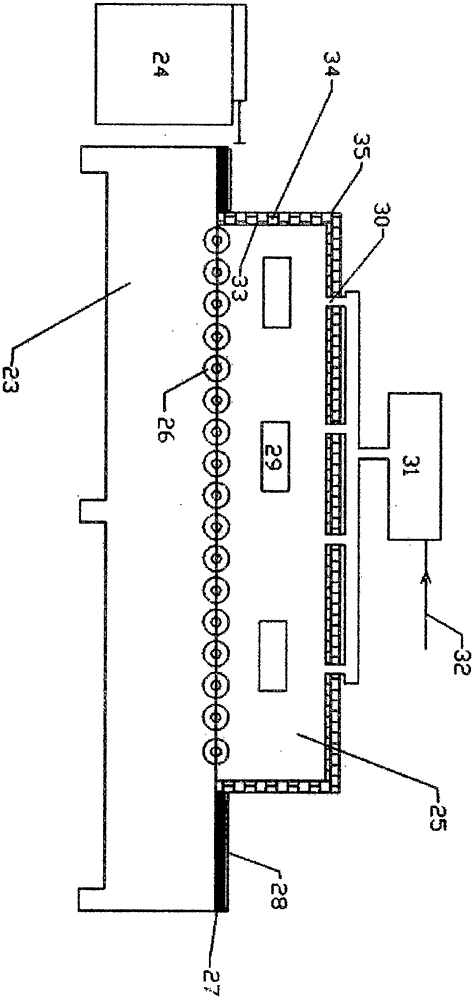

[0036] (1) Add ceramic powder, dispersant and part of solvent to ball mill 2 after ball milling for 8 hours, add the mixture of binder, plasticizer and the solvent of the remaining part mixed uniformly in premixer 1, con...

Embodiment 2

[0040] High-strength ceramic substrate, made of ceramic powder, binder, dispersant, plasticizer and solvent, the weight ratio of the ceramic powder, binder, dispersant, plasticizer and solvent is 1:0.15 : 0.03: 0.06: 0.8; wherein the ceramic powder is composed of alumina powder and zirconia powder, and the content of zirconia powder in the ceramic powder is 30wt%.

[0041] The particle size of alumina in the ceramic powder is 2.0 μm, the particle size of zirconia is 0.5 μm, and the specific surface area of the ceramic powder is 3000 m 2 / kg; the solvent is composed of absolute ethanol and butanone, and the weight ratio of absolute ethanol and butanone is 1: 1.5.

[0042] A method for preparing a high-strength ceramic substrate, comprising the following steps:

[0043] (1) After adding ceramic powder, dispersant and part of solvent to ball mill 2 for ball milling for 10 hours, add the mixture of binder, plasticizer and the solvent of the remaining part mixed uniformly in pre...

Embodiment 3

[0047] High-strength ceramic substrate, made of ceramic powder, binder, dispersant, plasticizer and solvent, the weight ratio of the ceramic powder, binder, dispersant, plasticizer and solvent is 1:0.1 : 0.02: 0.05: 0.6; wherein the ceramic powder is composed of alumina powder and zirconia powder, and the content of zirconia powder in the ceramic powder is 10wt%.

[0048] The particle size of alumina in the ceramic powder is 1.0 μm, the particle size of zirconia is 0.3 μm, and the specific surface area of the ceramic powder is 4000 m 2 / kg; the solvent is composed of absolute ethanol and butanone, and the weight ratio of absolute ethanol and butanone is 1: 1.2.

[0049] A method for preparing a high-strength ceramic substrate, comprising the following steps:

[0050] (1) Add the ceramic powder, dispersant and part of the solvent into the ball mill 2 for ball milling for 9 hours, then add the mixture of the binder, plasticizer and the remaining part of the solvent mixed unif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com