Anti-radiation dry-mixed mortar and preparation method thereof

A dry powder mortar and anti-radiation technology, which is applied in the field of building materials, can solve the problems that the mechanical properties are not fully exerted, the anti-cracking effect of the fiber mortar is detached, and the anti-radiation mortar is delaminated, so as to achieve good anti-radiation performance and mechanical properties. , improve performance, improve the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Correspondingly, the present invention also provides a preparation method of radiation-proof dry powder mortar, comprising the following steps: mixing 25-32 parts by weight of cement, 40-70 parts by weight of barite sand, 2-33 parts by weight of yellow sand and 0.5-2 parts by weight Mixing parts of admixture, adding iron-boron nano-alloy fiber, stirring for 20-30 minutes, adding plastic-steel fiber, and then adding Dura fiber during stirring to obtain radiation-proof dry powder mortar, the iron-boron nano-alloy fiber, plastic-steel fiber and Dura The sum of fibers is 1.3-2.3 parts by weight.

[0029] During the preparation process, since the iron-boron nano-alloy fibers are uniformly distributed in random directions, a virtual metal mesh will be formed, which can have a certain radiation protection function. Therefore, in order to make the fibers uniformly distributed in the mortar, the First add the metal nano-alloy fiber and stir for 20-30 minutes. Since Dura fiber i...

Embodiment 1

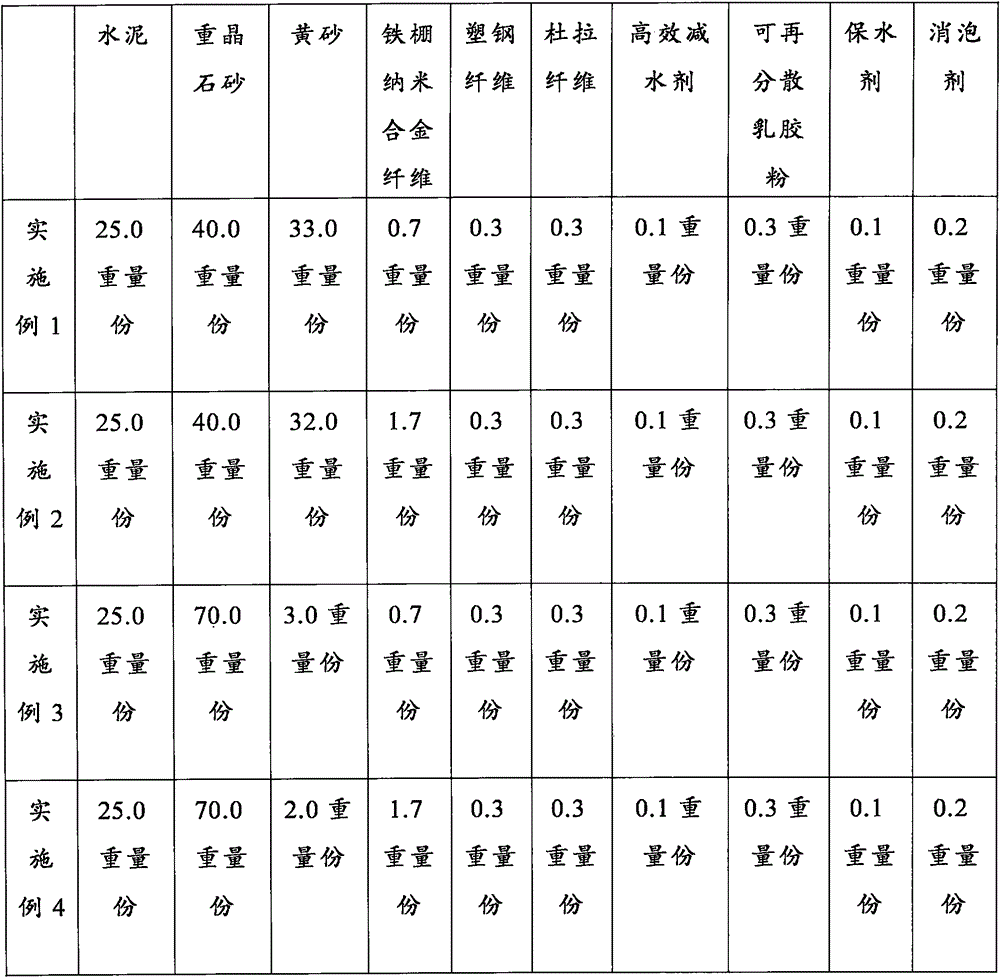

[0041] According to the raw materials and proportions shown in Table 1, mix cement, barite sand, yellow sand, high-efficiency water reducer, redispersible latex powder, water retention agent and defoamer, add iron-boron nano-alloy fiber, and stir for 20- After 30 minutes, add plastic steel fiber, and then add Dura fiber during stirring to obtain radiation-proof dry powder mortar.

[0042] The raw material and proportioning that table 1 embodiment of the present invention 1-3 adopts

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com