Purification method of gas purging sample and batch purification method thereof

A purification method and gas purging technology, applied in the field of chemical analysis, can solve problems such as easily damaged gaskets, and achieve the effect of preventing contamination, reducing the possibility, suitable length and position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

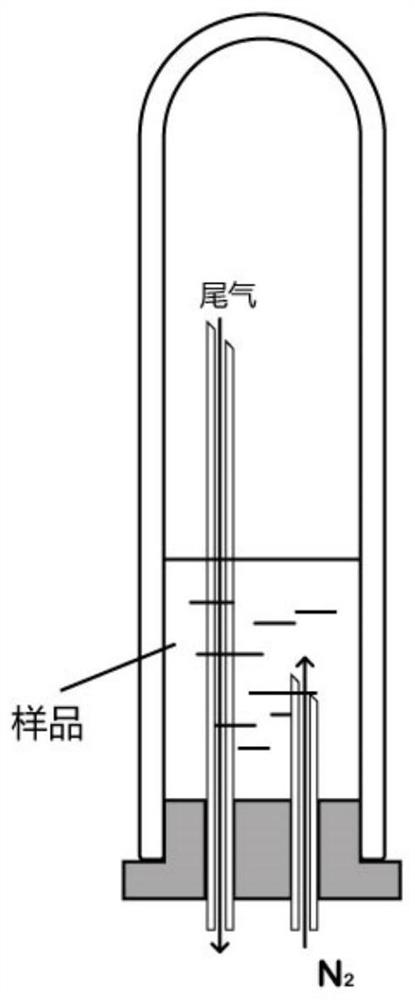

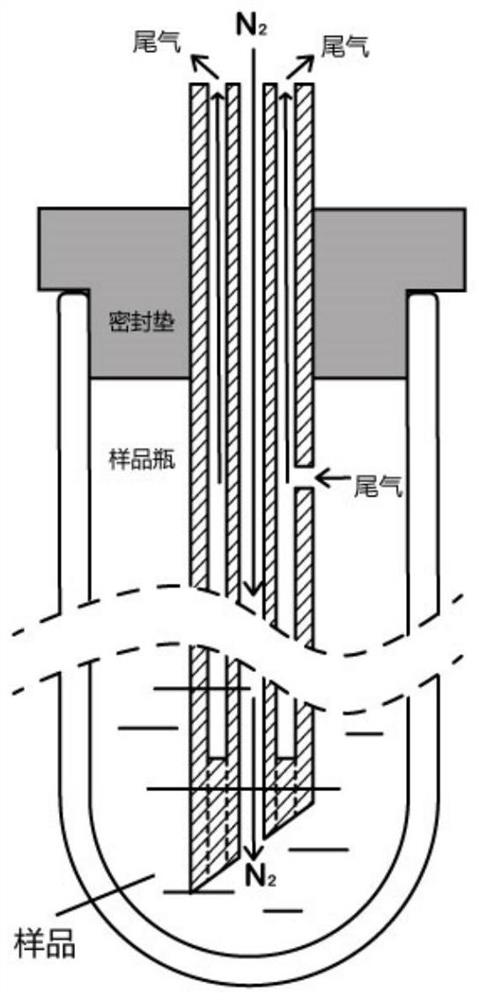

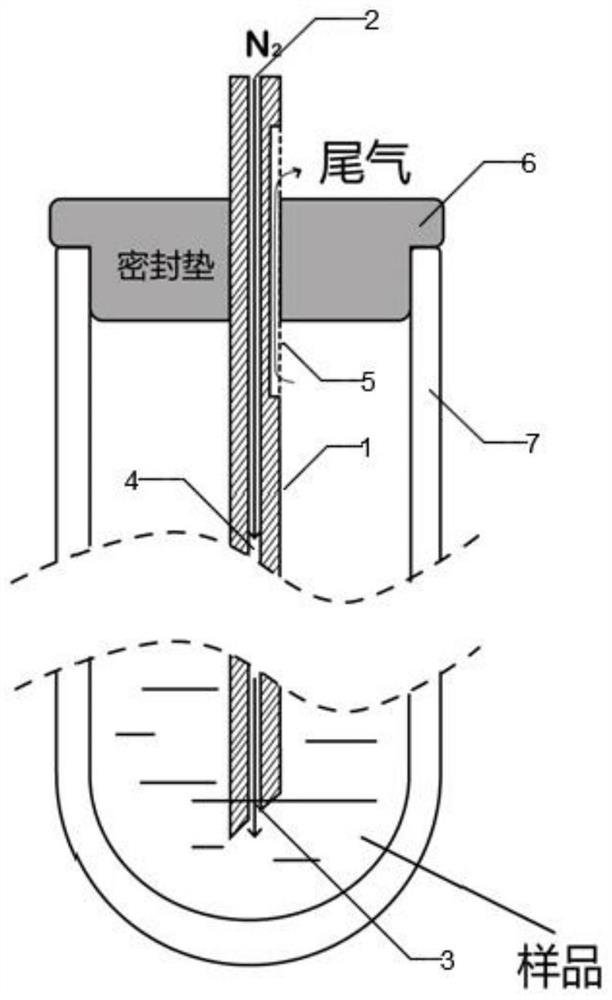

[0049] A method for purging a sample with gas, comprising the steps of:

[0050] Step 1, insert one or more of the purification needles on the sealing gasket 6 on the top of the sample bottle 7, the needle tip of the needle body 1 enters below the liquid surface, and the bottom of the air tank 5 extends into the sealing gasket 6, the top protrudes above the sealing gasket 6; when the sample bottle 7 is purged by a single gas purging sample purification needle, the loss of the sealing gasket 6 can be reduced;

[0051] Step 2, pass the purge gas through the inlet 2, and the tail gas containing impurities is discharged from the sample bottle 7 through the gas tank 5 until the impurity gas in the sample bottle 7 is completely discharged; the purging time of this step is generally 10 to 180 Minutes, determined according to purification requirements and purge flow)

[0052] Step 3, maintain the passage of purge gas, prevent air (or other impurity gas) from flowing back through the ...

Embodiment 2

[0060] An automatic batch purification method based on the purification method, comprising the following steps:

[0061] Step S1, press as Figure 5 As shown, 48 purification needles are fixed in a 6*8 matrix on the air outlet 18 at the bottom of the air needle shunt module 10 through the air needle joint, the joint is sealed, and the purification needle passes through the guide on the needle guide plate 12. hole 14;

[0062] Press as Figure 5 As shown, 48 sample vials 7 are placed on the sample holder 9 in a 6*8 matrix.

[0063] Step S2, finally put the sample holder 9 into the fixing groove 23 of the lower positioning plate 11 to fix it;

[0064] Step S3, such as Figure 6 As shown, the nitrogen bottle is connected to the purge gas inlet 16 of the intake module 15, the interface is sealed, and the nitrogen bottle is opened. The nitrogen gas is divided into 8 paths through the intake module 15, and enters the gas needle shunt module 10 after the flow rate is controlled b...

Embodiment 3

[0073] The automatic batch purification method described in Example 2 is completed through the execution system of gas purging sample purification, and the execution system includes a positioning frame, a driving device 8, a sample holder 9, and a gas needle splitting module 10, wherein:

[0074] The positioning frame includes a lower positioning plate 11, a needle guide plate 12, and an upper positioning plate 13 arranged sequentially from bottom to top, and the air needle shunting module 10 is located between the upper positioning plate 13 and the needle guide plate 12 , the bottom of the gas needle shunting module 10 is fixed with the purification needles arranged in a matrix as described in embodiment 1, and the purge gas enters each purification needle respectively after passing through the gas needle shunting module 10;

[0075] The needle guide plate 12 is provided with guide holes 14 arranged in a matrix, and the bottom of the purification needle passes through the corr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com