Production process of aluminum alloy gutter profile

A production process, aluminum alloy technology, applied in the production process field of aluminum alloy gutter profiles, can solve problems such as lack of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

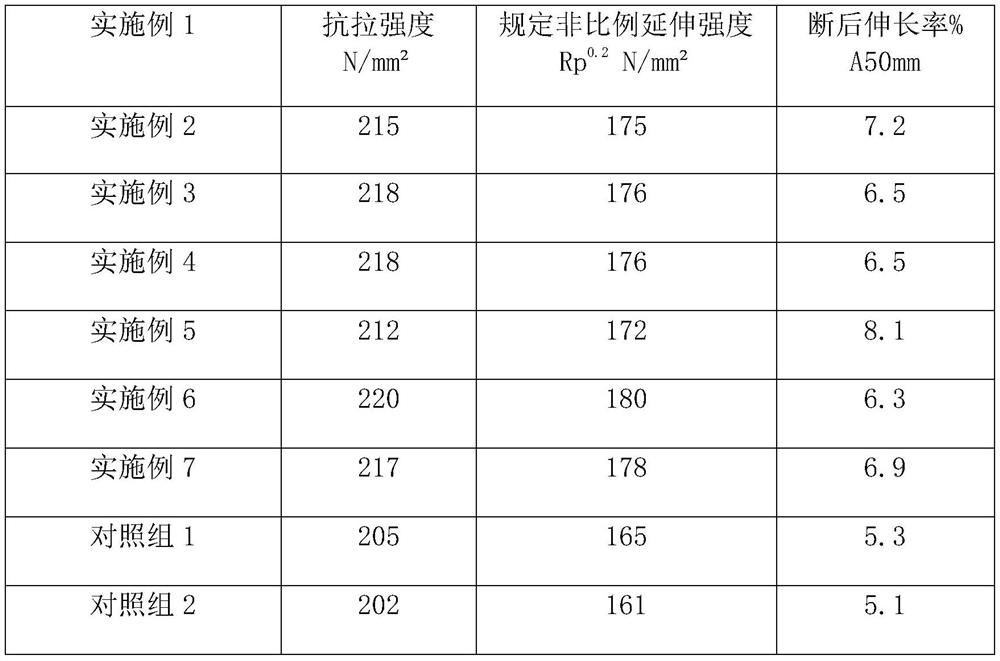

Examples

Embodiment 1

[0015] S1, the ingot casting process, the aluminum ingot is melted and poured into the mold to form a bar

[0016] S2. Preliminary heat treatment process, heating the bar to 580°C, then keeping it warm for 3 hours, and cooling it quickly to 25°C by spraying water mist after it is released from the furnace;

[0017] S3. Extrusion molding process, the bar is extruded through the extruder equipment, the bar is heated to 475°C, the temperature of the extrusion barrel of the extruder is 400°C, the temperature of the forming die is 465°C, and the extrusion speed is controlled at 7m / min;

[0018] S4, stretching and straightening process, the stretching deformation rate is controlled to 1%;

[0019] S5, the quenching process, adopts the online quenching method;

[0020] S6, aging treatment process, heating to 190° C. and holding for 2 hours to obtain the final product.

Embodiment 2

[0022] S1, the ingot casting process, the aluminum ingot is melted and poured into a mold to form a bar;

[0023] S2. Preliminary heat treatment process, heating the bar to 595°C, then keeping it warm for 6 hours, and cooling it quickly to 30°C by spraying water mist after it is released from the furnace;

[0024] S3. Extrusion molding process, the bar is extruded through the extruder equipment, the bar is heated to 495°C, the temperature of the extrusion barrel of the extruder is 420°C, the temperature of the forming die is 485°C, and the extrusion speed is controlled at 8m / min;

[0025] S4, stretching and straightening process, the stretching deformation rate is controlled at 2%;

[0026] S5, the quenching process, adopts the online quenching method;

[0027] S6, the aging treatment process, heating to 200° C. and keeping it warm for 3 hours to obtain the final product.

Embodiment 3

[0029] S1, the ingot casting process, the aluminum ingot is melted and poured into a mold to form a bar;

[0030] S2. Preliminary heat treatment process, heating the bar to 585°C, then keeping it warm for 4 hours, and cooling it quickly to 27°C by spraying water mist after it is released from the furnace;

[0031] S3. Extrusion molding process, the bar is extruded through the extruder equipment, the bar is heated to 485°C, the temperature of the extrusion barrel of the extruder is 410°C, the temperature of the forming die is 475°C, and the extrusion speed is controlled at 8m / min;

[0032] S4, stretching and straightening process, the stretching deformation rate is controlled at 1.5%;

[0033] S5, the quenching process, adopts the online quenching method;

[0034] S6, the aging treatment process, heating to 195° C. and keeping the temperature for 2.5 hours to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com