Carbon fiber reinforced polyethylene waterproof roll and preparation method thereof

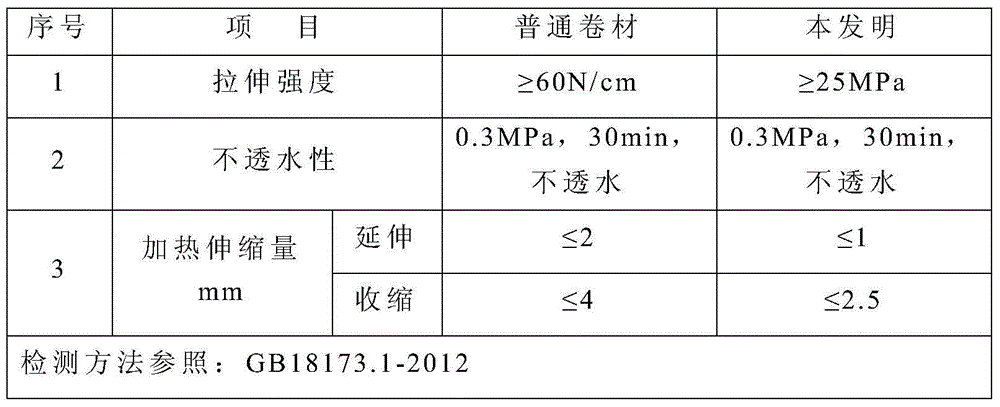

A technology of waterproof membrane and carbon fiber, which is applied in the field of waterproof building materials, can solve the problems of material elongation attenuation, weak lamination of fiber cloth and polyethylene sheet, low strength, etc., and achieves simple preparation process and low comprehensive cost. , the effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

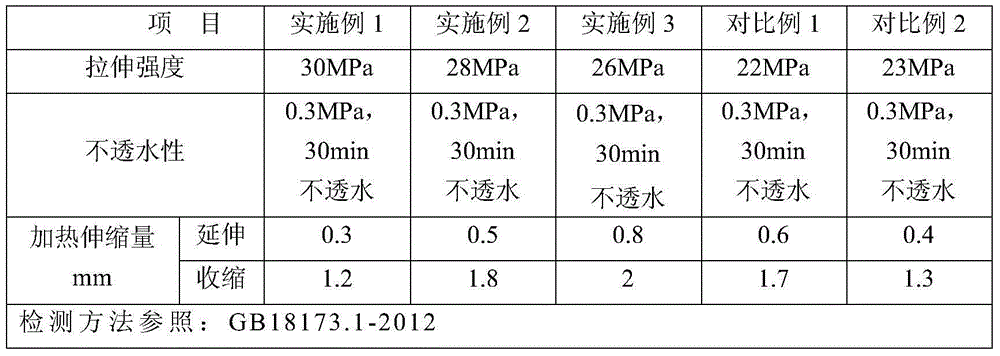

Embodiment 1

[0024] Mix ingredients 1 consisting of DFDA-704260 parts of linear low-density polyethylene resin (LLDPE) particles, 40 parts of 6mm chopped carbon fiber, 10100.1 parts of antioxidant, and 0.1 part of white oil 26# in a low-speed mixer for 5 minutes. The cold and hot cutting process is granulated in a 75-type twin-screw extruder. The temperature control of each zone of the extruder during the granulation process is: zone 1: 190°C, zone 2: 205°C, zone 3: 205°C, zone 4: 215°C , Zone five: 210°C, when the temperature in each zone reaches the control requirements, keep warm for 30 minutes, carry out granulation and extrusion, and then mix 97 parts of granulation products, 3 parts of carbon black, 0.1 part of antioxidant, and 0.1 part of white oil. After mixing, plasticize on the single-screw extruder. During the plasticizing process, the temperature control of each zone of the extruder is as follows: Zone 1: 195°C, Zone 2: 205°C, Zone 3: 205°C, Zone 4: 210°C, Zone 5 : 210 ℃, six z...

Embodiment 2

[0026] Mix ingredients 1 consisting of DFDA-704280 parts of linear low-density polyethylene resin (LLDPE) particles, 20 parts of 6mm chopped carbon fiber, 10100.1 parts of antioxidant, and 0.1 part of white oil 26# in a low-speed mixer for 3 minutes, and use wind The cold and hot cutting process is granulated in a 75-type twin-screw extruder. The temperature control of each zone of the extruder during the granulation process is: zone 1: 185°C, zone 2: 200°C, zone 3: 200°C, zone 4: 210°C , five zones: 205°C, when the temperature in each zone reaches the control requirements, keep warm for 30 minutes, carry out granulation extrusion, and then mix the ingredients consisting of 96 parts of granulation products, 4 parts of carbon black, 0.1 part of antioxidant, and 0.1 part of white oil After mixing, plasticize on the single-screw extruder. During the plasticizing process, the temperature control of each zone of the extruder is as follows: Zone 1: 190°C, Zone 2: 205°C, Zone 3: 205°C...

Embodiment 3

[0028]Mix ingredients 1 consisting of DFDA-704290 parts of linear low-density polyethylene resin (LLDPE) particles, 10 parts of 6mm chopped carbon fiber, 10100.2 parts of antioxidant, and 0.1 part of white oil 26# in a low-speed mixer for 3 minutes. The cold and hot cutting process is granulated in a 75-type twin-screw extruder. The temperature control of each zone of the extruder during the granulation process is: zone 1: 180°C, zone 2: 195°C, zone 3: 195°C, zone 4: 205°C , five zones: 200°C, when the temperature in each zone reaches the control requirements, keep warm for 35 minutes, carry out granulation extrusion, and then mix the ingredients consisting of 95 parts of granulation product, 5 parts of carbon black, 0.1 part of antioxidant, and 0.2 part of white oil After mixing, plasticize on the single-screw extruder. During the plasticizing process, the temperature control of each zone of the extruder is as follows: Zone 1: 185°C, Zone 2: 200°C, Zone 3: 200°C, Zone 4: 205°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com