High-strength heat-conductive plastic and preparation method thereof

A heat-conducting plastic, high-strength technology, applied in the field of plastics, can solve the problems of low strength and poor impact resistance, and achieve the effects of high mechanical strength, good cold deformation performance, and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

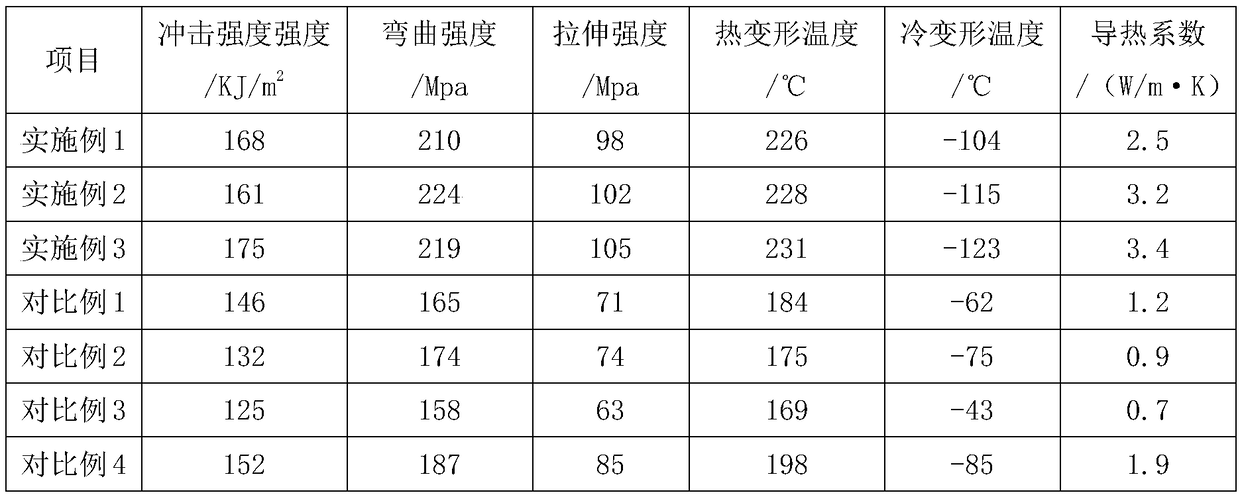

Examples

Embodiment 1

[0021] A high-strength thermally conductive plastic, the high-strength thermally conductive plastic includes the following raw materials in parts by weight: 65 parts of unsaturated polyester, 11 parts of 2,3,6,7-tetracarboxylic dianhydride triptycene, 2,4- 10 parts of diaminodiphenylmethane, 3 parts of 4,4-dichlorodiphenylsulfone, 4 parts of zinc dioxide, 5 parts of citric acid, and 6 parts of green algae.

[0022] A preparation method of a high-strength thermally conductive plastic, comprising the following steps: (1) mixing 2,3,6,7-tetracarboxylic dianhydride triptycene and 2,4-diaminodiphenylmethane, placing the mixture at 85°C Stir and react for 3 hours to obtain mixture A; (2) then cool the result of the previous step to 60°C, add 4,4-dichlorodiphenyl sulfone and 20 parts of 75% ethanol solution, and continue stirring for 1 hour to obtain a mixture B; (3) Mix zinc dioxide, citric acid and green algae, add 10 parts of water, place at 80°C and stir for 20 minutes to obtain ...

Embodiment 2

[0024] A high-strength thermally conductive plastic, the high-strength thermally conductive plastic includes the following raw materials in parts by weight: 80 parts of unsaturated polyester, 15 parts of 2,3,6,7-tetracarboxylic dianhydride triptycene, 2,4- 15 parts of diaminodiphenylmethane, 7 parts of 4,4-dichlorodiphenyl sulfone, 8 parts of zinc dioxide, 10 parts of citric acid, and 10 parts of green algae.

[0025] A preparation method of a high-strength thermally conductive plastic, comprising the following steps: (1) mixing 2,3,6,7-tetracarboxylic dianhydride triptycene and 2,4-diaminodiphenylmethane, placing the mixture at 90°C Stir and react for 5 hours to obtain mixture A; (2) Then cool the result of the previous step to 70°C, add 4,4-dichlorodiphenyl sulfone and 30 parts of 75% ethanol solution, continue to stir and react for 2 hours to obtain a mixture B; (3) Mix zinc dioxide, citric acid and green algae, add 30 parts of water, place at 90°C and stir for 30 minutes t...

Embodiment 3

[0027] A high-strength thermally conductive plastic, the high-strength thermally conductive plastic includes the following raw materials in parts by weight: 75 parts of unsaturated polyester, 13 parts of 2,3,6,7-tetracarboxylic dianhydride triptycene, 2,4- 13 parts of diaminodiphenylmethane, 6 parts of 4,4-dichlorodiphenylsulfone, 6 parts of zinc dioxide, 7 parts of citric acid, and 8 parts of green algae.

[0028] A preparation method of a high-strength heat-conducting plastic, comprising the following steps: (1) mixing 2,3,6,7-tetracarboxylic dianhydride triptycene and 2,4-diaminodiphenylmethane, placing the mixture at 88°C The reaction was stirred for 4h to obtain mixture A. (2) Then cool the product obtained in the previous step to 65° C., add 4,4-dichlorodiphenyl sulfone and 26 parts of 75% ethanol solution, and continue stirring for 1.6 hours to obtain mixture B. (3) Mix zinc dioxide, citric acid and green algae, add 20 parts of water, place at 85° C. and stir for 26 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com