Double-layer stainless steel composite thin plate and its processing method

A technology of stainless steel plate and composite thin plate, which is applied in the direction of metal processing equipment, chemical instruments and methods, layered products, etc., can solve the problems of no technical reports, welding problems and unfavorable cold rolling process, etc., to solve the problem of reprocessing, The processing method is simple and the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

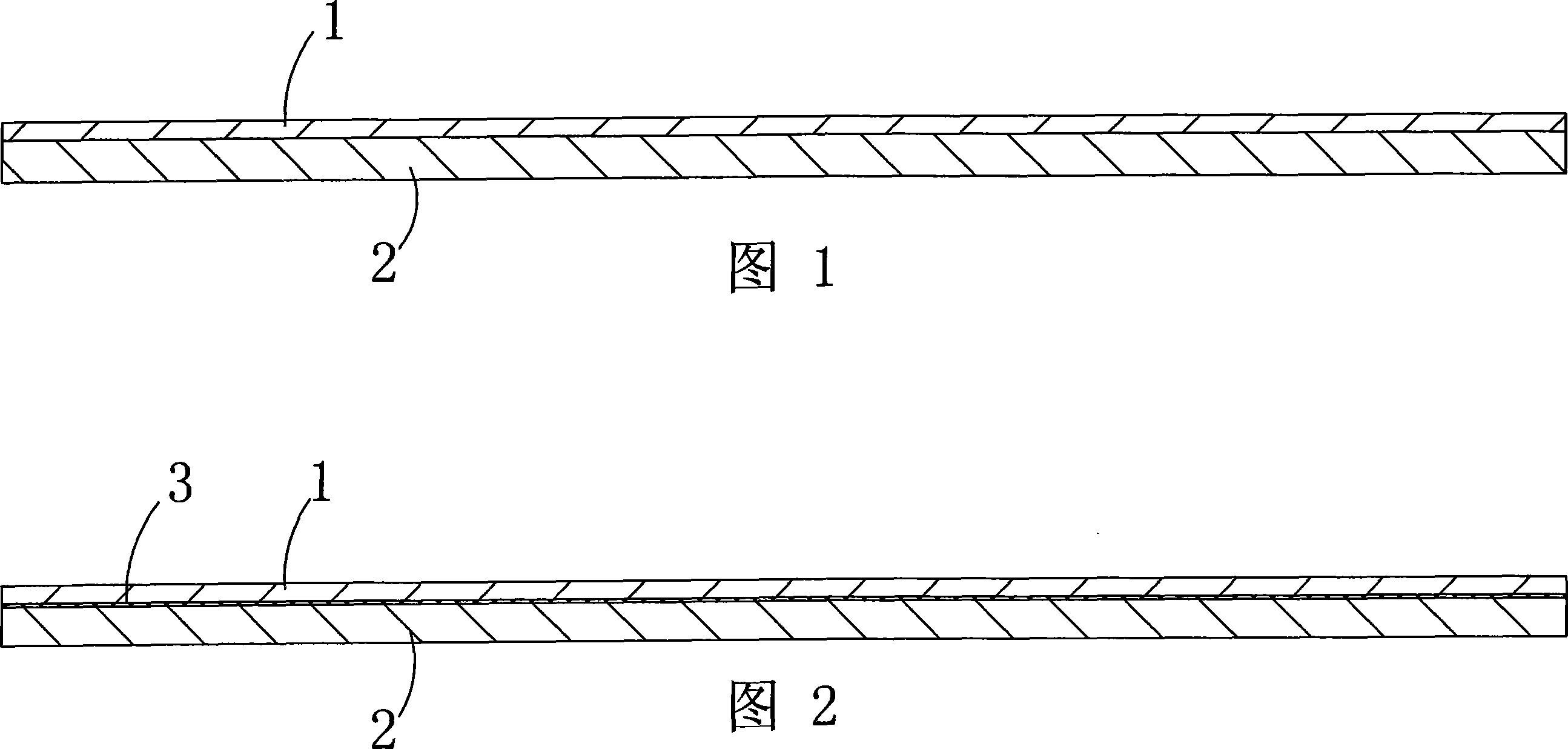

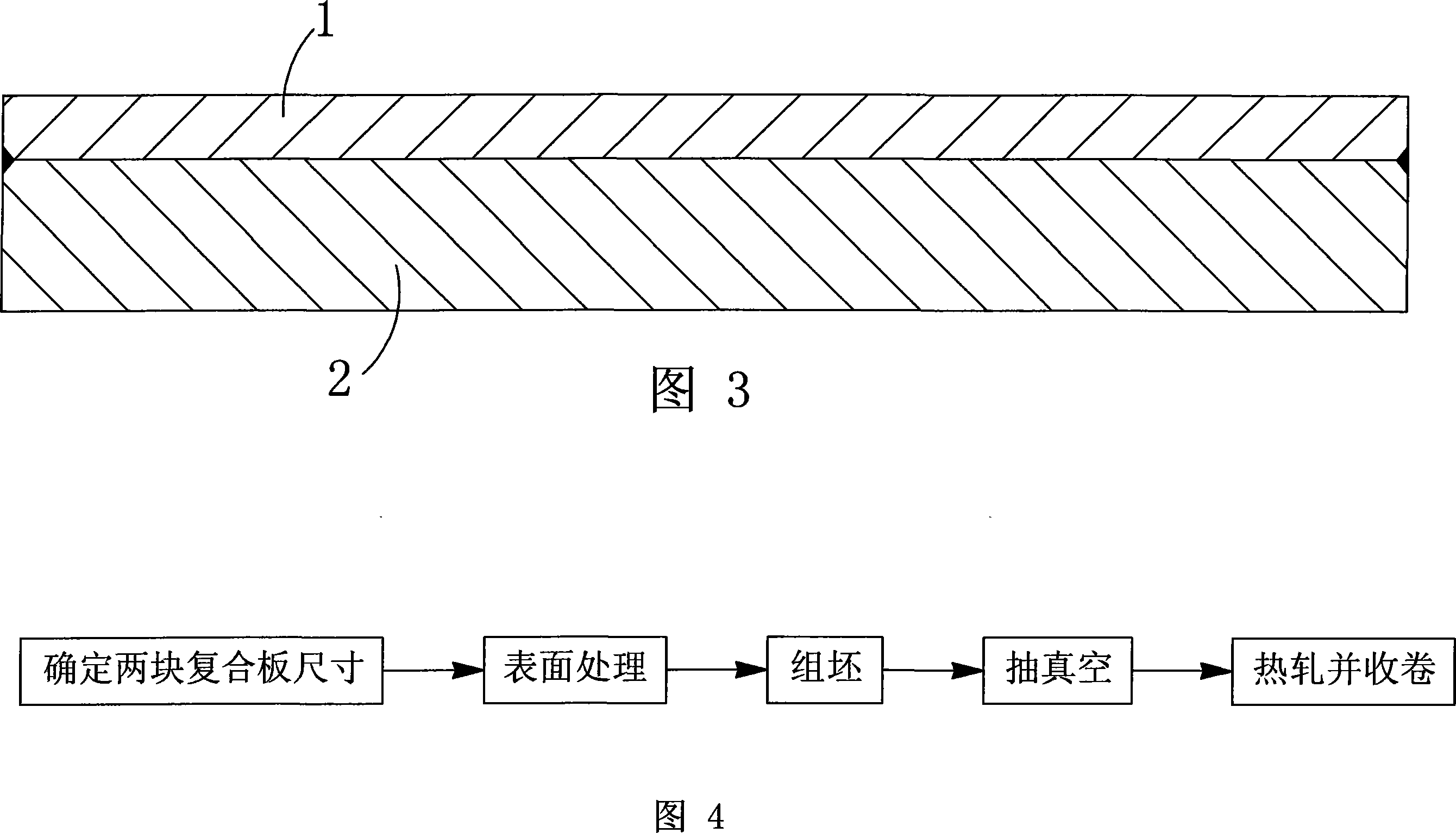

[0028] Referring to Figure 1 and Figure 3, a double-layer stainless steel composite thin plate with a width of 1219mm and a thickness of 3mm is manufactured. The thickness of the base stainless steel plate is 2.5mm, and the back of the clad stainless steel plate is 0.5mm. The base stainless steel plate is 201 stainless steel with a size of 1219×2440×225mm Plate 1, 1219×2440×45mm 304 stainless steel plate 2 is used for the multi-layer stainless steel plate. According to the method of forming blanks without brazing materials, the surfaces of the two stainless steel plates are cleaned and then welded and sealed on the 500T press platform. Then drill the hole and heat it to 400±10°C, keep it warm for 30 minutes, and keep vacuuming at 1×10 -3 About Pa, then close the vacuum port, put it in a heating furnace and heat it to 1150°C, and then roll it in an 8000T stainless steel continuous rolling mill and roll it up. The width of the double-layer stainless steel clad plate is 1219mm, th...

Embodiment 2

[0030] Referring to Figure 2 and Figure 3, a double-layer stainless steel composite thin plate with a width of 1500mm and a thickness of 3mm is manufactured, in which the thickness of the base stainless steel plate is 2.5mm, and the back of the clad stainless steel plate is 0.5mm. Plate 1, 304 stainless steel plate 2 of 1500×2500×45mm is selected as the multi-layer stainless steel plate. According to the blank formation method using brazing material, the thickness of the brazing material layer 3 is 10 microns. After cleaning the surfaces of the two stainless steel plates Weld and seal the blanks on the 500T press platform, then drill holes and heat to 400±10°C, keep it warm for 30 minutes, and keep vacuuming at 1×10 -2 About Pa, then close the vacuum port, put it into a heating furnace and heat it to 900°C, and then hot-roll it in a medium-sized stainless steel continuous rolling mill, and roll it into a double-layer stainless steel clad plate with a width of 1500mm and a thick...

Embodiment 3

[0032] Manufacture a double-layer stainless steel composite thin plate with a width of 1500mm and a thickness of 3mm. The thickness of the base stainless steel plate is 2.5mm, and the thickness of the clad stainless steel plate is 0.5mm. 2500×45mm 304L stainless steel plate, according to the preform assembly method using brazing material, the thickness of the brazing material is 1 micron, clean the surface of the two stainless steel plates, weld and seal the preform on the 500T press platform, and then drill and heat To 400±10°C, keep warm for 30 minutes, keep vacuuming at 1×10 -2 About Pa, then close the vacuum port, put it into a heating furnace and heat it to 1000°C, then hot-roll it in a medium-sized stainless steel continuous rolling mill, and roll it into a double-layer stainless steel clad plate with a width of 1500mm and a thickness of 3mm about 225m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com