Membrane method low-temperature methanol washing tail gas treatment method and device

A low-temperature methanol washing and tail gas treatment technology, which is applied in special data processing applications, structured data retrieval, database indexing, etc. The effect of low investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

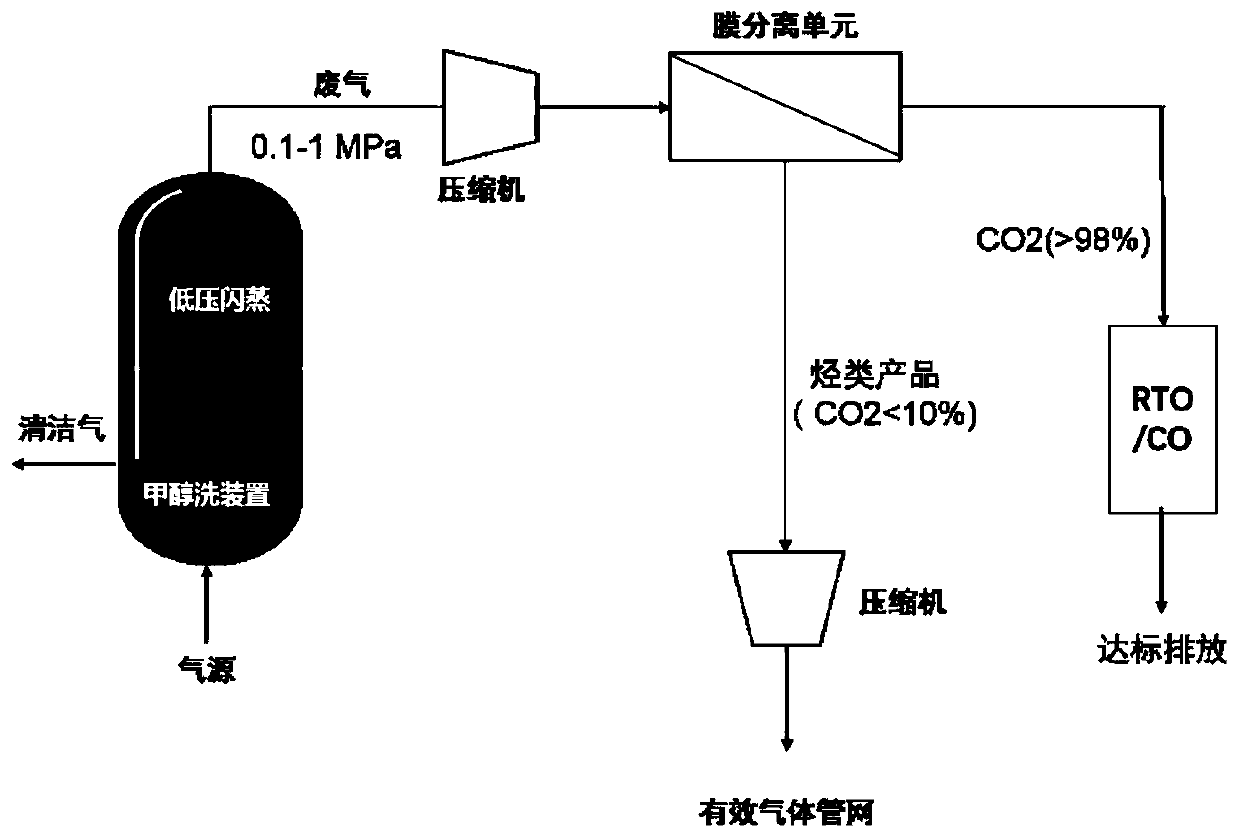

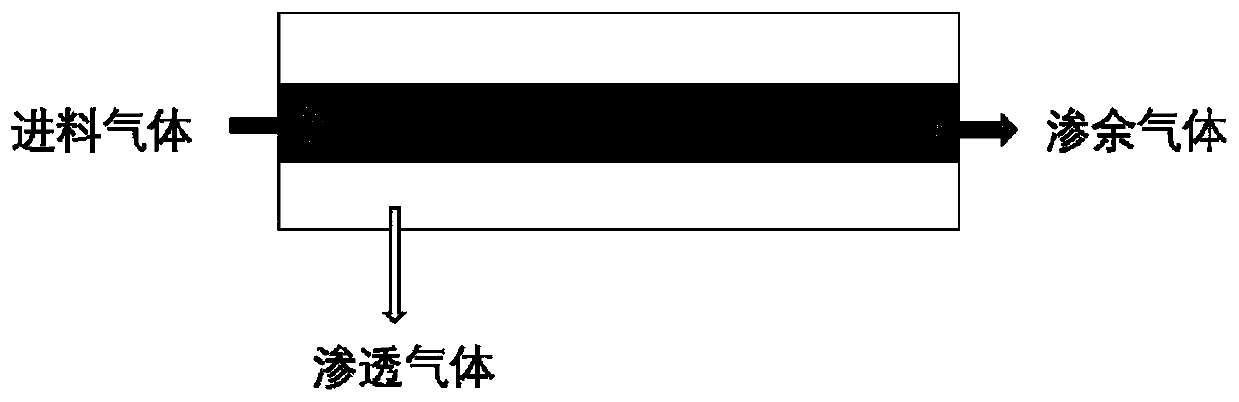

Embodiment 1

[0073] Such as figure 2 , put the low-temperature methanol washing device through CO 2 The tail gas decompressed to 0.2MPa in the flash tank is pressurized by a compressor to 1MPa, and the pressurized gas reaches 25°C after heat exchange. Exhaust gas CO 2 The concentration is 90%. After that, the tail gas enters the membrane separation unit. The membrane material of the membrane separation unit is polysulfone organic membrane, and the organic membrane module is in the form of hollow fiber, which has a very high packing density. The membrane module adopts the mixed connection method of multiple organic membrane modules (the raw material gas enters two sets of membrane modules respectively, one of which is one-stage and the other one is two-stage). The permeate side is kept at normal pressure. Under this condition, CO in the tail gas of the permeate side 2 The concentration is 98%, and the tail gas passes through the regenerative oxidation incinerator (RTO) to remove the h...

Embodiment 2

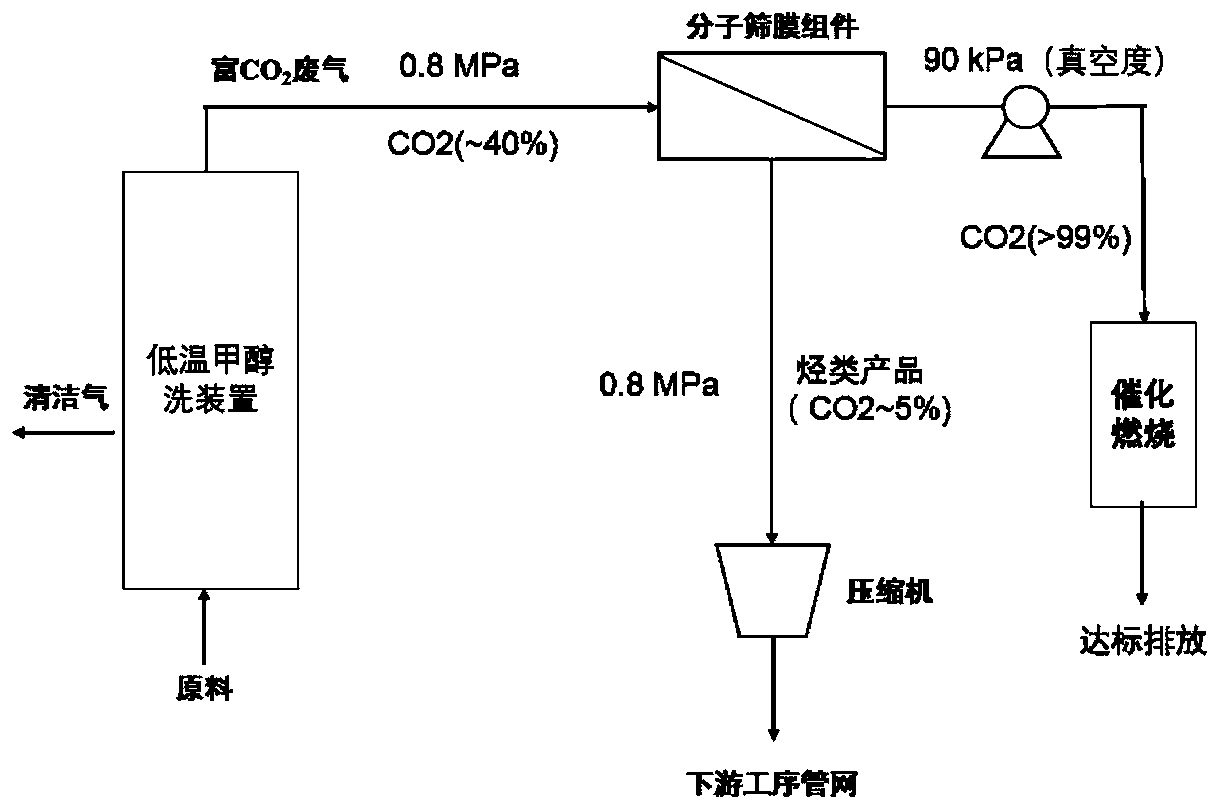

[0075] Such as image 3 , put the low-temperature methanol washing device through CO 2 Flash tank is decompressed to 0.8MPa tail gas, tail gas CO 2 The concentration is 40%. The exhaust gas is directly introduced into the membrane separation unit through the fan. The membrane material of the membrane separation unit is DD3R molecular sieve membrane. The pores of the DD3R molecular sieve membrane are uniform and orderly, and the inorganic material has excellent anti-aging performance. The molecular sieve membrane carrier is in the form of 4-channel hollow fiber, which has both high mechanical strength and high packing density. The vacuum on the permeate side is maintained at 90kPa by a vacuum pump.

[0076] Under this condition, the CO on the permeate side 2 The concentration is 99%, which can be discharged after being treated by catalytic oxidation combustion (CO). Retentate side CO 2 The concentration of the gas is 5%, and the hydrocarbon component is greater than 93%. T...

Embodiment 3

[0078] Such as Figure 4 , put the low-temperature methanol washing device through CO 2 The tail gas decompressed to 0.4MPa in the flash tank is pressurized by a compressor to 0.8MPa. Exhaust gas CO 2 The concentration is 65%. After that, the tail gas enters the membrane separation unit, and the membrane materials of the membrane separation unit are polyimide organic membrane and DD3R inorganic molecular sieve membrane. The organic membrane module is in the form of hollow fiber filaments with extremely high packing density, and the inorganic molecular sieve membrane has very high separation selectivity. The membrane module adopts a series connection of two-stage membrane modules. The front-stage membrane module adopts hollow fiber organic membrane, and the rear-stage membrane module adopts inorganic molecular sieve membrane. Under this condition, CO in the tail gas of the permeate side 2 The concentration is greater than 99%, and the tail gas removes combustible gas compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com