Environment-friendly vegetable oil-based polyurethane binder resin, ink for corrugated cardboard and its preparation method

A binder resin, vegetable oil-based technology, applied in the field of corrugated board printing ink, can solve the problems of poor decomposition and detachment performance, difficult recycling and detachment of printing ink, and difficulty in decomposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Embodiment 1 Preparation of environment-friendly vegetable oil-based polyurethane corrugated cardboard ink

[0077] The preparation process is as follows:

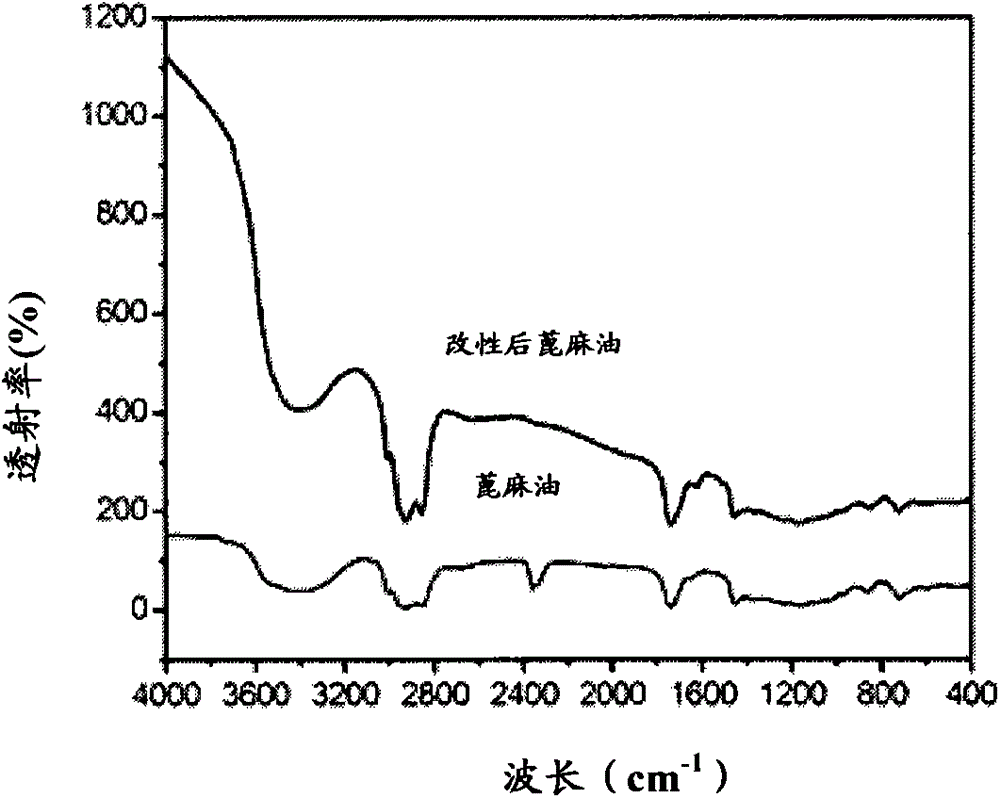

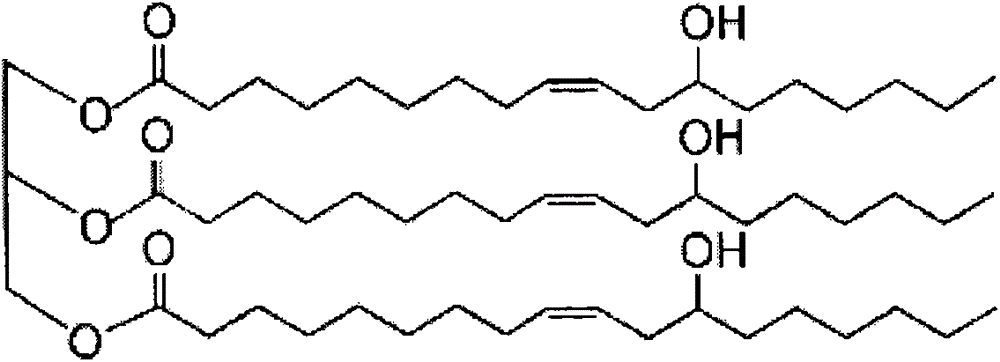

[0078] a. Add 30g of castor oil into a clean beaker with a stirring device, put the beaker into an ultrasonic cleaner, set the temperature at 70°C, and the ultrasonic power at 600W, add 1g of OP-10 to the flask, and stir Mix well; at the same time, take 4g of BMA, 6g of AA and 0.3g of AIBN into a clean empty beaker and use a glass rod to mix and stir to obtain a mixture. Then, when the ultrasonic cleaner started ultrasonic vibration, the mixture was added to the reaction system of castor oil and OP-10. The addition process adopted the method of starvation feeding, and the mixture was added within 2 hours. Obtain the castor oil after polyacrylate monomer modification;

[0079] b. Dry 46.4g of PNA and the modified castor oil in a at 120°C in a drying oven with a vacuum degree of 0.05Mpa for 2 hours, after the drying...

Embodiment 2

[0087] Embodiment 2 Preparation of environment-friendly vegetable oil-based polyurethane corrugated cardboard ink

[0088] The preparation process is as follows:

[0089] a. Add 25g of castor oil into a clean beaker with a stirring device, put the beaker into an ultrasonic cleaner, set the temperature at 65°C, and the ultrasonic power at 600W, add 0.8g of OP-10 to the flask, Stir and mix evenly; at the same time, take 2g of BMA, 3g of AA and 0.1g of AIBN into a clean empty beaker and use a glass rod to mix and stir to obtain a mixture. Then, when the ultrasonic cleaner starts ultrasonic vibration, the mixture is added to the reaction system of castor oil and OP-10, the addition process adopts the method of starvation feeding, and the mixture is added within 1.5 hours. Obtain the castor oil after polyacrylate monomer modification;

[0090] b. Dry 43g of PNA and the modified castor oil in a at 120°C in a drying oven with a vacuum degree of 0.05Mpa for 2 hours, after the drying...

Embodiment 3

[0097] Embodiment 3 Preparation of environment-friendly vegetable oil-based polyurethane corrugated cardboard ink

[0098] The preparation process is as follows:

[0099] b. Add 35g of castor oil into a clean beaker with a stirring device, put the beaker into an ultrasonic cleaner, set the temperature at 80°C, and the ultrasonic power at 600W, add 1.2g of OP-10 to the flask, Stir and mix evenly; at the same time, take 6g of BMA, 8g of AA and 0.5g of AIBN into a clean empty beaker and use a glass rod to mix and stir to obtain a mixture. Then, when the ultrasonic cleaner starts ultrasonic vibration, the mixture is added to the reaction system of castor oil and OP-10, the addition process adopts the method of starvation feeding, and the mixture is added within 2.5 hours. Obtain the castor oil after polyacrylate monomer modification;

[0100] b. Dry 50 g of PNA and the modified castor oil in a at 120° C. in a drying oven with a vacuum degree of 0.05 Mpa for 2 hours, after the dr...

PUM

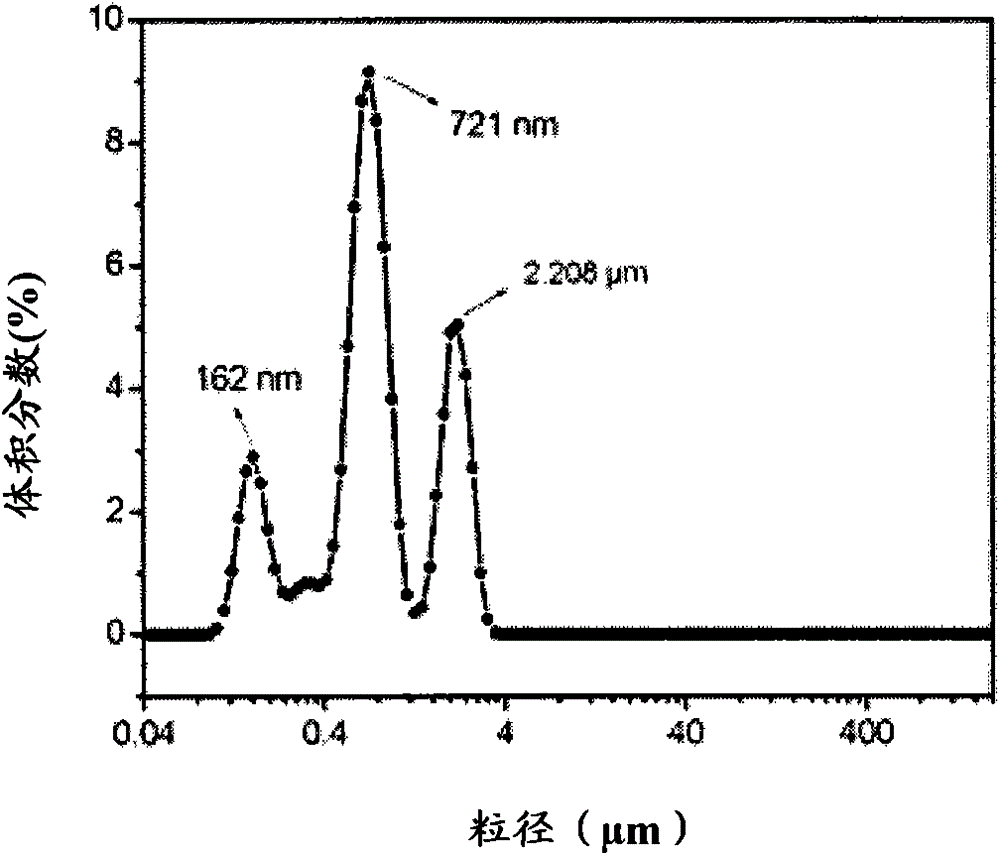

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com