Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

229 results about "Titanium coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-infectious, biocompatible titanium coating for implants, and method for the production thereof

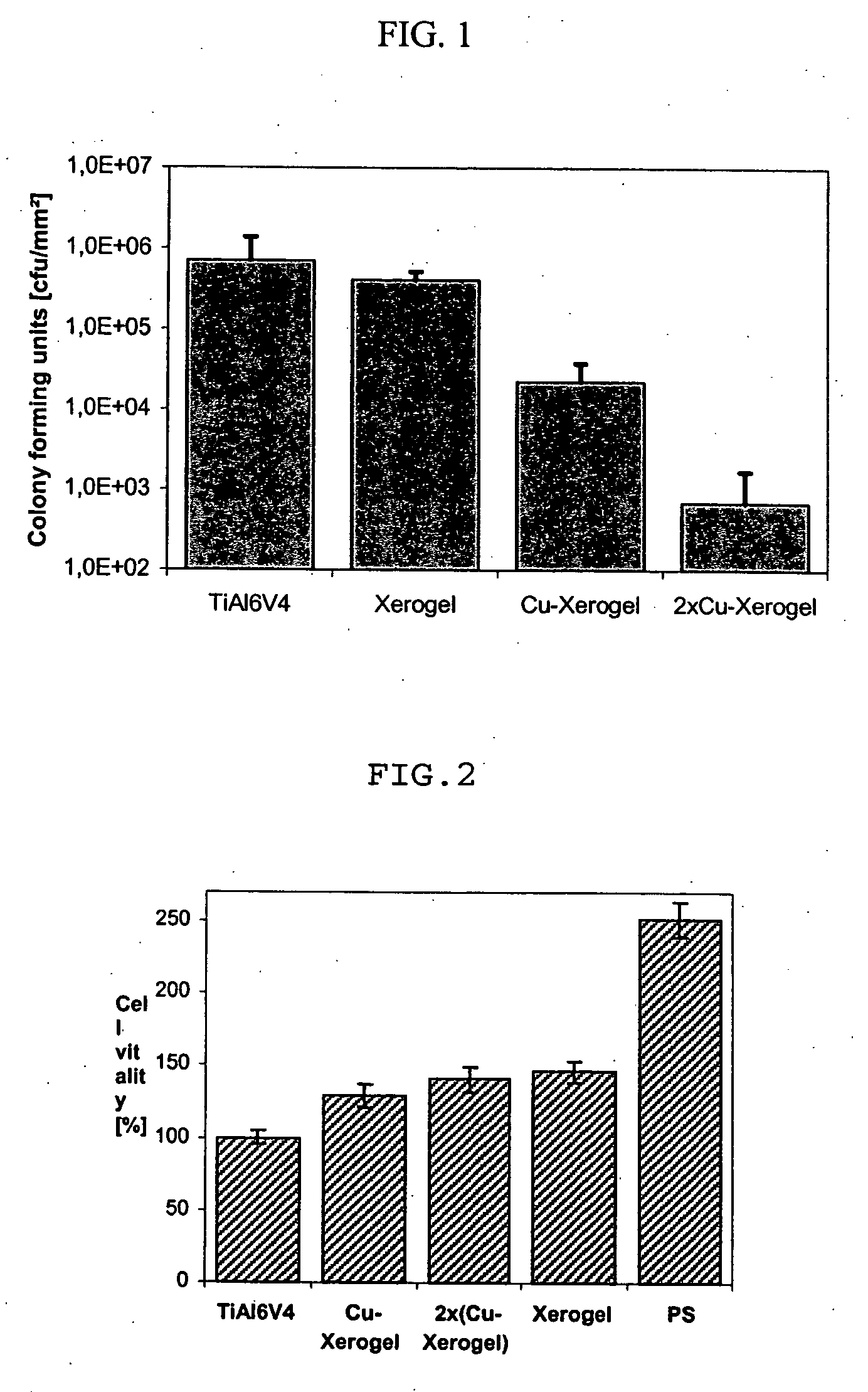

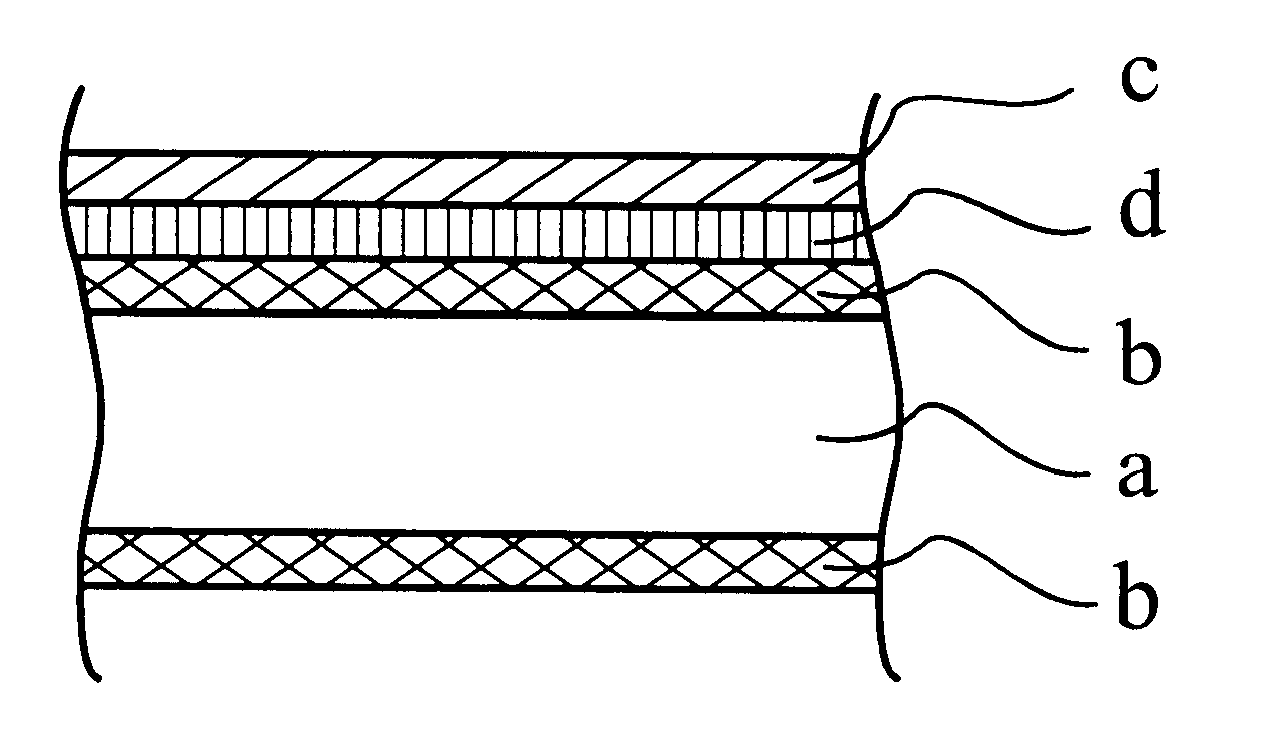

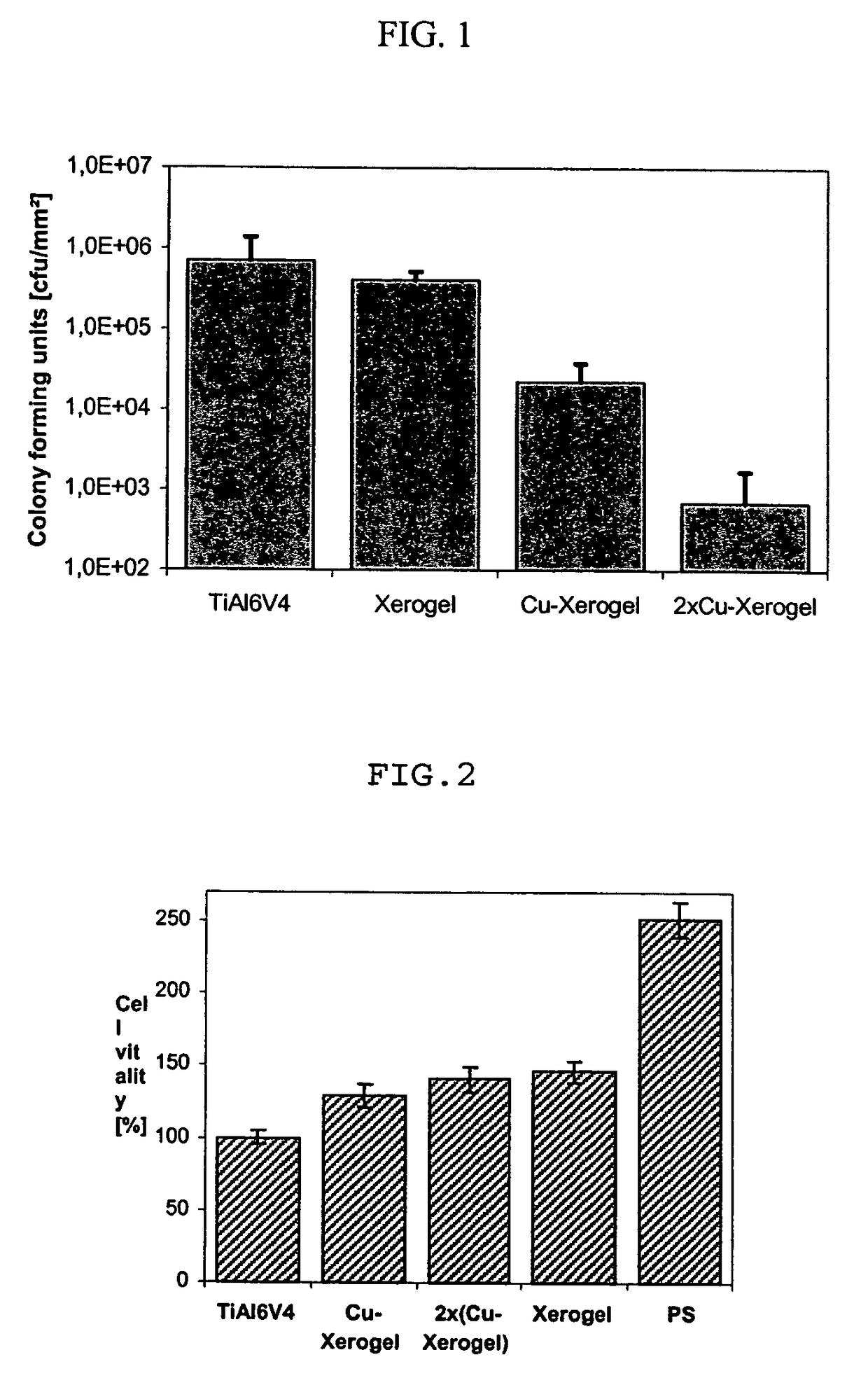

The present invention relates to a method for the preparation of a biocompatible metal ion-containing titanium oxide coating on an implant wherein the metal ions can be eluted under physiological conditions and are homogeneously dispersed within the coating, as well as to an implant which can be prepared according to the method of the present invention.

Owner:BIOCER ENTWICKLUNGS

Preparation method and electroplating method of normal-temperature environment-friendly sulfate trivalent chromium electroplating liquid

The invention provides a preparation method and an electroplating method of normal-temperature environment-friendly sulfate trivalent chromium electroplating liquid, which relates to electroplating liquid and electroplating technology. The invention solves the problems of poor stability of the traditional trivalent chromium electroplating liquid, low precipitating and depositing rate of harmful gas in an electroplating process, more components of the electroplating liquid, sensitivity for impurities, poor corrosion resistance of an electroplating layer, and the like. The normal-temperature environment-friendly sulfate trivalent chromium electroplating liquid mainly comprises the following components of main salt, a complexation stabilizing agent, a combined additive, a buffering agent and a conducting salt. The electroplating liquid can work at normal temperature, thereby saving energy resources and having simple technology and high deposition rate, wherein the deposition rate can reach above 0.22micron.min<-1> under 6A / dm<2>. An anode of the invention is a Ti-based rare-metal tantalum-iridium-titanium anode, the anode oxygen-evolution overpotential is low, and harmful hexavalent chrome can not be generated. The normal-temperature environment-friendly sulfate trivalent chromium electroplating liquid has good corrosion resistance and high stability.

Owner:HARBIN INST OF TECH

Method of manufacturing an assembly of brazed dissimilar metal components

InactiveUS6503640B2Improve abilitiesHigh strengthBuilding componentsElectron beam welding apparatusTitanium coatingSS - Stainless steel

Owner:DANA CANADA CORP

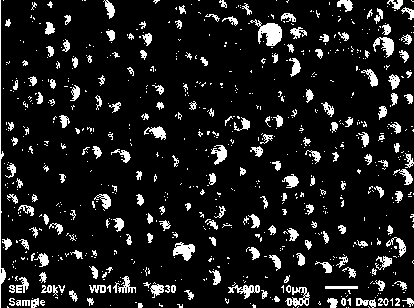

Composite technique of preparing lacunaris titanium coating by using cold spraying and vacuum sintering

InactiveCN101032633AGood pore uniformityHigh bonding strengthImpression capsSurgeryArtificial boneTitanium alloy

The present invention discloses composite cold spraying and vacuum sintering process for preparing porous titanium coating. Mixed titanium-magnesium powder is first sprayed onto the roughened titanium or titanium alloy substrate to form composite titanium-magnesium coating, which is then sintered at high vacuum and high temperature to obtain porous titanium coating. Thus produced porous titanium coating has no oxide, thickness greater than 0.5 mm, opened and communicated pore structure, pores of 30-200 microns, porosity of 30-65 %, and metallurgical combination with the substrate with combination strength higher than 60MPa and elastic modulus adjustable in 30-50 GPa. The present invention is suitable for making bearing hard tissue implant, such as artificial joint, artificial bone, artificial tooth root, etc. with improved long term stability.

Owner:XI AN JIAOTONG UNIV

Anti-infectious, biocompatible titanium coating for implants, and method for the production thereof

Owner:BIOCER ENTWICKLUNGS GMBH

Titanium-coated aluminium laminated composite plate and preparation method thereof

InactiveCN101574861AGood surface bindingImprove conductivityHot-dipping/immersion processesMolten spray coatingInternal resistanceComposite plate

The invention discloses a titanium-coated aluminium laminated composite plate used for an insoluble anode in electrolysis process and a preparation method thereof, belonging to the technical field of wet-process metallurgy. The preparation method comprises the following steps of: adopting one or more of techniques of electric arc spraying, spray deposition, composite rolling, melt plating and thelike to coat an aluminium layer on the single surface of the surfaces of the titanium plate, obtaining two titanium / aluminium composite plates which are then prepared into the titanium-coated aluminium laminated composite electrode material which takes aluminium as an inner core (for improving the electric conductivity of the electrode) and is coated by titanium at the outer layer. The prepared titanium-coated aluminium laminated composite plate has the advantages of excellent interface coherency, good electric conductivity, good corrosion resistance, low cost and the like, a coating titaniumanode prepared by adopting the laminated composite plate as a substrate leads the internal resistance of inert electrode to be reduced, the current distribution to be even and the electrolytic productpurity to be improved, thus achieving the effects of saving energy and reducing consumption; and the bath voltage is reduced by 10 to 30 percent compared with that of the pure titanium coating anode.

Owner:KUNMING UNIV OF SCI & TECH

Multifuntional green environmental protection nanometer titania coating and preparing method thereof

InactiveCN1583907ASolve technical problems that are easy to reuniteGood weather resistanceCoatingsSilicic acidTalc

This invention is that a kind of multi-functional green nanometer two of environmental protection is oxidized Titanium coating and method of preparing, this coating can not merely be solved now. There is coating that is able to bear staining difference, is able to bear waiting difference, not the skills, such as environmental protection, etc. Skill question, it is clean to give the coating at the same time, disinfect and disinfect, Purify new functions, such as air, etc., it is the green environmental protection of more than one kind of kinetic energy Coating. Coating this by titanium white powder, exceed detailed silicic acid aluminium, nanometer Oxidize the titanium and disperse the liquid two times, the calcium carbonate of light quality, the calcium carbonate of heavy quality, Silicon lime powder, lithopone, talc powder, dispersant is moist. It is the dispersant, thickener, disappear and steep and pharmaceutical, become membrane auxiliary, flow flat pharmaceuticla, water, the cream base material, etc. make up, it is simple to prepare the craft. The cost performance is high, have very good economic benefits and social result Benefit.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

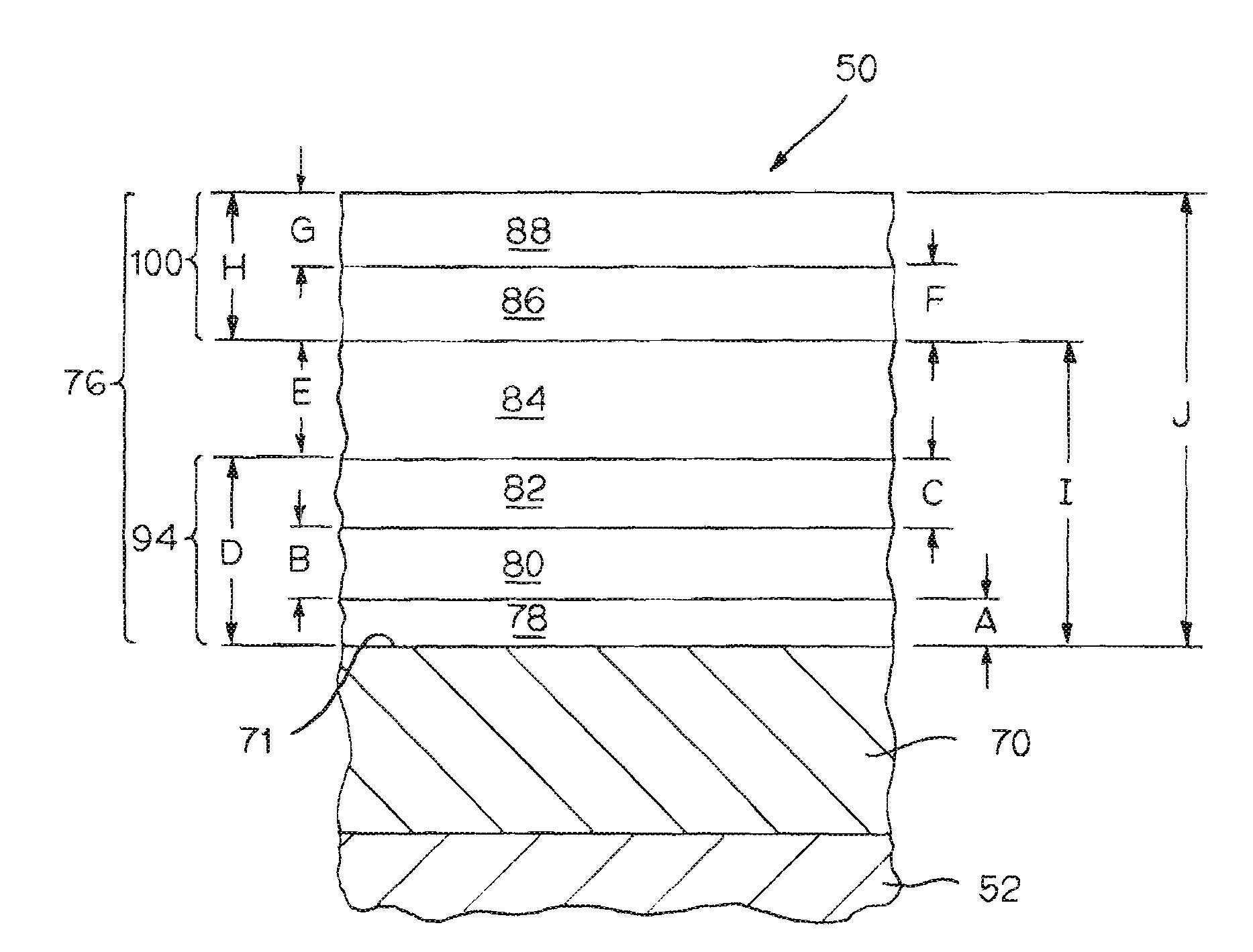

Coated pcbn cutting insert, coated pcbn cutting tool using such coated pcbn cutting insert, and method for making the same

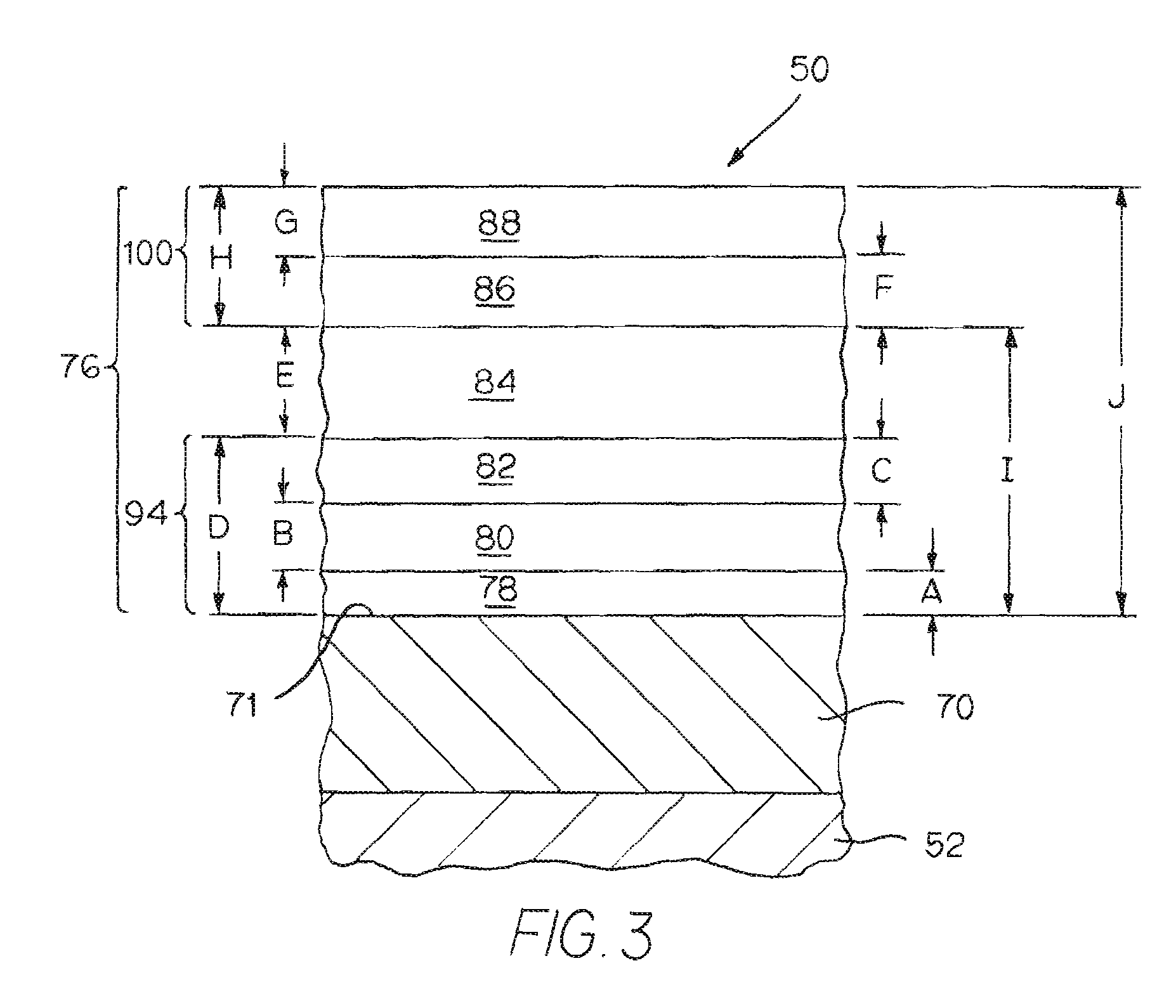

A coated polycrystalline cubic boron nitride cutting insert useful in a cutting tool for removing material from a workpiece, and a method for making the same. The cutting insert including a polycrystalline cubic boron nitride substrate with a rake surface and at least one flank surface, and a cutting edge formed at the juncture between the rake surface and the flank surface. A wear-resistant coating scheme is on the polycrystalline cubic boron nitride substrate. The wear-resistant coating scheme includes the following coating layers. An inner coating layer region is on at least some of the rake surface and at least some of the flank surface of the polycrystalline cubic boron nitride substrate. An alumina-containing coating layer region, which has at least one exposed alumina coating layer, is on the inner coating layer region. The exposed alumina coating layer exhibiting a post-blasted stress condition with stress ranging between about 50 MPa (tensile stress) and about −2 GPa (compressive stress) as measured by XRD using the Psi tilt method and the (024) reflection of alumina. The exposed coating layer is the result of wet blasting an outer titanium-containing coating layer from the surface of the alumina-containing coating layer region.

Owner:KENNAMETAL INC

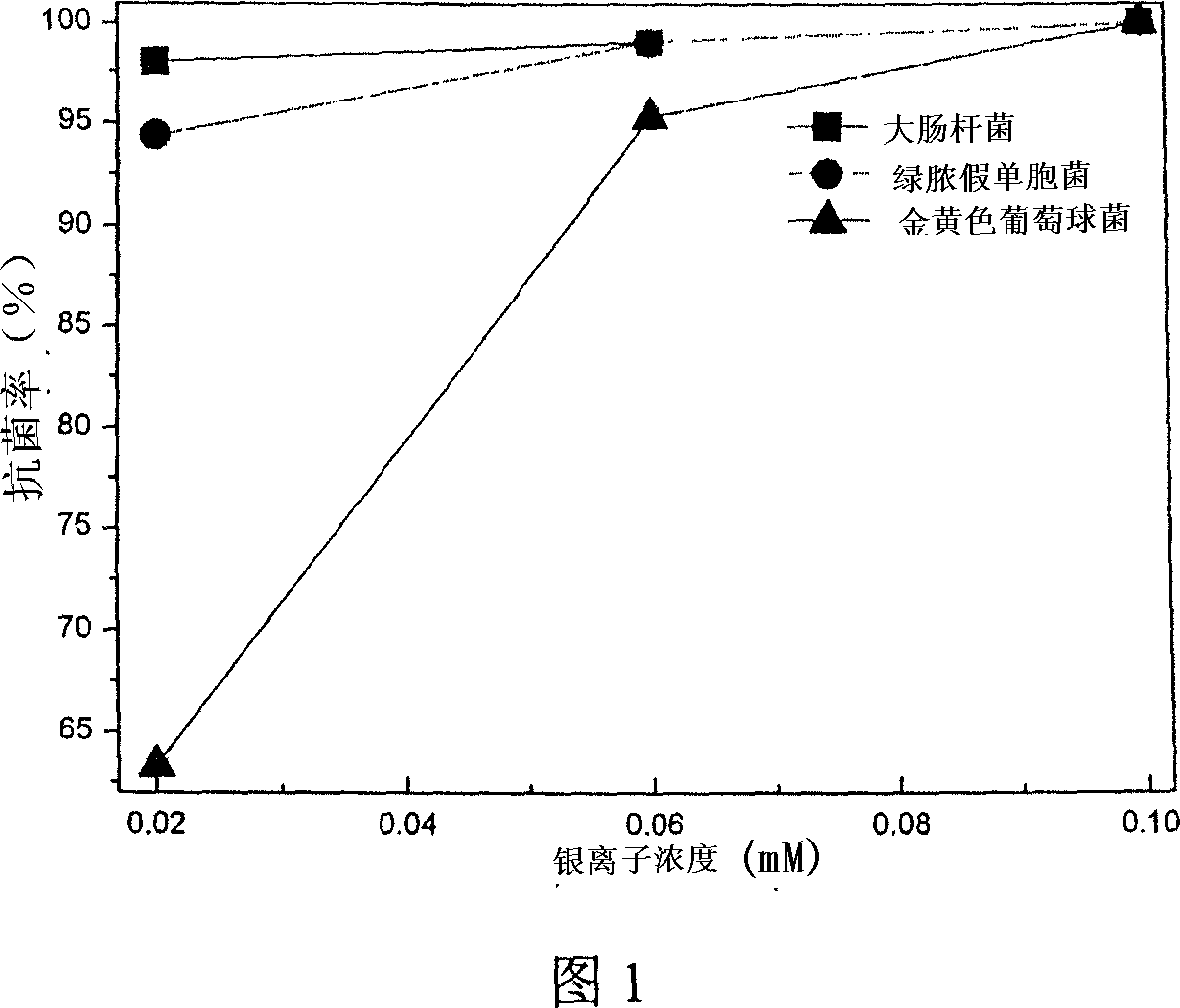

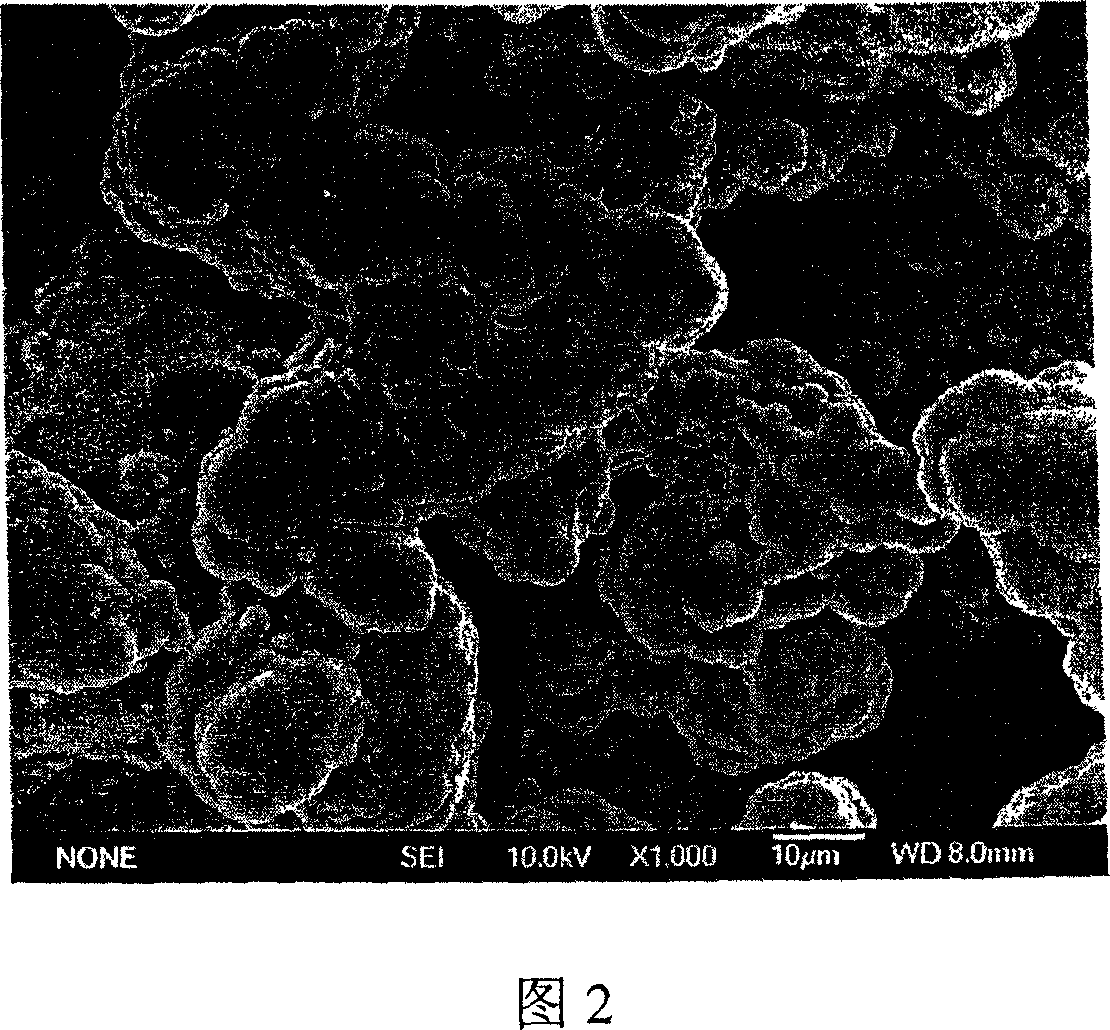

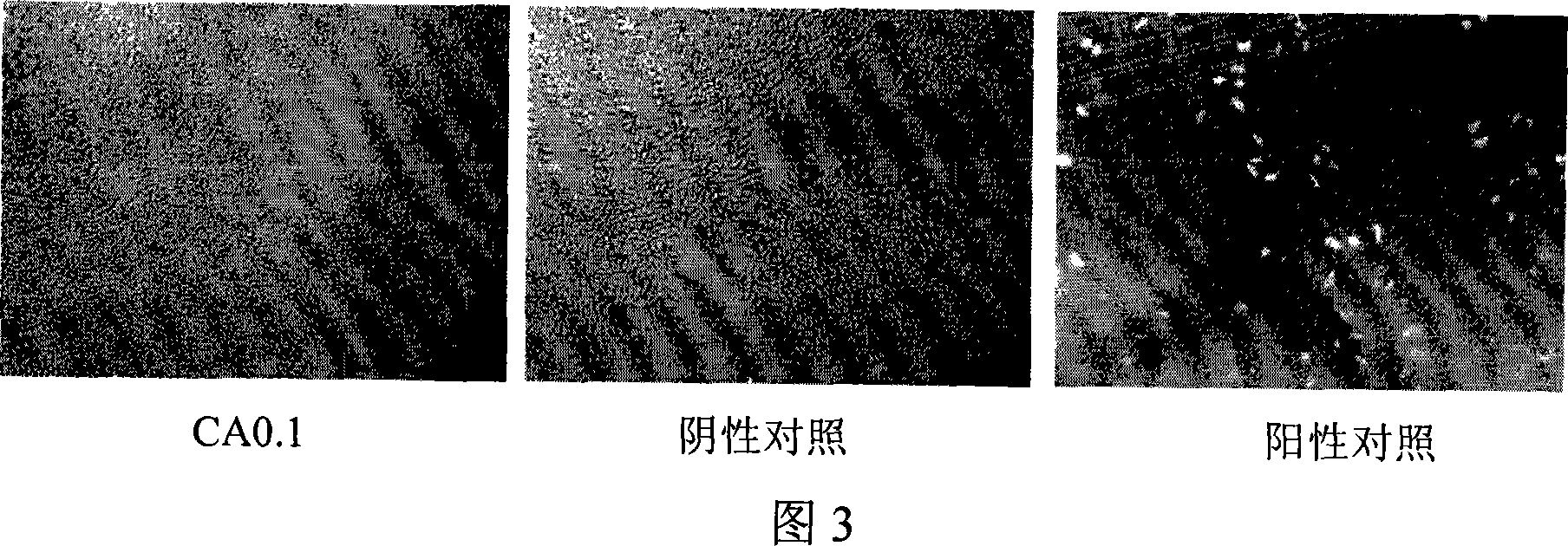

Antiseptic biological active titanium coating and its production

InactiveCN101073675AImprove antibacterial propertiesImprove biological activityMolten spray coatingTitanium coatingCalcium biphosphate

The invention is concerned with antibiotic resistance biological activity coating and its produce method. It adopts NaOH solution and supersaturated calcium phosphate solution with Ag+ to dispose the titanium coating, makes the coating with biological activity and antibiotic resistance capability. The titanium coating with Ag+ ion is 0.01 to 0.1 mm. Dispose titanium powder on the metal basal body (for example, titanium alloy) which having been cleaned and disposed with sand blasting through vacuum plasm sprying technology with favourable technology parameters. Dip the prepared titanium coating into 3 to 10 mol NaOH solution and keep warm for 12 to 48 hours under 20 to 80 degree, take out and ultrasonic clean with deionized water for 2 to 6 times and each time is 3 to 10 minutes, dry for 12 to 48 hours with 20 to 80 degree. Dip the dried titanium coating into supersaturated calcium phosphate solution with Ag+ and keep warm for 12 to 48 hours with 20 to 37 degree and dry for 2 to 6 hours with 100 to 150 degree. The titanium coating has nice antibiotic resistance performance without obvious cytotoxicity.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Graphite surface titanium metallization method and product manufactured with the same

InactiveCN104694897ASolve the technical difficulties of low bonding strengthGood for diffusion reactionVacuum evaporation coatingSputtering coatingMetallic materialsGraphite substrate

The invention discloses a graphite surface titanium metallization method and a product manufactured with the same to solve the problem that when graphite is connected with Cu or Cu alloy, it is difficult to wet graphite with liquid metal, the difference between graphite and Cu or Cu alloy is large in terms of expansion factor and elasticity modulus, and connection is hard. According to the method, a titanium film is deposited on the surface of a graphite substrate with the magnetron sputtering method, and then hot isostatic pressing is conducted on the deposited titanium film, so that a titanium thin film is formed on the surface of the graphite substrate. The problem that coating-substrate combination strength of a surface titanium metallization layer is low during diffusion bonding of the non-metal material graphite can be effectively solved, and the metal titanium thin film high in coating-substrate combination strength can be prepared on the graphite substrate. According to the titanium thin film, the concentration of titanium becomes larger gradually from the graphite substrate to the outside in a gradient mode, and the strength of combination between a titanium coating and the substrate is high. The method can meet the requirement for research of fusion reactor plasma facing materials and has great significance for development of fusion reactor elements.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

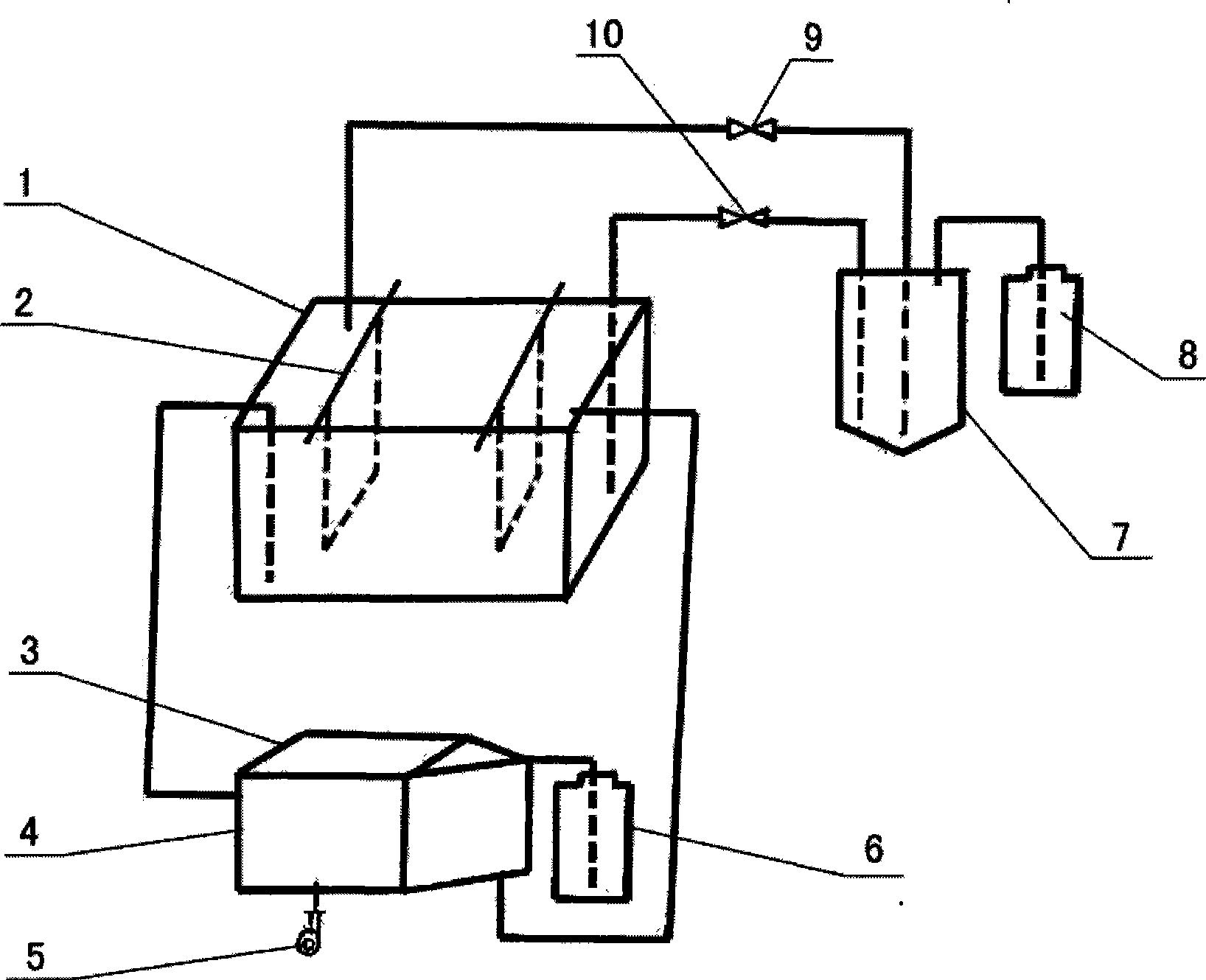

Method for leaching molybdenum and rhenium from molybdenum concentrate by mineral slurry electrolysis method

InactiveCN101353803AImprove leaching rateNo pollution in the processElectrolysis componentsProcess efficiency improvementRheniumIridium

The invention discloses a slurry electrolysis method applied to leach molybdenum and rhenium from molybdenum ore concentrate. The method comprises the following steps: molybdenum ore concentrate containing rhenium is put into an electrolysis bath, wherein, water is added in the electrolysis bath to keep the mass rate of liquid to solid in the range of 10-20: 1, and a mechanical stirring device is used for stirring the slurry obtained so as to cause the slurry to be in suspension status; sodium chloride is added into the electrolysis bath as an electrolyte, appropriate quantity of dextrin with the mass percentage concentration of 0.1 percent is added and sodium carbonate is added to control pH value of the slurry in electrolysis process at 8 to 10; after slurry mixing, a titanium plate of ruthenium-iridium-titanium coating is used as an anode, a pure titanium plate is used as a cathode, direct current is provided to carry out slurry electrolysis, simultaneously stirring is carried out, and the molybdenum and the rhenium are leached from the molybdenum ore concentrate after electrolysis. The method has the advantages of moderate reaction conditions, simple technology, high leaching rate of the molybdenum and the rhenium, and no pollution, wherein, the leaching rate of the molybdenum is not less than 99 percent, the leaching rate of the rhenium is not less than 95 percent, and the electrolysis current efficiency is not less than 92 percent, thereby being capable of effectively recycling the rhenium from the molybdenum ore concentrate and improving the utilization rate of molybdenum resource.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

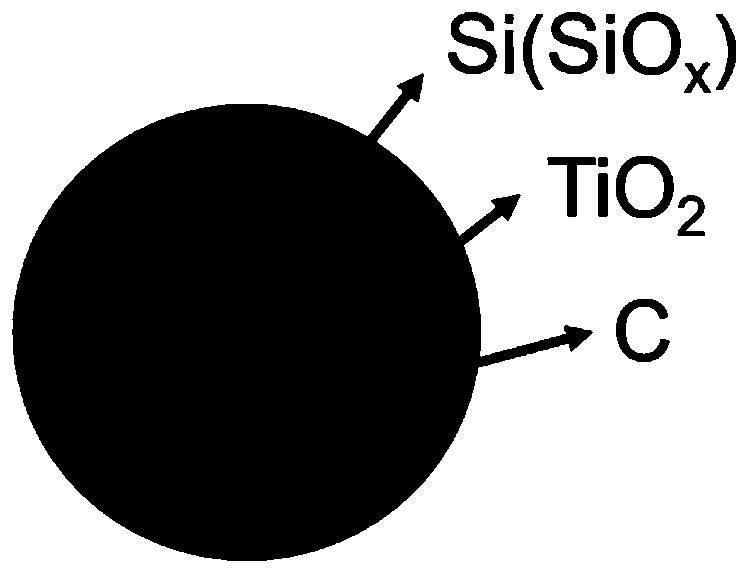

Silicon/silicon oxide-titanium dioxide-carbon core-shell structure composite particle and preparation thereof

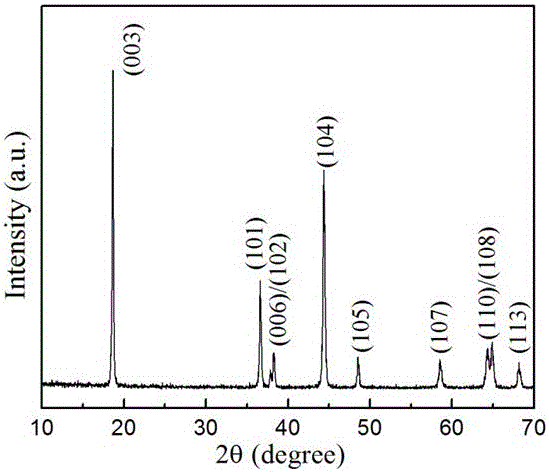

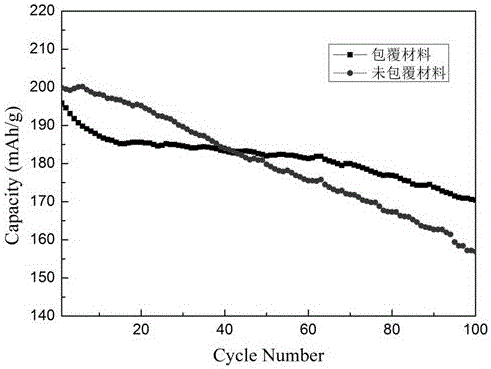

ActiveCN109817949AUniform multi-layer coating structureDense high crystallinityCell electrodesSecondary cellsCarbon coatingTitanium coating

The invention discloses a silicon / silicon oxide-titanium dioxide-carbon core-shell structure composite particle, and belongs to the field of lithium ion battery negative electrode materials. The composite particle is of a compact three-layer structure and comprises a core, a middle layer and an outer layer, wherein the core contains silicon or an oxide thereof, the middle layer contains titanium dioxide TiO2, and the outer layer is a carbon-containing C layer. In addition, the invention also provides a preparation method of the composite particle, comprising a titanium coating step and a carbon coating step, wherein the titanium coating step and the carbon coating step are both completed in a fluidized bed reactor. The core-shell structure composite particle prepared by the preparation method disclosed by the invention is high in specific capacity and has excellent cycling stability and rate capability.

Owner:TSINGHUA UNIV

Method for electrowinning copper nitrate solution

InactiveCN101392387ADirect electrowinningSolve corrosivePhotography auxillary processesProcess efficiency improvementTitanium coatingNitrogen dioxide

The invention relates to an electro-winning method of cupric nitrate solution. The invention relates to an electro-winning method by which the cupric nitrate solution produced by the wet-process metallurgy of precious metal is directly electrolyzed to reclaim the copper and nitric acid. The method adopts a titanium coating electrode plate as the anode and adopts stainless steel as the cathode to electrolyze the cupric nitrate solution in an electrolytic tank directly. During the electrolytic process, the cupric nitrate electrolytic solution is led into a blowing tank and the flow forms a circulation; air or nitrogen is blown into the cupric nitrate solution in the blowing tank to remove the nitrogen dioxide gas in the solution. The cupric nitrate electrolytic solution is led into a vacuum separation chamber and the flow forms a circulation; the pressure is reduced to separate the nitric acid in the solution to keep the nitric acid concentration of the electrolytic solution between 40g / L to 80g / L. The electro-winning method can efficiently solve the problem of corrosivity of the nitric acid during the process of nitric acid system electro-winning, thereby achieving the purpose of protecting the anode and preventing the cathode from back-dissolving; therefore, the direct electro-winning of the cupric nitrate can be carried out continuously.

Owner:SIHUI CITY HONGMING PRECIOUS METALS +1

Lithium ionic sieve adsorbent with self-cleaning function and preparation method and application thereof

InactiveCN106390951AImprove adsorption efficiencyExtended service lifeOther chemical processesWater/sewage treatment by sorptionSorbentManganese

The invention discloses lithium ionic sieve adsorbent with the self-cleaning function and preparation method and application thereof. The preparation method includes the steps of 1), under nitrogen atmosphere, dissolving titanium containing organic matters in organic solvent, adding a manganese lithium ionic sieve adsorbent powder, and performing stirring and ball milling to obtain suspension liquid; 2), drying the suspension liquid to obtain the powder, grinding and calcining the powder to obtain the adsorbent powder coated with the nano titanium-containing oxide; 3), blending the adsorbent powder coated with the nano titanium-coating oxide and the polymer containing solvent, and dropwise adding the mixture into water to obtain the millimeter-scale spherical adsorbent uniform in size. The lithium ionic sieve with the self-cleaning function is prepared by coating the surface of the manganese lithium ionic sieve adsorbent with the titanium-coating oxide, super-hydrophilic properities of the titanium-containing oxide are utilized, impurities or organic matters possibly adhered to the surface of the adsorbent in the actual environment of brine during adsorption can be washed out, stability of the adsorbent is improved, and service life of the adsorbent is prolonged.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

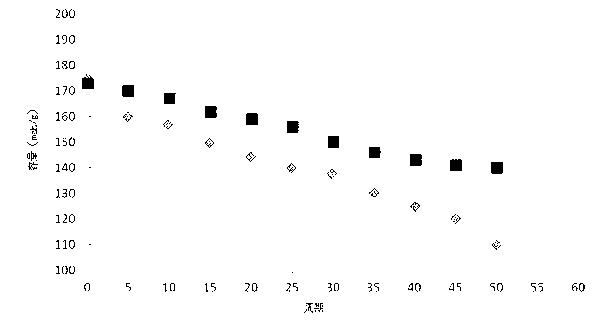

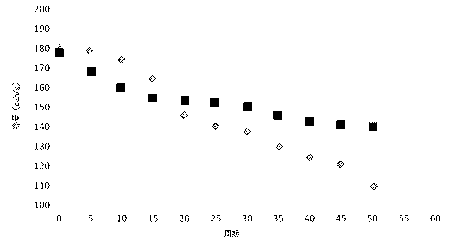

Lithium ion battery positive electrode material aluminum-titanium coating preparation method

InactiveCN103325996AImprove high temperature stabilityExcellent cycle characteristicsCell electrodesNickel saltManganese

The invention discloses a lithium ion battery positive electrode material aluminum-titanium coating preparation method comprising the steps that: nickel salt, manganese salt, a cobalt salt solution and a sodium hydroxide solution containing ammonia water are introduced into a reaction container, and a precipitation reaction is carried out; a hydroxide precursor M containing nickel-manganese-cobalt and lithium salt are mixed according to a molar ratio of 1.0-1.2; the mixture is calcined, cooled, crushed, and sieved, such that the lithium ion battery positive electrode material is obtained; the obtained material is prepared into slurry and is introduced into a well dispersed mixed solution of alumina and titania, and a reaction is carried out; the material obtained after the reaction is subjected to solid-liquid separation, and is washed by using deionized water; and bake-drying and sintering are carried out, such that an aluminum-titanium-coated lithium ion battery positive electrode material is obtained. With the method disclosed by the invention, high-manganese ternary positive electrode material processing performance and tap density are improved, and material capacity and stability defects are overcome. Through controlling precursor morphology and particle size, physiochemical performances of the high-manganese ternary positive electrode material can be controlled, and material stability is improved.

Owner:NANTONG RESHINE NEW MATERIAL

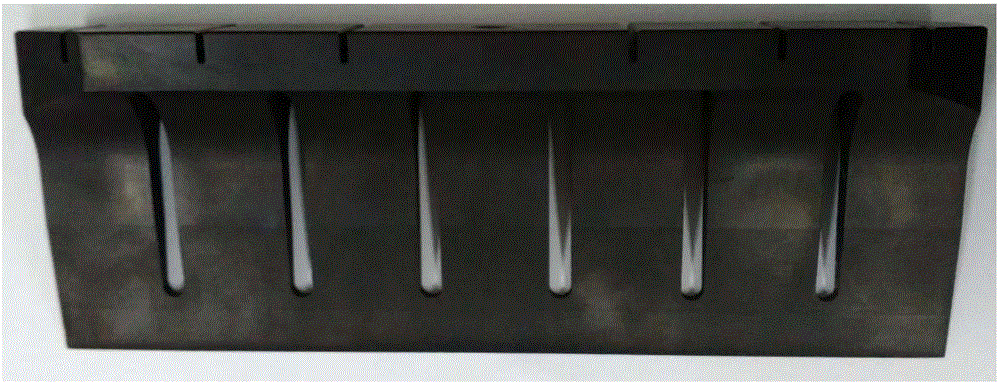

Preparation method of ZTA particle-reinforced steel matrix composite broken wall based on chemical method activating treatment

ActiveCN106623863AHigh bonding strengthEnhanced interface bindingSuperimposed coating processMetallic NickelTitanium coating

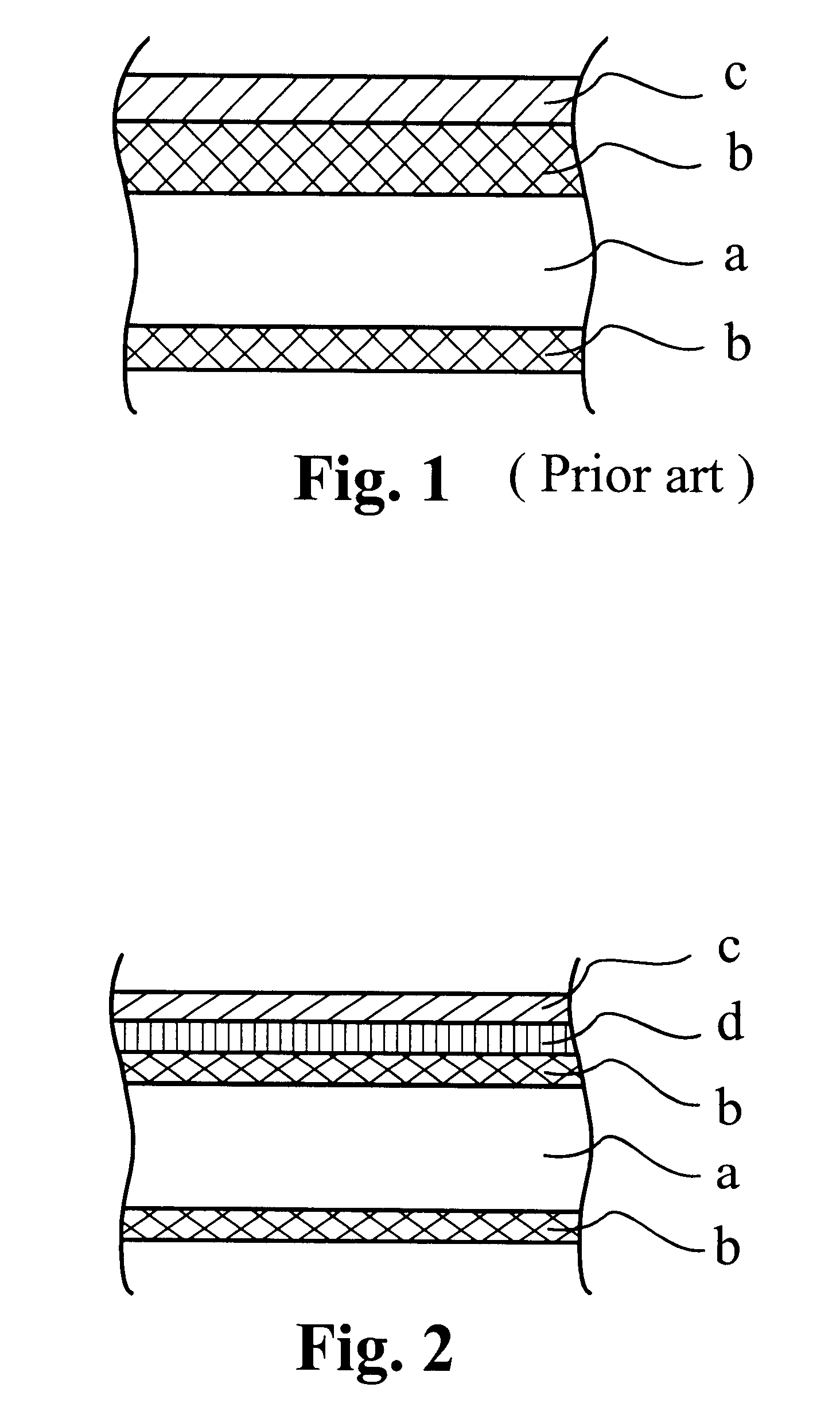

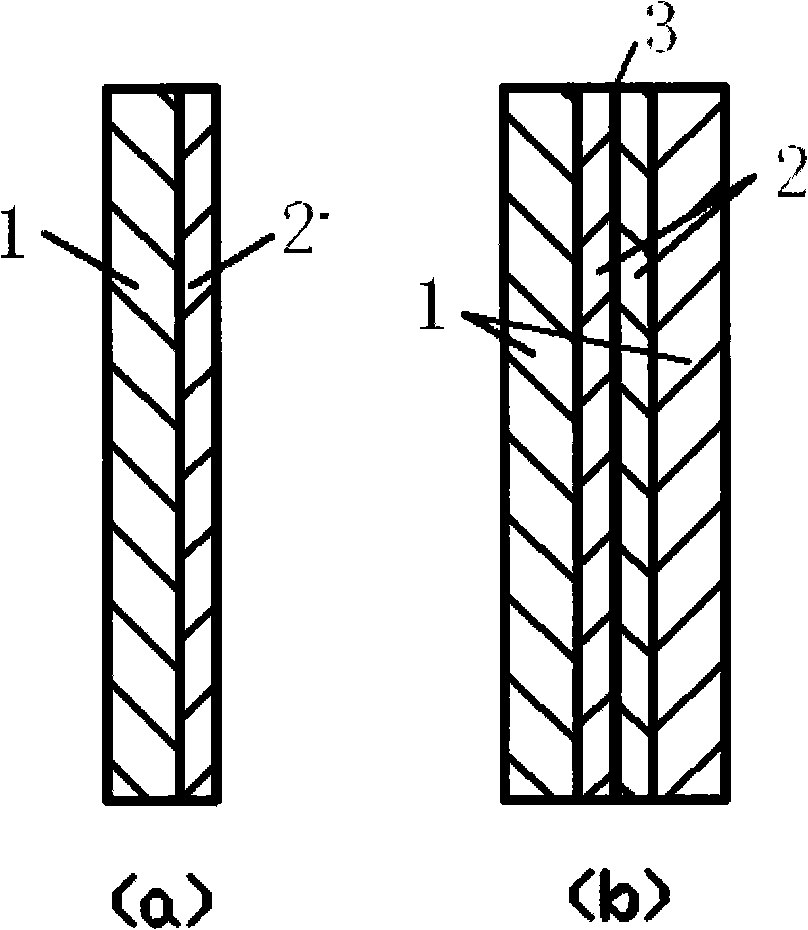

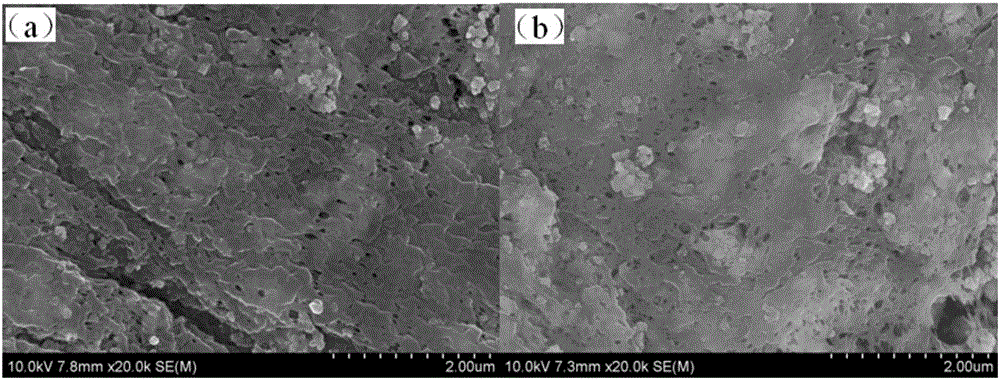

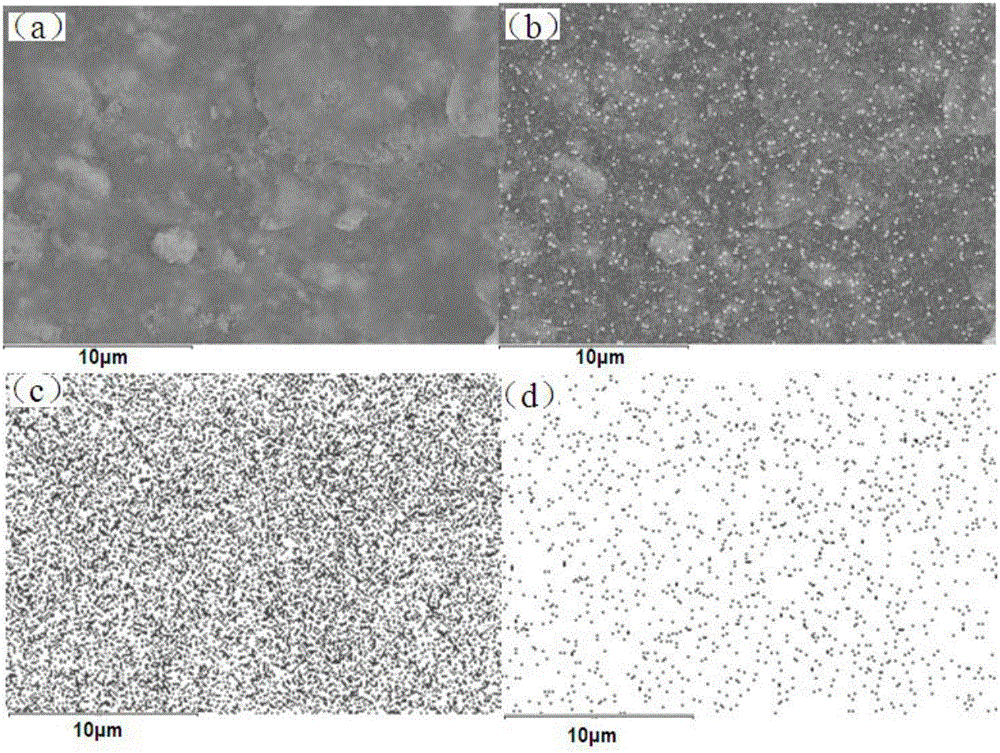

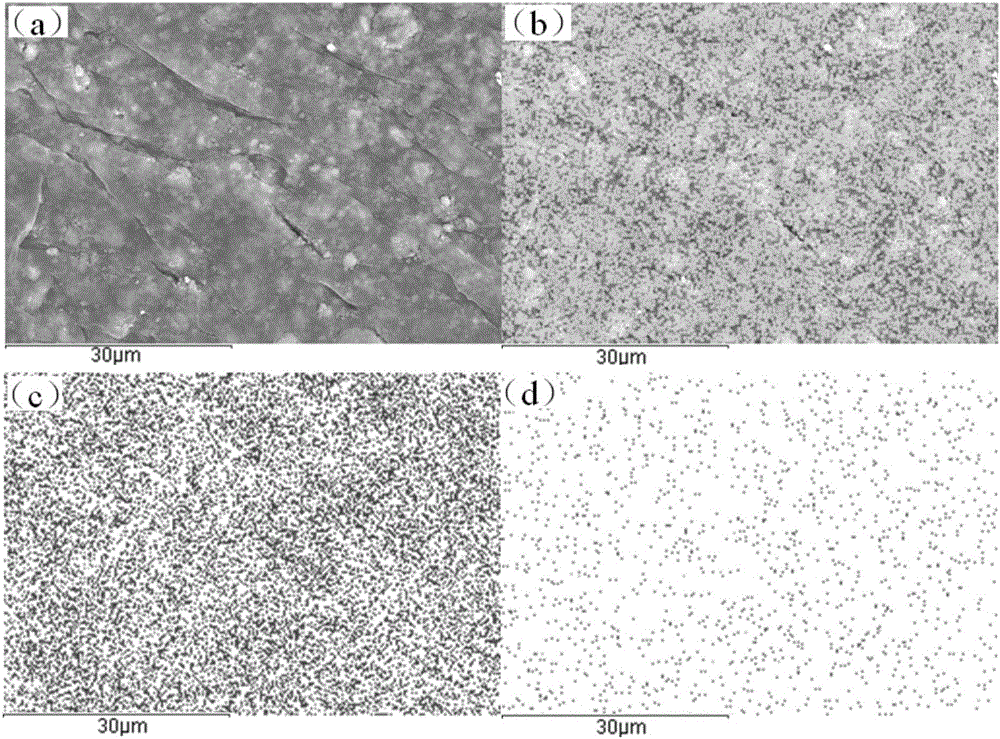

The invention discloses a preparation method of a ZTA particle-reinforced steel matrix composite broken wall based on chemical method activating treatment. The preparation method comprises the following steps: 1) ZTA particles are subjected to high temperature salt bath plating, and uniform titanium coatings are obtained on the surfaces of the ZTA particles; 2) nickel layers are formed at the peripheries of the titanium coatings; 3) the ZTA particles after plating are sintered, the ZTA particles are connected mutually to form a pore-shaped prefabricated body; and 4) the prefabricated body is fixed to a moulded end face or working face, then steel matrix material molten metal is cast by adopting a cast-infiltration technology, and after cooling, the ZTA particle-reinforced steel matrix composite broken wall is obtained. Active elements introduced in the preparation method can improve the interface boding property between the ZTA particles and metal, mechanical bonding between the ZTA particles and metal is changed to metallurgical bonding, and a macro bonding situation is shown in figure 1. The preparation method can improve the wear resistance of a composite, and ensures that the service life of the ZTA particle-reinforced steel matrix composite broken wall is long.

Owner:XI AN JIAOTONG UNIV

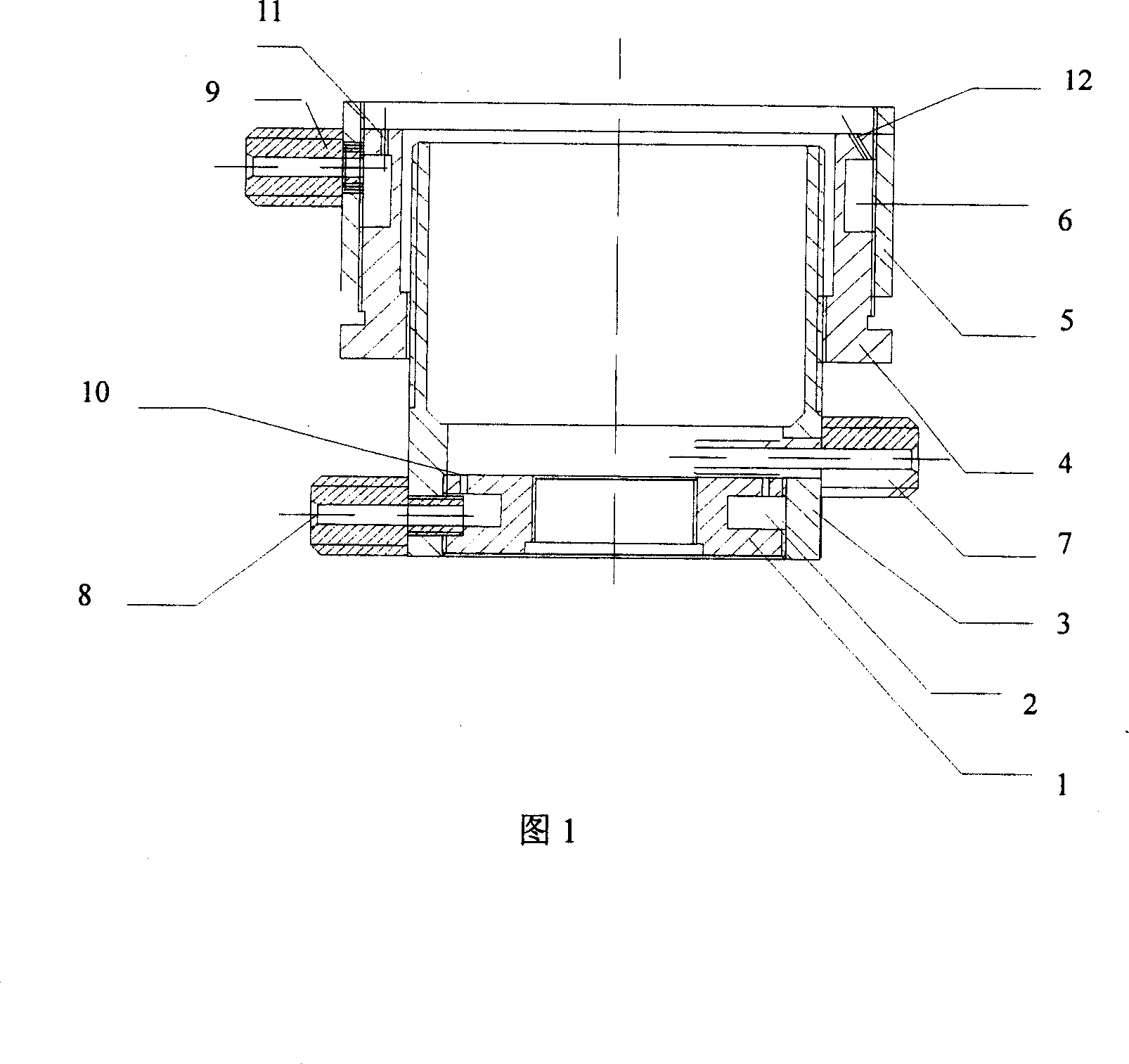

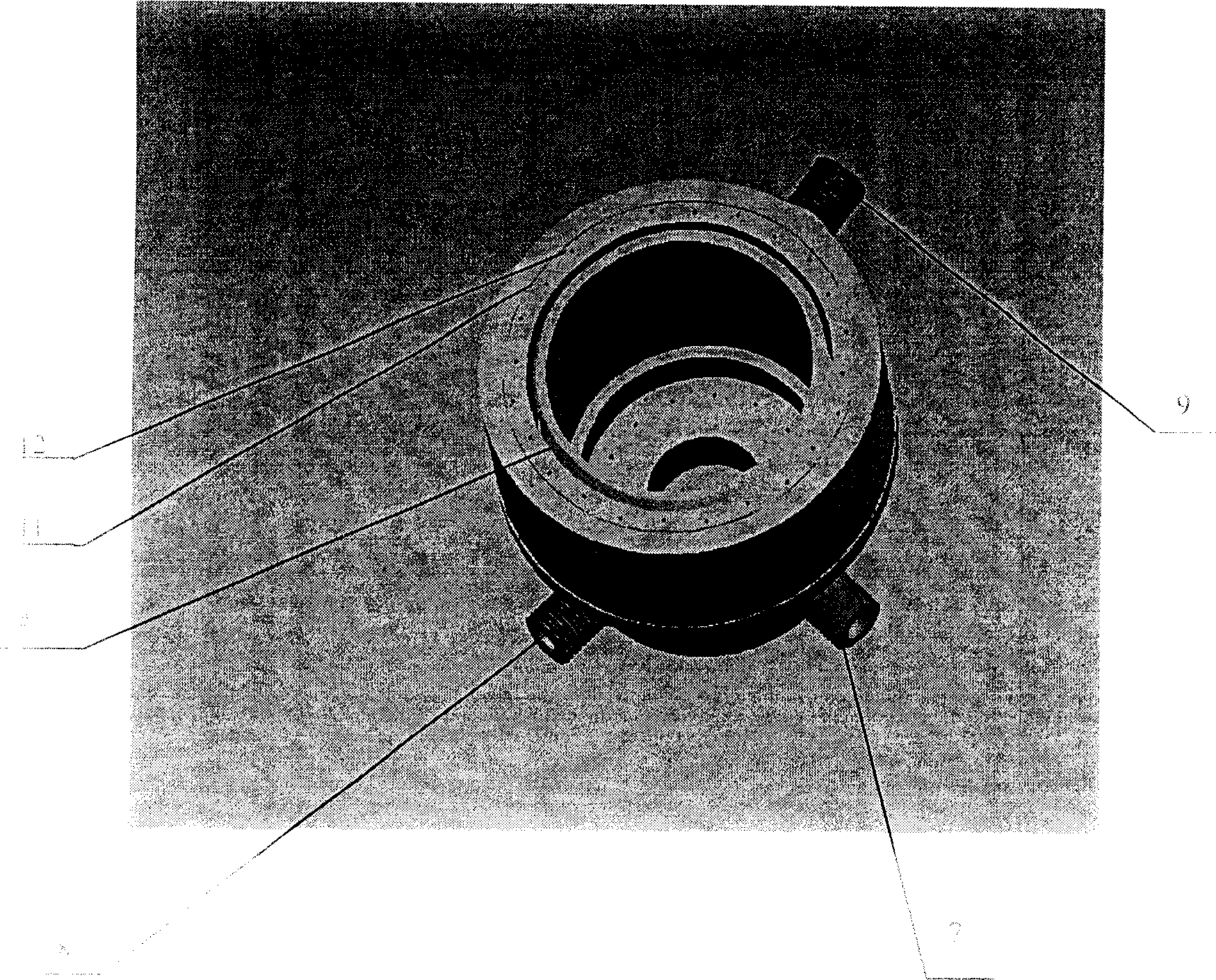

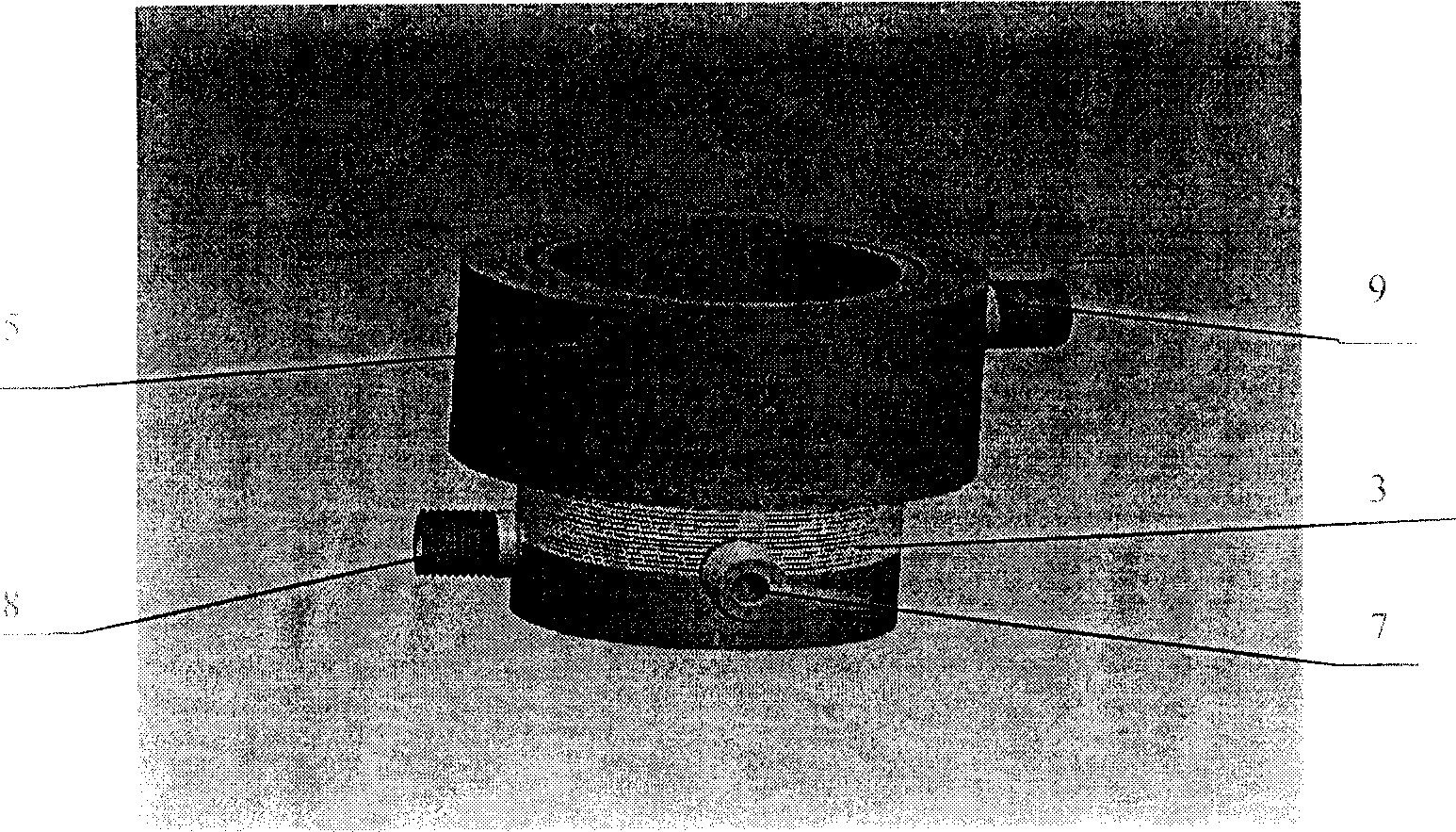

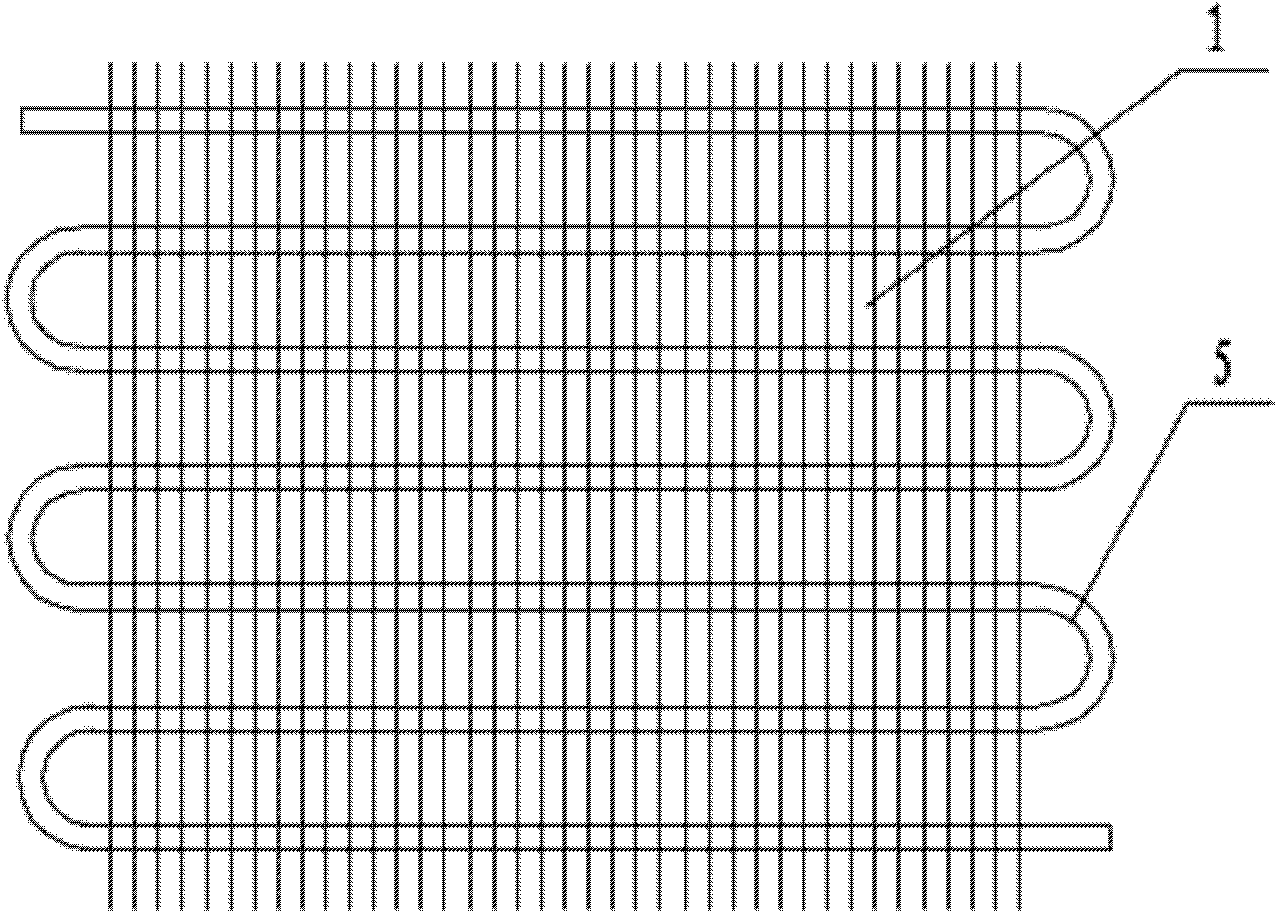

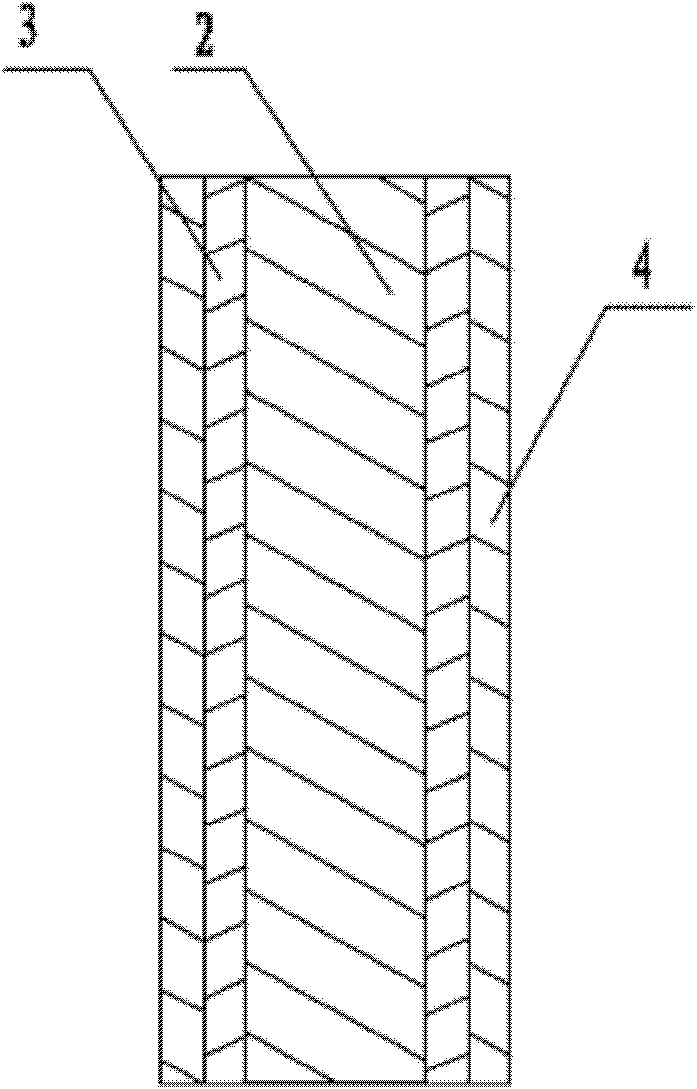

Porous titanium coating atmospheric plasma spraying gas protecting apparatus and its spraying method

InactiveCN1743493APrevent fast escapeImprove spraying efficiencyMolten spray coatingProduct gasGas protection

This invention relates to a spraying gas protection device of multi-hole Ti coating atmosphere plasma and its method. Said device is composed of a base with a hole at the center, a hollow tube connected with the base, a protecting gas inlet mouthpiece designed on the hollow tube, a protection gas distribution chamber, a jet exhaust of the protection gas and a powder mouthpiece. Said device is connected with the nozzle on an ordinary atmosphere plasma spraying device to spray Ti coating to meet the needs of using different sizes of Ti powder as the raw material to be immersed in alcohol and mixed evenly with supersonic waver to be dried and manufactured to Ti coating with optimized spraying parameters under the protection cover of an inert gas formed in this device.

Owner:SICHUAN UNIV

Coating method of super-hard antifriction abrasion-resistance composite film layer on surface of titanium alloy and titanium alloy material

InactiveCN106191794AImprove tribological conditionsReduce coefficient of frictionVacuum evaporation coatingSputtering coatingTitanium coatingComposite film

The invention relates to a coating method of a super-hard antifriction abrasion-resistance composite film layer on the surface of titanium alloy and a titanium alloy material. A magnetron sputtering method is adopted, a titanium film, a carbonitride titanium film and a diamond-like film are sequentially deposited on the surface of the titanium alloy, and a Ti / TiCN / DLC composite film layer is established, wherein the titanium film serves as a metal bonding layer, the carbonitride titanium film serves as a bearing layer, and the diamond-like film serves as a surface antifriction abrasion-resistant layer. Compared with the prior art, the coating method of the super-hard antifriction abrasion-resistance composite film layer on the surface of the titanium alloy and the titanium alloy material effectively overcome the defects that a single-layer diamond-like film is poor in bonding force, and the antifriction effect of a carbonitride titanium coating is not remarkable. The method is simple in technique and can be widely applied to antifriction, abrasion resistance and reinforcement of the surface of the titanium alloy.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

Surface treatment process for forming alloy by carrying out titanium-coating and titanizing on metal surface

InactiveCN103060745ANoveltyGood effectSolid state diffusion coatingChemical vapor deposition coatingTitanium coatingMetal device

The invention discloses a surface treatment process for forming alloy by carrying out titanium-coating and titanizing to a metal surface. The surface treatment process comprises the following steps: a, adding metal magnesium, granular titanium sponges and metal devices needing surface treatment into a container, and sealing the container; b, heating up the container, and carrying out degassing treatment in the container at the temperature of 140-310 DEG C; c, continuously heating up the container, and ventilating titanium tetrachloride to the container during a heat-up process, and maintaining the pressure in the container at 0.02-0.04 MPa; and keeping the temperature constant for 9-11 hours when the temperature is raised to 990-1010 DEG C; and d, taking out and cooling the metal devices from the container. The surface treatment process disclosed by the invention is simple, scientific and reasonable; the effect for forming the alloy by titanium-coating and titanizing is excellent; and the surface treatment process has a good popularization and application value.

Owner:四川恒为制钛科技有限公司

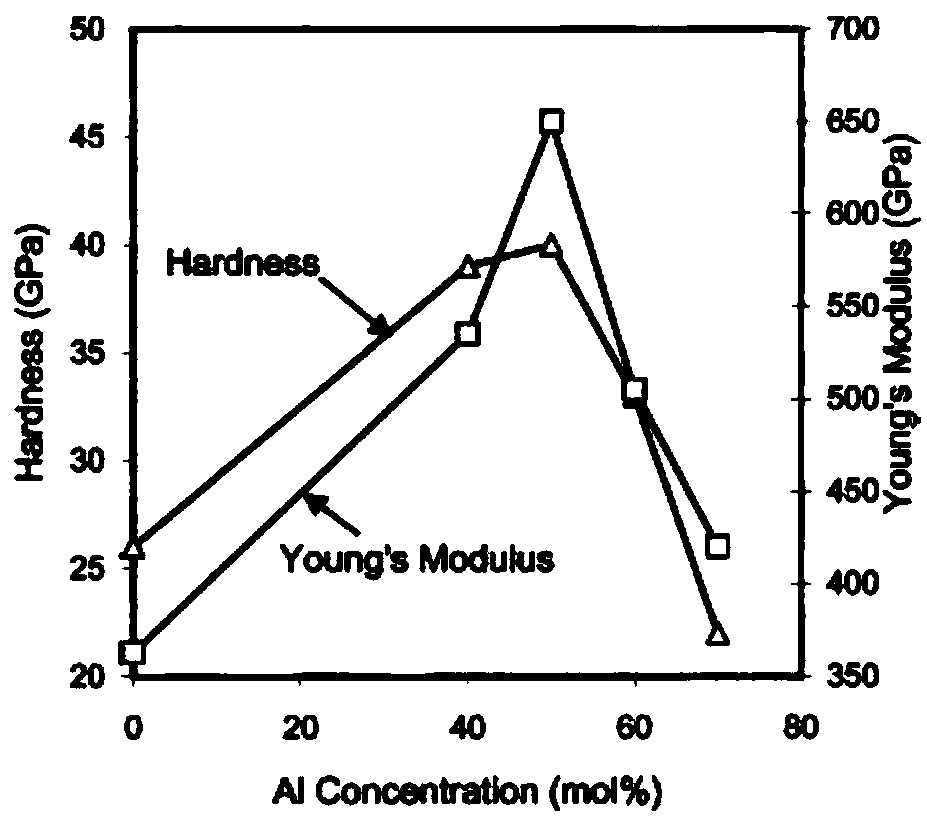

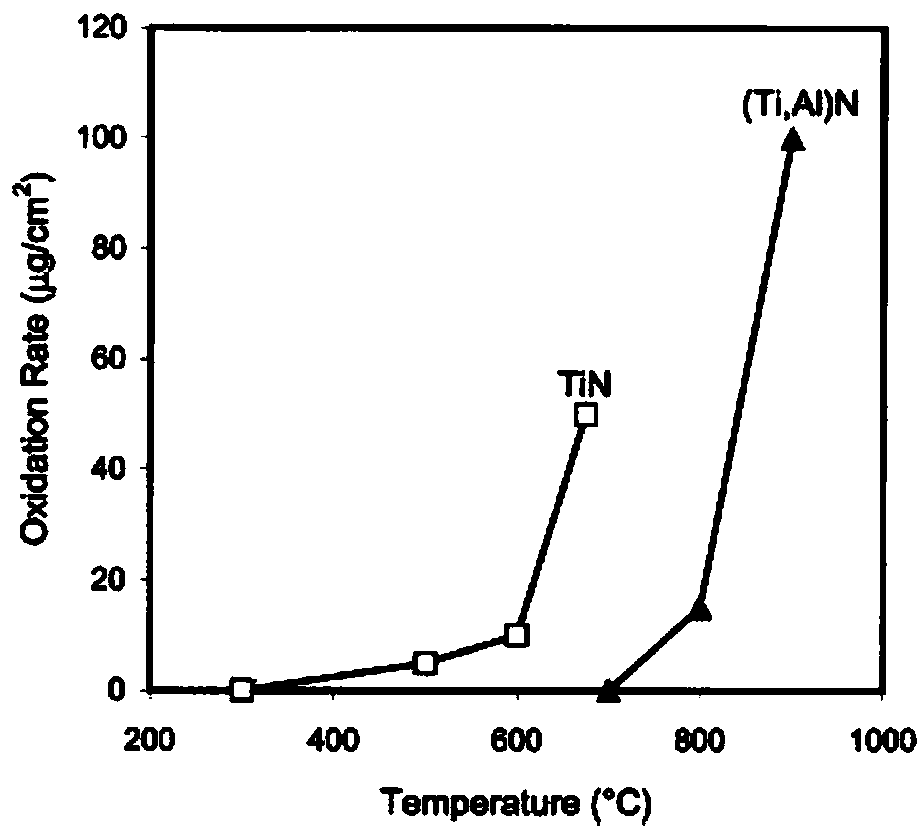

TiAlN ultra-hard composite coating provided with hardness gradient layer for supporting and preparation method of TiAlN ultra-hard composite coating

PendingCN107937876AThe lattice constant decreasesExtend your lifeVacuum evaporation coatingSputtering coatingTitanium coatingThermal fatigue

The invention discloses a TiAlN ultra-hard composite coating provided with a hardness gradient layer for supporting and a preparation method of the TiAlN ultra-hard composite coating. The TiAlN ultra-hard composite coating provided with the hardness gradient layer for supporting sequentially comprises a matrix material, an expansion layer and a deposition layer from bottom to top. The matrix material is a conductive material. The expansion layer is a plasma nitrocarburizing layer. The deposition layer is a nitrogen-aluminum-titanium coating. Through a compact TiAlN ultra-hard film, the matrixmaterial has sufficient wear resistance. The plasma nitrocarburizing layer has a hardness gradient and thus can remarkably improve the capacity to support a hard and brittle surface layer, and the bearing capacity of the TiAlN ultra-hard film is effectively improved. In addition, the residual stress value of the surface of a part is increased through nitrogen and carbon, and the fatigue resistanceof the part is made higher. Furthermore, nitride and carbide of the nitrocarburizing layer are better matched with the TiAlN film in thermophysical performance, a film / matrix interface is better fused, and thus the film has higher and more reliable bonding force and also has better thermal fatigue resistance.

Owner:NO 43 INST OF CHINA ELECTRONICS TECH GRP CETC

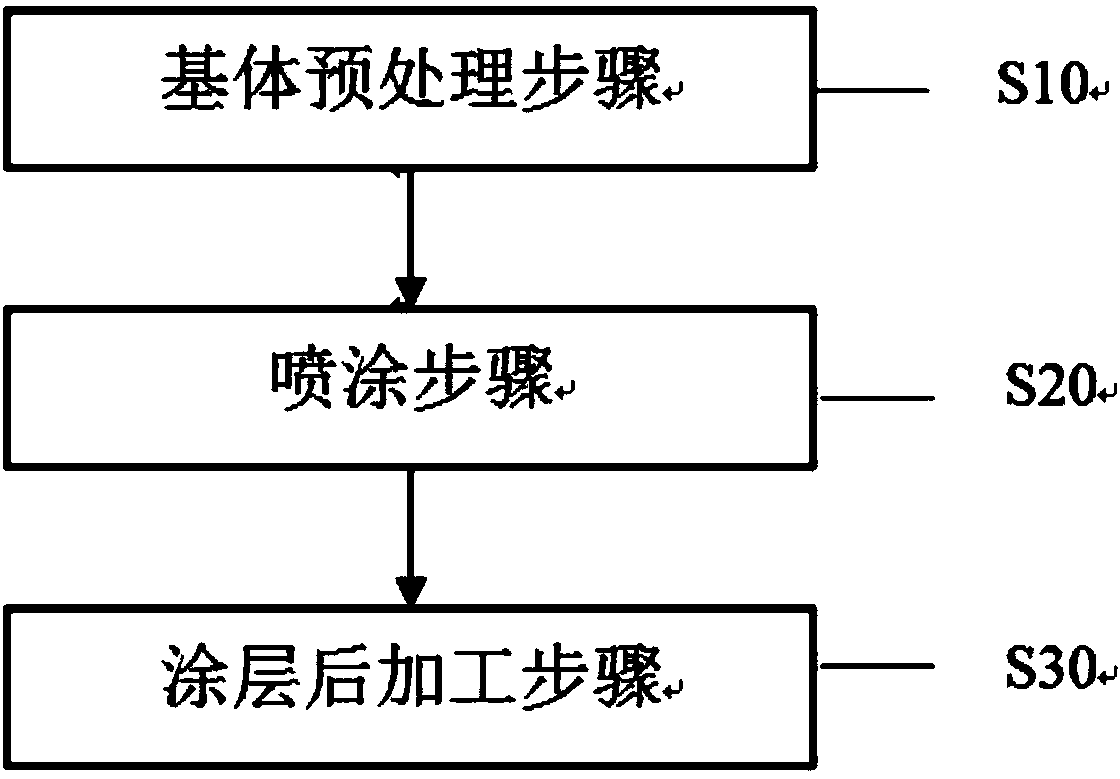

Method for spraying titanium coating on substrate

The invention relates to a method for spraying a titanium coating on a substrate. The method is characterized by comprising the following steps: performing substrate pre-processing to clear away oil and dust on the surface of the substrate; performing one-time or repeated spraying to prepare the titanium coating on the surface of the substrate. The titanium coating is sprayed by adopting a supersonic plasma coating method, and can be sprayed on the substrates such as steel, aluminum and aluminum alloy. Through the adoption of the titanium coating spraying technology, original titanium equipment can be made of steel, aluminum and aluminum alloy, and then is sprayed with a titanium coating, so that the titanium equipment has excellent corrosion resistance, and meanwhile, the manufacturing cost of the titanium equipment is reduced.

Owner:BAOJI XINFUQUAN MACHINERY TECH DEV

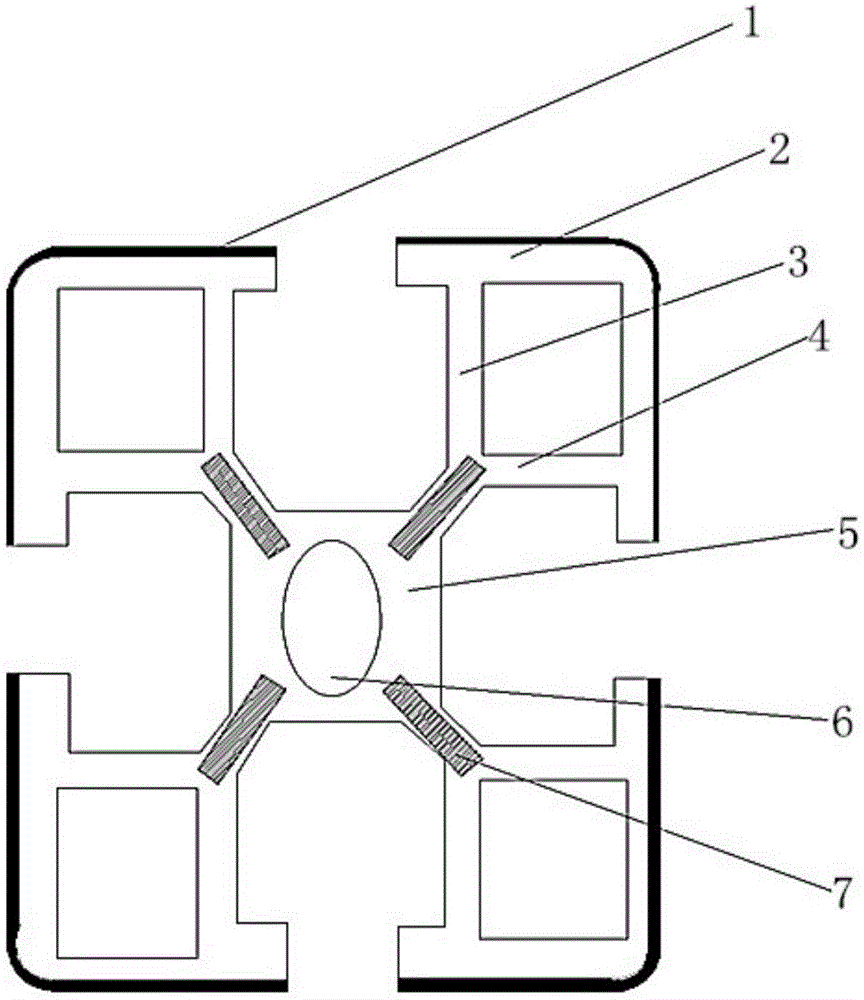

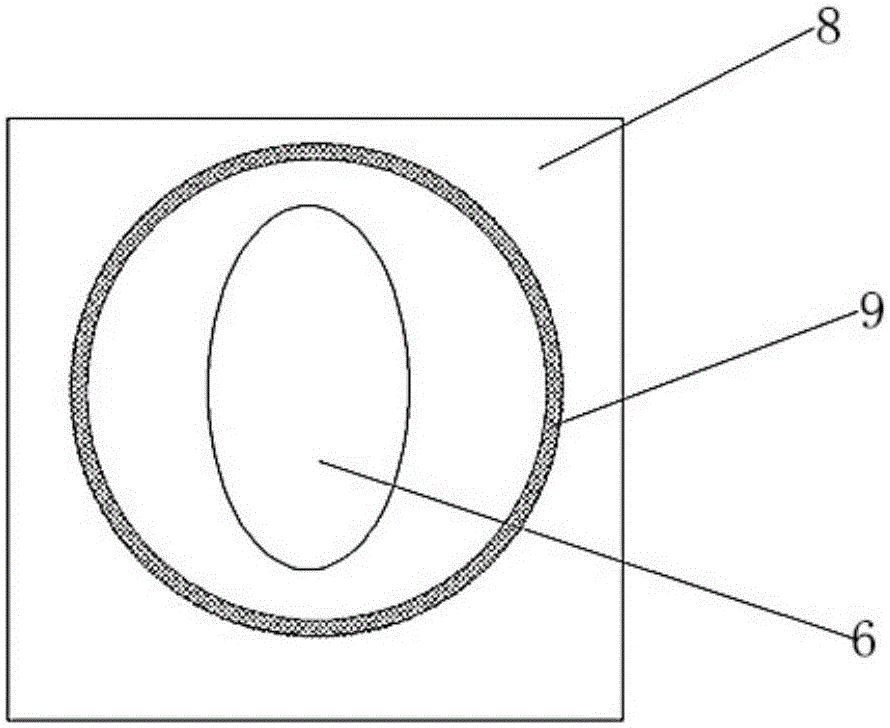

High-stability aluminum alloy section and manufacturing process thereof

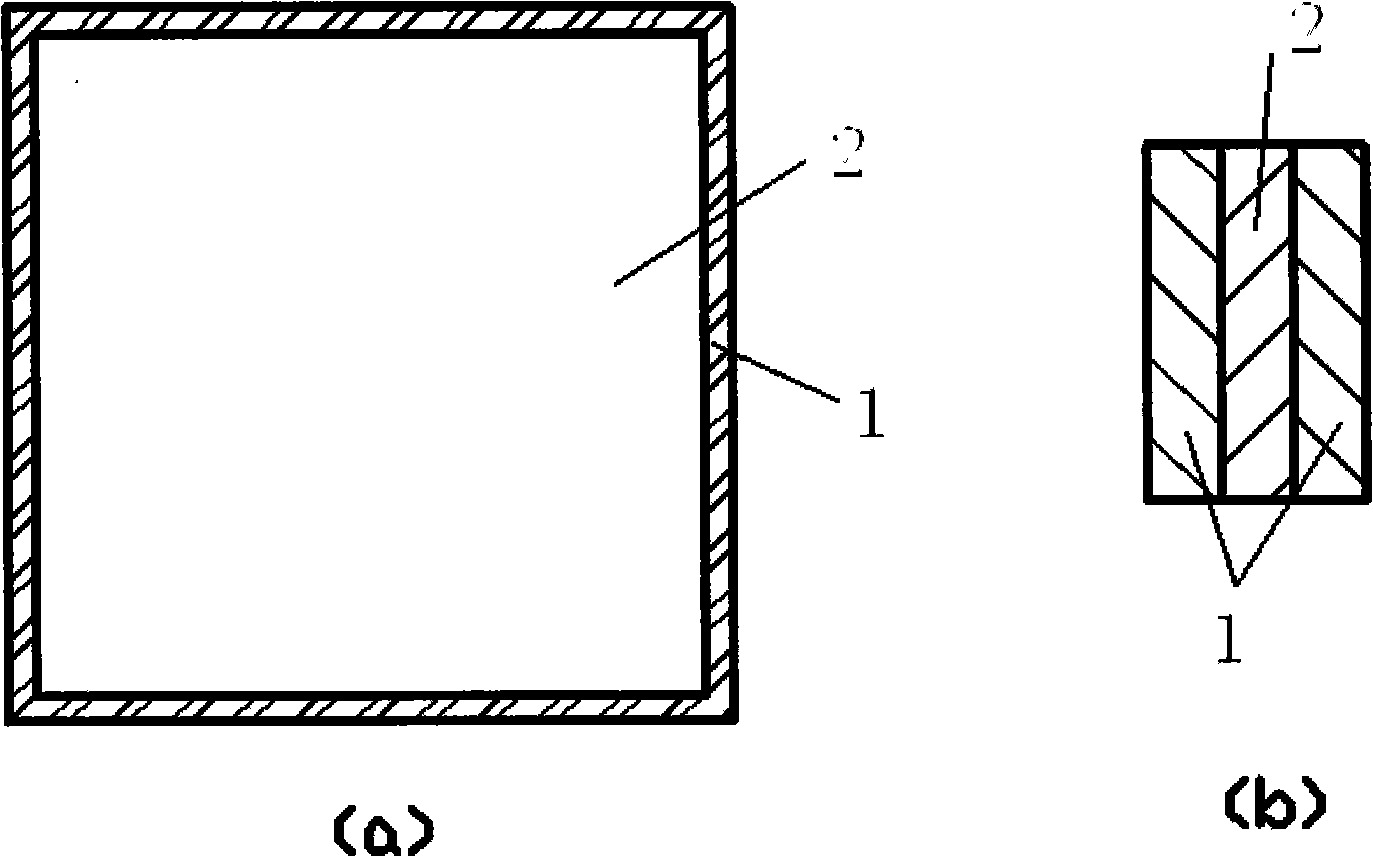

InactiveCN105135204AImprove stabilityAvoid breakingElongated constructional elementsTitanium coatingBearing surface

The invention discloses a high-stability aluminum alloy section and a manufacturing process thereof. The high-stability aluminum alloy section is composed of titanium coating layers, bearing surfaces, vertical beams, transverse beams, a center skeleton, a center hole and steel liners, wherein the center skeleton is square, one pair of the vertical beam and the transverse beam are in right-angle arrangement at each corner of the center skeleton, the bearing surfaces are arranged on the vertical beams and the transverse beams, each bearing surface forms a square with one pair of the vertical beam and the transverse beam, the corresponding four bearing surfaces on the center skeleton form a square, the steel liners are arranged in the connecting positions of the center skeleton and the vertical beams as well as the transverse beams, the titanium coating layers are arranged on the bearing surfaces, and the center hole is formed in the center of the center skeleton. According to the high-stability aluminum alloy section, a unique square structure of the center skeleton is adopted, so that the stability of the section is greatly improved.

Owner:ANHUI LANT ALUMINUM

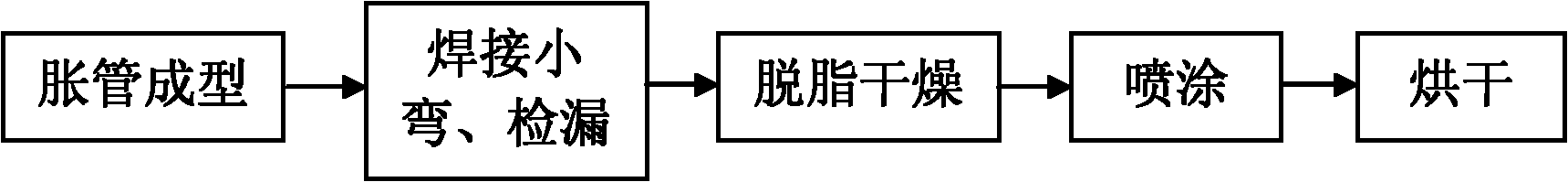

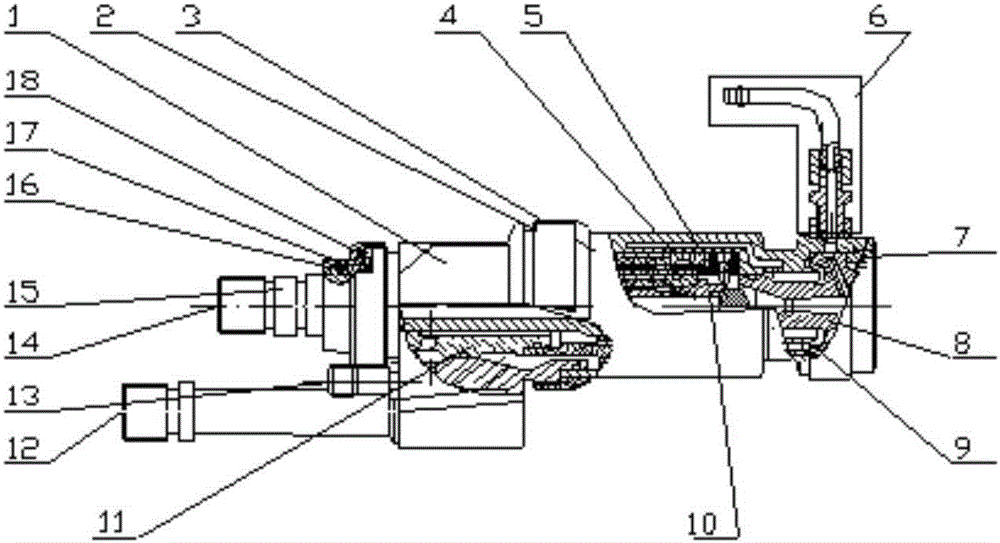

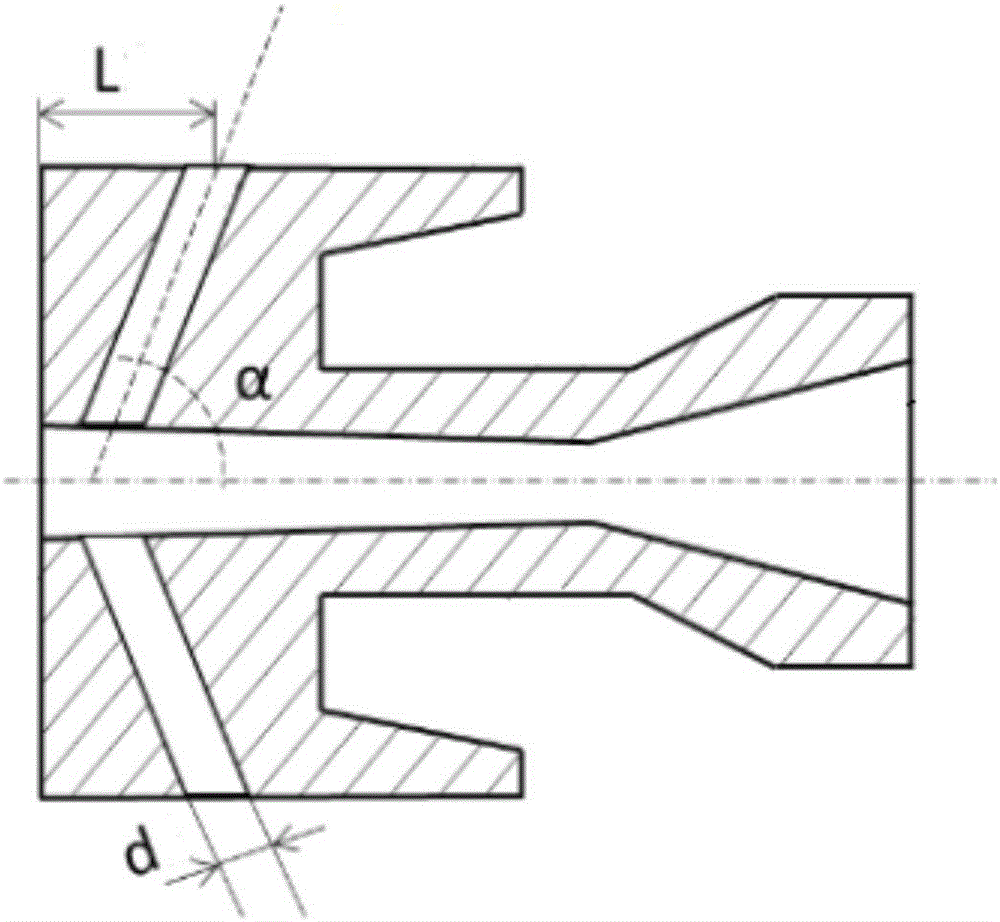

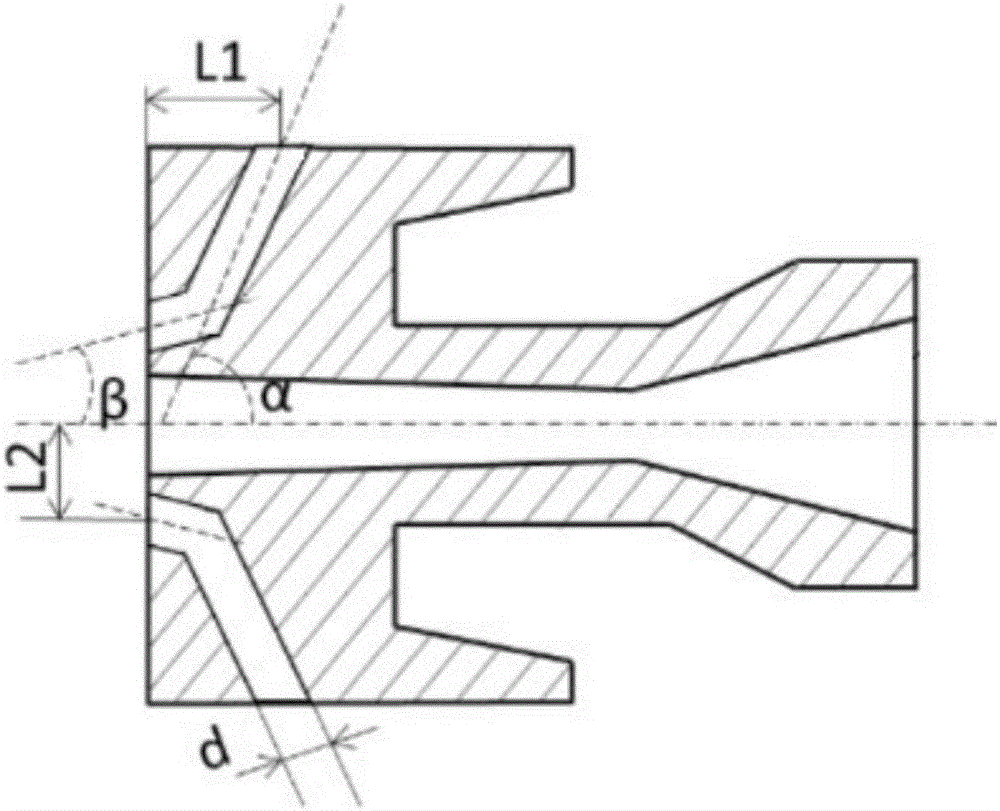

Titanium heat exchanger for air conditioner and processing method thereof

ActiveCN102192620ALong-term stable antibacterial and mildew removal effectGood for healthEvaporators/condensersCoatingsTitanium coatingPlate heat exchanger

The invention discloses a titanium heat exchanger for an air conditioner, and a processing method thereof. The titanium heat exchanger comprises a heat exchange pipe and cooling fins. The surface of each cooling fin is provided with a TiO2-containing titanium coating, the titanium coating contains CuO and Ag2O, the mass percentage of CuO is 10%-15%, and the mass percentage of Ag2O is 10%-15%. When the light is sufficient, the titanium coating of the heat exchanger is decomposed under the photochemical catalysis of the ultraviolet light, and various organics attached on the titanium oxide surface are removed. When the light is insufficient, titanium oxide also can make the internal electrons excited to generate hydroxyl atomic groups and hydrogen peroxide under the action of nano silver and nano copper, so as to decompose the organics. Therefore the heat exchanger has long-term and stable effect of anti-bacterial and mildew-removal.

Owner:TCL AIR CONDITIONER ZHONGSHAN CO LTD

Heat-pump water heater titanium evaporator and manufacturing method thereof

InactiveCN103062961AStable antibacterial and mildew removal effectImprove wear resistanceAntifouling/underwater paintsEvaporators/condensersTitanium coatingAdhesive

The invention discloses a heat-pump water heater titanium evaporator and a manufacturing method thereof. The heat-pump water heater titanium evaporator comprises evaporation pipes and fins, wherein titanium coatings are coated on the fins, each titanium coating is mainly composed of nanometer titanium dioxide, nanometer silver nitrate, polymeric dispersants and adhesives, and the nanometer titanium dioxide is processed through surface organic and inorganic compound film wrapping. Due to the facts that the titanium coating is mainly composed of anatase nanometer titanium dioxide, and the nanometer titanium dioxide is processed through surface organic and inorganic compound film wrapping, various organics attached to the surfaces of the coatings can be dissolved and removed, and therefore a heat exchanger has long-term stable antibiosis and mildew removing effects, and the problem that in an existing heat-pump water heater, heat exchanging property is affected by dust and bacterium which are easily generated on the fins of the evaporator is solved.

Owner:TCL AIR CONDITIONER ZHONGSHAN CO LTD

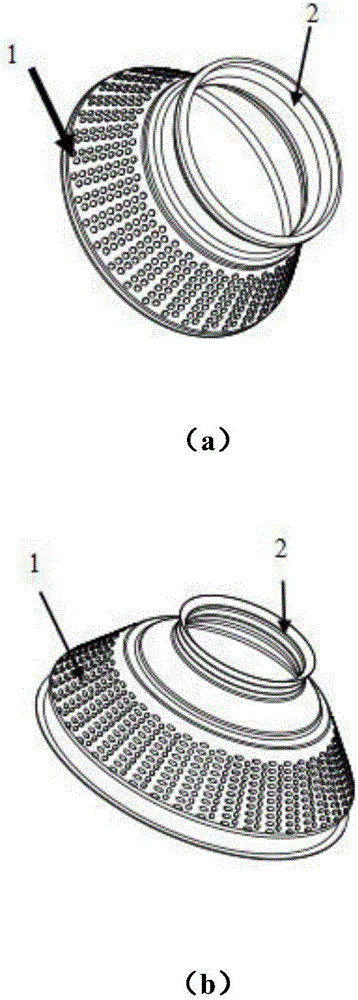

Method for obtaining bioactivity and open type stephanoporate titanium coating from implant surface

ActiveCN101138649AIncrease interface areaIncreased shear strengthSurface reaction electrolytic coatingEngineeringBone growth

The present invention relates to an open-typed porous titanium coating method, which acquires the biological activity on the implant surface. The present invention is applicable for the biological fixing-typed implants in the orthopedics and dentistry, which can improve the bone growth effect of the implant and the Osseo integration strength. The method is that the titanium ball in accordance with the implanting requirements is arranged on the implant surface after cleaning the implant material. The processed implant material is transported to the vacuum furnace, which is vacuum pumped till above 10-2 Pa before heating and sintering. The sintering method is as following. The room temperature is heated to the sintering temperature of 1,000 DEG C to 1,600 DEG C at the speed of 1 DEG C per minute to 100 DEG C per minute. The temperature is maintained for 0 hour to 10 hours. The temperature reduces from the sintering temperature to the room temperature at the speed of 0.1 DEG C per minute to 100 DEG C per minute. The implant material with the sintering titanium coating is taken out and put into the alkali solution with the concentration from 0.1N to 10N, before heating till 40 DEG C to 100 DEG C. The implant material is soaked for 0.5 hours to 100 hours before cleaning by the distilled water and the medical alcohol. The last step is packaging.

Owner:CHANGZHOU TIANLI BIOLOGICAL COATING TECH

Method of preparing titanium coating through atmosphere supersonic plasma spraying based on gas protection

ActiveCN106148880AReduce the chance of oxidationHeating fastMolten spray coatingTitanium coatingSpray nozzle

The invention discloses a method of preparing a titanium coating through atmosphere supersonic plasma spraying based on gas protection. The method comprises the following steps of: step one. cleaning and roughening the surface of a base material; step two. feeding Ti powder into a supersonic plasma spraying gun, feeding an Ar gas serving as a protecting gas into a protecting gas hole of a radial protecting gas positive pole nozzle or an axial protecting gas positive pole nozzle, wherein the flow rate of Ar is 100-190L / min, and the amount of the fed powder is 15-50g / min; and step three. maintaining a spraying distance at 60-90mm, and spraying the surface of the base material. The method has the beneficial effects that the content of oxide and nitride in the coating can be reduced; the high-purity Ti coating can be obtained; and the corrosion resistance of the coating is improved.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Preparation method of in situ coating modified NCA cathode material

InactiveCN106711444AImproved magnification performanceImprove structural stabilityCell electrodesAnhydrous ethanolTitanium coating

The invention provides a preparation method of an in situ coating modified NCA cathode material. The method includes the steps of: 1. dissolving a titanium source in anhydrous ethanol to prepare a titanium coating solution; 2. adding a Ni0.80Co0.15Al0.05(OH)2 precursor, a lithium source and a complexing agent into the titanium coating solution, and performing heating stirring at 60-80DEG C to obtain a sol; 3. carrying out drying, grinding and sieving on the sol in order, placing the obtained powder mixture in a resistance furnace to perform sintering at 800-900DEG C for 10-20h, and conducting cooling to obtain a sintered material; and 4. crushing and sieving the sintered material so as to obtain a NCA cathode material coated with Li4Ti5O12 on the surface. The coated material prepared by the method provided by the invention is a lithium-containing compound, adopts Li4Ti5O12 as the coating layer, and can greatly improve the cycle performance under the premise of not significantly affecting the capacity of the NCA cathode material.

Owner:JINGMEN GEM NEW MATERIAL

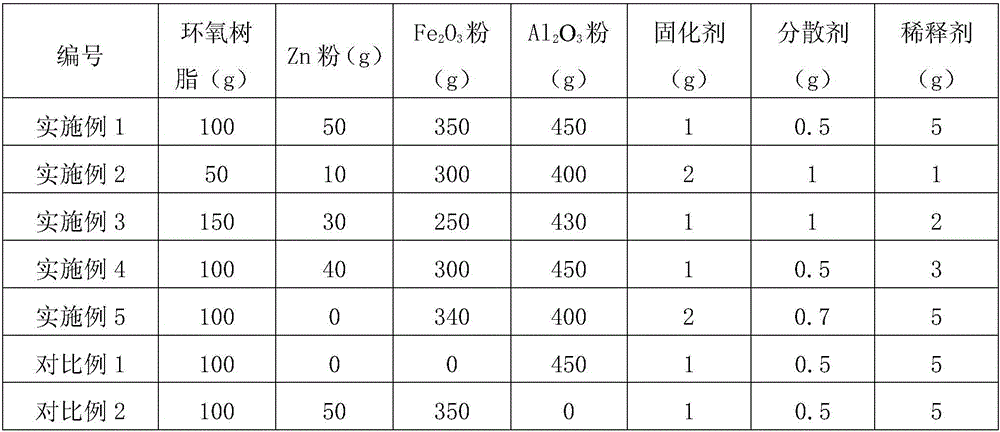

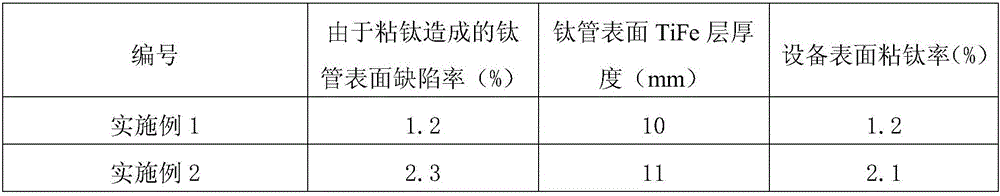

Oily high-temperature-resisting bonding prevention titanium coating and application thereof

ActiveCN105969084AHigh yieldIncrease productivityFireproof paintsPolyurea/polyurethane coatingsTitanium coatingIsolation layer

The invention relates to an oily high-temperature-resisting bonding prevention titanium coating and application thereof, belongs to the technical field of titanium-steel bonding prevention coatings and aims at providing an oily high-temperature-resisting bonding prevention titanium coating used in titanium tube rolling. The coating is prepared from, by weight, 50-150 parts of an oily film-forming agent, 0-50 parts of zinc powder, 250-350 parts of ferric oxide and 400-450 parts of aluminum oxide powder. The oily high-temperature-resisting bonding prevention titanium coating is applied to a steel and iron device, a roller or a winch to form a very good isolation layer and can ensure that titanium ingots do not produce bonding reaction with the steel and iron device, the roller or the winch in the 900 DEG C rolling or perforation process, improve the size precision and surface quality of products, improve the machining yield and production efficiency of titanium materials and reduce the production costs.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

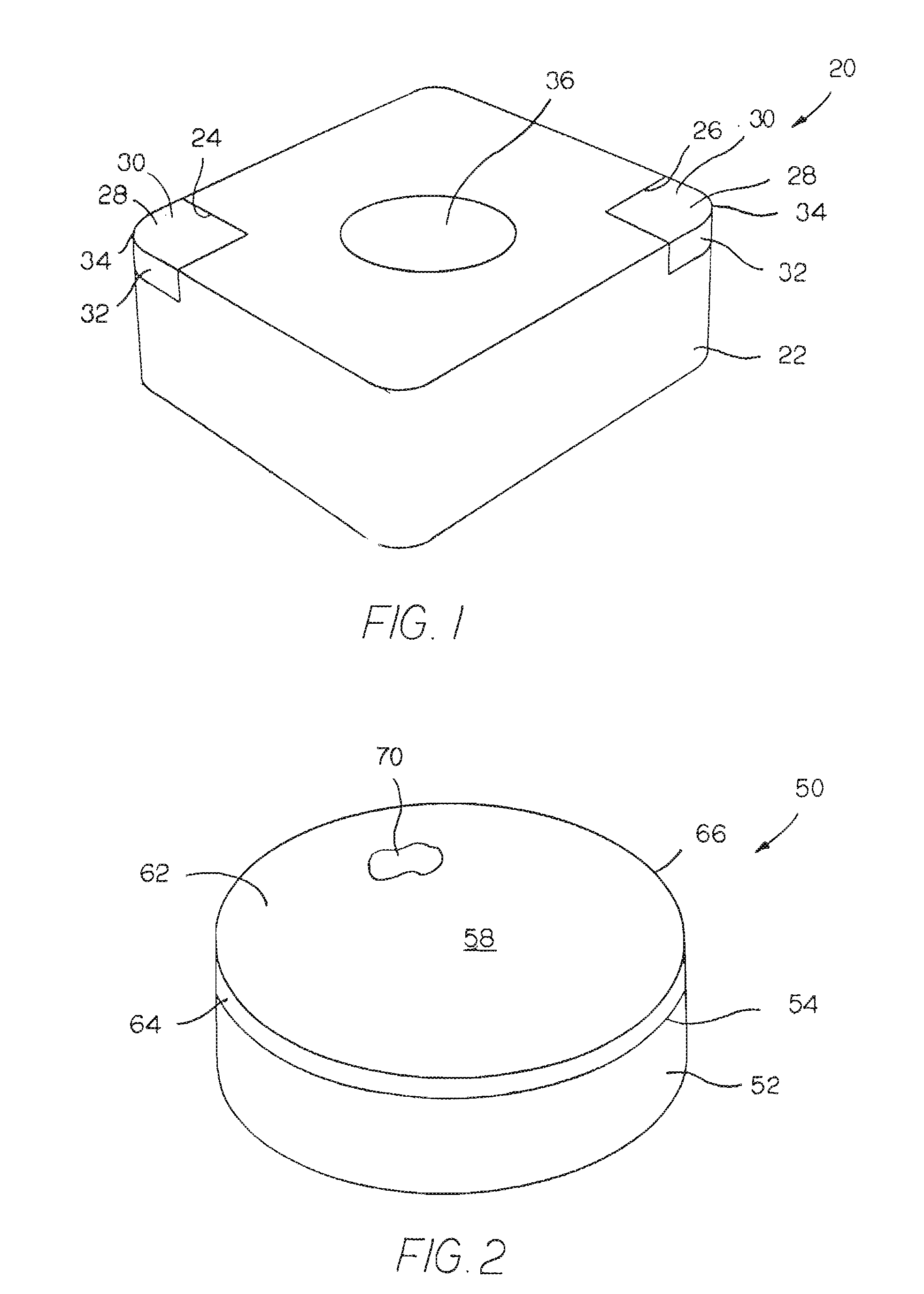

Biocompatible implants made of nanostructured titanium with antibacterial properties

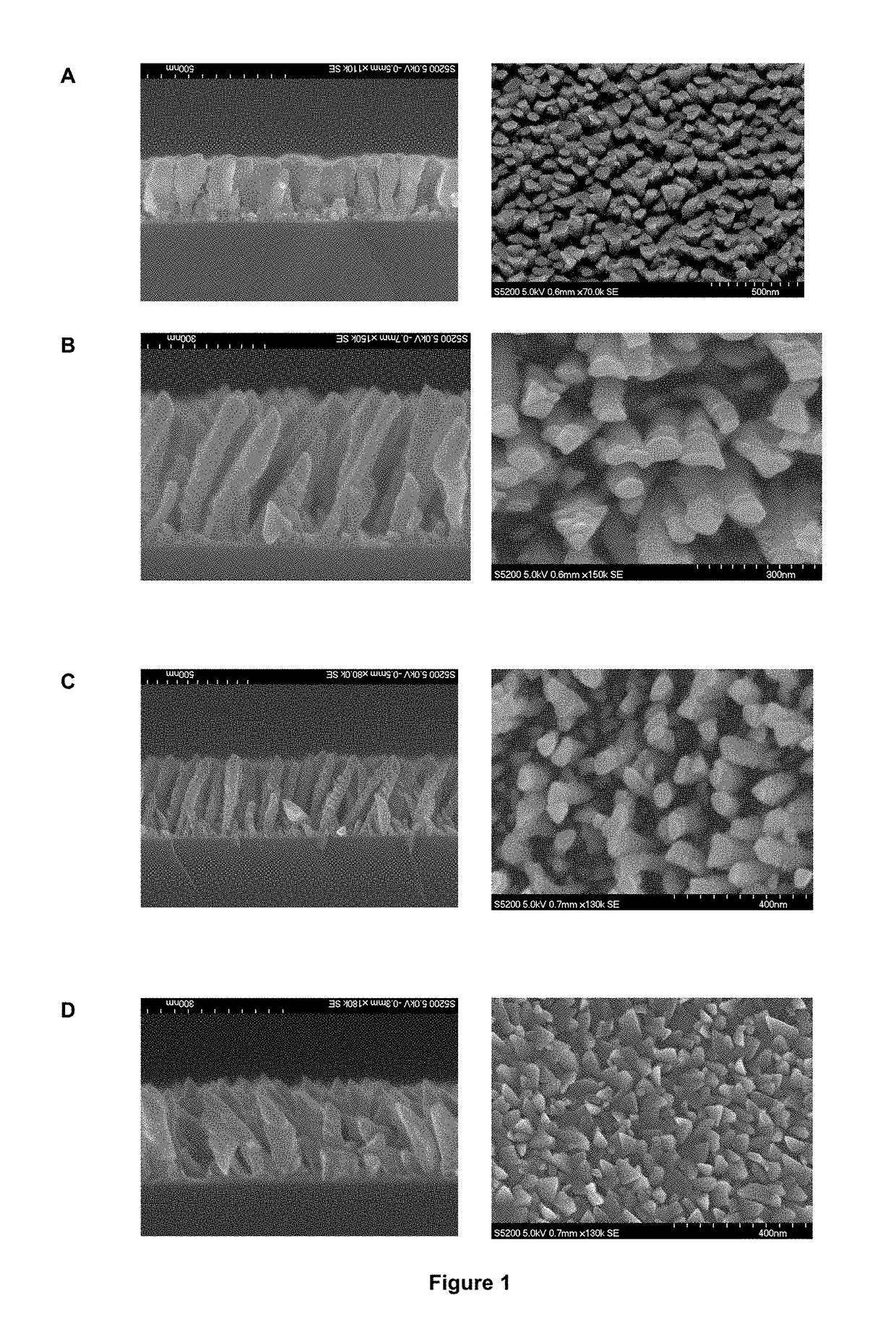

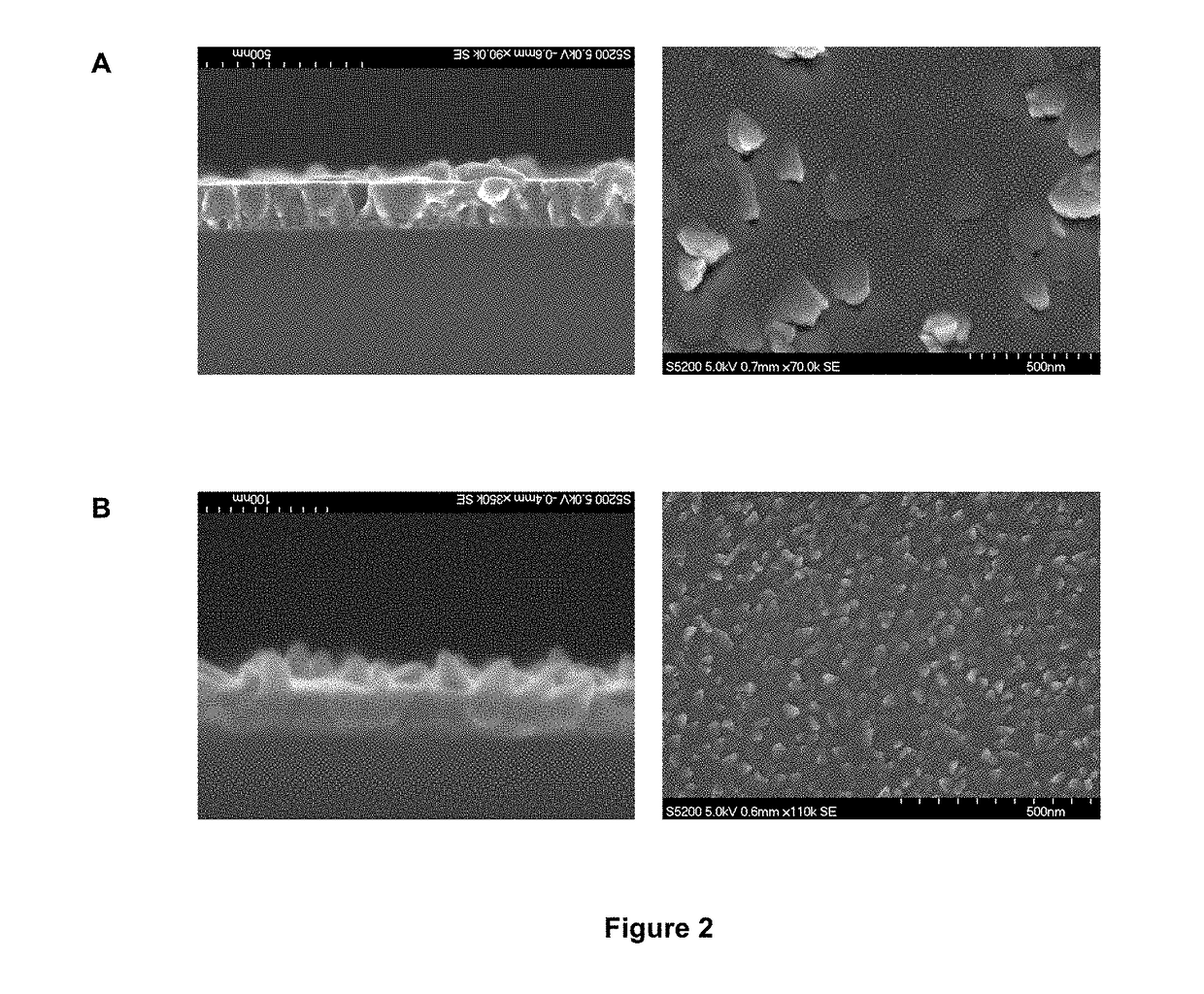

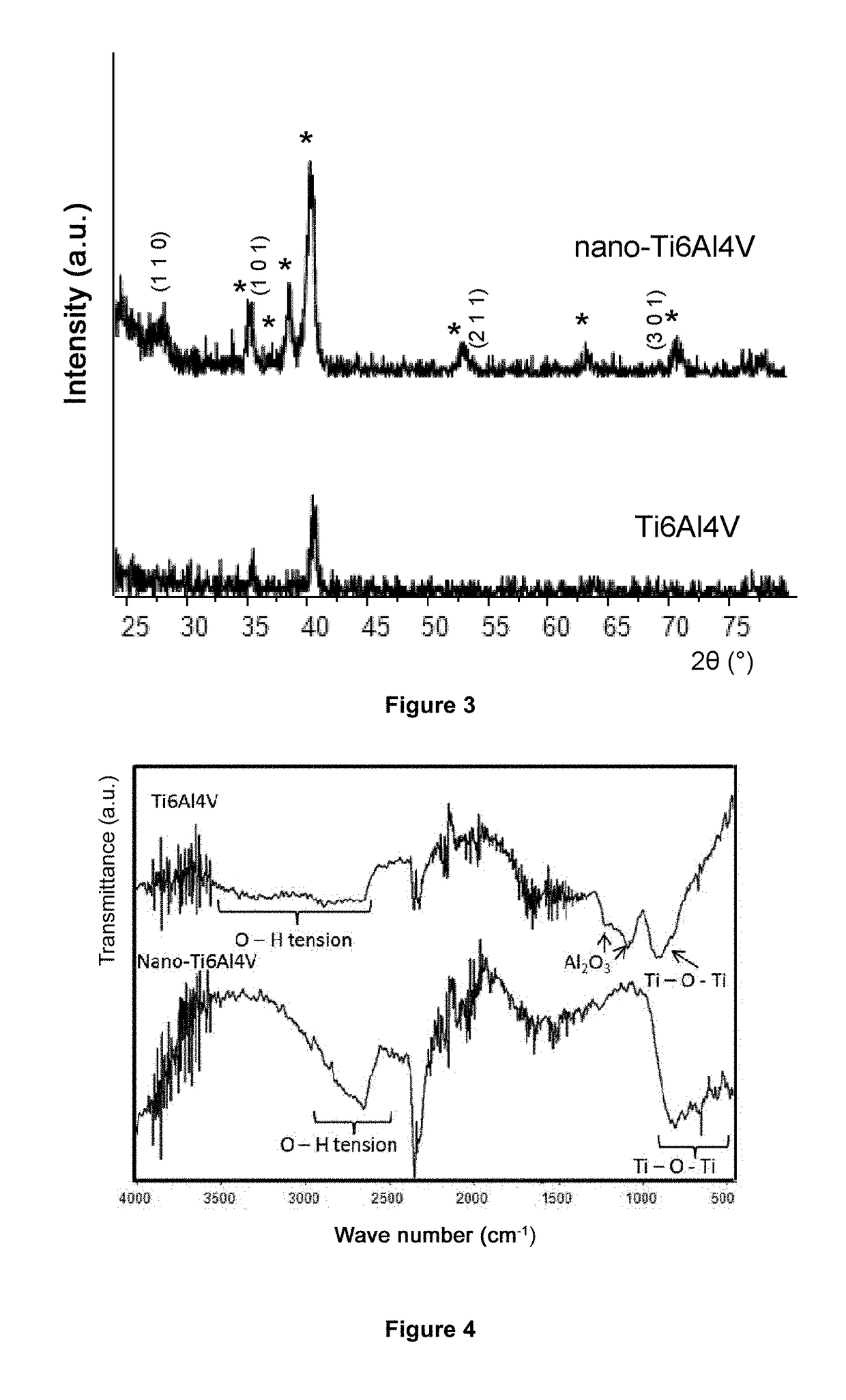

InactiveUS20170224458A1High densityShorter spacingDental implantsBone implantTitanium coatingBacterial Adhesions

A new titanium-based implant is disclosed, which is formed by a titanium coating manufactured with biomaterials with applications in osseous implantology. The nanotopographical characteristics of these implants inhibit bacterial adhesion and the formation of a bacterial biofilm on the surface, whilst simultaneously presenting suitable properties for the adhesion, stretching and proliferation of bone-forming cells. Moreover, the invention comprises a method for manufacturing the implant by means of oblique-incidence techniques and the use thereof in osseous implantology.

Owner:UNIV COMPLUTENSE DE MADRID +1

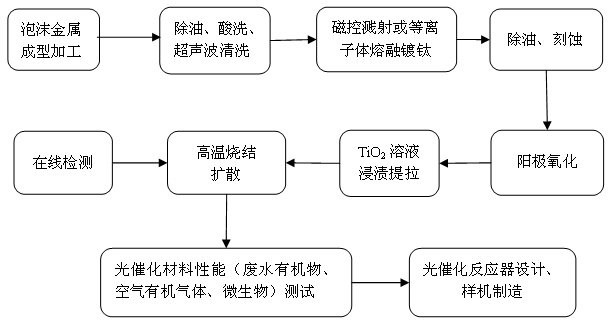

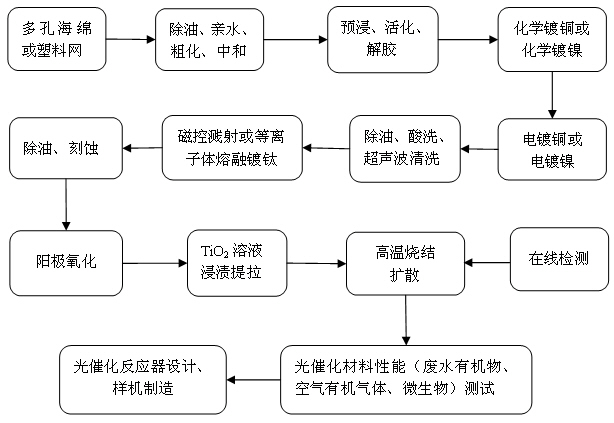

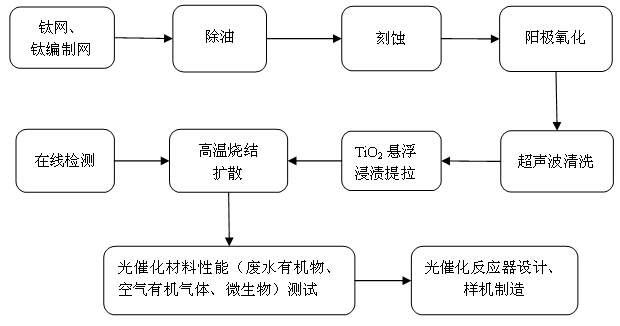

Method for preparing multidimensional photocatalytic material

InactiveCN102580740AImprove photocatalytic performanceAvoid the problem of easy sheddingOrganic-compounds/hydrides/coordination-complexes catalystsMetal/metal-oxides/metal-hydroxide catalystsSputteringTitanium coating

The invention provides a method for preparing a multidimensional photocatalytic material, comprising the following steps of: (1) preparing a titanium coating material; and (2) preparing a titanium dioxide photocatalytic film on the surface of the titanium coating. The titanium coating material is prepared through any one or the combination of chemical plating, electroplating, magnetron sputtering or plasma smelting coating. The method has the main advantages that: (1) the photocatalytic property is high. to the specific, as the whole surface is completely covered by TiO2. anatase and rutile are evenly inlaid together to play a part in photocatalysis. and therefore, the photocatalytic performance of the material is greatly improved, which is generally 3-20 times of that of the traditional material; (2) the stability is good, to be specific, in the use process, the inactivation of the photocatalyst is not easy to occur, and the photocatalyst is easy to regenerate and can be used a plurality of times; (3) the bonding force is powerful, to be specific, the layers of films penetrate through each other and are pinned one another, so that the problem that the traditional material is easy to fall off is avoided; and (4) the corrosion resistance is good, to be specific, as a substrate foam material is completely covered by the titanium metal and the corrosion resistance of titanium is excellent, the corrosion resistance of the material is improved by 3-10 times.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com