Lithium ion battery positive electrode material aluminum-titanium coating preparation method

A technology for lithium-ion batteries and cathode materials, which is applied in battery electrodes, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

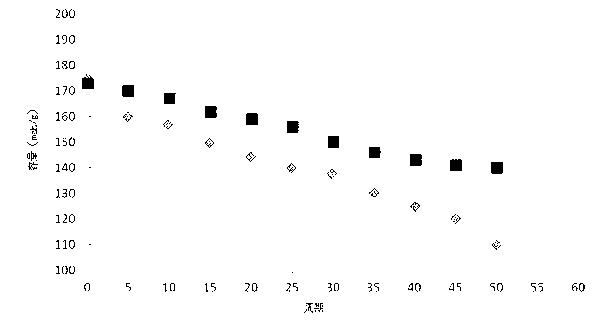

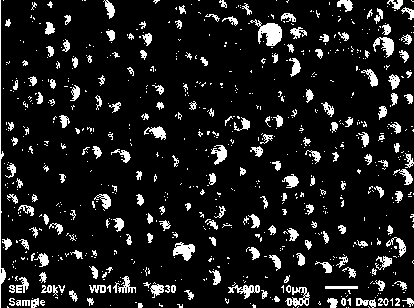

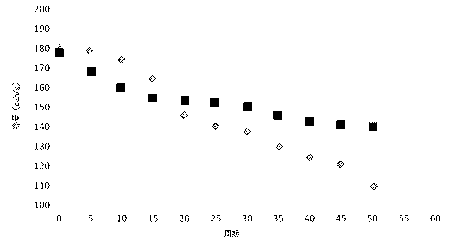

Image

Examples

Embodiment 1

[0026] Mix NiSO4, CoSO4, and MnSO4 in a molar ratio of Ni:Co:Mn=5:2:3, dissolve them in deionized water, and make a nickel-cobalt-manganese mixed solution with a comprehensive ion concentration of 2mol / 1. Add ammonia water to 8mol / 1 sodium hydroxide solution, and NH 3 :NaOH= 1:5; introduce the two mixed solutions into the reaction vessel, under the protection of nitrogen or inert gas, carry out the precipitation reaction in a continuous reaction mode, and ensure that the pH in the reaction vessel is 10~12 and the temperature is 50~ 60°C, when the particle size of the precipitate reaches the requirement, filter and wash the precipitate until the pH of the washing water is less than 8, and then dry it at 120°C to obtain Ni 0.5 co 0.2 mn 0.3 (OH) 2 Precursor.

[0027] will Ni 0.5 co 0.2 mn 0.3 (OH) 2 The precursor and lithium carbonate were uniformly mixed for 4 hours with a molar ratio of Li / (Ni+Co+Mn)=1.1, and the mixed material was put into a sintering furnace for si...

Embodiment 2

[0034] Mix NiSO4, CoSO4, and MnSO4 in a molar ratio of Ni:Co:Mn=6:2:6, dissolve in deionized water, and make a nickel-cobalt-manganese mixed solution with a comprehensive ion concentration of 2mol / 1. Add ammonia water to 8mol / 1 sodium hydroxide solution, and NH 3 :NaOH= 1:5; introduce the two mixed solutions into the reaction vessel, under the protection of nitrogen or inert gas, carry out the precipitation reaction in a continuous reaction mode, and ensure that the pH in the reaction vessel is 10~12 and the temperature is 50~ 60°C, when the particle size of the precipitate reaches the requirement, filter and wash the precipitate until the pH of the washing water is less than 8, and then dry it at 120°C to obtain Ni 0.6 co 0.2 mn 0.6 (OH) 2 Precursor.

[0035] will Ni 0.5 co 0.2 mn0.3 (OH) 2 The precursor and lithium carbonate were uniformly mixed for 4 hours with a molar ratio of Li / (Ni+Co+Mn)=1.1, and the mixed material was put into a sintering furnace for sintering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com