Method for preparing double side mosaic type hot-rolling composite silver copper strip

A hot-rolled composite and inlaid technology, used in metal rolling, metal rolling, heat treatment equipment, etc., can solve the problems of unsatisfactory cladding firmness and bonding strength, and achieve obvious silver saving effect, high precision, and guaranteed The effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

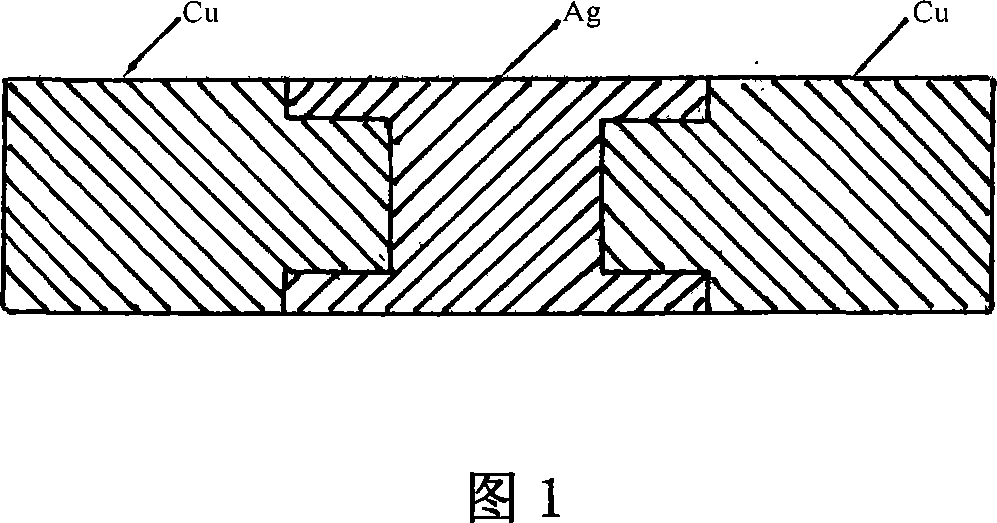

[0012] Embodiment 1: the silver plate is rolled to a thickness of 12 mm, a groove of a certain size is finished with a milling machine on both sides of the silver plate, and a boss of a certain size is finished with a milling machine at one side of a copper plate with a thickness of 12 mm, The grooves and bosses are interference-fitted into a copper / silver / copper composite billet. The composite billet is heated and kept at 600°C for 10 minutes under the protection of argon, and is hot-rolled on a φ350 hot rolling mill to a thickness of 1.80mm, and then rolled on a cold rolling mill. Cold rolled to 0.20mm, annealed at 450°C under argon protection for 30 minutes, finish rolled to 0.10mm, slit to 80mm wide, and finished products after cleaning.

Embodiment 2

[0013] Embodiment 2: Extrude the silver ingot into a double-sided groove-shaped silver profile, and then cut it into a double-sided groove-shaped silver composite billet; extrude the copper ingot into a single-side protruding copper profile, and then cut it into a single-side protruding copper profile. Composite billet: after the interference fit of the copper / silver / copper composite billet, under the protection of argon, it is heated and kept at 600°C for 10 minutes, hot rolled on a φ350 hot rolling mill to a thickness of 1.80mm, and then cold rolled on a cold rolling mill to 0.20mm, annealed at 450°C for 30 minutes under argon protection, finish rolling to 0.10mm, slitting to 80mm width, and finished products after cleaning.

Embodiment 3

[0014] Embodiment three: the silver plate is rolled to be 12mm thickness, go out the groove of certain size with mould, die-pressing the groove of certain size at two sides of silver plate, make double-sided groove shape silver composite billet; A boss of a certain size is molded on the side to make a single-side protruding copper composite billet. After interference fitting the copper / silver / copper composite billet, it is heated and kept at 700°C for 10 minutes under the protection of argon, and hot rolled at φ350 Hot rolling on the machine to a thickness of 1.80mm, then cold rolling to 0.20mm on a cold rolling mill, annealing at 450°C under argon protection for 30 minutes, finish rolling to 0.10mm, slitting to a width of 80mm, and cleaning to become finished products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com