Preparation of foamed metal sandwich board using clad rolling method

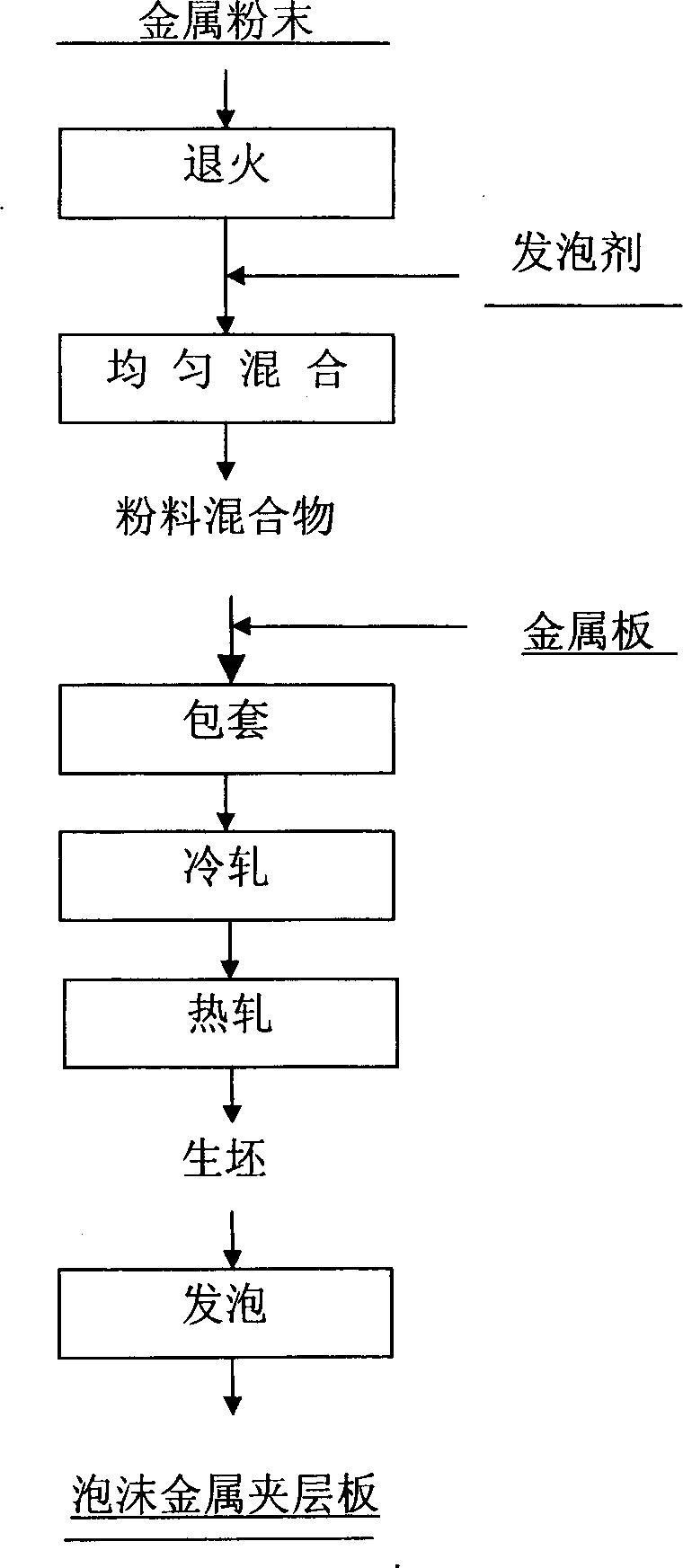

A foamed metal and sandwich panel technology, applied in the direction of metal layered products, metal rolling, metal rolling, etc., can solve the problems of long preparation process cycle, unsatisfactory combination of foamed metal and metal plate, etc., and achieve simple equipment conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] After the AlSi6 aluminum alloy powder is annealed, after passing through a 200-mesh sub-sieve, mix it with titanium hydride of the same particle size (consumption is 2% of the total mass of the powder mixture) in a ball mill (ball-to-material ratio 1: 1, 100 rpm / min), after grinding the surface of pure aluminum plate with a thickness of 0.8 mm, it is wrapped with a mixture of metal powder and titanium hydride (the height of the sleeve is 15 mm), cold-rolled to a thickness of 5 mm, and then hot-rolled at a temperature of 450 ° C (30% reduction) to 3.5 mm, foaming at 620 ° C for 10 minutes, can obtain aluminum with a thickness of 15-17 mm, a surface layer thickness of 0.6 mm, a pore diameter of 0.8-2 mm, and a porosity of 60%-70% - Aluminum sandwich panel with porous foam.

Embodiment 2

[0033] After the 6061 aluminum alloy powder is annealed and passed through a 300-mesh sieve, it is mixed evenly with titanium hydride of the same particle size (the amount is 2% of the total mass of the powder mixture) in a ball mill (ball-to-material ratio 1:1, speed 120 rpm / min), the surface of the pure copper plate with a thickness of 0.6 mm is polished, and then wrapped with a mixture of metal powder and titanium hydride (the height of the sleeve is 15 mm), cold-rolled to a thickness of 5 mm, and then hot-rolled at a temperature of 500 ° C ( 30% reduction) to 3.5 mm, foaming at 680 degrees for 12 minutes to obtain copper with a thickness of 15-17 mm, a surface layer thickness of 0.5 mm, a pore size of 1-3 mm, and a porosity of 60%-80% - Aluminum sandwich panel with porous foam.

Embodiment 3

[0035] After the H68 copper alloy powder is annealed, after passing through a 200-mesh sub-sieve, mix it with calcium carbonate of the same particle size (the amount is 3% of the total mass of the powder mixture) in a ball mill (ball-to-material ratio 1: 1, 100 rpm / min), the surface of the Q235 steel plate with a thickness of 0.6 mm is ground, and then wrapped with a mixture of metal powder and calcium carbonate (the height of the sleeve is 15 mm), cold-rolled to a thickness of 5 mm, and then hot-rolled at a temperature of 700 ° C ( 30% reduction) to 3.5mm, foaming at 1000°C for 8 minutes to obtain steel with a thickness of 15-17mm, a surface layer thickness of 0.5mm, a pore diameter of 0.3-0.6mm, and a porosity of 60%-80%- Porous foam copper sandwich panel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com