Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Guaranteed Thickness Requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of manufacturing thin titanium/steel composite board

InactiveCN101428389AHigh bonding strengthGuaranteed Thickness RequirementsMetal rolling arrangementsNon-electric welding apparatusSheet steelTitanium

The invention discloses a method for preparing a thin-type titanium or steel composite plate, and particularly relates to a method for preparing a composite plate manufactured by the titanium steel-based composite plate through explosion and pack rolling. The method is characterized in that in the preparation process of the thin-type titanium or steel composite plate, the titanium or steel composite plate is compounded and formed by the titanium plate and the steel plate through explosion, then two composite plates are folded and welded into a billet body, and then the thin-type titanium or steel composite plate is formed through rolling. The preparation method adopts the explosive composite process, the rolling billet body has high bonding strength after explosive compounding, the titanium or steel composite plate billet is folded and welded for rolling, and the deformation amount is in 4 to 7 times; therefore, the preparation method not only ensures higher bonding strength of the titanium or steel composite plate after rolling, but also ensures the respective thickness requirements, the prepared titanium or steel composite plate has good processing technological property, the explosive composite billets of the titanium plate and the steel plate after pack rolling have good bonding property, the bending test is performed without layering, the titanium plate surface is free from cracks and impurities, and the method has the advantages of higher bonding strength, corrosion resistance and fatigue resistance.

Owner:XIAN TIANLI CLAD METAL MATERIALS

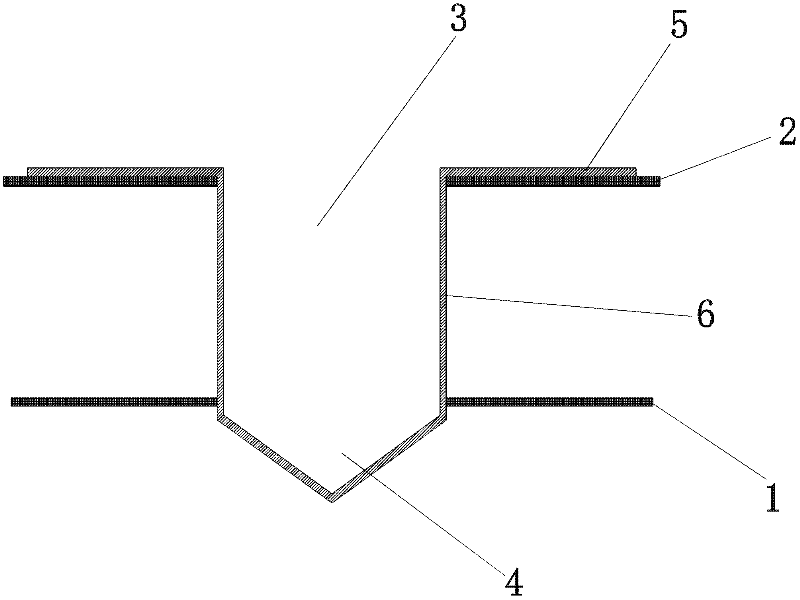

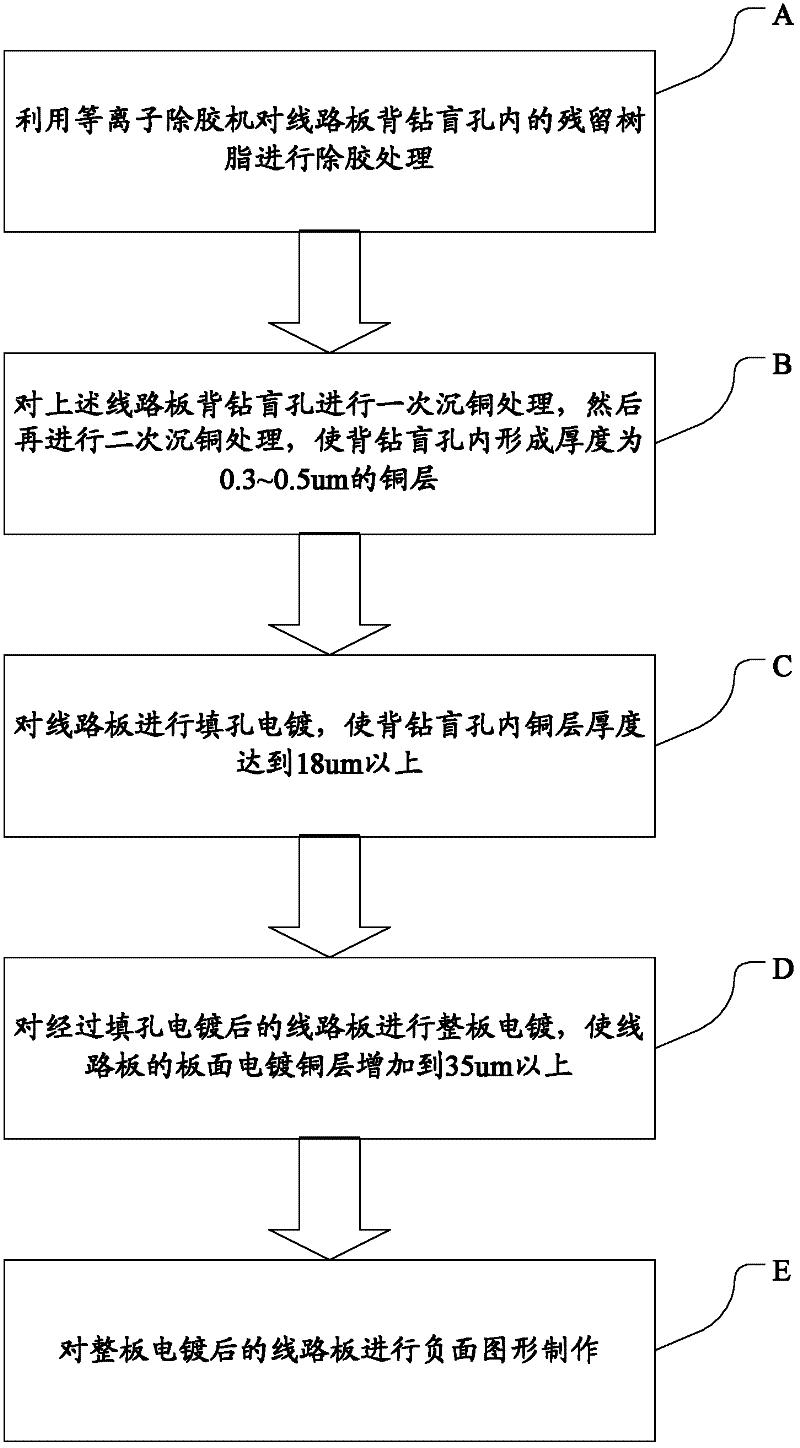

Electroplating manufacturing process of circuit board with back-drilled blind hole

InactiveCN102523702AGuaranteed Thickness RequirementsSolve the problem of glue removalPrinted element electric connection formationBinding forceElectroplating

The invention discloses an electroplating manufacturing process, comprising the following steps of: A, utilizing a plasma degumming machine to carry out degumming treatment on residual resin in a back-drilled blind hole of a circuit board; B, carrying out primary copper deposition treatment on the back-drilled blind hole of the circuit board and then carrying out secondary copper deposition treatment to form a copper layer with the thickness of 0.3-0.5 microns in the back-drilled blind hole; and C, carrying out hole-filling electroplating on the circuit board to lead the thickness of the copper layer in the back-drilled blind hole to be more than 18 microns. According to the invention, by utilizing a plasma degumming way to treat the residual resin in the back-drilled blind hole of the circuit board, the problem that a chemical degumming speed is lower is solved, and the plasma degumming way has a good degumming effect and no residues; two times of copper deposition solve the problems that the thickness of deposited copper generated by the primary copper deposition is thin, and hollow copper depositing layers, broken copper or an open circuit is easy to generate in a process of storing or electrically pre-treating a board; and the thickness of the copper layer in the blind hole can reach to be more than 18 microns through the hole-filling electroplating, so that the thickness requirement of the back-drilled blind hole is met. Compared with the prior art, the electroplating manufacturing process provided by the invention effectively overcomes the quality defects that: the back-drilled blind hole cannot be completely degummed, the binding force is poor, and the copper in the hole is thinner and the like.

Owner:SHENZHEN SUNTAK MULTILAYER PCB +1

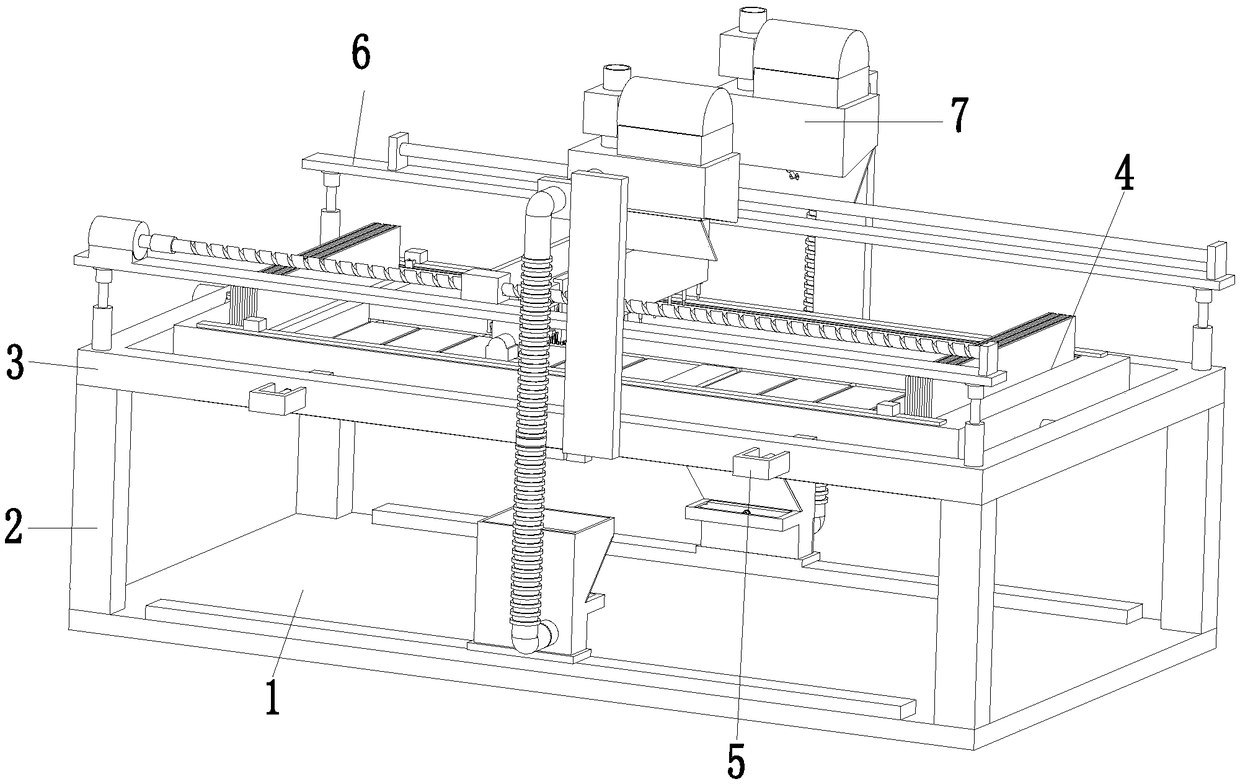

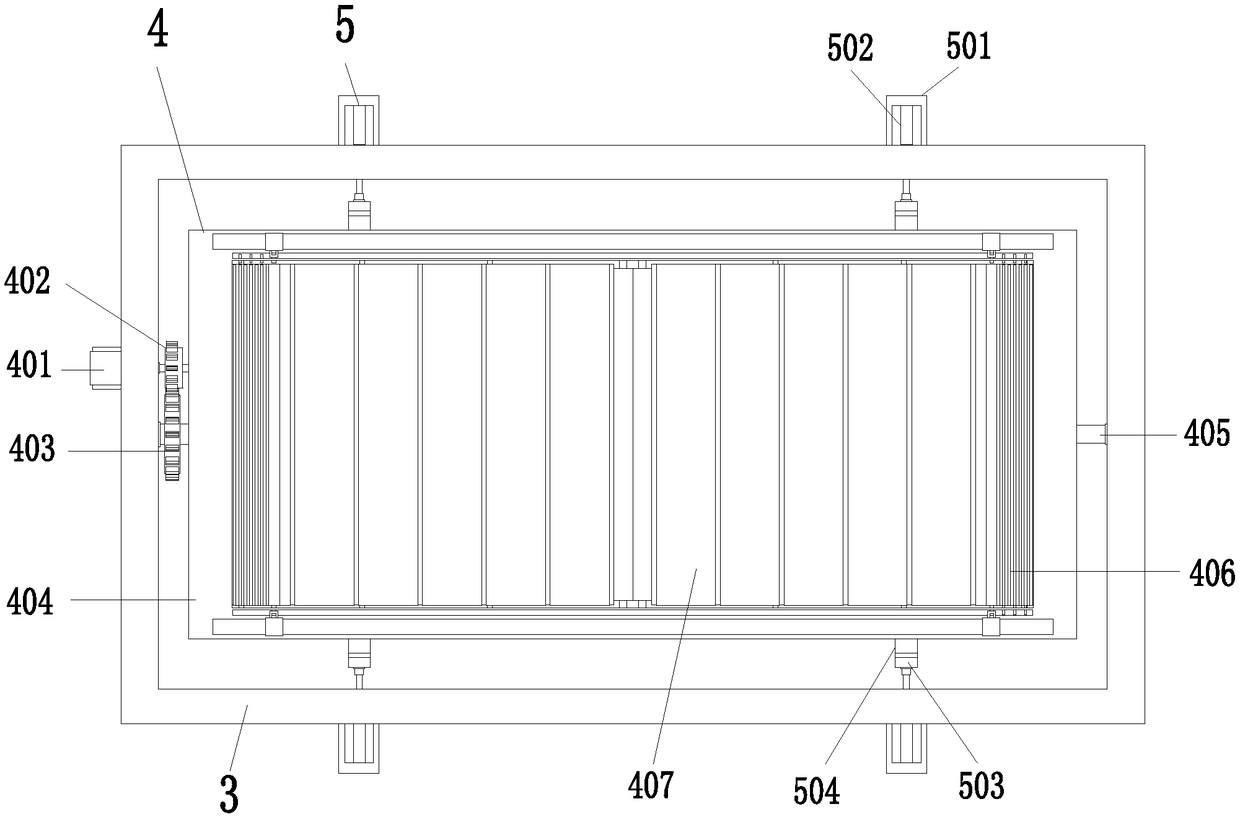

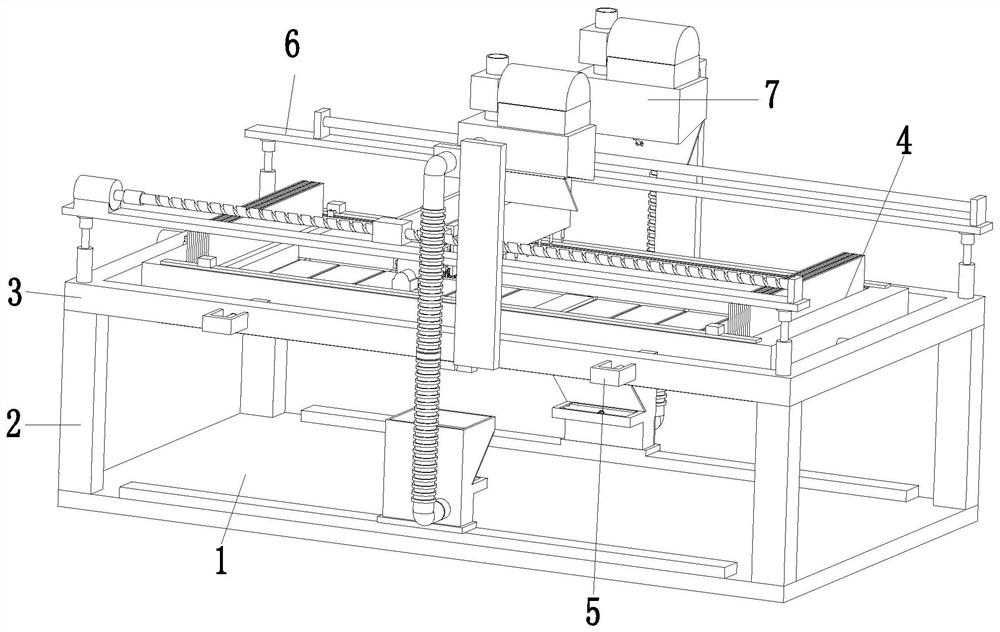

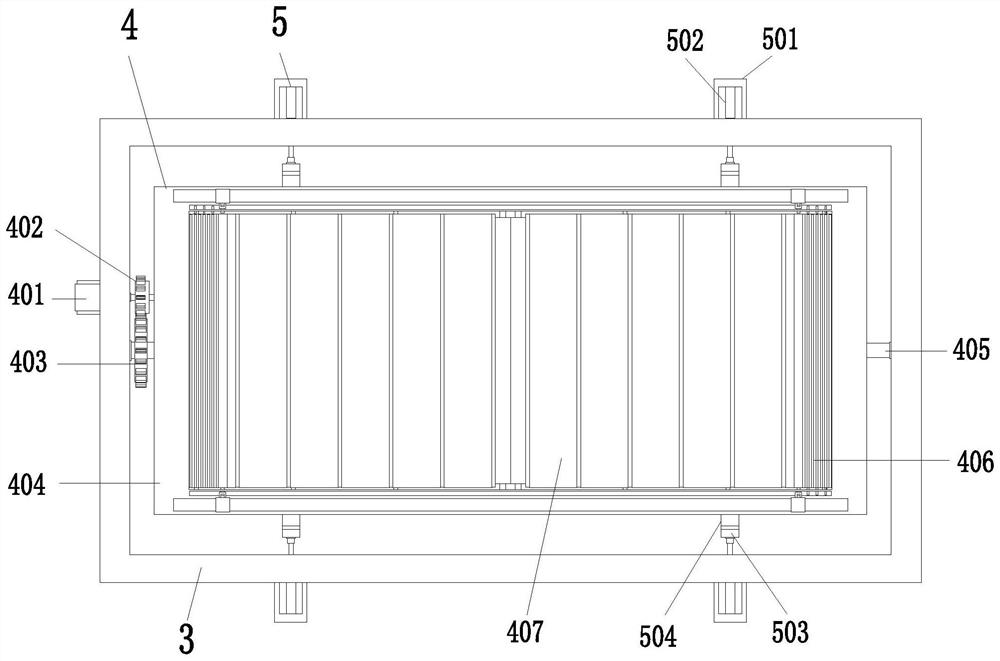

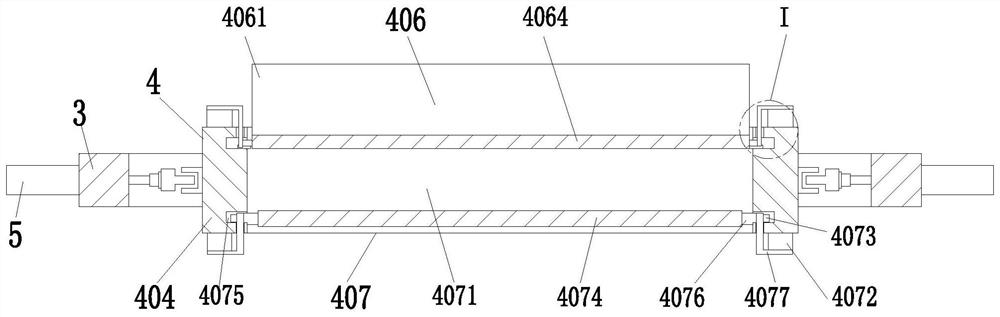

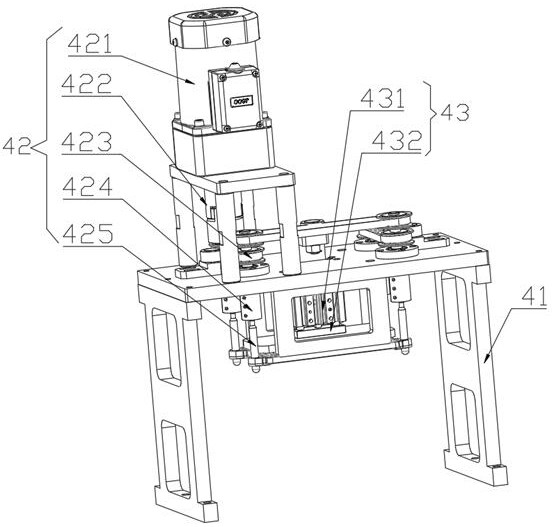

Tea leaf tedding and processing system and tea leaf tedding and processing method thereof

ActiveCN108782829AHigh degree of automationIncrease moisture contentPre-extraction tea treatmentLoss rateFixed frame

The present invention relates to a tea leaf tedding and processing system and a tea leaf tedding and processing method thereof. The tea leaf tedding and processing system comprises a bottom plate, four support columns, a supporting and fixing frame, a turning device, two positioning devices, a tedding device and two recycling devices; the upper end of the bottom plate is provided with the four support columns; the upper ends of the support columns are provided with the supporting and fixing frame; the middle part of the supporting and fixing frame is provided with the turning device; the two positioning devices are symmetrically arranged on the front and rear sides of the fixing and supporting frame; and the upper end of the turning device is provided with the tedding device. The tea leaftedding and processing system solves the following problems during tedding of tea leaves in the prior art: manual operations are usually used; the labor intensity of the manual tedding is high; the efficiency is low; the artificial tedding is uneven in thickness and cannot satisfy the thickness requirement of the tea leaves during the tedding of the tea leaves; besides, the tea leaves on the bottom layer are not easy to be turned over on the upper layer; the tea leaves on the bottom layer cannot be fully air-dried; the water loss rate of the tea leaves is affected; at the same time, the tea leaves are easy to fall during the tedding; the tea leaves cannot be collected automatically; the operation is complicated; the production efficiency is low; the stability is poor; and the tea leaves cannot be turned over automatically.

Owner:湖南壶瓶山茶业有限公司

Three-in-one card seat connector and mobile phone

InactiveCN105811195AEasy to useGuaranteed Thickness RequirementsCoupling device connectionsTelephone set constructionsEngineeringContact zone

The invention relates to a mobile phone and provides a three-in-one card seat connector which comprises a plastic seat and a conductive plate. The plastic seat is divided into a first contact zone, a second contact zone and a third contact zone. A first conductive terminal, a second conductive terminal and a third conductive terminal are arranged on the conductive plate, and are respectively located in the first contact zone, the second contact zone and the third contact zone in sequence. A card tray is arranged in an installation slot. The card tray is provided with a first card slot, a second card slot and a third card slot. The first card slot, the second card slot and the third card slot are one-to-one corresponding to the first conductive terminal, the second conductive terminal and the third conductive terminal in sequence. The invention further provides the mobile phone which comprises the card seat connector. The card seat connector provided by the invention has three functions. Three cards of different functions can be clamped in the card seat connector, which is very convenient. When the card seat connector is applied to the mobile phone, on the premise that the functions are ensured, the thickness requirement of the mobile phone can be effectively ensured.

Owner:SHENZHEN LINKCONN ELECTRONICS

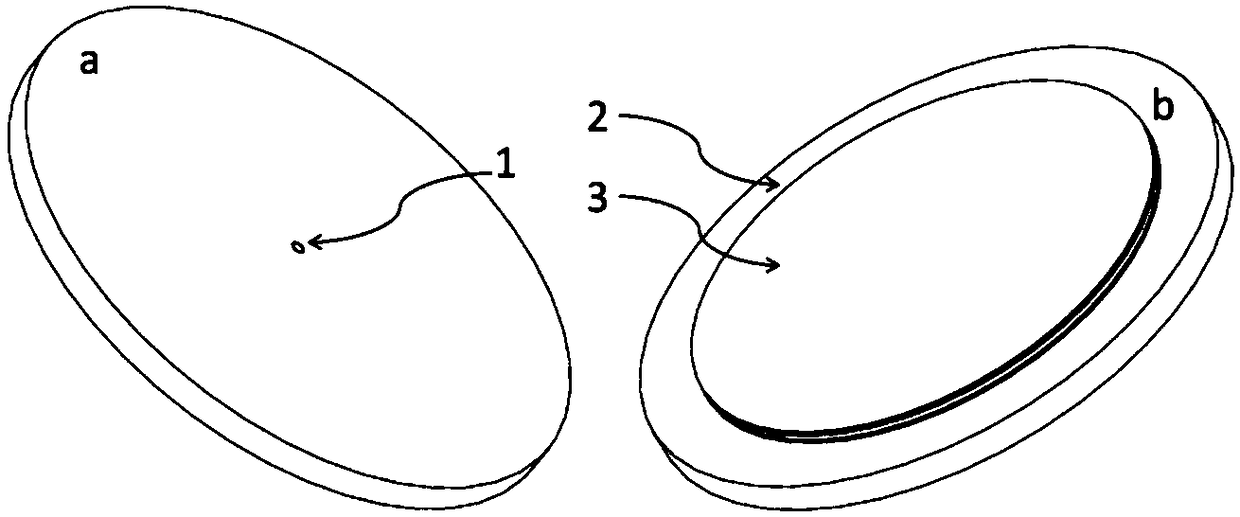

Machining method and device of curved-surface workpiece

The invention discloses a machining method and device of a curved-surface workpiece. A shape follow-up tool and a fixing piece are utilized, one side of the shape follow-up tool is a horizontal plane,and the other side of the shape follow-up tool is a curved surface. The curved surface can be tightly attached to the first curved surface of the to-be-prepared curved-surface workpiece. The fixing piece comprises a bottom plate and a plurality of supporting parts arranged on the bottom plate. The bottom surface of the bottom plate is a horizontal plane. The arrangement positions and heights of all the supporting parts are different. The ends of the supporting parts are matched with the second curved surface to bear and fix the to-be-prepared curved-surface workpiece, and mutual matching of the curved-surface workpiece and the shape follow-up tool as well as the fixing piece is achieved. According to the machining method and device of the curved-surface workpiece, the machining difficultproblem of the curved-surface workpiece is solved through building of a datum plane and matching of the shape follow-up tool and the fixing piece.

Owner:山东豪迈精密机械有限公司

Material distribution device

ActiveCN108382831AReduce work intensityImprove work efficiencySievingConveyorsEngineeringMaterial distribution

The invention relates to a material distribution device, and belongs to the technical field of transportation devices. The material distribution device comprises a conveyor belt, wherein fixed bases are arranged on the two sides of a discharging end of the conveyor belt; a material distributing plate is arranged between the two fixed bases in a sliding manner; the material distributing plate comprises a first material distributing plate, a second material distributing plate, a third material distributing plate and a fourth material distributing plate sequentially arranged; a material distributing strip is also arranged between the two adjacent material distributing plates; the material distributing strip comprises a first material distributing strip, a second material distributing strip and a third material distributing strip; the first material distributing strip is arranged between the first material distributing plate and the second material distributing plate; the second material distributing strip is arranged between the second material distributing plate and the third material distributing plate; the third material distributing strip is arranged between the third material distributing plate and the fourth material distributing plate; a first groove in which the conveyor is put and a second groove in which the material distributing plate is put are formed in each of the material distributing plates; and an adjustment mechanism for adjusting a space between the adjacent material distributing plates is also arranged on the material distributing plates. According to the material distribution device disclosed by the invention, materials are distributed through the material distributing plates, so that the working efficiency can be improved.

Owner:重庆友强高分子材料股份有限公司

Method for preparing bionic hollow human body part model through 3D printing

PendingCN112497728AEasy to prepareEfficient preparation methodAdditive manufacturing apparatusAdditive manufacturing with liquidsHuman bodyPhysical medicine and rehabilitation

The invention relates to a method for preparing a human body part model, in particular to a method for preparing a bionic hollow human body part model through 3D printing. The defects that a traditional casting and injection molding technology is long in model preparation time, high in cost and small in individual difference, and a medical model obtained through 3D printing cannot be applied to training such as surgical suture and repeated tearing are overcome. The method comprises the steps of data acquisition, data processing, model building, shell mold, hollow inner mold and assembly part mold preparation, mold treatment, mold assembly and retention, silica gel infusion, mold drawing and the like. The bionic hollow human body part model prepared through the method is real and is close to the real surface hardness of a target human body part, the surface is smooth and not sticky, the thickness and distribution of the model are consistent with those of the human body part, the tissuestructure is observed obviously, and repeated tearing is resisted. The method is suitable for surgical simulation, suture surgery training, clinical teaching and the like.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

Flexible positioning method for Z-shaped stringer of composite material stiffened wall plate

InactiveCN111590907AGuaranteed positionPrecise positioningDomestic articlesStringerInvestment material

The invention discloses a flexible positioning method for a Z-shaped stringer of a composite material stiffened wall plate. According to the method, a flexible positioning device is used for positioning. The flexible positioning device comprises a positioning angle seat, a specially-made high-temperature-resistant pressure spring, a special pin and a composite material gasket. By using the method,the position degree control requirement of the Z-shaped stringer can be met when a dry-state Z-shaped stringer and a wet-state wall plate skin are jointly glued, the situation that a positioning coremold causes indentations on the surface of the wet-state wall plate skin is avoided, and the surface flatness and thickness requirements of the wall plate skin are ensured. Meanwhile, cutting of avoiding notches in auxiliary materials such as a vacuum bag, a breathable felt and an isolating membrane is not needed during gluing, curing and bag making, the integrity of the vacuum bag is ensured, bag bursting during curing is avoided, and the curing and forming quality of a workpiece is effectively ensured. The bag making process is easy and convenient to operate, and the production efficiency is high.

Owner:XIAN AIRCRAFT IND GROUP

Preparation method of titanium steel compound plate

The invention discloses a preparation method of a titanium steel compound plate. The preparation method comprises the following steps of: firstly performing explosive welding on a titanium plate and asteel plate; and then hot-rolling the titanium plate and the steel plate to obtain the titanium steel compound plate. By performing explosive welding on the titanium plate and the steel plate, the bonding strength of a rolled blank after explosive compounding is high, and during hot rolling, the titanium / steel compound plate blank is heated and the rolling deformation is controlled at 4-7 times,so that the rolled titanium / steel compound plate has relatively high bonding strength and guarantees the thickness demands the titanium and steel.

Owner:陕西海恩得工贸股份有限公司

Production method of diffuser used in aerodynamic experiments

InactiveCN104596723AGuaranteed Thickness RequirementsFast assemblyAerodynamic testingManufacturing technologyPulp and paper industry

The invention discloses a production method of a diffuser used in aerodynamic experiments and belongs to the technical field of design and production of high temperature and hypersonic velocity aerodynamic experiment equipment. The production method can effectively improve product quality and has fast assembly speed. The production method includes: processing flange parts with inner cylinder positioning steps and outer cylinder positioning steps on flange blanks, drilling positioning holes in outer cylinder blanks, making inner cylinder parts and outer cylinder parts through rolling, and assembling the inner cylinder parts and the outer cylinder parts on the basis of the inner cylinder positioning steps and the outer cylinder positioning steps. In addition, the thickness of cavities between the inner cylinder parts and the outer cylinder parts is controlled through a positioning short pipe so the purposes of improving product quality and assembling speed can be achieved.

Owner:SICHUAN SHANGYUAN TIANJIAO CONSTR ENG CO LTD

Design method of turbine support plate blade with supporting and flow guiding functions and blade

PendingCN114542216ASmall spatial structureReduce axial sizeStatorsHydro energy generationSuction forceStructural engineering

The invention belongs to the field of design of inter-turbine casing support plates in axial-flow turbines, and relates to a design method of turbine support plate blades with supporting and flow guiding functions, the blade ring number and the blade height radius are given firstly, so that the positions and the pitch of the blades are determined, and then according to the supporting structure space needed by an engine, the flow guiding function is achieved. Determining centers and radiuses of small circles at the front and tail edges of the blade according to strength and processing technology requirements; an inlet upper wedge angle and an inlet lower wedge angle of the blade are arranged to ensure that the interior of the front half part of the blade has enough space, an effective air outlet angle and an outlet deflection angle are arranged to realize a flow guide effect on airflow, and an outlet wedge angle is arranged to ensure the thickness requirement of the rear half part of the blade; and then a suction surface control curve and a pressure surface control curve are respectively set to complete the design of the outer envelope line of the blade. According to the design, the blade profile integrates the design of the supporting plate and the guide blade, the front stage flow condition is better adapted, the pneumatic loss is lower, the total efficiency of turbine parts is improved, the axial size of the turbine stage is smaller, the number of components is smaller, the weight is light, and the cost is low.

Owner:AECC SHENYANG ENGINE RES INST

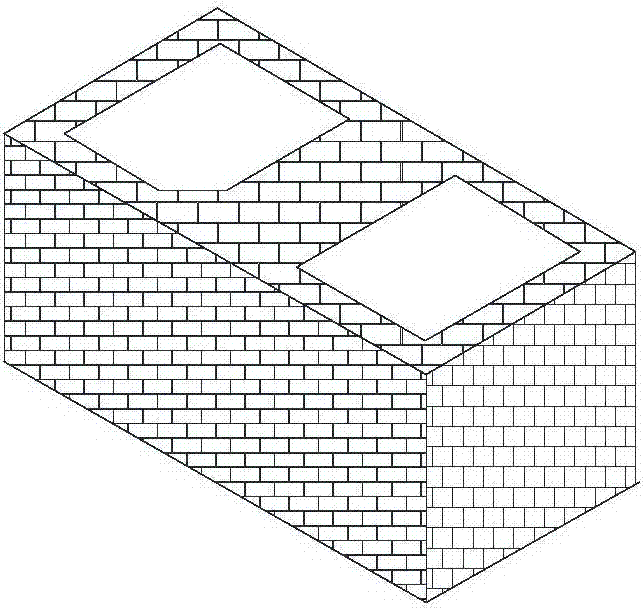

Cast stone microcrystal plate

The invention relates to a cast stone microcrystal plate and belongs to the field of the novel wear-resistant and anti-corrosion material. The invention is characterized in that the cast stone microcrystal plate comprises the following chemical components in percentage by weight: 44 to 53 percent of silicon dioxide; 15 to 20 percent of aluminium oxide; 8 to 18 percent of calcium oxide; 6 to 8 percent of magnesium oxide; and 9 to 16 percent of iron sesquioxide and ferrous oxide. The production process of the invention comprises a melting temperature, a melt condensing temperature before crystallization, a crystallization temperature, a crystallization temperature time, an initial annealing temperature and an annealing rate, wherein the melting temperature is between 1380 and 1420 DEG C; the melt condensing temperature before crystallization is between 800 and 850 DEG C; the crystallization temperature is between 950 and 1,020 DEG C; the crystallization time is between 20 and 30 minutes; the initial annealing temperature is between 650 and 750 DEG C; and the annealing rate is between 150 and 170 DEG C per hour. The thickness of the cast stone microcrystal plate of the invention is between 12 and 18mm to meet the market demand.

Owner:大同市骏腾铸石有限责任公司

Ceramic chip antenna and preparation method thereof

PendingCN109400178AGuaranteed performanceImprove bindingRadiating elements structural formsPlatinumCopper

The invention discloses a ceramic chip antenna. Metal circuits are attached to the outer surface of a ceramic base and a via hole formed in the ceramic base, the metal circuit positioned on the outersurface serves as a ceramic antenna body, the metal circuit positioned at the via hole serves as a circuit functioning in conduction, the metal circuits comprise a first metal circuit, a second metalcircuit, a third metal circuit, a fourth metal circuit and a fifth metal circuit, the first metal circuit is selected from high-temperature-resistant tungsten, molybdenum and platinum, the third metalcircuit is selected from copper, silver, chromium, iron and cobalt with high conductivity, the second metal circuit is arranged between the first metal circuit and the third metal circuit and used for transition, and the fourth metal circuit and the fifth metal circuit are arranged on an outer layer and used for protection and welding. As a plurality of metal circuits are designed, the ceramic base and the metal circuits can be subjected to a co-firing process to form the ceramic chip antenna, cost is controlled, metal materials with excellent conductivity can be adopted, and antenna performances are ensured.

Owner:SHANGHAI AMPHENOL AIRWAVE COMM ELECTRONICS CO LTD

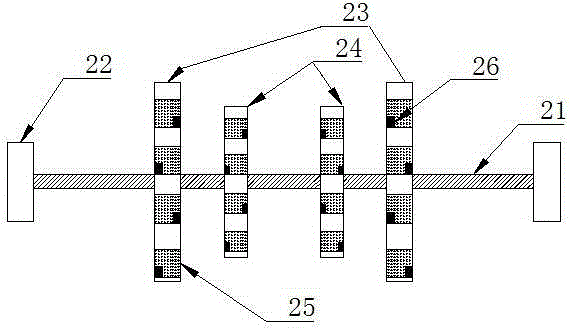

Continuous vacuum ion plating machine

InactiveCN104404474ASimple structureReduce volumeVacuum evaporation coatingSputtering coatingSputteringIon plating

The invention discloses a continuous vacuum ion plating machine which is provided with a tank-type vacuum plating chamber, wherein the left and right sides in the tank-type vacuum plating chamber are respectively provided with a base film decoiling mechanism and a base film coiling centering mechanism; the inside of the tank-type vacuum plating chamber is provided with a plurality of rows of plane magnetron sputtering targets at intervals from left to right, the plane magnetron sputtering targets on the left and right rows are single-side-sputtering plane magnetron sputtering targets, and the plane magnetron sputtering targets between the left and right rows are double-side-sputtering plane magnetron sputtering targets; a plating channel is formed between every two adjacent rows of plane magnetron sputtering targets; the front and back sides of the plurality rows of plane magnetron sputtering targets are respectively provided with a water cooling backing plate; the outer side of each water cooling backing plate is provided with a driving roller which is positioned between every two adjacent rows of plane magnetron sputtering targets; and the base film arranged on the base decoiling mechanism passes through the plating channel via the driving rollers, and is centered by the base film coiling centering mechanism and then coiled. The continuous vacuum ion plating machine completes the decoiling, plating and coiling of the base film in one tank-type vacuum plating chamber, has the advantages of simple equipment structure and small size, and greatly lowers the manufacturing cost.

Owner:辽宁北宇真空科技有限公司

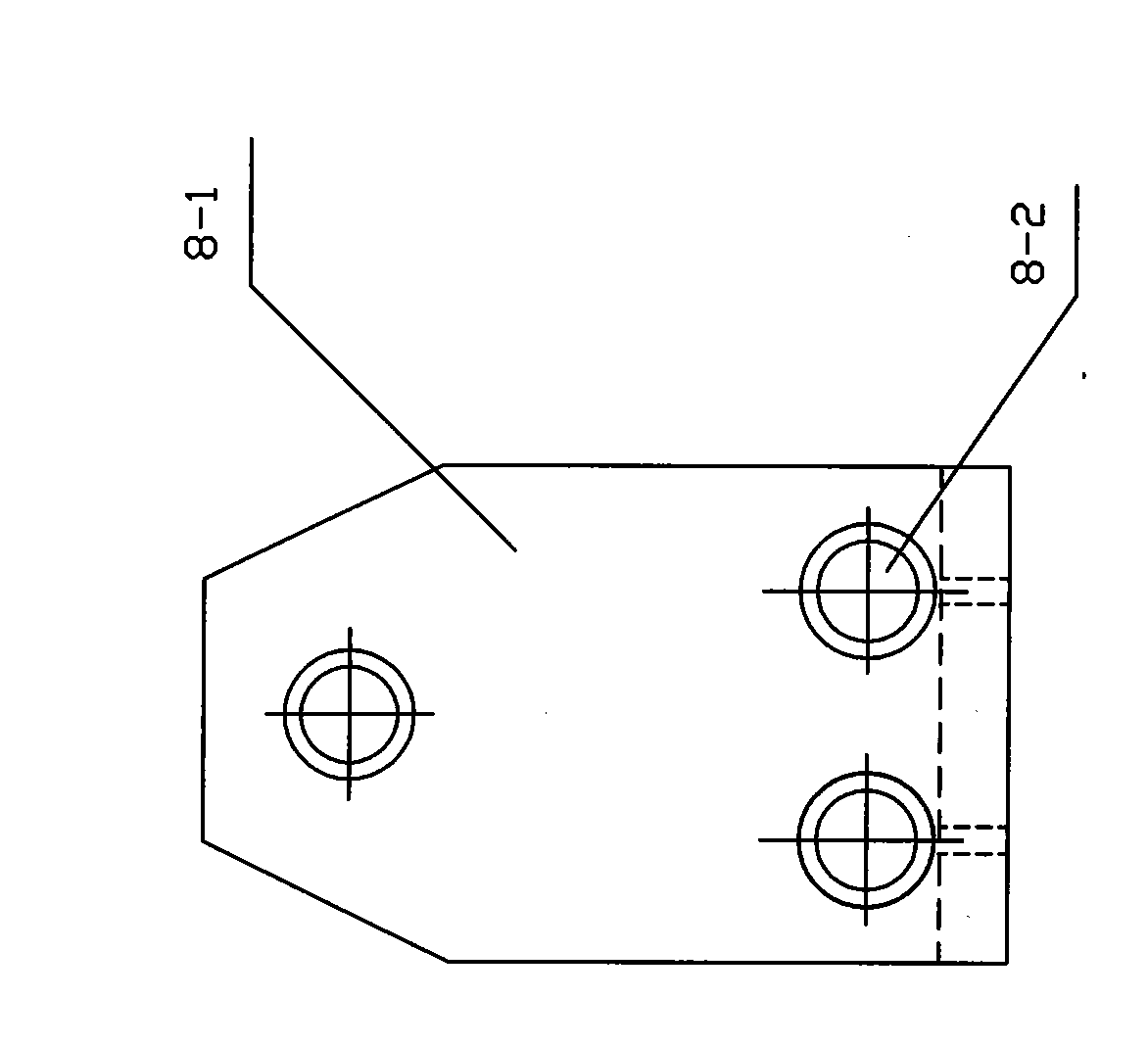

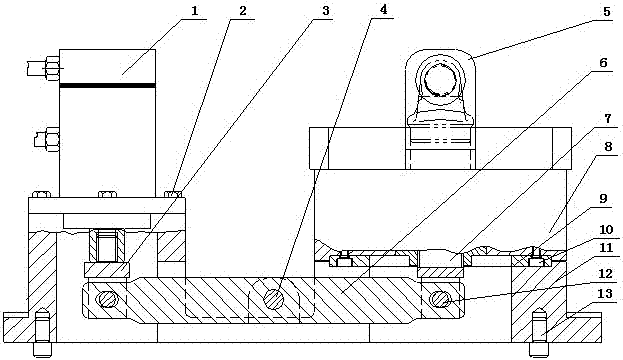

Universal joint fork lug side face milling clamp

ActiveCN105382604AGood effectSimple processWork clamping meansMilling cuttersHydraulic cylinderUniversal joint

The invention relates to a universal joint fork lug side face milling clamp. The universal joint fork lug side face milling clamp comprises a hydraulic cylinder, a hexagon bolt, a hinge fork base A, a pin shaft B, a hinge fork base B, a hydraulic three-jaw chuck, a middle transition disc, an internal hexagonal column head screw A, a pin shaft A, a positioning pin, a cotter pin, an internal hexagonal column head screw B, a cylindrical pin, an internal hexagonal column head screw C and an internal hexagonal column head screw D. The output end of the hydraulic cylinder is connected with a connecting rod through the hinge fork base A. One end of the connecting rod is connected with the middle transition disc through the hinge fork base B. A positioning supporting plate is arranged on the chuck face of the hydraulic three-jaw chuck. The positioning supporting plate is in an L shape. A positioning hole is formed in a protrusion, perpendicular to the upper end face of the chuck, of the positioning supporting plate. The protrusion of the positioning supporting plate is perpendicular to one disc of the chuck. The positioning hole in the protrusion of the positioning supporting plate is provided with a core rod matched with the positioning hole. On the whole, the universal joint fork lug side face milling clamp has the advantages of being fast in positioning, high in precision, portable to assemble and disassemble, safe and rapid.

Owner:XUCHANG YUANDONG DRIVE SHAFT +1

Precision and performance control method for superplastic forming sudden-change wall thickness thin-wall hemisphere

PendingCN113909368APrecise control over distributionGuaranteed Wall Thickness RequirementsDistribution controlMetallurgy

The invention relates to a precision and performance control method for superplastic forming sudden-change wall thickness thin-wall hemisphere, and belongs to the technical field of titanium alloy superplastic forming. The method comprises the steps that 1, the size of a thin-wall hemisphere after a thin-wall blank is formed into the thin-wall hemisphere is determined; 2, a lower mold for forming the thin-wall hemisphere is designed; 3, an upper mold for forming the thin-wall hemisphere is designed; 4, polishing treatment is carried out on the inner molded surface of the lower mold and the inner molded surface of the upper mold; 5, the inner molded surface of the lower mold and the inner molded surface of the upper mold are evenly coated with welding stopping agents, and heating treatment is carried out; 6, the thin plate blank is placed on the top of the lower mold, and the upper mold covers the thin plate blank, and heating treatment is carried out; 7, reverse expansion treatment and forward expansion treatment are sequentially carried out on the thin plate blank, and the thin-wall hemisphere is formed; and 8, cooling is carried out, and the formed thin-wall hemisphere is taken out. The method can be used for forming titanium alloy hemispherical shell bodies with various sizes and large wall thickness distribution difference, and has good thickness distribution control and performance maintaining effects.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Structure and process for realizing WLCSP six-side plastic sealing of TVS chip

InactiveCN107068628AThe overall thickness is thinSimple processSemiconductor/solid-state device detailsSolid-state devicesWafer thinningEngineering physics

The invention discloses a structure and process for realizing WLCSP six-side plastic sealing of a TVS chip and is same as the routine WLCSP process. The process comprises steps that firstly, metal convex points are prepared at a front surface of a wafer; the wafer is cut to prepare a gap according to a final TVS product structure, depth of the gap is controlled during cutting, and the wafer can not be cut through; first plastic sealing is carried out from the front surface of the wafer, and the gap acquired through cutting is covered; wafer thinning is carried out from the front surface of the wafer, and an electrode is guaranteed to expose; if the electrode need be higher than a plastic sealing surface, the primary planting or coating process is carried out at the metal convex point portion; wafer thinning is carried out at a back surface of the wafer till size requirements of the final TVS product are satisfied; plastic sealing is carried out for the back surface of the wafer, and protection of the back surface of the wafer is accomplished; cutting is carried out along the center of the gap, through cutting is realized, and chip separation is accomplished. The method is advantaged in that the process flow is simple, process control requirements are not high, and thickness of finished products can be controlled for being quite thin.

Owner:SHANGHAI CHANGYUAN WAYON MICROELECTRONICS

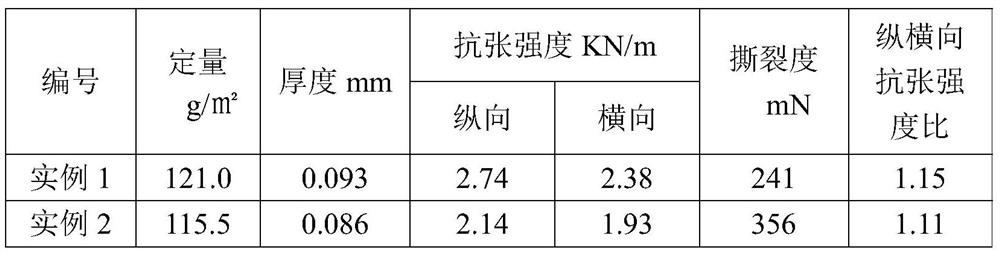

Preparation method of LCP film

InactiveCN112501954AImprove mechanical propertiesEasy to prepareTextiles and paperSlurryNonwoven fabric

The invention discloses a preparation method of an LCP film. The preparation method comprises the following steps: step 1, defibering and dispersing raw material LCP chopped fibers; step 2, carrying out fiber surface treatment to obtain slurry; step 3, filtering and forming the slurry, and drying to obtain an LCP non-woven fabric; and 4, melting the LCP non-woven fabric to form a film, thereby obtaining the LCP film. The method has the beneficial effects that filtering forming is conducted through a paper machine, the slurry amount and the vehicle speed are controlled, the LCP non-woven fabricwith the small longitudinal and transverse strength difference is achieved, in the forming process, a certain amount of dispersing agent and a certain amount of defoaming agent are added, and the uniformity of the non-woven fabric is guaranteed; through high-temperature secondary hot pressing treatment, the LCP non-woven fabric flows during melting to fill gaps in the non-woven fabric, a gaplessfilm is formed, the thickness requirement of the film is met by adjusting the pressure during hot pressing of a hot roller, and lubricating oil is smeared on the surface of the hot roller in order toprevent the roller from being stuck.

Owner:JIANGSU ZANPOD NEW MATERIAL CO LTD

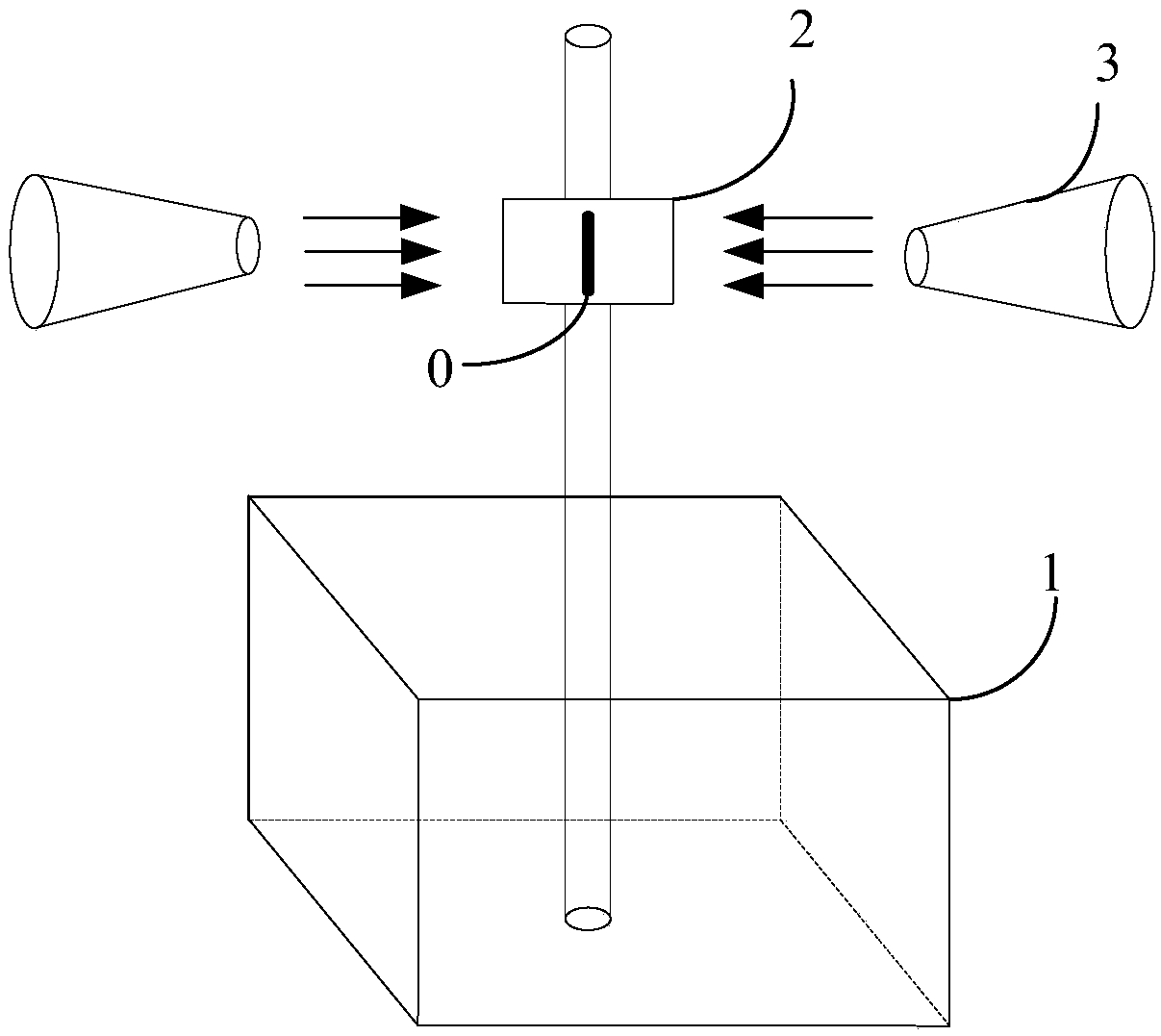

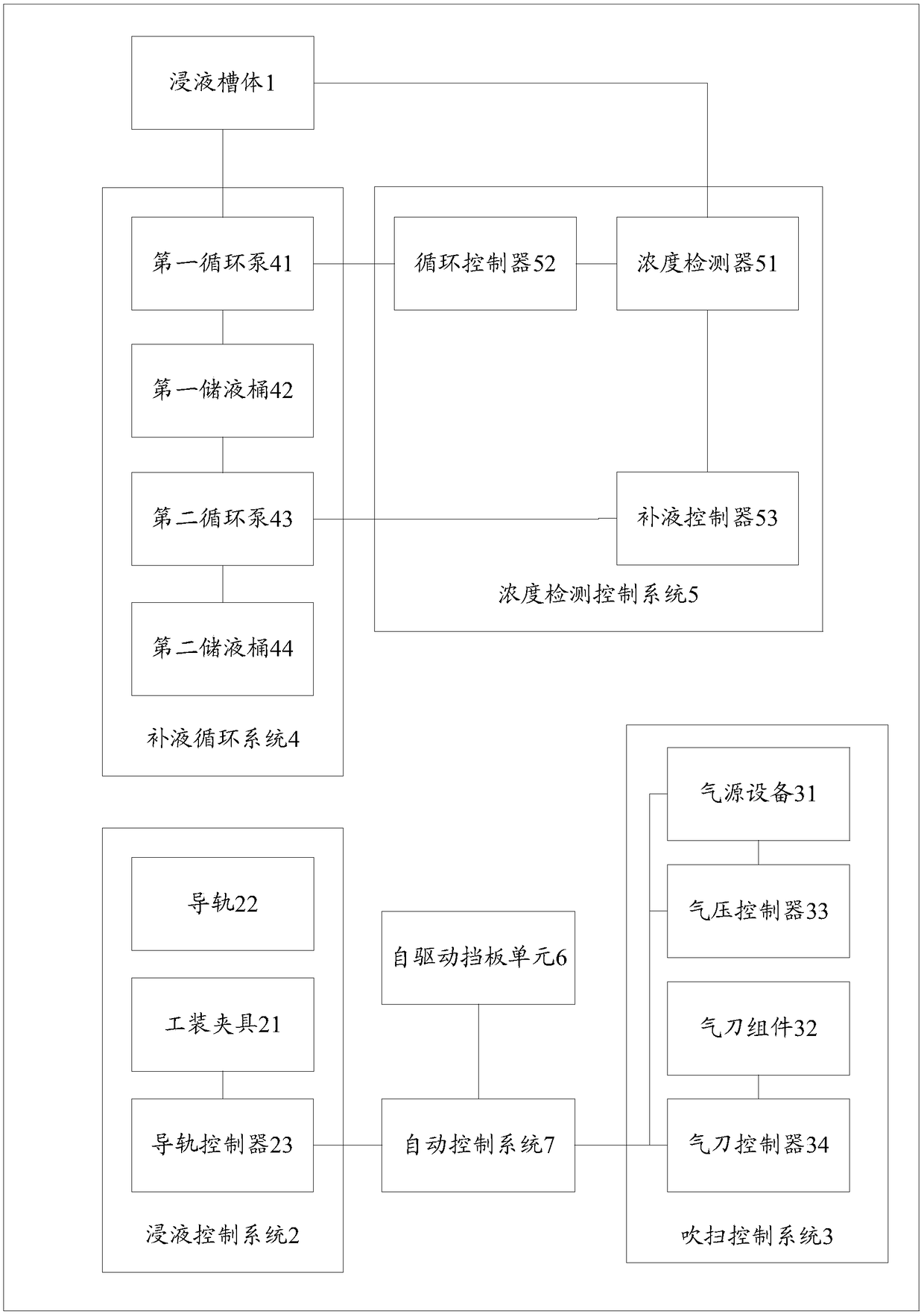

Surface coating apparatus and method for thread-shaped device

ActiveCN108453001AAvoid beadingNot easy to damageLiquid surface applicatorsCoatingsControl systemBiomedical engineering

The invention discloses a surface coating apparatus and method for a thread-shaped device, relating to the field of a coating device. The surface coating apparatus comprises an immersion trough body,an immersion control system and a purging control system, wherein the immersion trough body is filled with a coating solution, the immersion control system is used for immersing the thread-shaped device in the coating solution, a coating layer is formed on the surface of the thread-shaped device, and the purging control system is used for uniformly purging the coating layer on the surface of the thread-shaped device. By adopting the surface coating apparatus and method, the beading on the surface of the thread-shaped device can be avoided, so that the coating solution uniformly covers the surface of the thread-shaped device, so that the surface uniformity and thickness requirement of the device can be ensured, the thread-shaped device is unlikely to damage, and the yield of the product canbe increased.

Owner:BEIJING INST OF RADIO MEASUREMENT

Manufacturing method of diffuser for aerodynamic test

InactiveCN104596723BGuaranteed Thickness RequirementsFast assemblyAerodynamic testingManufacturing technologyPulp and paper industry

The invention discloses a method for manufacturing a diffuser for aerodynamic testing, and belongs to the technical field of design and manufacturing of high-temperature, hypersonic aerodynamic testing equipment. Provided is a method for manufacturing a diffuser for aerodynamic testing that can effectively improve product quality and quickly assemble. The manufacturing method adopts firstly processing the flange blank to have inner cylinder positioning steps and outer cylinder positioning steps to make flange parts, drilling positioning holes on the outer cylinder blank, and then rolling them into inner and outer cylinders. Cylinder parts, then use the inner cylinder positioning step and the outer cylinder positioning step as the base to assemble the inner and outer cylinder parts, and control the cavity thickness between the inner and outer cylinder parts through the positioning short tube to achieve improved The purpose of product quality and loading speed.

Owner:SICHUAN SHANGYUAN TIANJIAO CONSTR ENG CO LTD

Galvanizing sink roll

InactiveCN107794479AImprove long-term stabilityMeet molding requirementsHot-dipping/immersion processesMetal stripsSlag

The invention discloses a galvanized sinking roller, which is installed and arranged in a zinc pot and lower than the zinc liquid surface, and is used for coating a metal strip; the feature is that the extending direction of the metal strip above the sinking roller is also provided with roller shafts parallel to each other The stabilizing roll and the positioning roll; the metal strip extends from the zinc pot below the zinc liquid level and is at the lowest point at the sinking roll. After the metal strip contacts the sinking roll, it goes around the sinking roll and turns upward to extend and is placed on the stabilizing roll. Between the stabilizing roller and the positioning roller, there is no contact between the stabilizing roller and the positioning roller up and down, so that the metal belt can smoothly move between the stabilizing roller and the positioning roller without swinging; the surface of the sinking roller is covered with The circumferential single helix or double helix slag discharge groove. The invention has reasonable structure and stable operation, so that the surface of the obtained galvanized layer is uniform without marks and the quality is stable.

Owner:马中亮

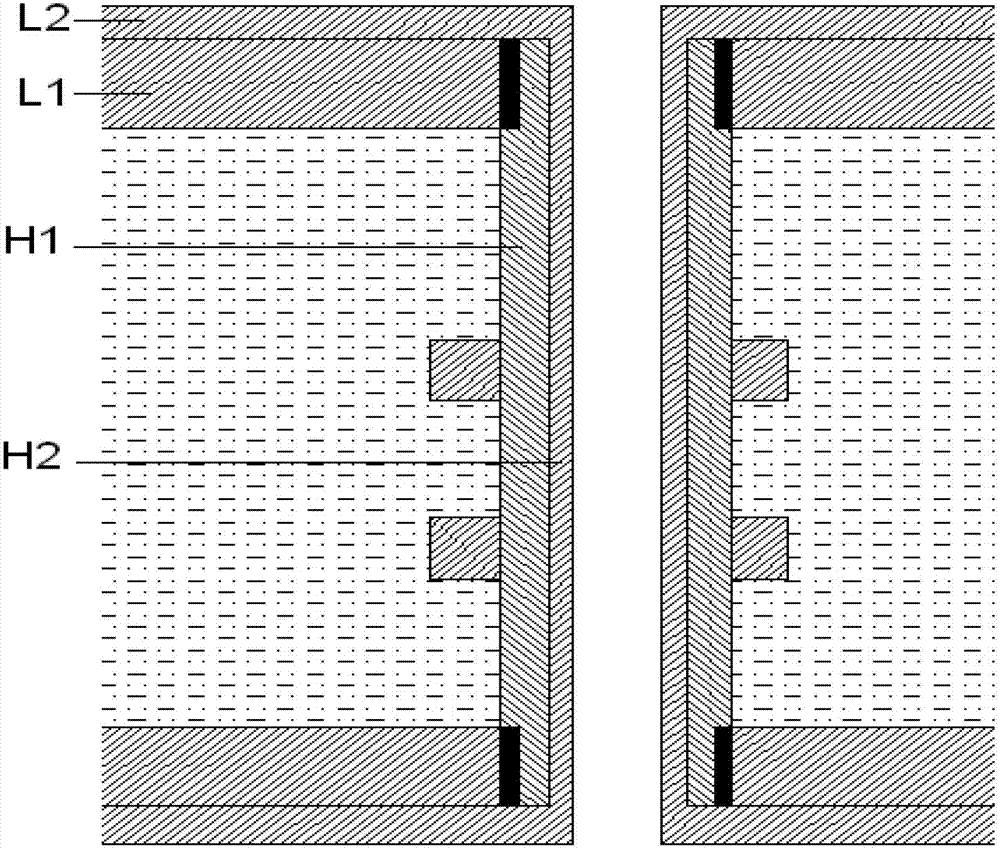

A printed circuit board and its manufacturing method

ActiveCN104053305BReduce thicknessGuaranteed thickness uniformityElectrical connection printed elementsMetallic pattern materialsResistCopper

The invention discloses a printed circuit board and a manufacturing method thereof. The surface copper thickness L=L1+L2, the hole copper thickness H=H1+H2, wherein the copper layer L2 and the copper layer H2 are obtained by electroplating at the same time, and the copper layer L1 It can be manufactured and controlled separately from the copper layer H1. During the production process, the difference between the surface copper thickness and the hole copper thickness can be realized by controlling the thickness of the copper layer L1 and the copper layer H1, so that it can meet the thickness requirements at the same time. In addition, the present invention uses pre-plated tin-lead layer as the anti-corrosion layer (3), which can protect the surface copper layer from damage, and minimize the thickness of the electroplated surface copper to ensure the thickness uniformity of the surface copper; the present invention also uses anti-corrosion The adhesive material (4) protects the hole copper layer and can ensure that the thickness of the final hole copper layer meets the requirements.

Owner:NEW FOUNDER HLDG DEV LLC +1

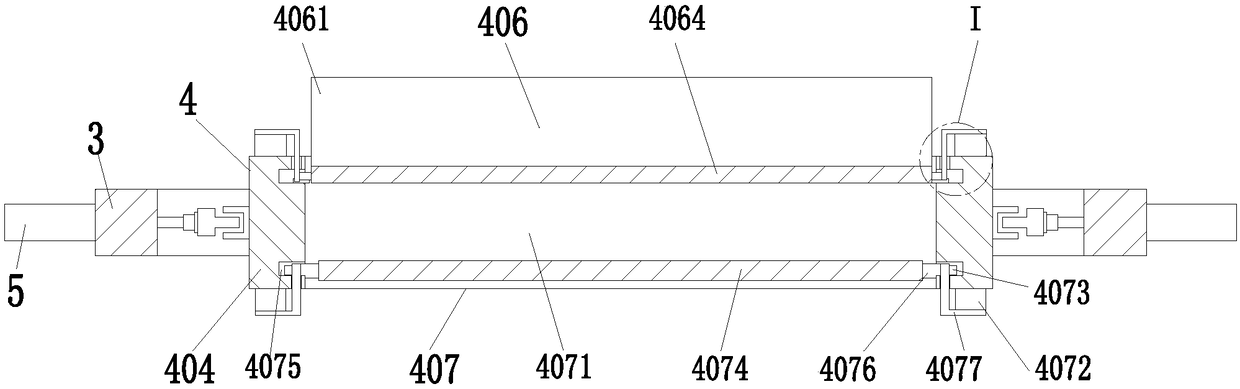

Puller resetting device on shifting bearing block of twin-roll cast-rolling mill

A puller resetting device on a shifting bearing block of a twin roller caster comprises a support seat fixed on a bottom plate of a casting roller set of the twin roller caster by a bolt. Three shaftsleeve installation holes are arranged on a support plate of the support seat and are respectively provided with a shaft sleeve with an internal thread. The shaft sleeves are fixed on the support plate of the support seat by nuts. Each shaft sleeve is connected with an elastic puller device by a thread. The elastic puller device comprises a casing with one end closed and the other end opened. Thecasing is provided with a disk spring and a mandril inside. An external thread is processed on the excircle of the mandril and is connected with the internal thread of the shaft sleeve. A plane bearing is arranged on a round table at one end of the mandril and is fixed on the round table by a plane gland nut which is put against the disk spring in the casing.

Owner:HUNAN 91 CONTINUOUS CASTING IND

A clamp for the side of milling ear of universal joint fork

ActiveCN105382604BGood effectSimple processWork clamping meansMilling cuttersHydraulic cylinderUniversal joint

The invention relates to a universal joint fork lug side face milling clamp. The universal joint fork lug side face milling clamp comprises a hydraulic cylinder, a hexagon bolt, a hinge fork base A, a pin shaft B, a hinge fork base B, a hydraulic three-jaw chuck, a middle transition disc, an internal hexagonal column head screw A, a pin shaft A, a positioning pin, a cotter pin, an internal hexagonal column head screw B, a cylindrical pin, an internal hexagonal column head screw C and an internal hexagonal column head screw D. The output end of the hydraulic cylinder is connected with a connecting rod through the hinge fork base A. One end of the connecting rod is connected with the middle transition disc through the hinge fork base B. A positioning supporting plate is arranged on the chuck face of the hydraulic three-jaw chuck. The positioning supporting plate is in an L shape. A positioning hole is formed in a protrusion, perpendicular to the upper end face of the chuck, of the positioning supporting plate. The protrusion of the positioning supporting plate is perpendicular to one disc of the chuck. The positioning hole in the protrusion of the positioning supporting plate is provided with a core rod matched with the positioning hole. On the whole, the universal joint fork lug side face milling clamp has the advantages of being fast in positioning, high in precision, portable to assemble and disassemble, safe and rapid.

Owner:XUCHANG YUANDONG DRIVE SHAFT +1

Thin-specification strip steel shearing method

PendingCN113477715AAvoids the problem of rethreadingSolve the technical problem that the belt threading cannot be realized automaticallyRoll mill control devicesMetal rolling arrangementsStructural engineeringStrip steel

The invention discloses a thin-specification strip steel shearing method. According to the thin-specification strip steel shearing method, an end of strip steel is provided with an ultra-thick section, and the thickness of the ultra-thick section exceeds a set thickness. The thin-specification strip steel shearing method comprises the following steps: controlling a feeding roller and a guide roller of a rolling mill to press the ultra-thick section; controlling the strip steel to move, and after the ultra-thick section moves to the position between the guide roller and a curling mandrel of the rolling mill, shearing the strip steel located on the feeding side of the guide roller to form a notch; and controlling the notch to move, and after the notch moves to the position between the guide roller and the mandrel, pulling the strip steel so that the strip steel can be pulled apart from the notch. The problem of secondary strip penetrating caused by improper shearing is avoided while shearing of the ultra-thick section of the strip steel is achieved, the technical problem that strip penetrating cannot be achieved due to the fact that the strip steel is thin is solved, and manual intervention of operators entering a rolling mill area is reduced.

Owner:SHOUGANG ZHIXIN QIAN AN ELECTROMAGNETIC MATERIALS CO LTD

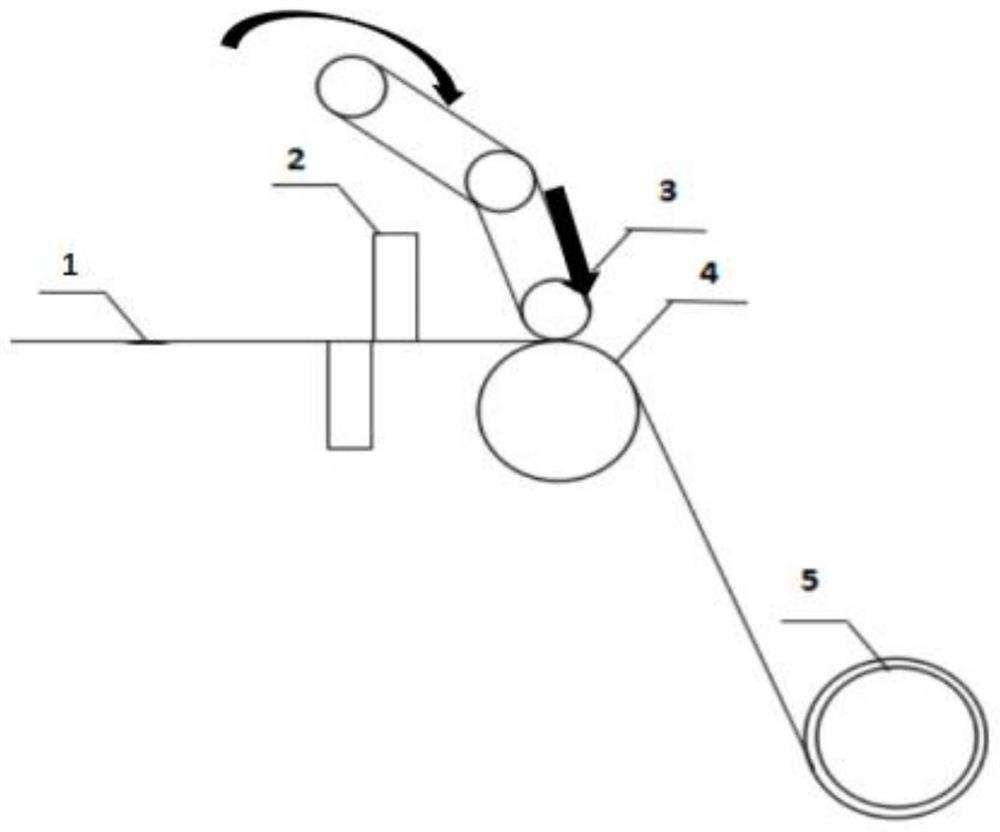

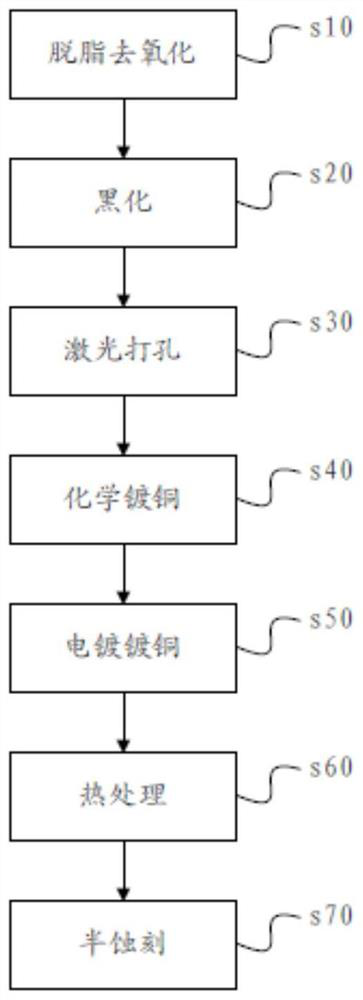

A processing method for copper-plating hole filling in core board layer through-holes

ActiveCN110446349BLarge apertureUniform pore sizePrinted element electric connection formationEtchingCopper plating

The present application provides a core plate through-hole copper-plated hole-filling processing method with excellent performance, which can eliminate the virtual connection of the through-hole copper-plated hole of the core plate. It includes the following steps: degreasing and deoxidizing, blackening, laser drilling, electroless copper plating, electroplating copper plating, heat treatment, and half etching. Among them, laser drilling adopts double-sided drilling, and electroplating copper plating includes two stages of copper plating; since the above technical scheme is adopted in this application, blackening, double-sided alternate drilling, electroless copper plating and two-stage electroplating copper plating, The processes of heat treatment and semi-etching are interlocking, adopting the idea of interference copper plating, from the forming of the through hole of the core board to the step-by-step forming of the copper plating, and the tight treatment of the copper plating in the through hole. Form dense copper-plated through-holes with excellent electrical connection performance.

Owner:清河电子科技(山东)有限责任公司

Puller resetting device on shifting bearing block of twin-roll cast-rolling mill

A puller resetting device on a shifting bearing block of a twin roller caster comprises a support seat fixed on a bottom plate of a casting roller set of the twin roller caster by a bolt. Three shaft sleeve installation holes are arranged on a support plate of the support seat and are respectively provided with a shaft sleeve with an internal thread. The shaft sleeves are fixed on the support plate of the support seat by nuts. Each shaft sleeve is connected with an elastic puller device by a thread. The elastic puller device comprises a casing with one end closed and the other end opened. Thecasing is provided with a disk spring and a mandril inside. An external thread is processed on the excircle of the mandril and is connected with the internal thread of the shaft sleeve. A plane bearing is arranged on a round table at one end of the mandril and is fixed on the round table by a plane gland nut which is put against the disk spring in the casing.

Owner:HUNAN 91 CONTINUOUS CASTING IND

A kind of tea spread green processing system and tea spread green processing method

ActiveCN108782829BHigh degree of automationIncrease moisture contentPre-extraction tea treatmentProcess engineeringTea leaf

The invention relates to a green tea stand processing system and a tea stand green processing method thereof, comprising a base plate, a support column, a support fixing frame, a turning device, a positioning device, a green spread device and a recovery device, and a support column is installed on the top of the base plate , the upper end of the supporting column is equipped with a supporting fixed frame, the middle part of the supporting fixed frame is equipped with a turning device, the front and rear sides of the supporting fixed frame are symmetrically equipped with positioning devices, and the upper end of the turning device is equipped with a spreading device. The present invention solves the problem that the existing tea leaves are usually manually operated, the labor intensity is high, the efficiency is low, the thickness of the manual spreading is uneven, and the thickness requirements of the tea cannot be met, and the tea leaves at the bottom are not easy to turn over To the upper layer, the tea leaves at the bottom layer cannot be fully dried, which affects the water loss rate of the tea leaves. At the same time, the tea leaves are prone to fall when they are spread green, and cannot be collected automatically. The operation is complicated, the production efficiency is low, the stability is poor, and the tea leaves cannot be turned over automatically. Wait for the problem.

Owner:湖南壶瓶山茶业有限公司

A Dispensing Shaping Inspection Line for Control Panels

ActiveCN111112016BReduce thickness requirementsGuaranteed Thickness RequirementsLiquid surface applicatorsMeasurement devicesAssembly lineWorkbench

The invention discloses a dispensing and reshaping detection assembly line for a control panel. The dispensing and reshaping detection assembly line is characterized in that the dispensing and reshaping detection assembly line comprises a workbench; and the dispensing and reshaping detection assembly line is characterized in that a transmission line is fixed on the workbench, a dispensing part, areshaping part and a detection part are successively arranged along the transmission line, the dispensing part, the reshaping part and the detection part correspondingly span the transmission line, and the dispensing part, the reshaping part and the detection part carry out dispensing operation, reshaping operation and detection operation successively for products on the transmission line. According to the dispensing and reshaping detection assembly line, degree of automation is high, the space occupied by the equipment is reduced, the production efficiency is improved, the production cost ofan enterprise is saved, the dispensing quality is ensured, continuous production is achieved, and good market application value is achieved.

Owner:HEFEI WISDOM DRAGON MACHINERY DESIGN CO LTD

Method for improving corrosion resistance of nickel-phosphorus chemical coating

InactiveCN102899642BReduce bond strengthGuaranteed bonding strengthLiquid/solution decomposition chemical coatingPorosityCopper plating

The invention relates to a method for improving corrosion resistance of a nickel-phosphorus chemical coating. The method comprises the following steps: plating a thin layer of nickel and phosphorus on the surface of a carbon steel substrate, and plating a layer of copper using a chemical exchange method; and then plating a layer of nickel and phosphorus. According to the invention, chemical copper plating is adopted for sealing holes and improving corrosion potential; in the process of the primary nickel and phosphorus plating, nickel and phosphorus are plated on most of the carbon steel substrate, so that the possibility that lower bonding strength of the coating is caused by reaction between copper and iron in a large amount during the secondary copper plating step is reduced, thereby ensuring the bonding strength of the coating. The method is suitable for occasions that the corrosion resistance of the coating is reduced due to small thickness and high porosity of the coating. By using the method, the corrosion resistance effect can be greatly improved under the condition that the thin coating is obtained.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com