Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

638 results about "Control curve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

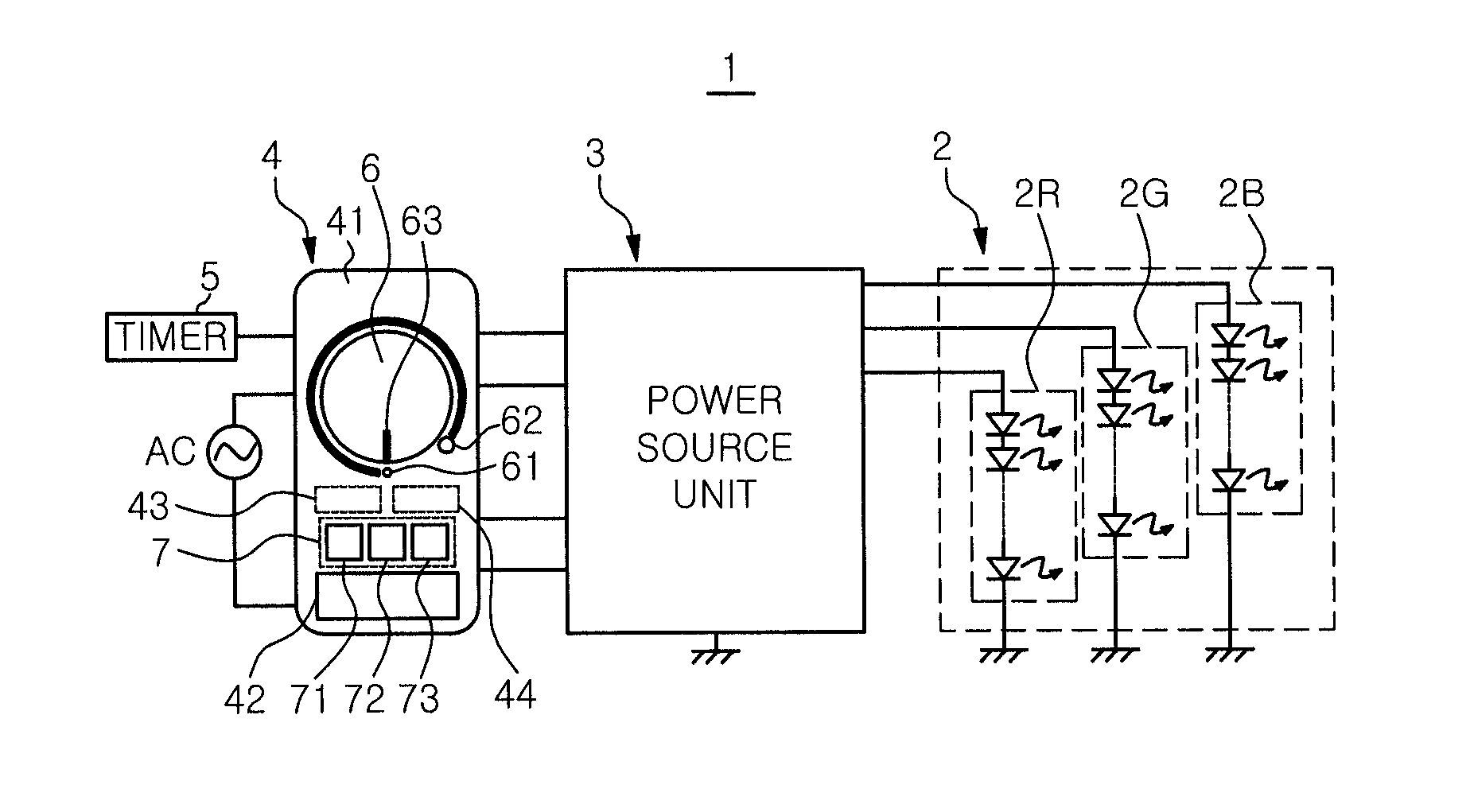

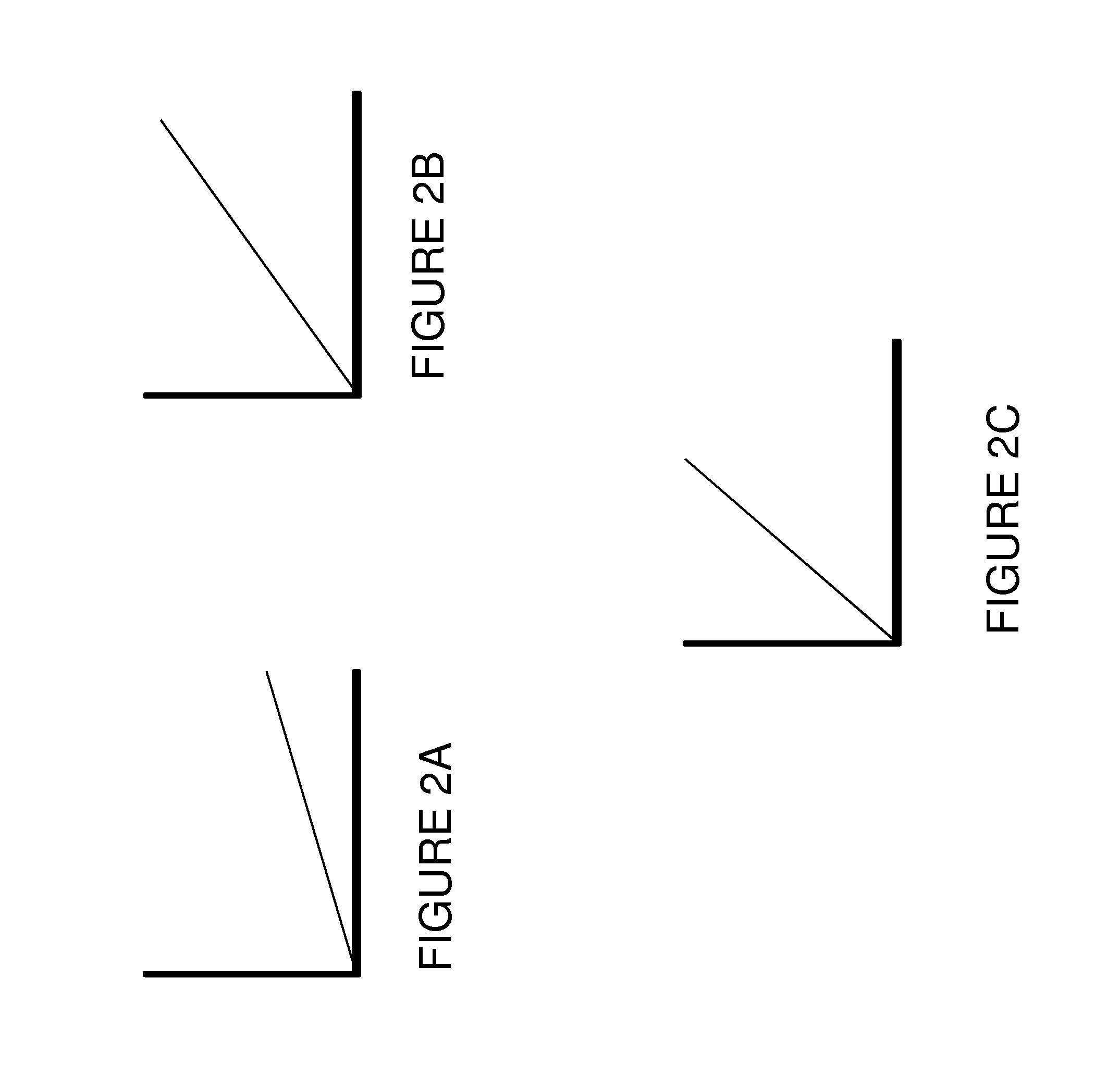

Illumination controller and illumination system including same

InactiveUS20130328500A1Improve balanceEasy to set upElectrical apparatusElectroluminescent light sourcesLighting systemControl curve

An illumination controller, which is configured to control a light source unit, includes: a dial, which is rotatable, used to adjust a color temperature and a quantity of light irradiated from the light source unit, a memory which stores one or more control curves in which the color temperature and the quantity of light irradiated from the light source unit change in conjunction with each other; and a curve selection unit used to select one curve among the control curves stored in the memory. When the dial is rotated, the color temperature and the quantity of light irradiated from the light source unit change according to values defined on the control curve selected by the curve selection unit.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

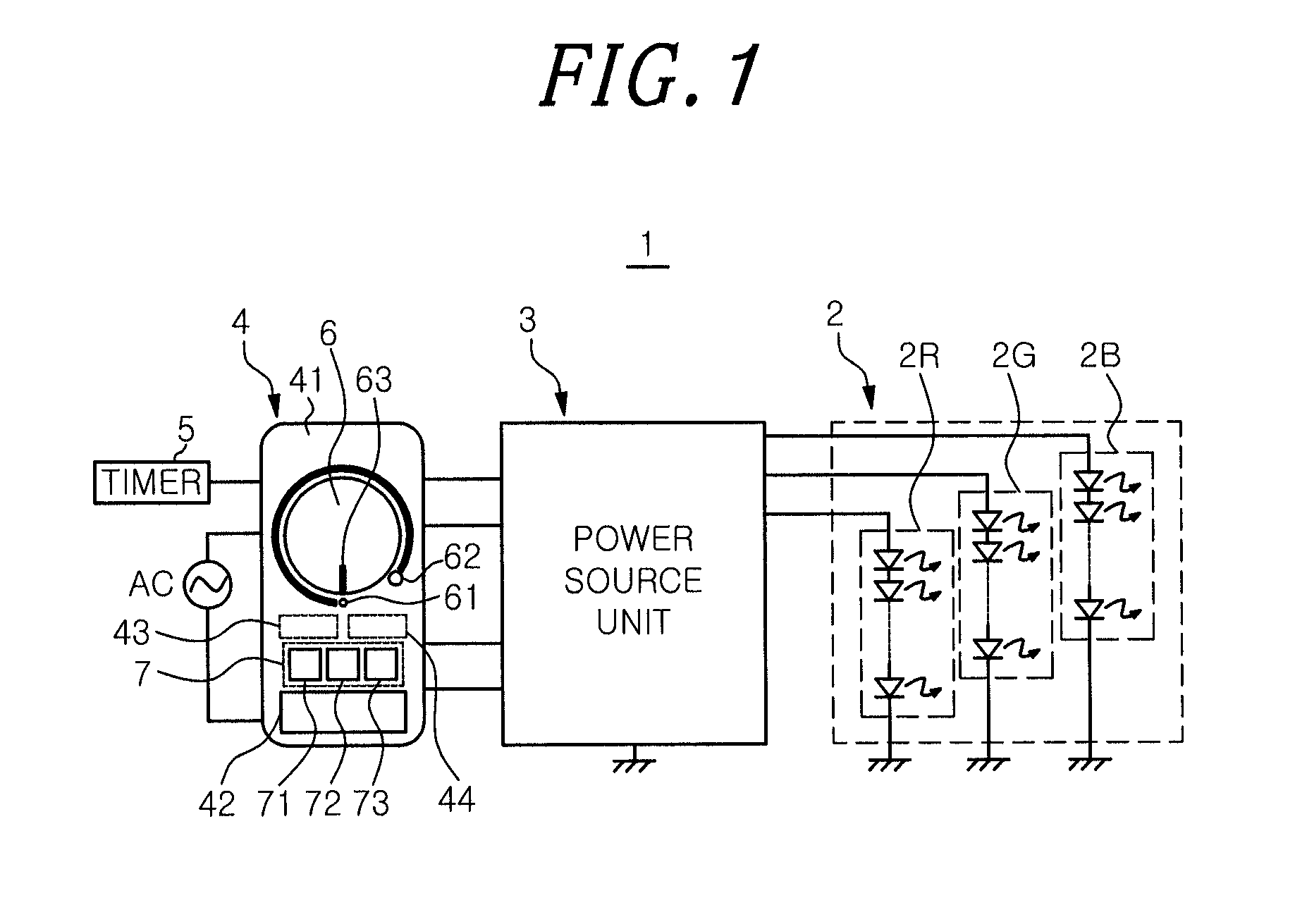

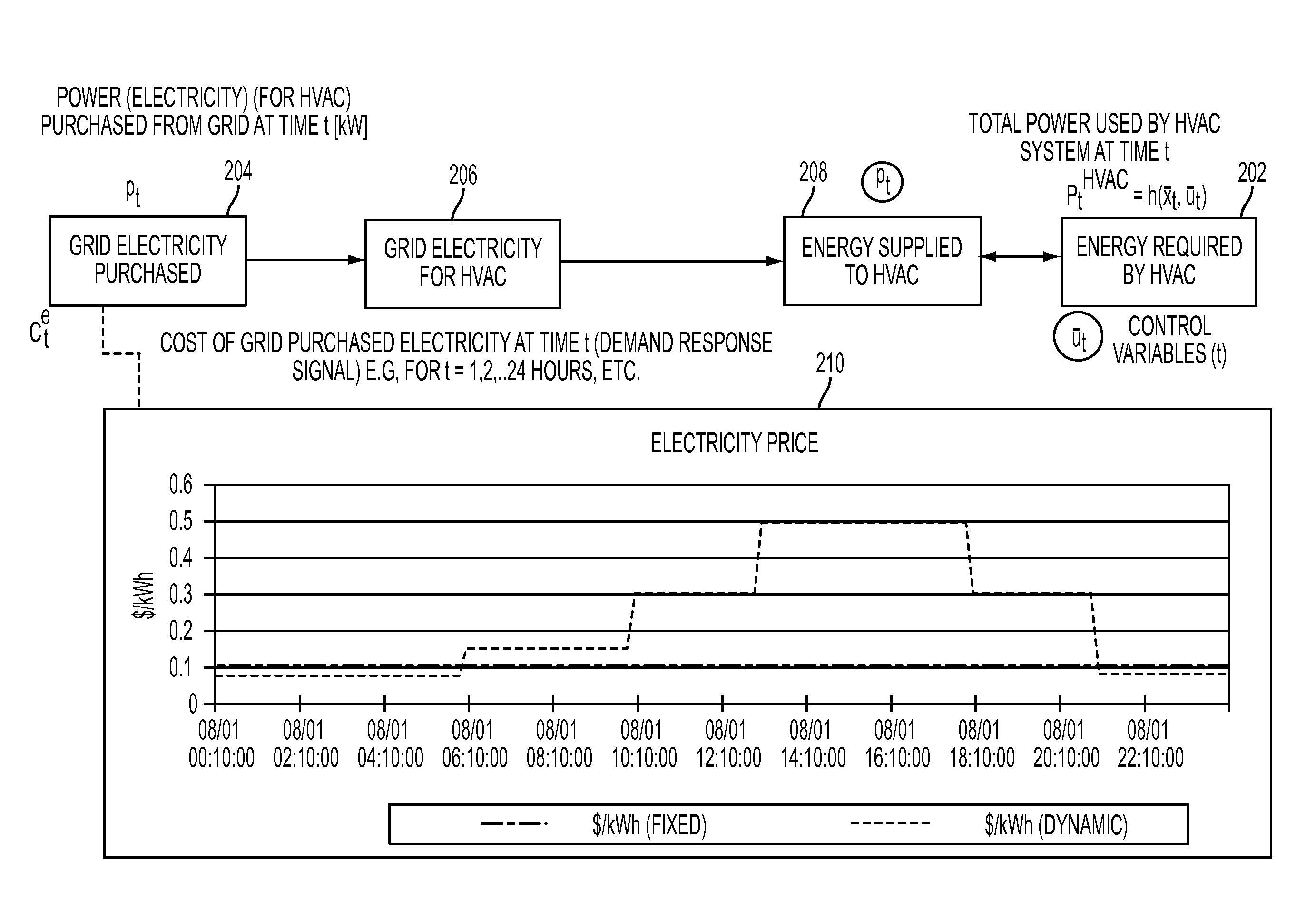

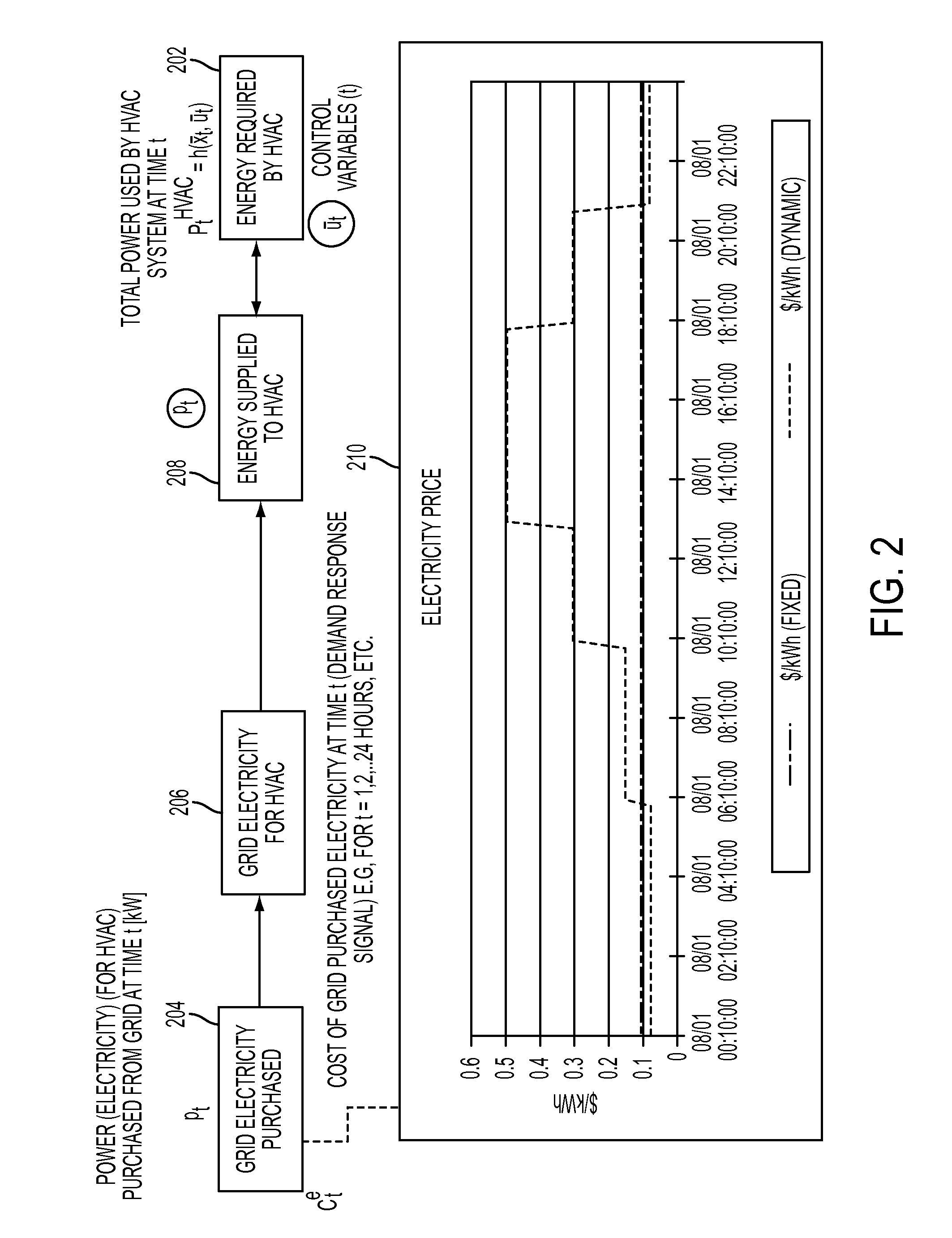

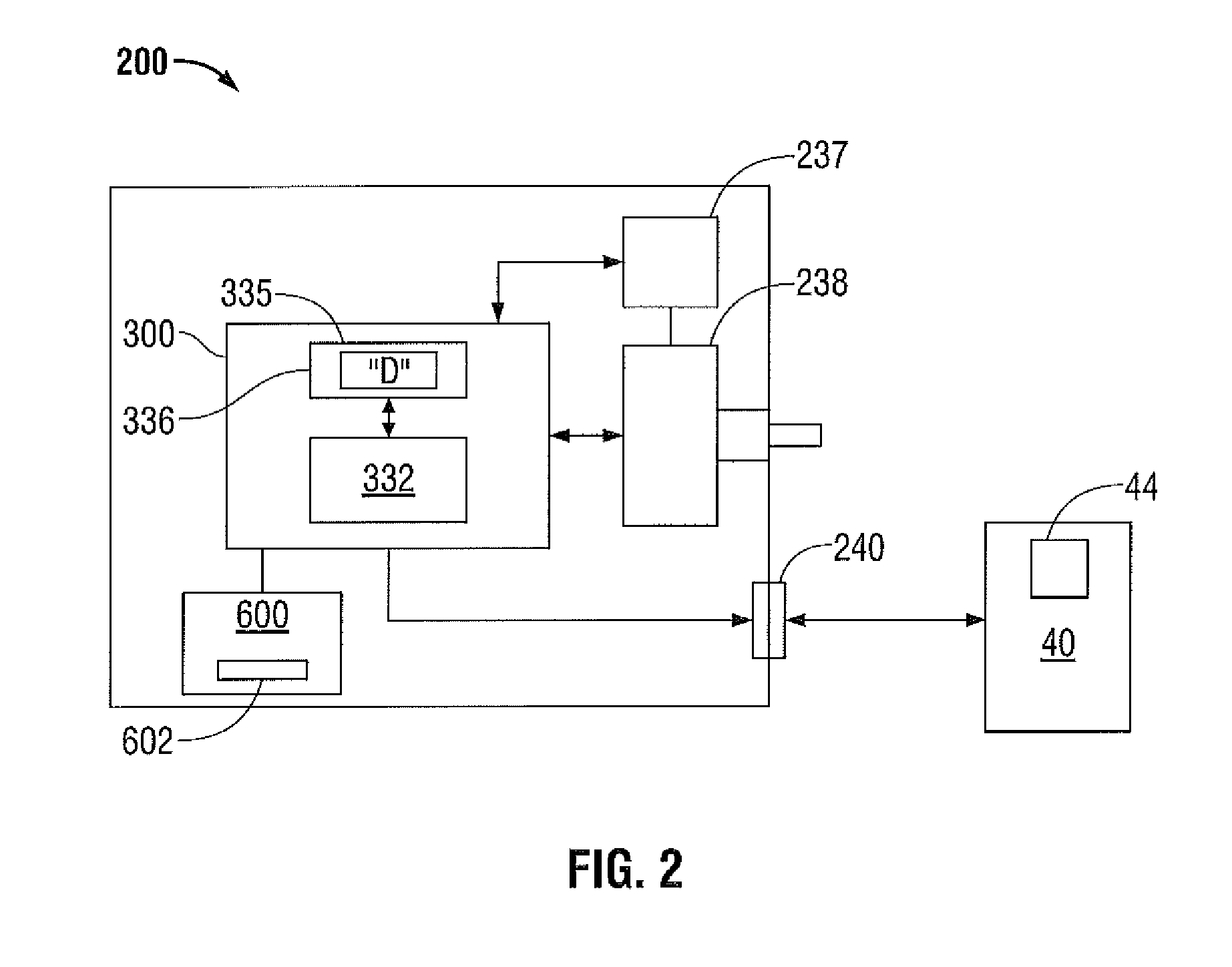

HVAC system control integrated with demand response, on-site energy storage system and on-site energy generation system

InactiveUS20160091904A1Mechanical apparatusLighting and heating apparatusOperational costsThermal energy storage

A thermal behavior model of a building may be constructed based on time series data. Based on the constructed thermal behavior model, forecasted zone temperature and energy usage for a next control time period may be predicted. An objective function may be constructed based on at least a dynamically priced grid energy cost, occupant comfort matrix, and one or more of: energy storage system cost and associated operational cost, and energy generation system cost and associated green house emission cost and associated operational cost. Constraints may be constructed based on at least the forecasted zone temperature values and energy usage values for the next control time period. A control profile of the HVAC system and sourcing decision of energy load of the HVAC system may be determined simultaneously based on the objective function and the plurality of constraints.

Owner:IBM CORP

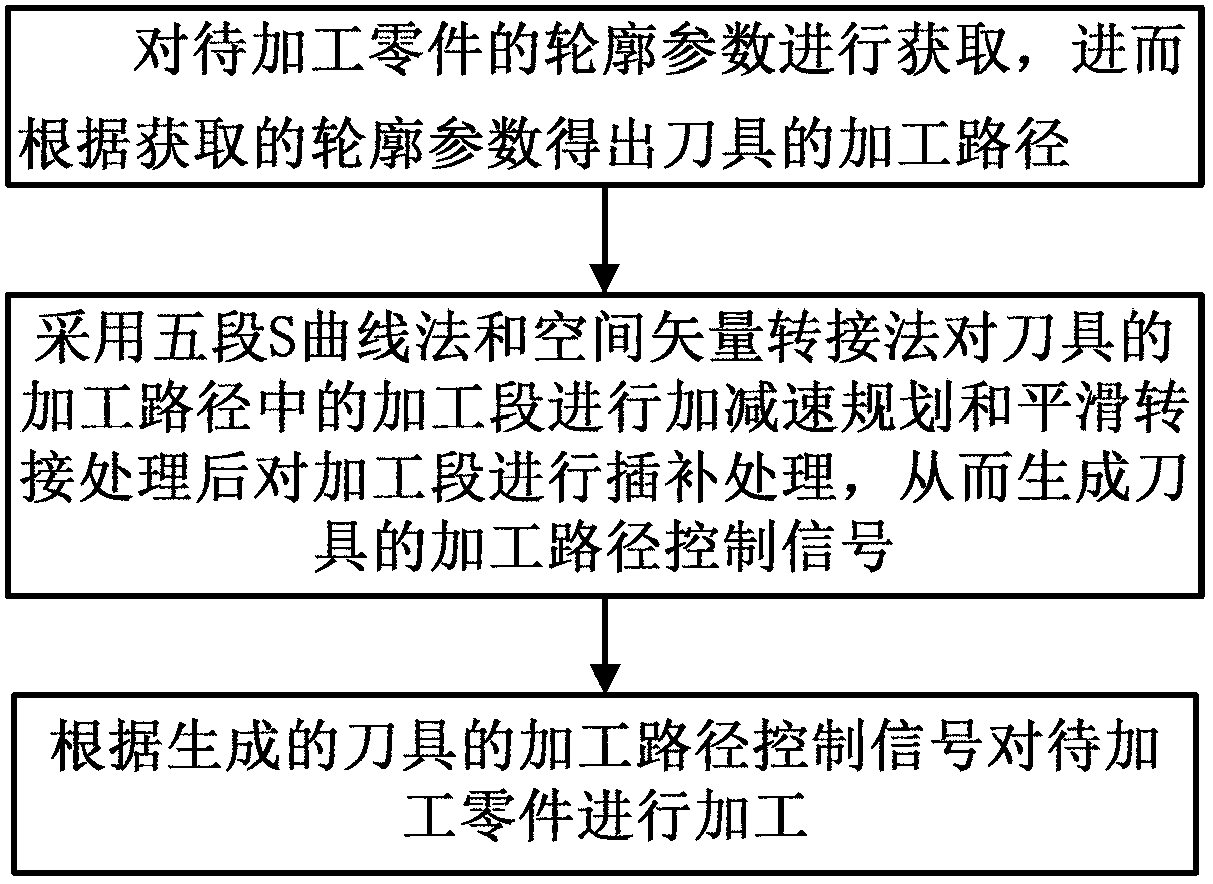

Non uniform rational B spline (NURBS) interpolation based speed smooth control method

ActiveCN103064344AGuaranteed real-timeGuaranteed processing efficiencyNumerical controlNumerical controlControl signal

The invention discloses a non uniform rational B spline (NURBS) interpolation based speed smooth control method which comprises obtaining contour parameters of to-be-processed parts and cutting tool processing path according to the obtained contour parameters; utilizing five section S curve method and the space vector transfer method to conduct acceleration and deceleration planning and smooth transfer processing to the processing section of the cutting tool in the processing path, and then conducting interpolation processing to the processing section, so that processing path control signal of the cutting tool can be generated; processing the to-be-processed parts according to the generated processing path control signal of the cutting tool. The NURBS interpolation based speed smooth control method can not only guarantee the instantaneity and processing efficiency of numerical control machining, but also improve transfer speed and processing efficiency between tracks, and prevent mechanical shock on the corner of track section, so that machining precision is improved. Furthermore, only three stages of time of acceleration speed, uniform velocity and deceleration need to be confirmed, and whole section of acceleration and deceleration control curve can be constructed. The NURBS interpolation based speed smooth control method has the advantages of being simple in algorithm, easy to achieve and capable of being widely applied to the field of numerical control machining.

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

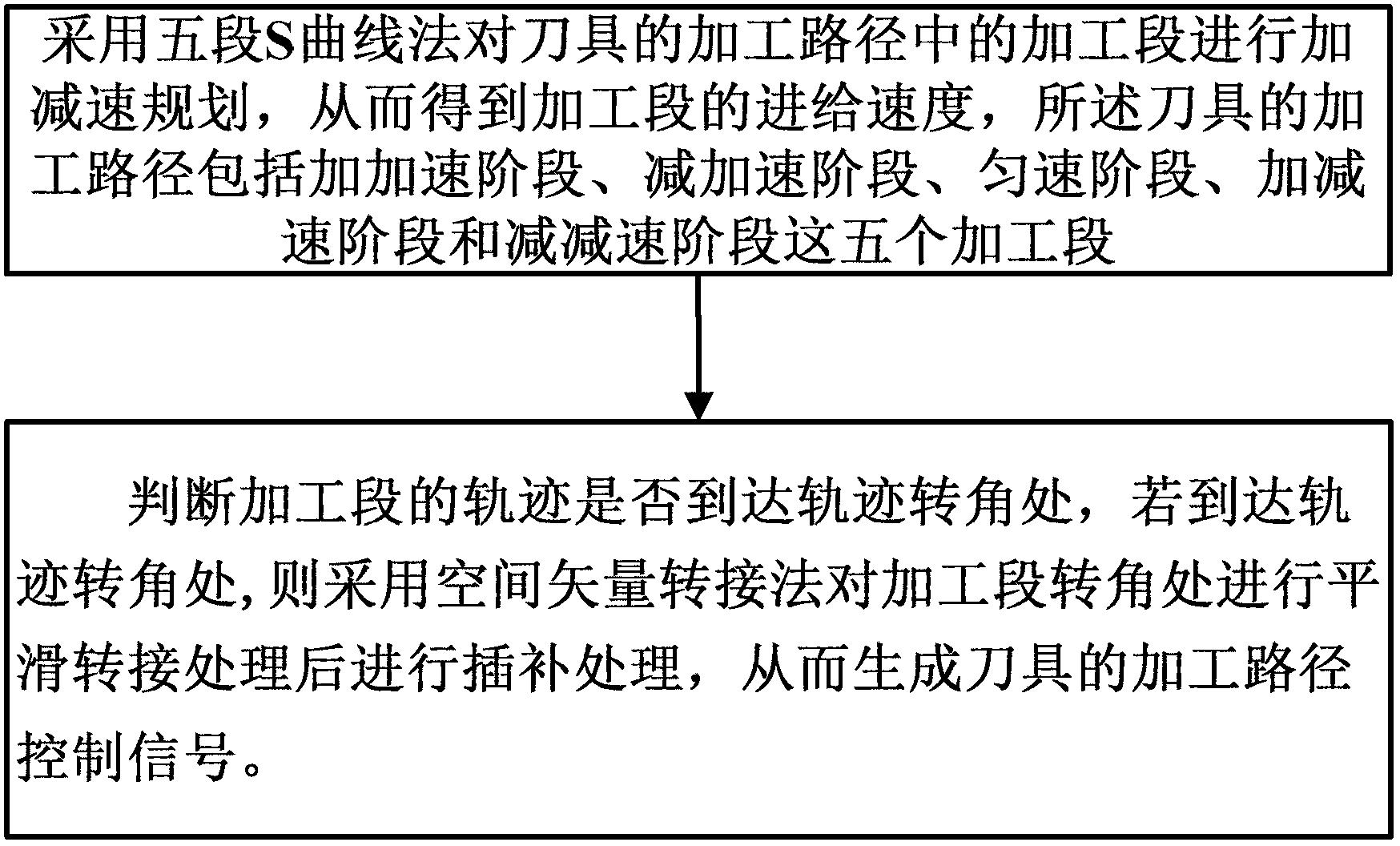

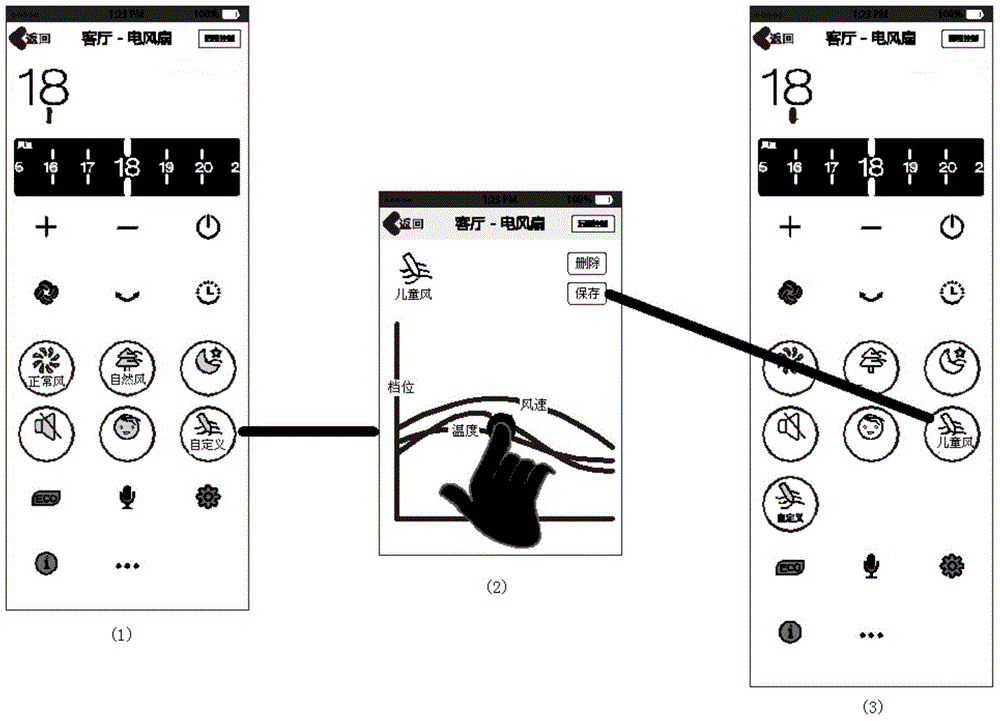

Household appliance, control system and method of household appliance, mobile terminal and cloud server

The invention provides a control system of a household appliance. The control system comprises a mobile terminal, a cloud server and the household appliance, wherein the mobile terminal comprises an application which provides a setting interface, the setting interface receives a control instruction and control parameters input by a user, and the application generates a customized control mode and / or a control curve for the user according to the control instruction and the control parameters; the cloud server is used for analyzing the customized control mode and / or the control curve for the user so as to generate a control command; the household appliance works according to the control command of the cloud server. According to the control system of the household appliance, a private customized function mode can be generated according to hobbies and habits of the user, then the ambient environment is adjusted to meet the individual demand of the user, high flexibility is realized, linkage control can be realized, and the living environment is optimized. The invention further provides a control method of the household appliance, the mobile terminal, the cloud server and the household appliance.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

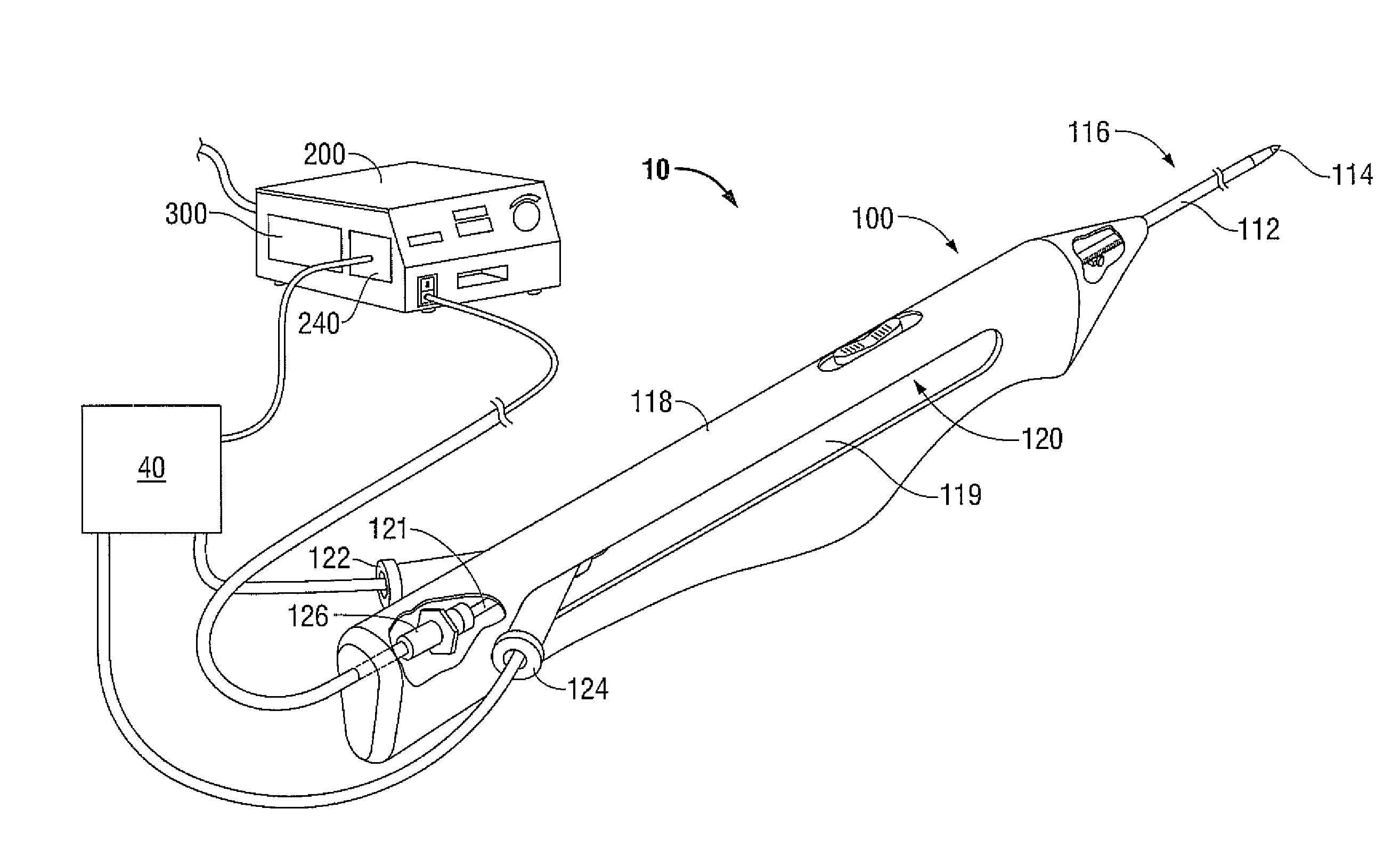

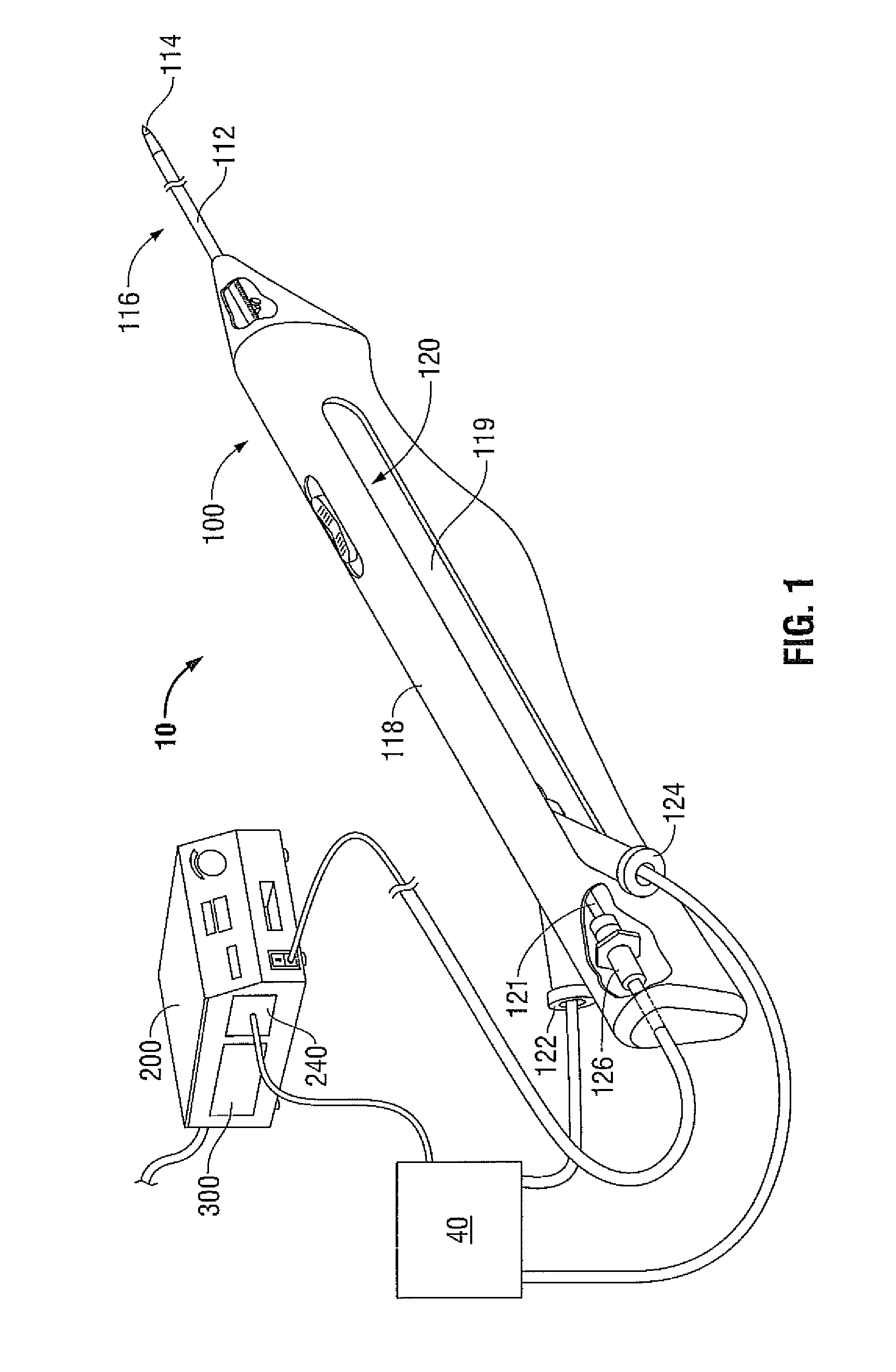

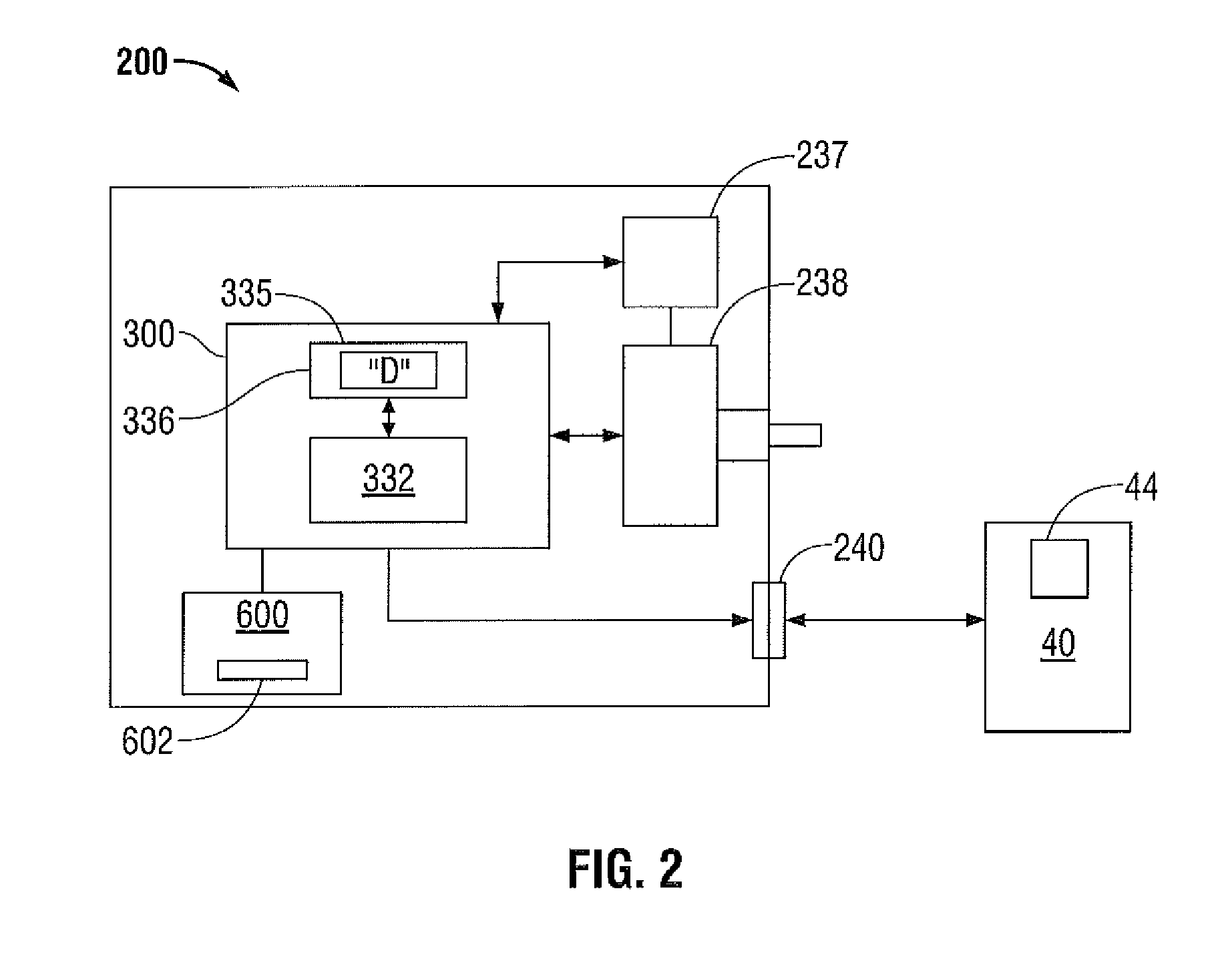

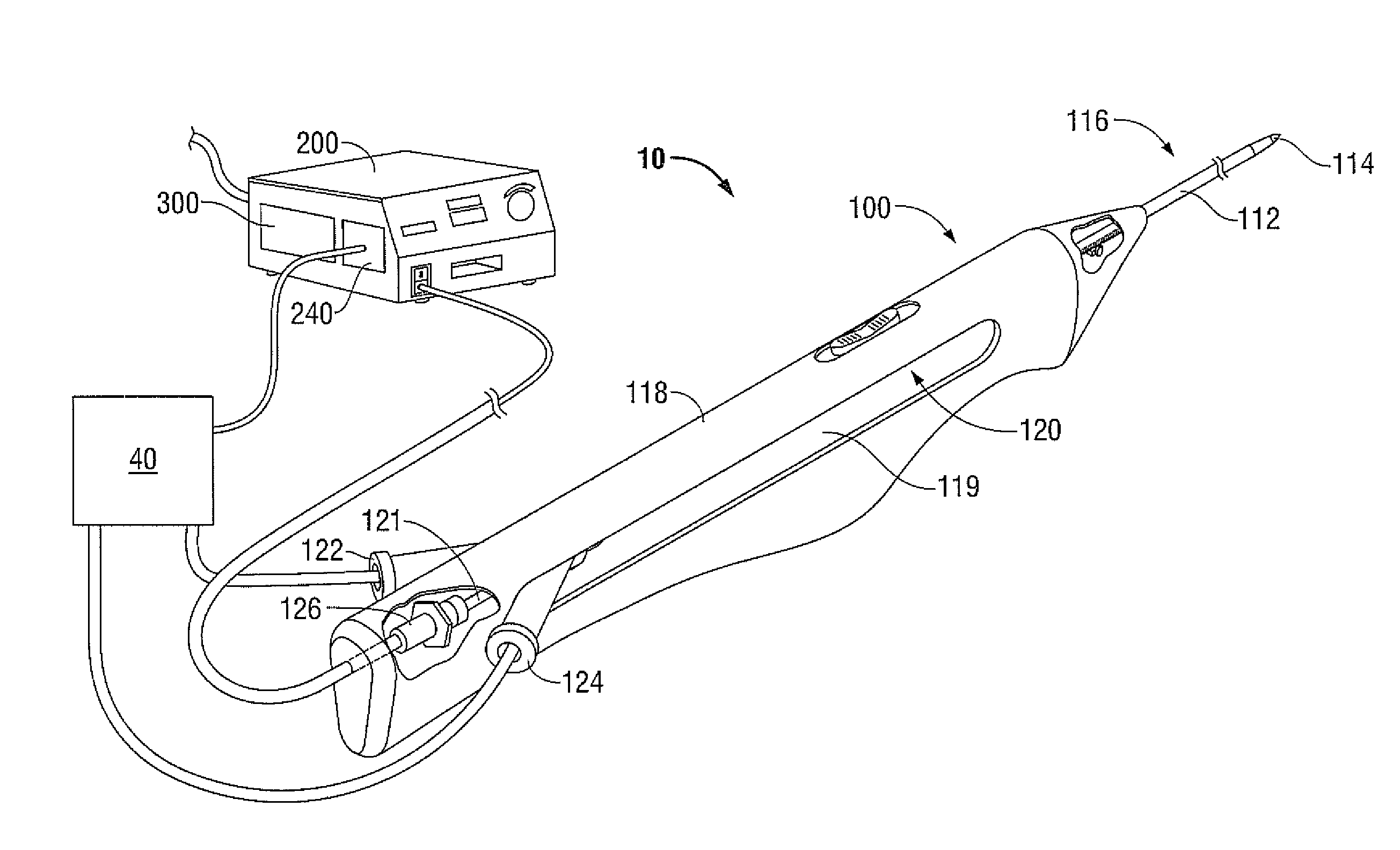

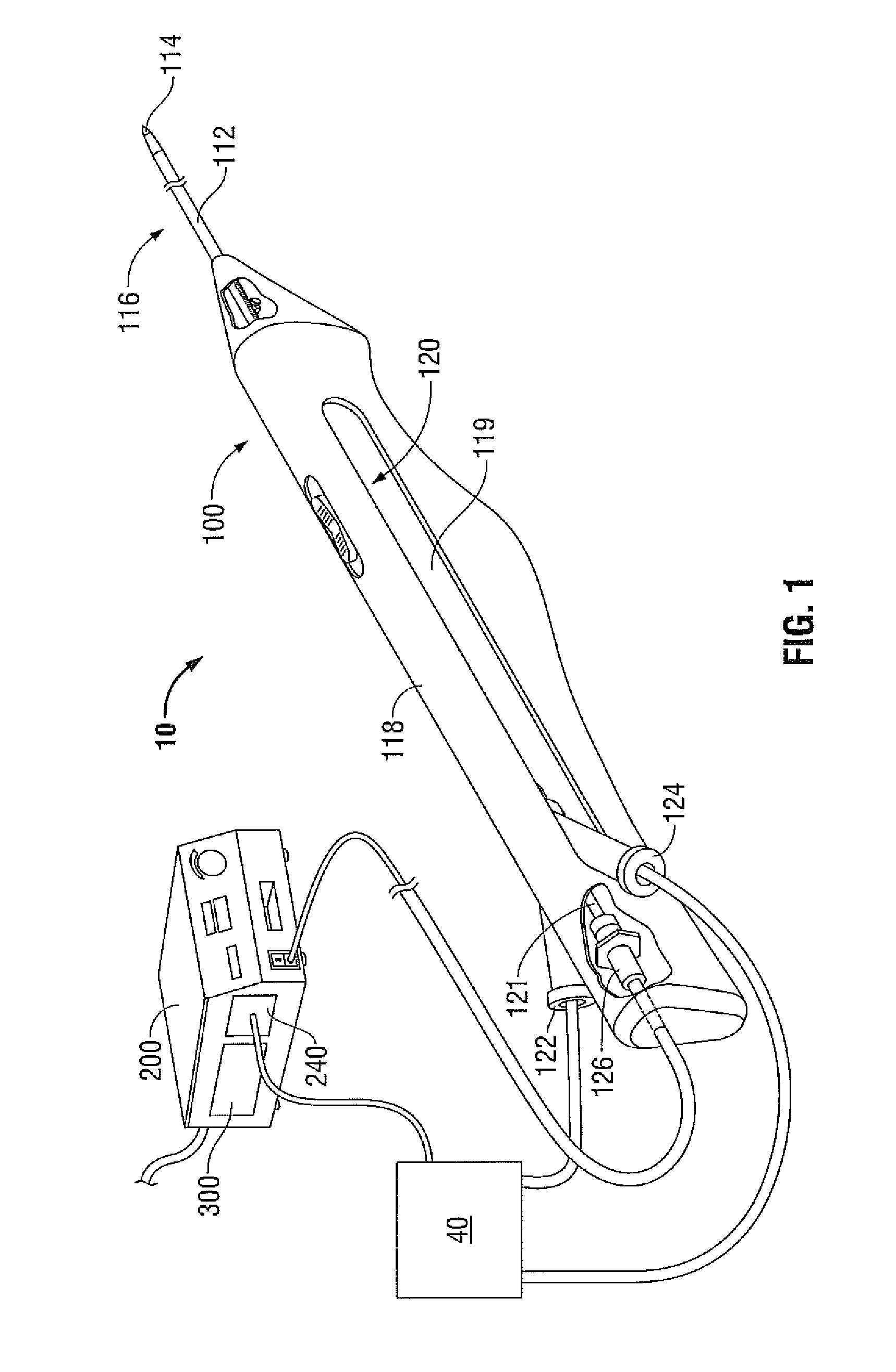

System and method for monitoring ablation size

A system for monitoring ablation size is provided and includes a power source including a microprocessor for executing at least one control algorithm. A microwave antenna is configured to deliver microwave energy from the power source to tissue to form an ablation zone. An ablation zone control module is in operative communication with a memory associated with the power source. The memory includes one or more data look-up tables including data pertaining to a control curve varying over time and being representative of one or more electrical parameters associated with the microwave antenna. Points along the control curve correspond to a value of the electrical parameters and the ablation zone control module triggers a signal when a predetermined threshold value of the electrical parameter(s) is measured corresponding to the radius of the ablation zone.

Owner:TYCO HEALTHCARE GRP LP

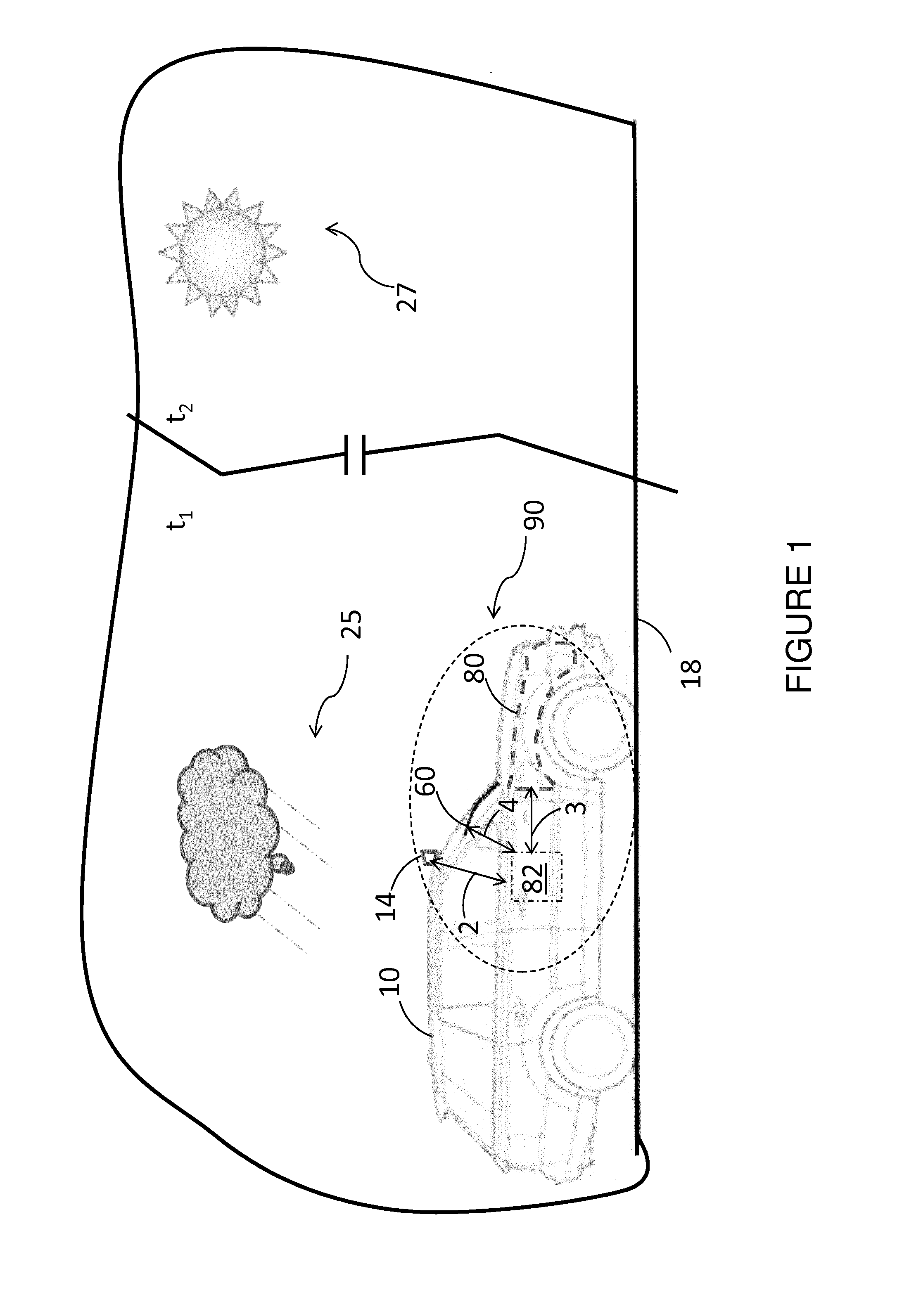

Cruise Control System for a Vehicle

The disclosure relates to a system for cruise controlling a vehicle. The system comprises a control unit configured to select a current driving control profile in dependence upon a determination by the system of an environmental and / or situational status of the vehicle. The said driving control profile optionally comprises an acceleration profile selected from two or more different acceleration profiles in dependence upon a determination by the system of an environmental and / or situational status of the vehicle. The said driving control profile comprises a deceleration profile selected from two or more different deceleration profiles in dependence upon a determination by the system of an environmental and / or situational status of the vehicle. The environmental and / or situational status of the vehicle may be determined by consideration of signals comprising data obtained from sensors or control modules comprised within or mounted to the vehicle and / or from information sources external to the vehicle.

Owner:JAGUAR LAND ROVER LTD

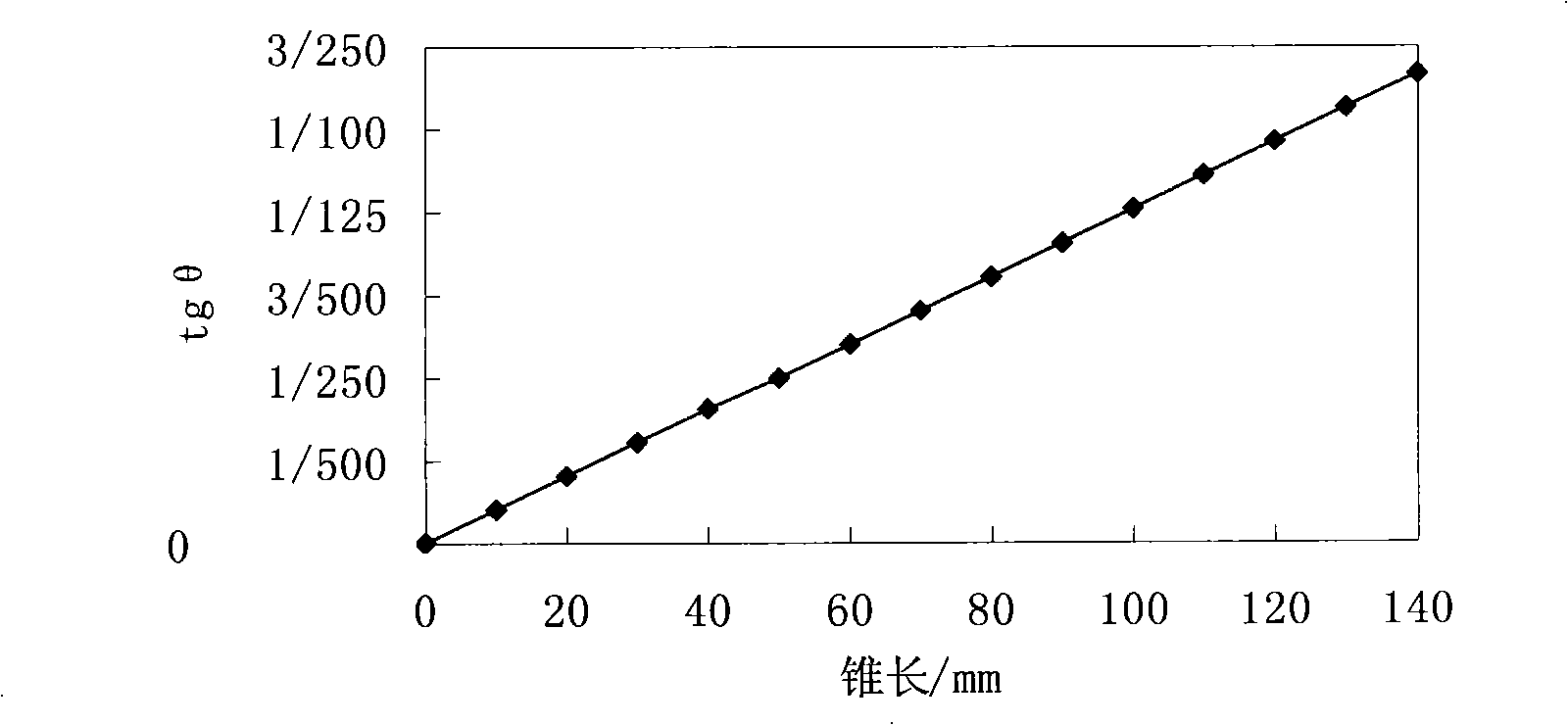

Control method of tandem cold rolling mill emulsion section cooling

The invention discloses a control method of tandem cold rolling mill emulsion section cooling, comprising the following steps: a. collecting the device parameter of a rolling mill and the key parameter of band steel to be rolled; b. collecting a technological lubrication institution parameter; c. giving emulsion section cooling flow distribution initial value and iteration precision; d. calculating corresponding work roll thermal crown; e. calculating the lateral distribution value of a slipping factor; f. comparing the slipping factor maximum value with a critical value; g. calculating the lateral distribution value of a slip injury index; h. comparing the maximum value of the slip injury index with the critical value; i. calculating the corresponding strip shape distribution value; j. calculating the function value of a strip shape objective function; and k. judging whether Powell condition is available, and obtaining the control curve of the optimal section cooling flow. The controlmethod of the invention combines device section condition with practical flow control precision to set the emulsion flow in sections, reduces problems of slipping, hot slip injury and the like causedby lubrication and ensures the strip shape and the surface quality index of chassis outlet strip steel rolled stock.

Owner:BAOSHAN IRON & STEEL CO LTD

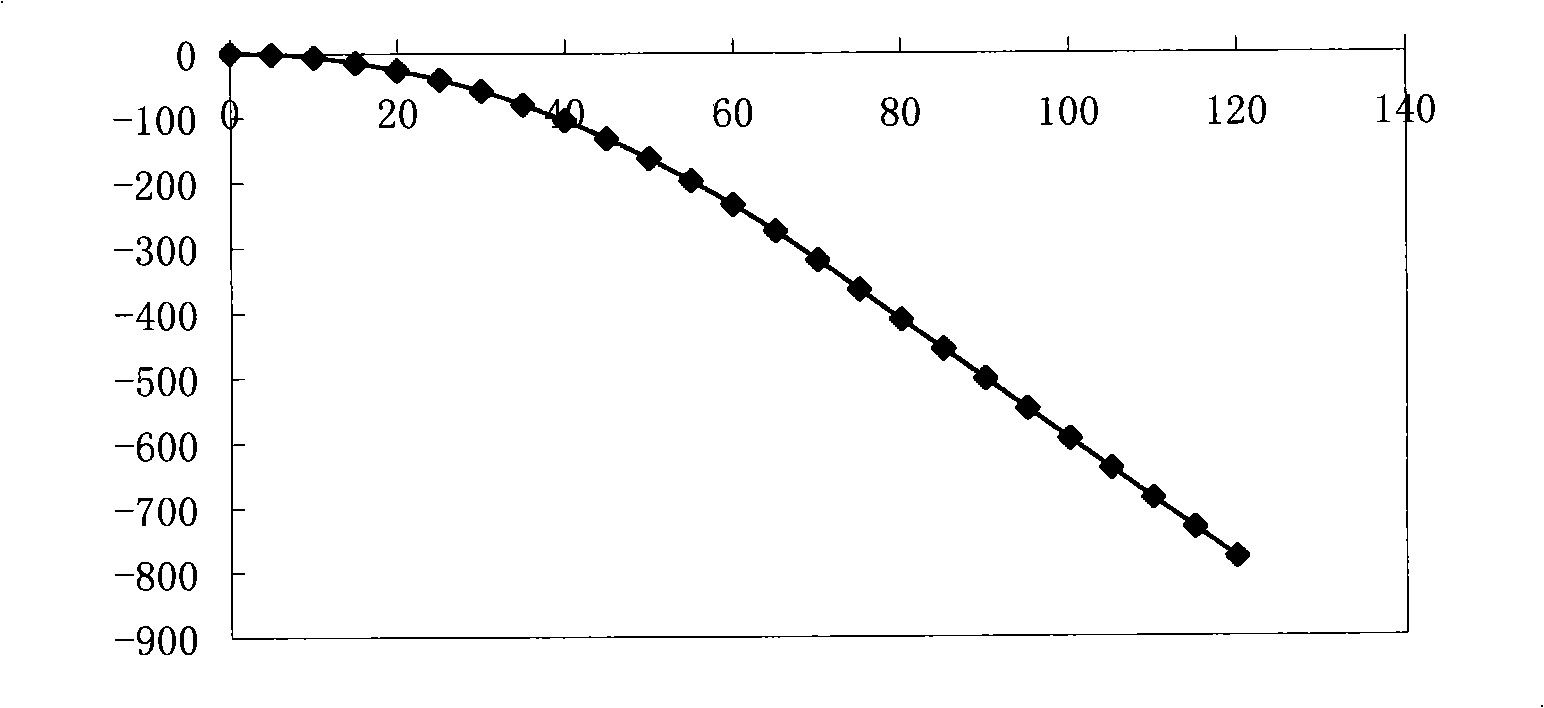

Correction method for optimization of sliding pressure of large steam turbine

ActiveCN101864994ABest sliding pressure operation modeImprove operational efficiencyMachines/enginesEngine componentsSteam pressureLow load

The invention discloses a correction method for optimization of sliding pressure of a large steam turbine generator set of a power plant. The current research on optimization of the sliding pressure of the large steam turbine generator set operating under the low load to ensure that the generator set can operate with excellent performance under the sliding pressure during the low-load operation has great significance in improvement of the operating efficiency of the generator set. The correction method is characterized in that correction factors are adopted to correct the sliding pressure control curve of the generator set, that is, the relevance relation of the load of the generator set, the main steam pressure and the opening of the high-pressure regulating valve is expressed as Cn*Ng varies as Cp*P0*Cv. Since the specific correction factors are introduced for control elements, the load of the generator set and the main steam pressure of the control curve of the generator set under the sliding pressure in the sliding pressure deviation factor correction method, the invention ensures that the steam turbine generator is in the mode of operating under the best sliding pressure, andcan maintain the high operating efficiency of the generator set all the time.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +2

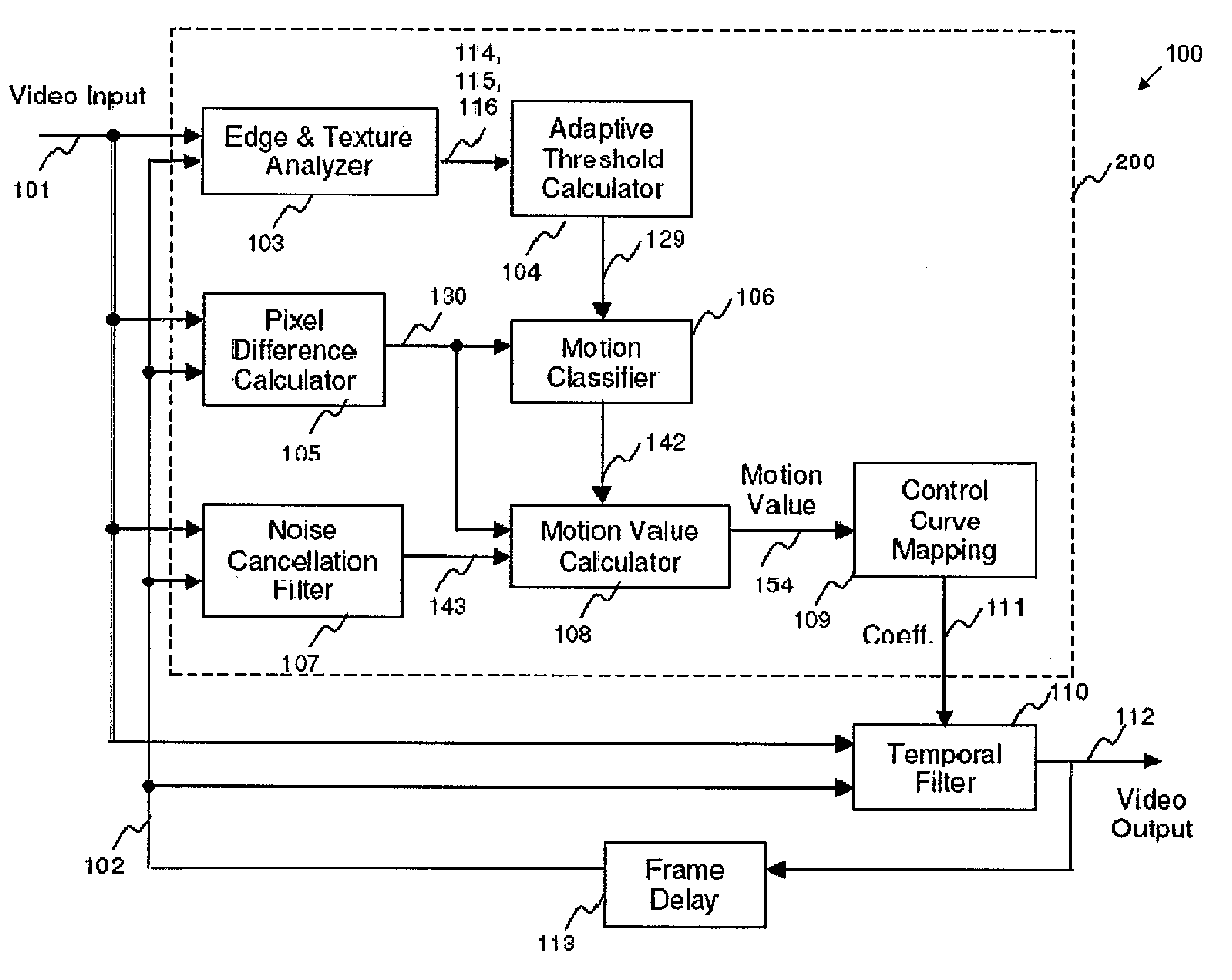

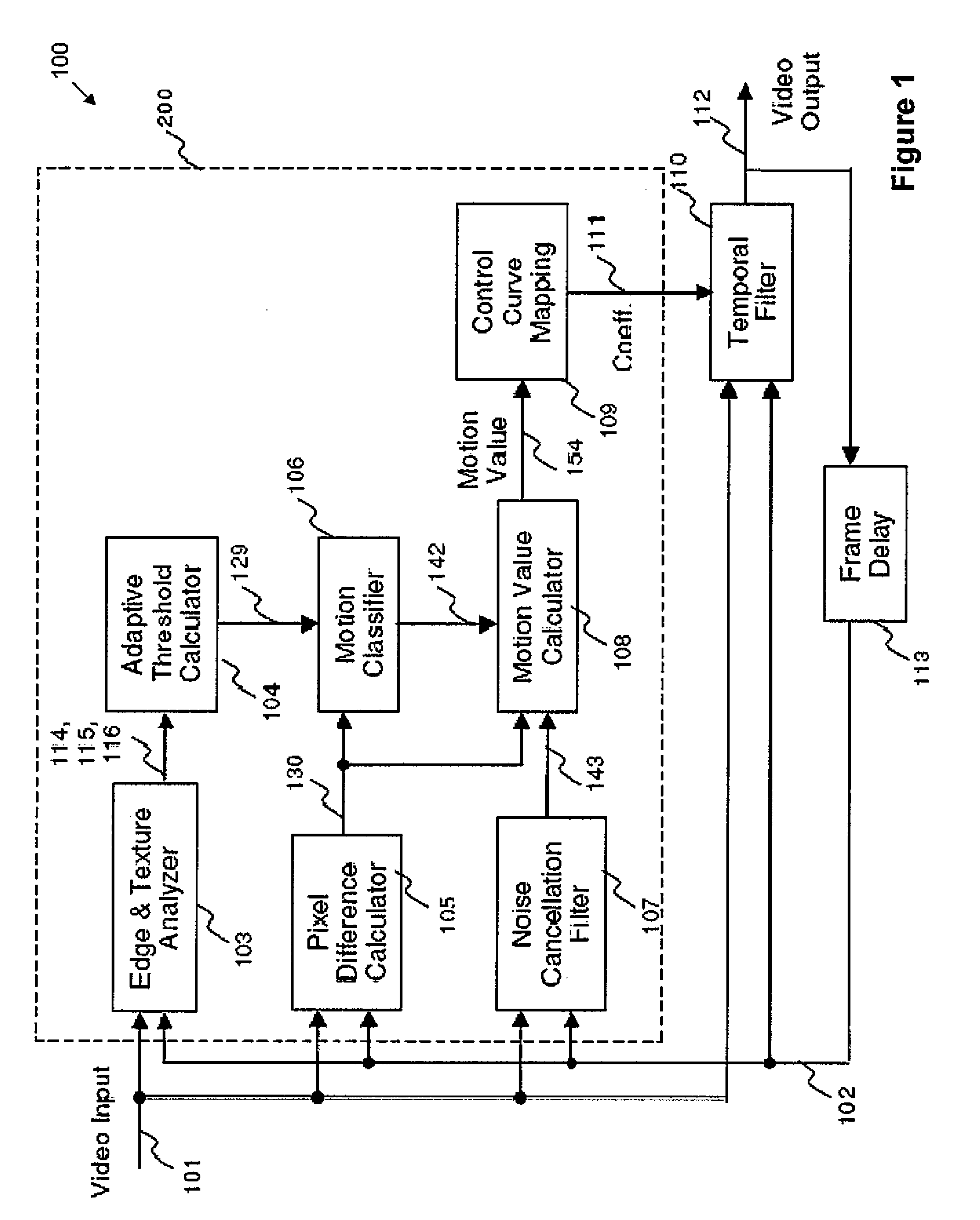

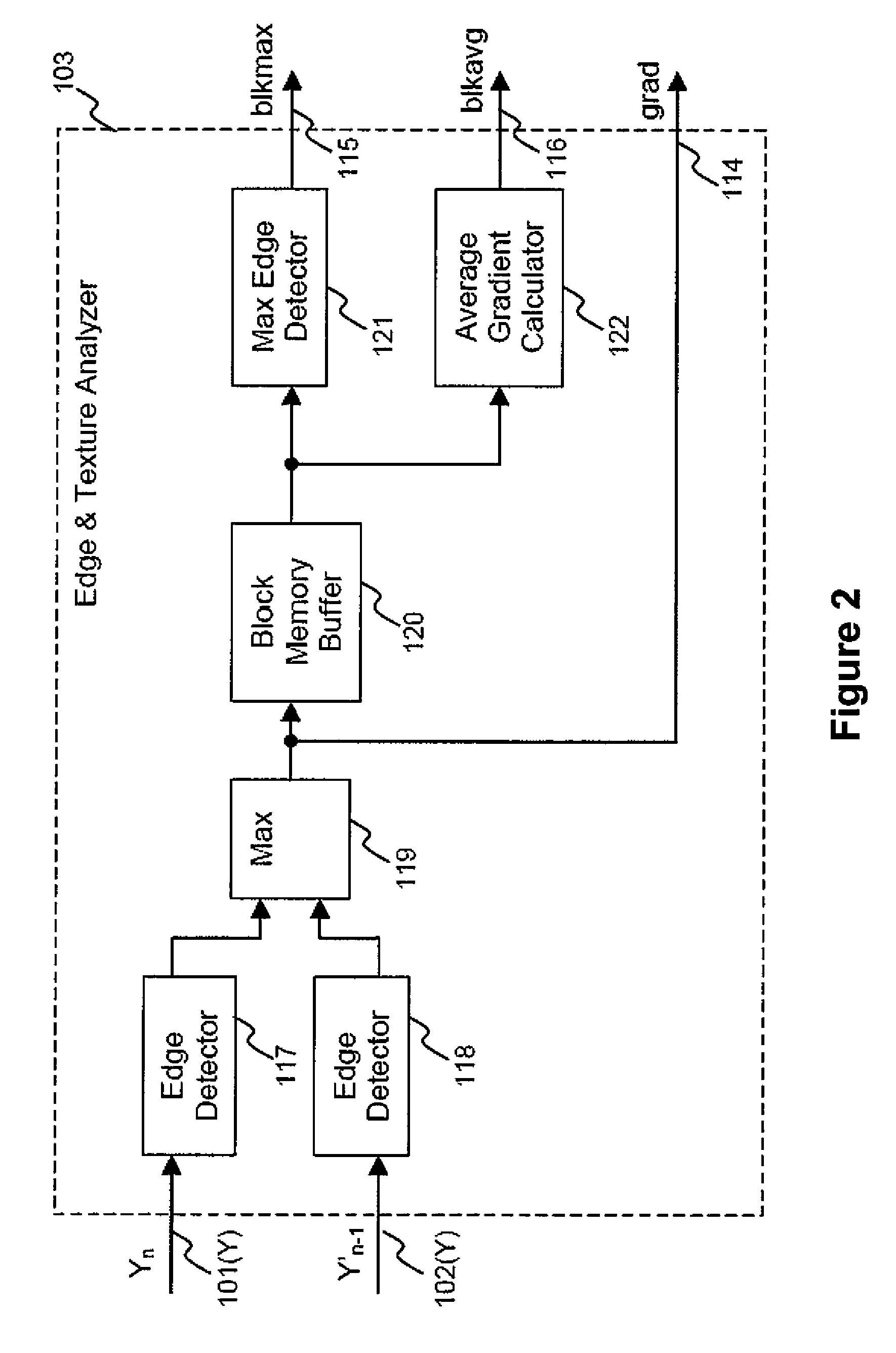

Apparatus and method of motion detection for temporal mosquito noise reduction in video sequences

ActiveUS20100165207A1Improve robustnessReduce noiseTelevision system detailsPicture reproducers using cathode ray tubesDigital videoVideo sequence

Apparatus and methods of motion detection for mosquito noise reduction in video sequences are provided. In one aspect, a method of motion detection in a sequence of digital images classifies a pixel of a plurality of pixels of a current image frame represented by a digital video input signal as a motion or non-motion pixel. A motion value for the pixel is calculated based on the classification of the pixel. The motion value is mapped to a coefficient of a temporal filter based on a control curve. A digital video output signal is generated based on the coefficient.

Owner:STMICROELECTRONICS ASIA PACIFIC PTE

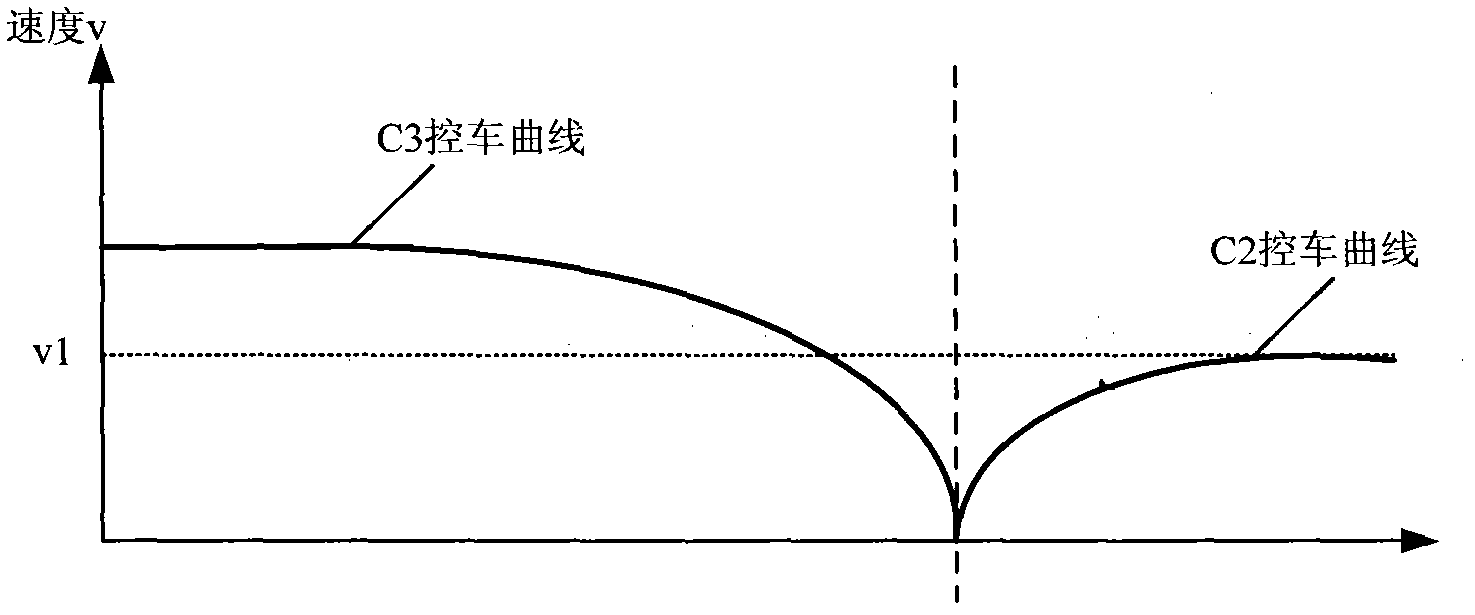

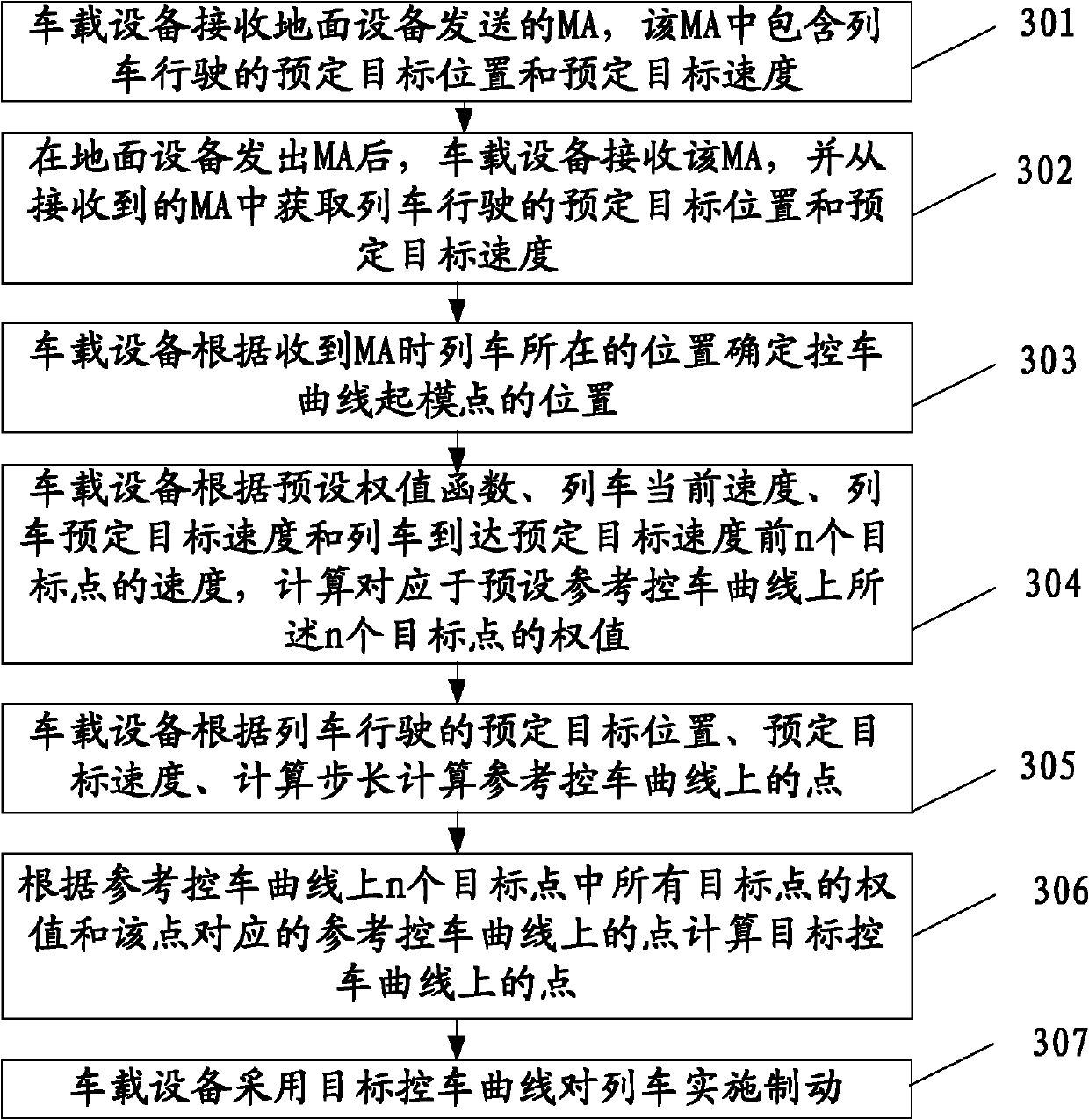

Train operation control method, device, vehicle-mounted equipment and train operation control system

ActiveCN101941452ATroubleshooting Control Switching IssuesRailway traffic control systemsEmbedded systemControl curve

The invention discloses a train operation control method comprising the following steps: two control devices simultaneously receives the train travelling parameters transmitted by ground equipment, and the train travelling parameters received by the different control devices are different; each control device substitutes the received train travelling parameters to a segmented curve algorithm for calculating to generate corresponding train control curves; vehicle-mounted equipment selects a control device which corresponds to the current line grade CTCS; and the control device controls the train travelling speed according to the train control curve thereof. By adopting the above technical scheme, the segmented curve algorithms adopted by the different control devices are similar, the difference between the train control curves generated by each control device is small; and when the train travels to the next line grade CTCS, the train travelling speed is directly controlled by the control device corresponding to the next line grade CTCS, thus realizing non-parking automatic transformation control from the control device corresponding to the current line grade to the control device corresponding to the next line grade.

Owner:CRSC RESEARCH & DESIGN INSTITUTE GROUP CO LTD

System and Method for Monitoring Ablation Size

Owner:TYCO HEALTHCARE GRP LP

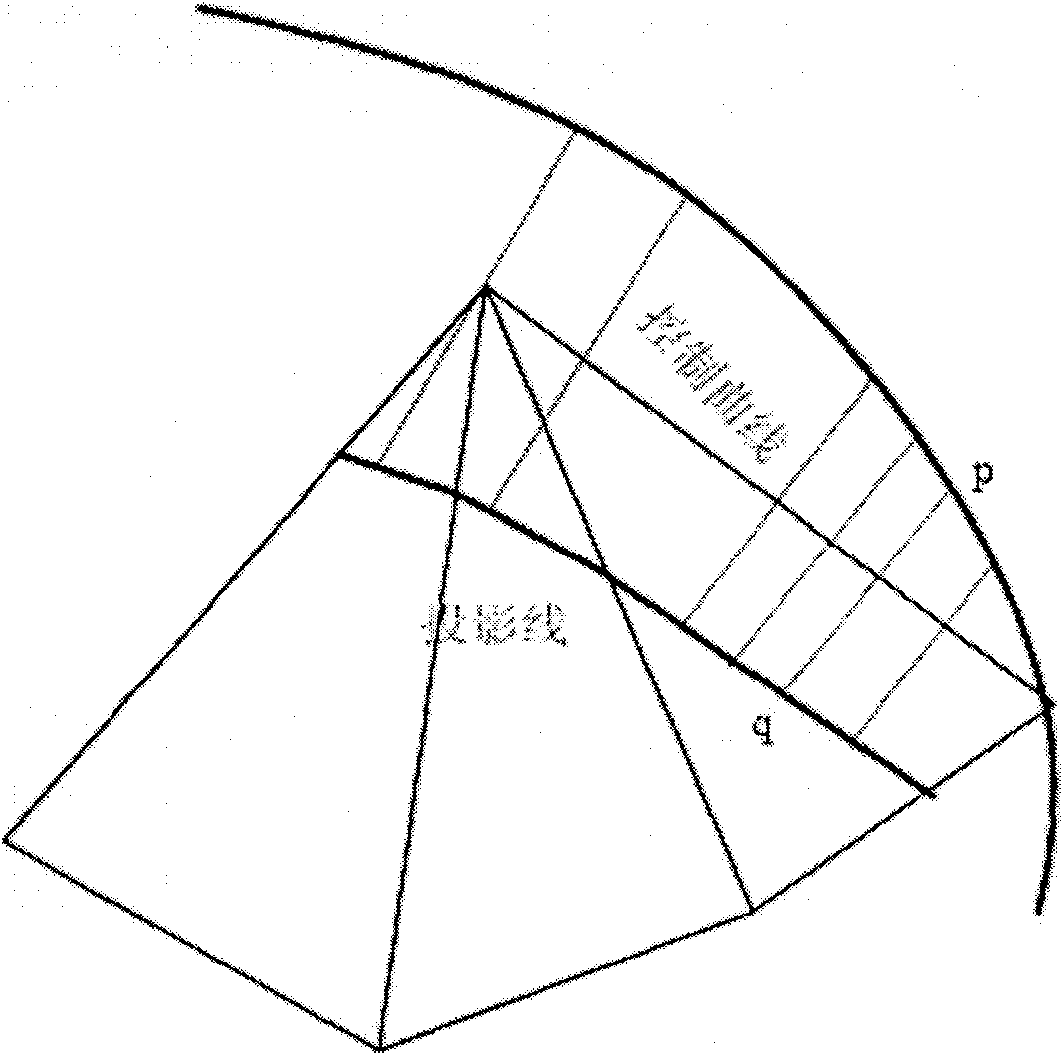

Method suitable for segmenting dental triangle mesh curved surface from dental jaw triangle mesh curved surface

ActiveCN102147935ALow efficiencyOthrodonticsSpecial data processing applicationsDentistryBiomedical engineering

The invention belongs to the technical field of model segmentation in digital geometry processing, and discloses a method suitable for segmenting a dental triangle mesh curved surface from a dental jaw triangle mesh curved surface. The method integrates the three advantages of accuracy, high efficiency and smooth boundary, and finally realizes segmentation of the dental triangle mesh curved surface by the operations of interactive pickup of a dental jaw area to be segmented, primary segmentation of the increased area, automatic generation and accurate positioning of a spatial control curve, generation of segmentation line projection, smooth optimization of a segmentation line and the like.

Owner:CHANGZHOU HI TECH DISTRICT MULTIPLE DIMENSION IND TECH INST

Work roll with steel rim drop-control and flat degree control

InactiveCN101254508AGood control effectTo achieve the purpose of edge landing controlRollsMetal rolling arrangementsWork rollStrip steel

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

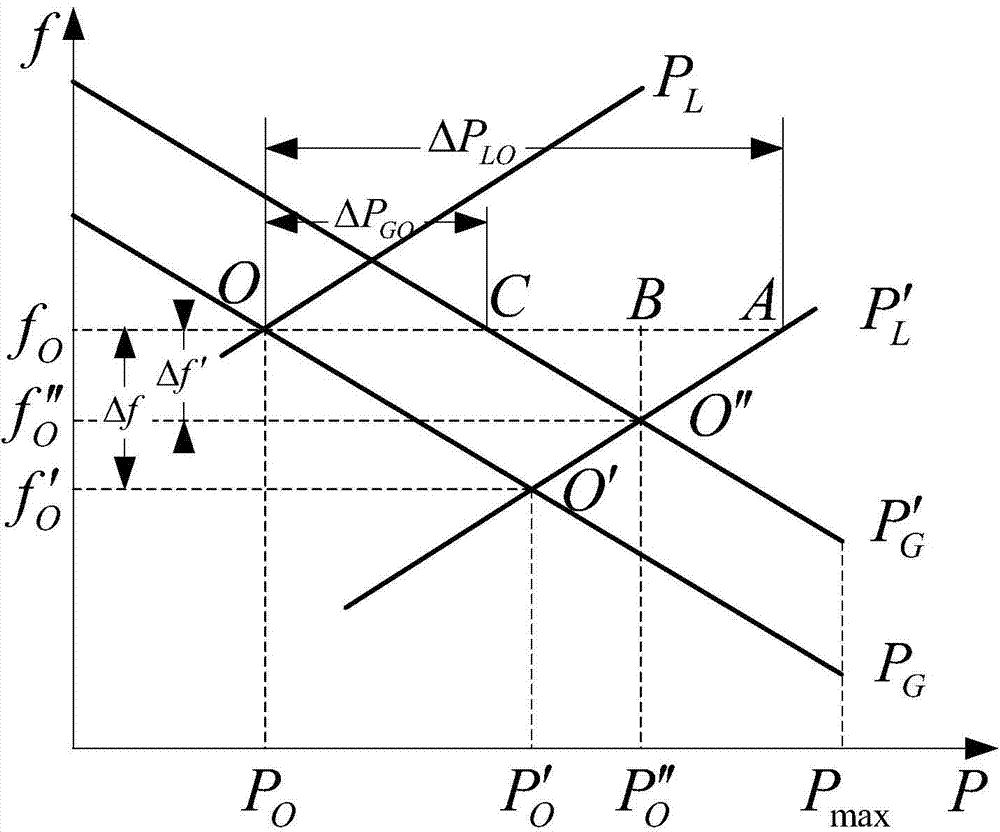

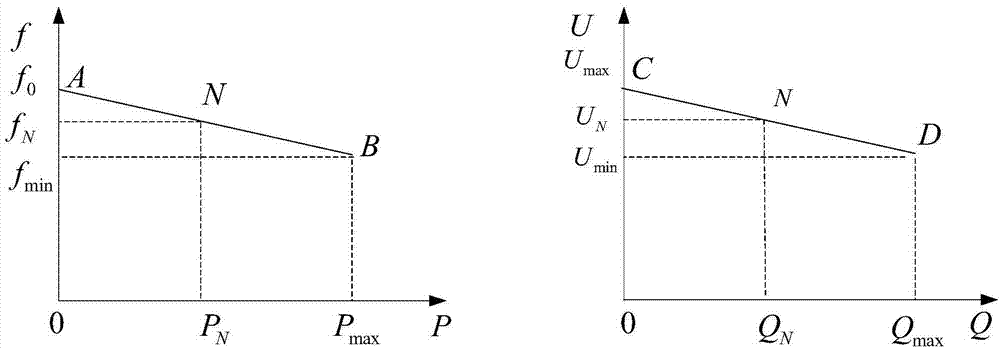

Inverter droop control method capable of achieving secondary frequency modulation and pressure regulation

InactiveCN103501021ARealize the second frequency modulation effectGuaranteed uptimeEfficient power electronics conversionSingle network parallel feeding arrangementsLower limitPower inverter

The invention discloses an inverter droop control method capable of achieving secondary frequency modulation and pressure regulation and belongs to the technical field of distributed power supply inverter output control. According to the inverter droop control method capable of achieving secondary frequency modulation and pressure regulation, aiming at the defect that a traditional local inverter droop control method can not achieve secondary frequency modulation and pressure regulation, with the restriction of the purpose of meeting the upper limit, the lower limit and the specified working point of power output of an inverter, an S-shaped droop control curve is constructed based on a traditional droop control curve with the specified working point as a middle transition point; modeling is achieved by means of a cubic function or a piecewise function, traditional droop control constant coefficients are replaced with a quadratic function, so that power output can be adjusted dynamically along with load change; due to the fact that when a traditional electric generator operates under the control of a frequency modulator / pressure regulator, the movement track of the intersection point of the secondary frequency modulation and pressure regulation power output curve of the electric generator and a load characteristic curve is an S-shaped curve, the curve can be directly used for controlling the inverter, and then secondary frequency modulation and pressure regulation are achieved, and operation performance of the inverter is better than that when the inverter is under traditional droop control.

Owner:NANJING INST OF TECH

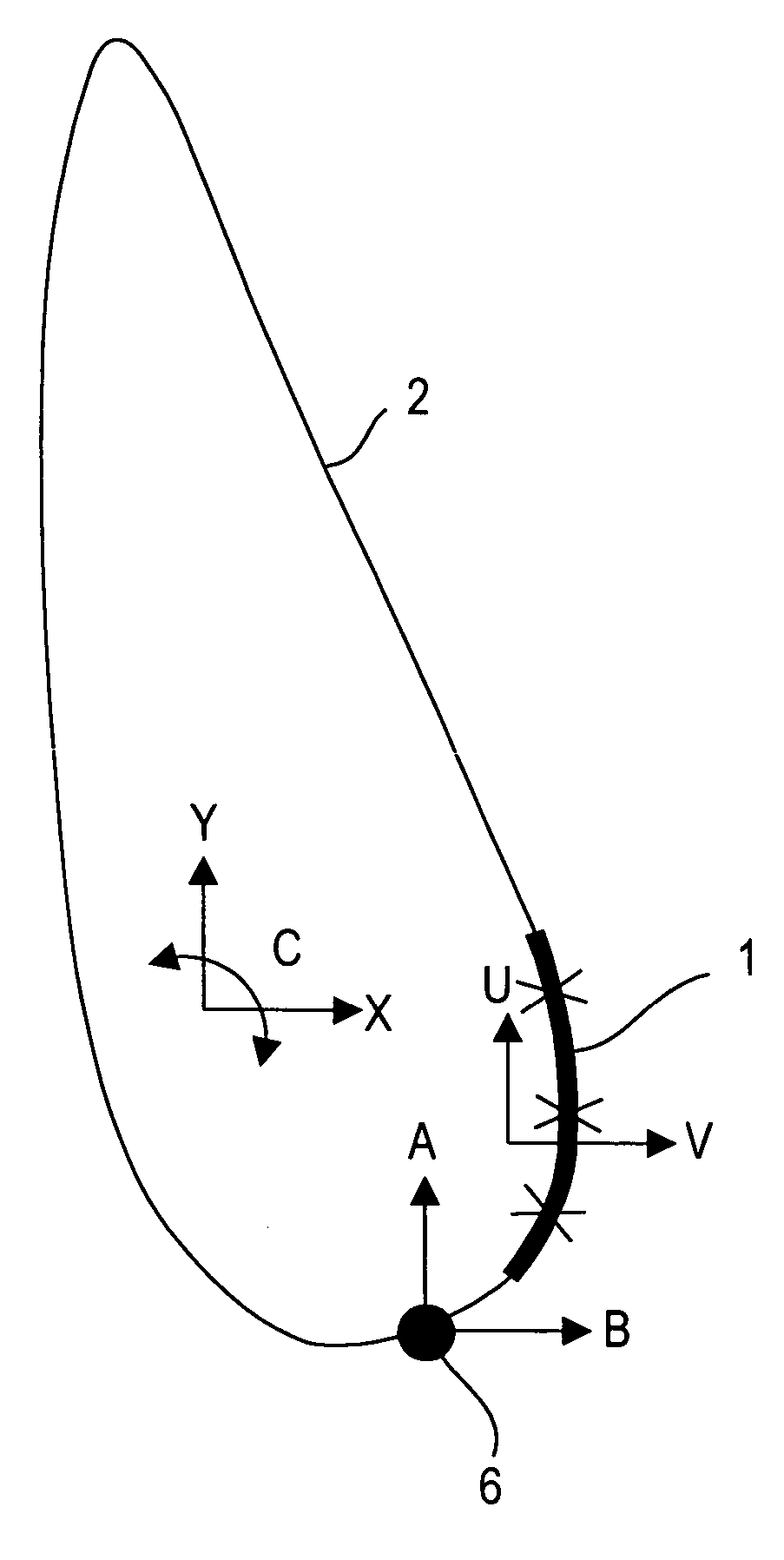

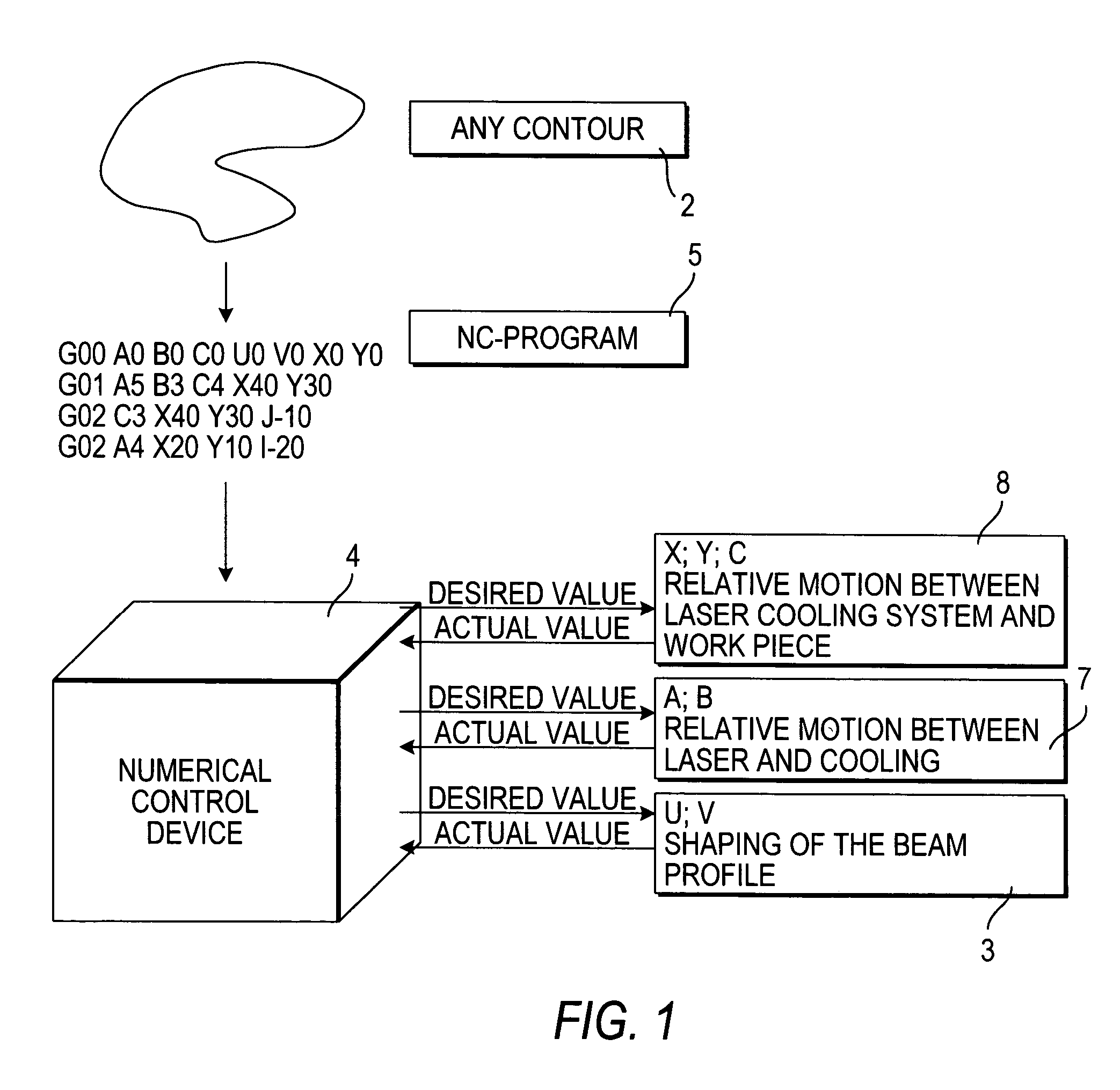

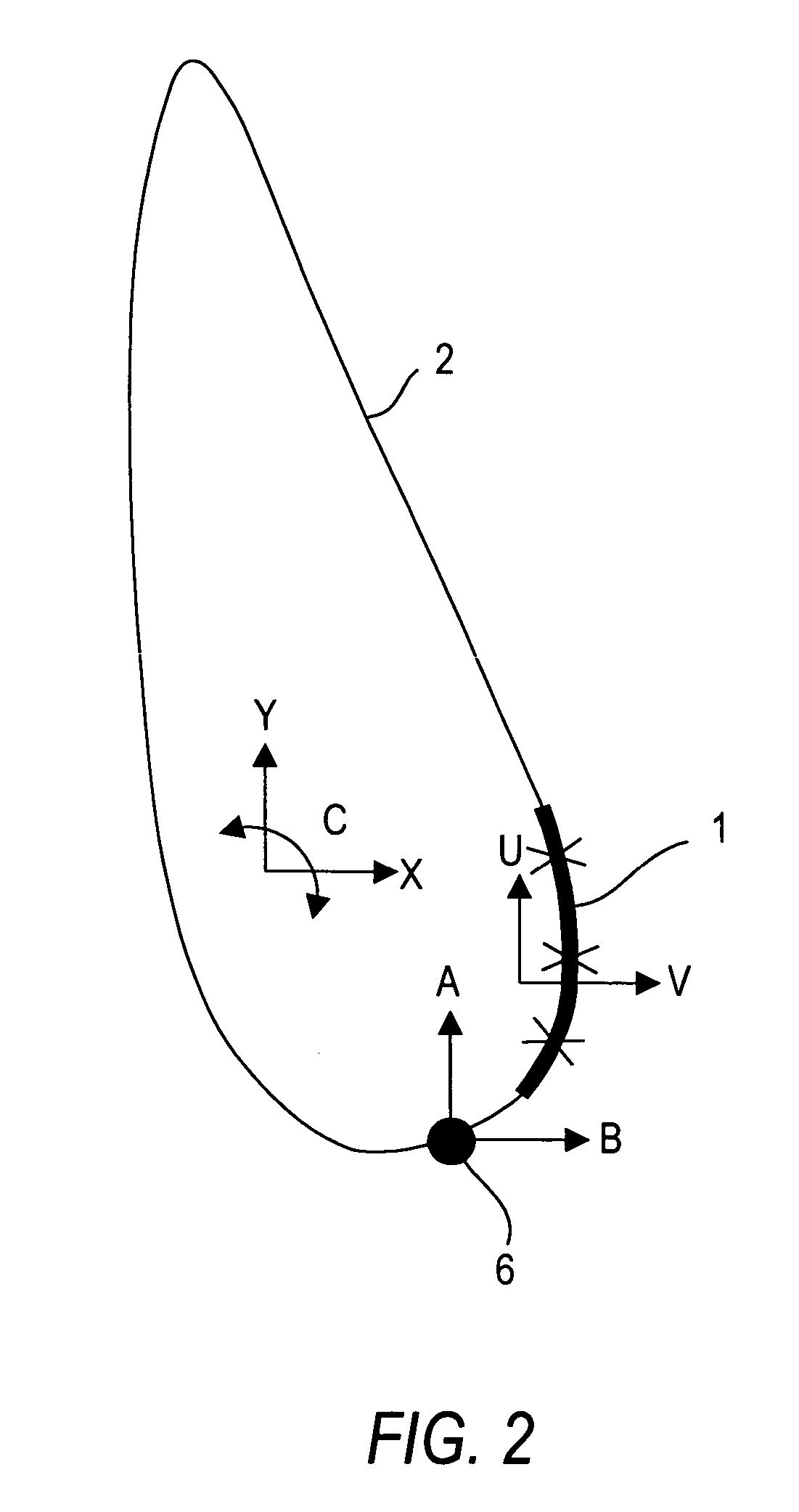

Method and device for cutting flat work pieces made of a brittle material

InactiveUS7014082B2Easy to cutAvoid meltingGlass severing apparatusWelding/soldering/cutting articlesFlat glassData control

The apparatus for cutting a flat glass work piece along a curved dividing line includes a laser generating a laser beam having a linear beam profile and an optical system with a scanner for producing a curvilinear focal point from the laser beam. The apparatus also moves a cold spot along the curved dividing line following the curvilinear focal point. A trajectory control device controls the position of the curvilinear focal point on the curved dividing line via actuators. A profile control device controls the contour of the curvilinear focal point according to trajectory data from the curved dividing line, so that all points of the curvilinear focal point lie on or coincide with the curved dividing line. The apparatus adjusts the length of the curvilinear focal point by adjusting scanning amplitude of the scanning motion.

Owner:SCHOTT AG

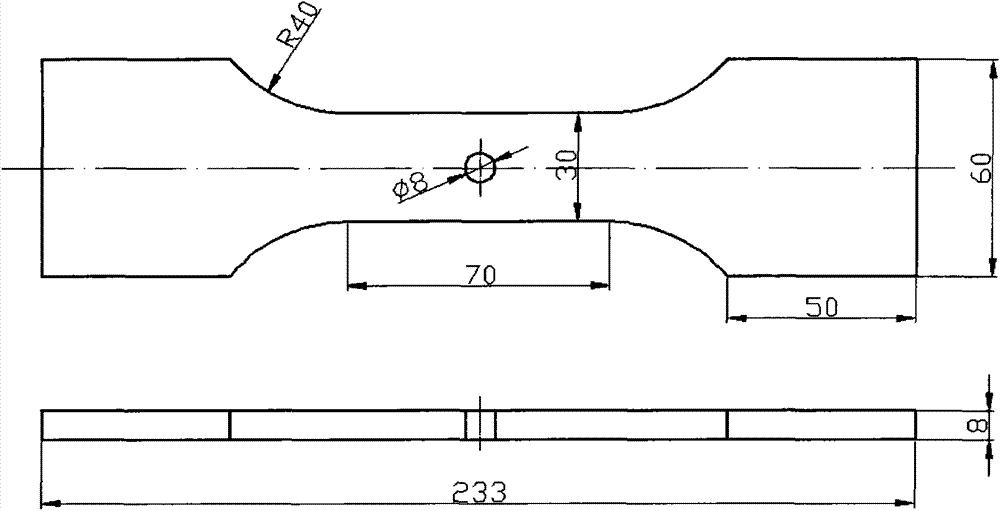

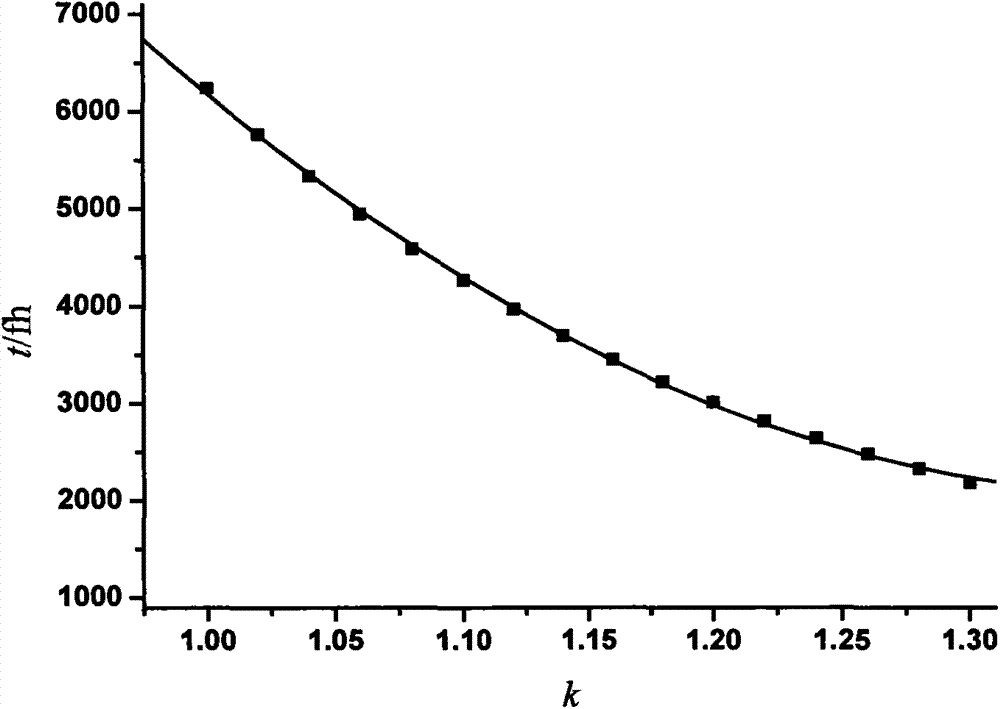

Method for analyzing service life of high maneuverability aircraft base on detail fatigue rating

InactiveCN104809321AEasy to understandEasy to masterSpecial data processing applicationsStrength propertiesStructural reliabilityStress level

The invention belongs to the field of an aircraft fatigue theory and relates to a method for analyzing service life of a high maneuverability aircraft base on detail fatigue rating. The analyzing method comprises the following steps: step1, preparing load spectrum analyzed based on the DFR (detail fatigue rating) of the high maneuverability aircraft; step2, analyzing the reference value of the DFR; step3, calculating the DFR0 value; step4, calculating the fatigue rating coefficient RC of the component; step5, confirming the allowable value [DFR] of the structure DFR; step6, calculating the allowable stress [sigma max]; step7, calculating and assessing the fatigue strength margin; step8, calculating the reliable lifetime of the structure; step9, creating a stress level control curve and providing the allowable stress value of the objective service life. The analyzing method has the advantages that the process of performing fatigue design and service life assessment by the DFR method is relatively simple, the calculation workload is relatively low, the operating efficiency of the whole department can be dramatically improved, and thus the analyzing method has the important significance to shorten the research period of a new machine and to save the research cost, and the economic benefit is obvious.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

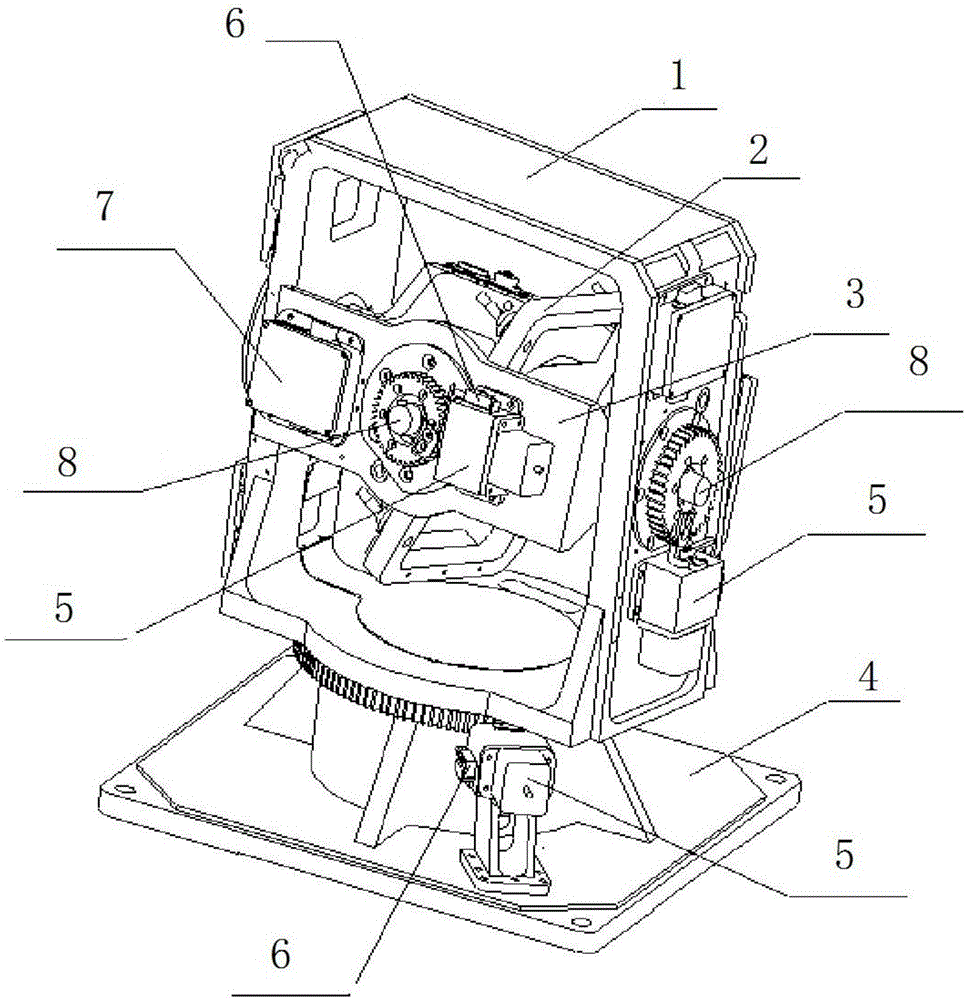

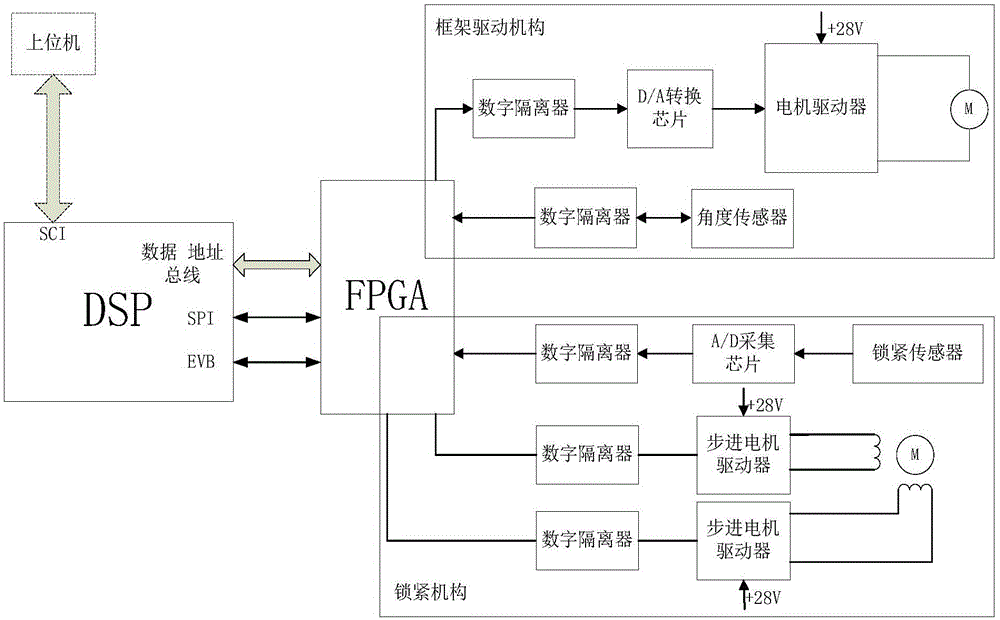

On-vehicle turntable control system and control method thereof

ActiveCN105007012AExquisite structureEasy to transportDynamo-electric converter controlControl systemDrive motor

The invention discloses an on-vehicle turntable control system and a control method thereof. The on-vehicle turntable control system comprises a driving device, a locking device and a control device for controlling the driving device and the locking device. The driving device comprises an angle sensor, a D / A conversion chip, a motor driver and a driving motor. The locking device comprises a position sensor, an A / D acquisition chip, a stepping motor driver and a stepping motor. The control device comprises a digital signal processor. The control method comprises the steps of inputting an instruction to the digital signal processor, automatically unlocking the turntable, calculating an acceleration control curve and a deceleration control curve of the turntable, computing the voltage of the driving motor and driving the turntable according to the voltage, and automatically locking the turntable. The on-vehicle turntable control system has a greatly reduced turntable size and can be integrated with other equipment. Furthermore automatic locking and unlocking of the turntable at a random position can be realized. Furthermore stable operation and precise positioning of the turntable can be realized.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

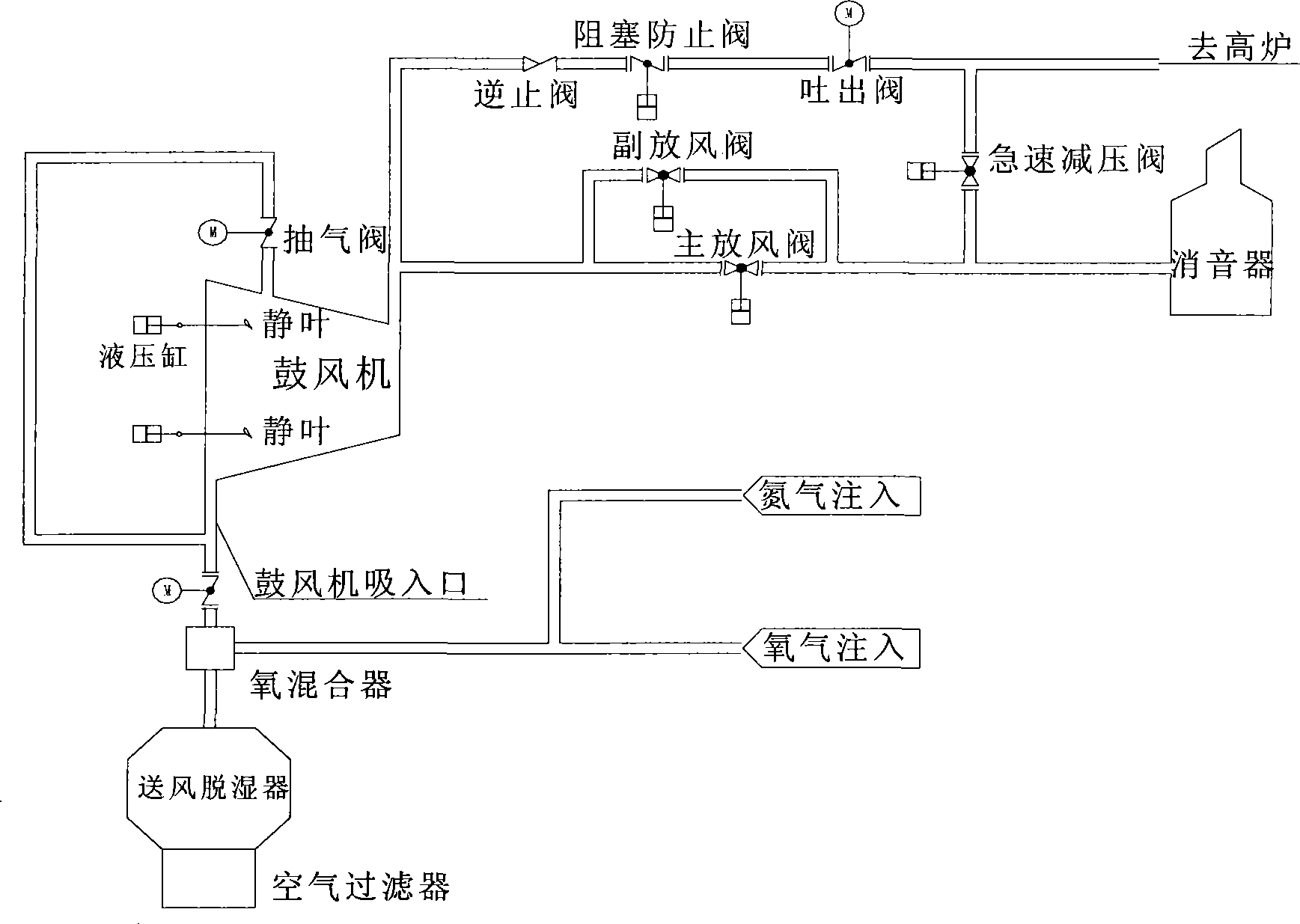

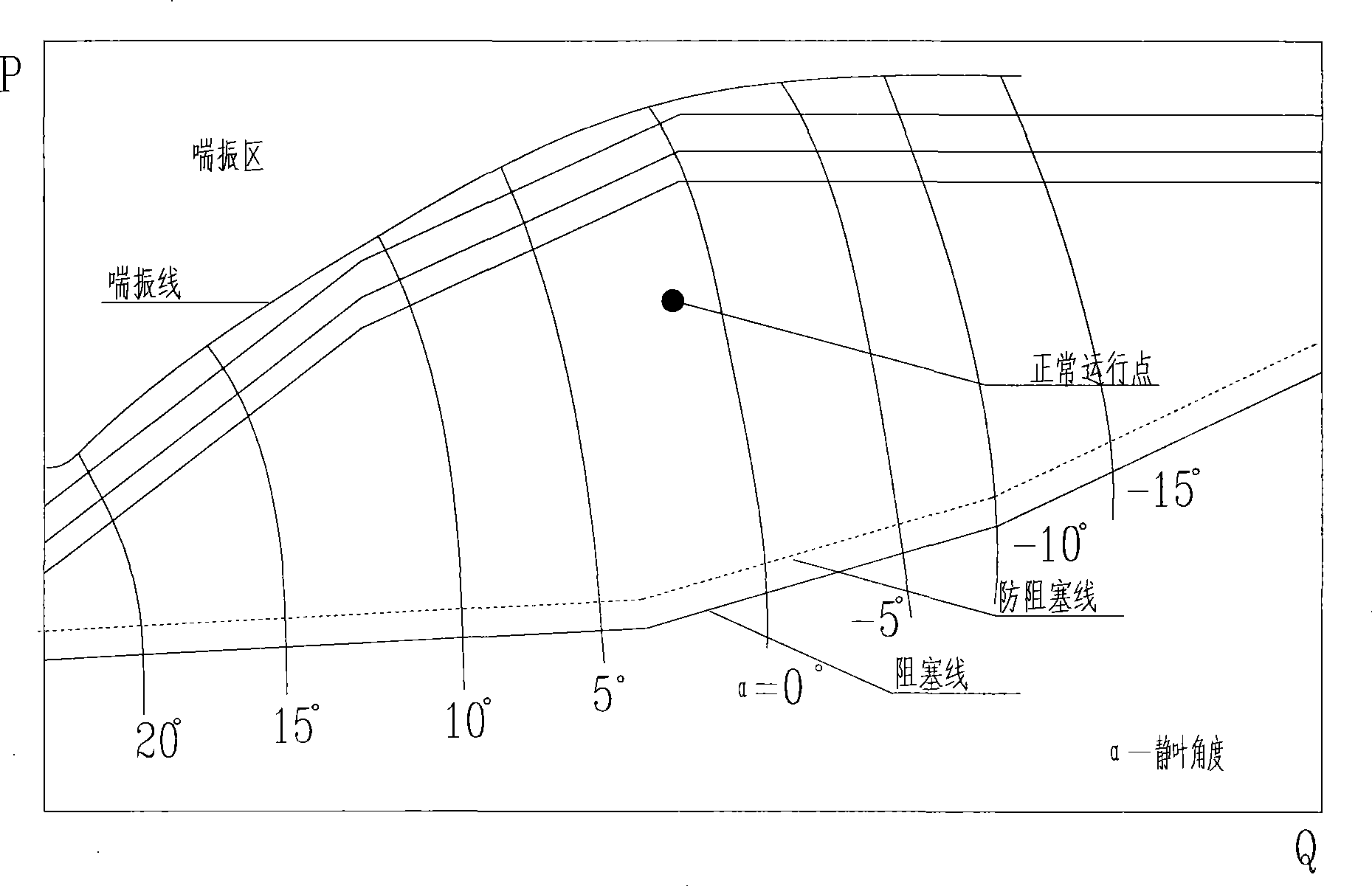

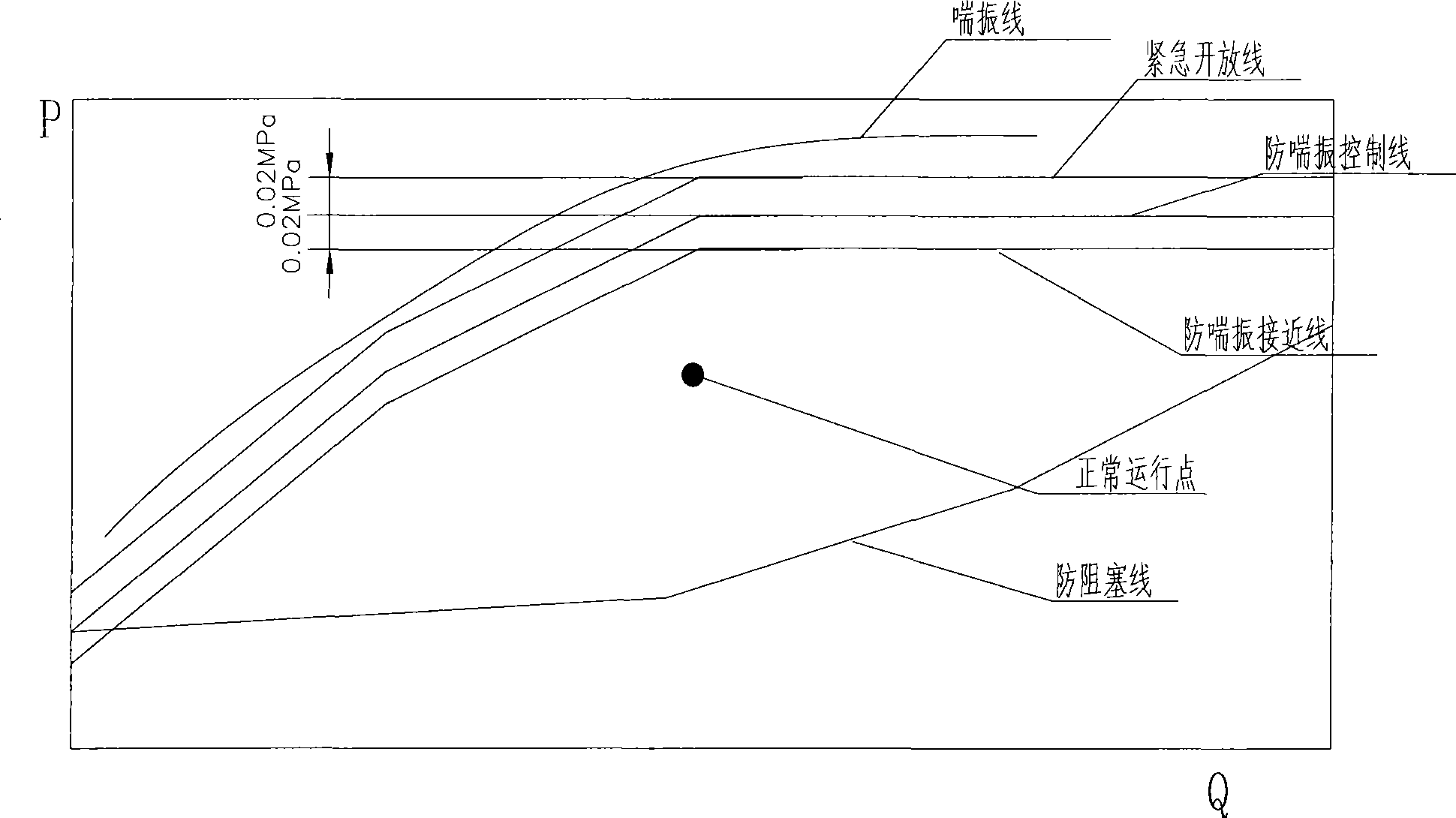

Device and method for controlling anti-surging of a blast blower

ActiveCN101545495AGuaranteed safe operationAnti-surge control implementationPump componentsPump controlStandard stateControl signal

The invention discloses a device for controlling anti-surging of a blast blower, which comprises a sensor module, a standard flow conversion module, a dynamic anti-surging control module, an anti-surging adjuster and an execution mechanism. The invention also discloses a method for controlling the anti-surging, which comprises the following steps: step one, measuring temperature and pressure of an inlet and pressure of an outlet; step two, converting flow of the inlet into the flow in a standard state; step three, calculating a dynamic anti-surging control curve according to the temperature and the pressure of the inlet and a static anti-surging control curve; step four, finding out anti-surging control pressure corresponding to the converted flow in the standard state according to the dynamic anti-surging control curve, and outputting an anti-surging control signal when the pressure of the outlet is equal to or larger than the anti-surging control pressure; and step five, controlling a normal operation point of the operation of the blast blower according to the anti-surging control signal. The method establishes the dynamic anti-surging control curve and realizes the anti-surging control under different ambient temperatures and pressure states.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

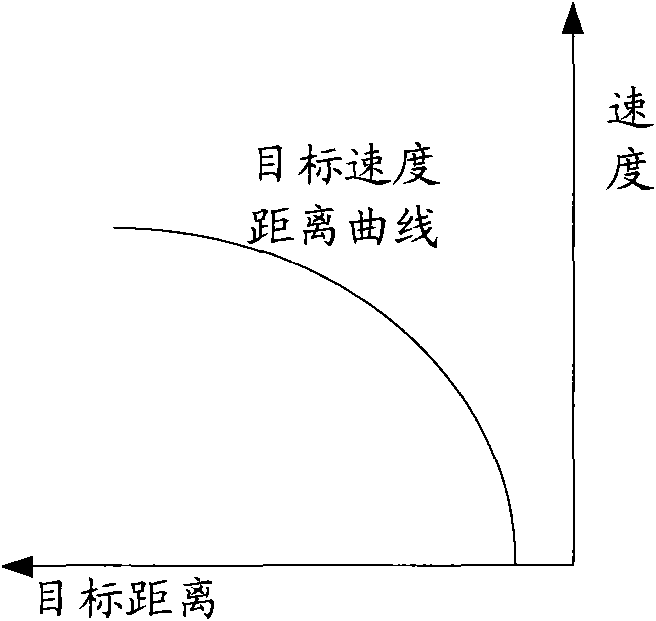

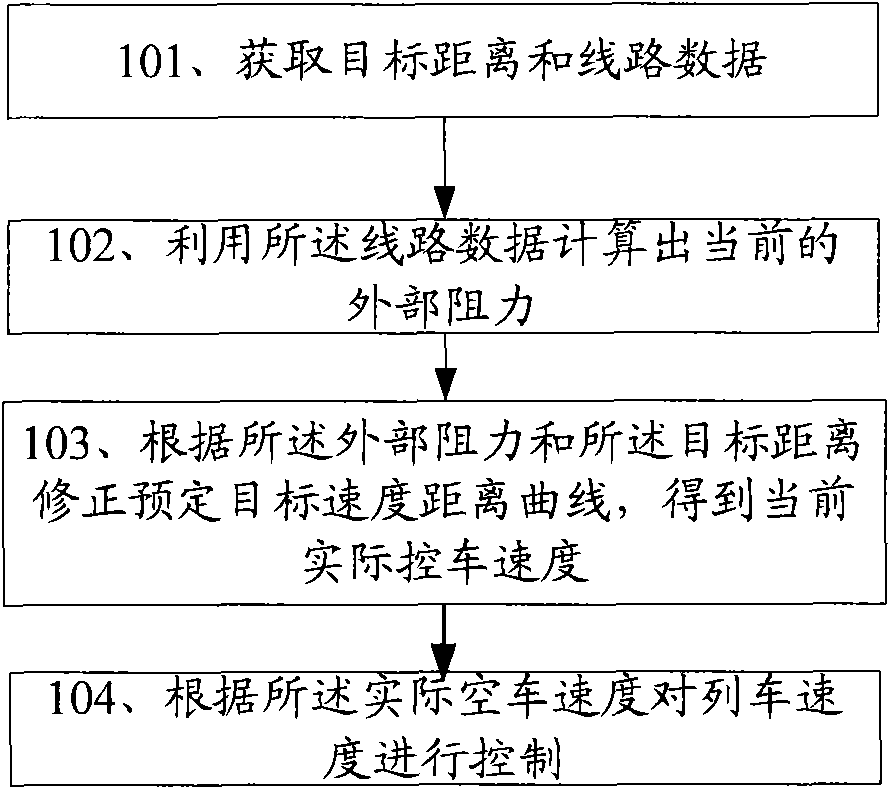

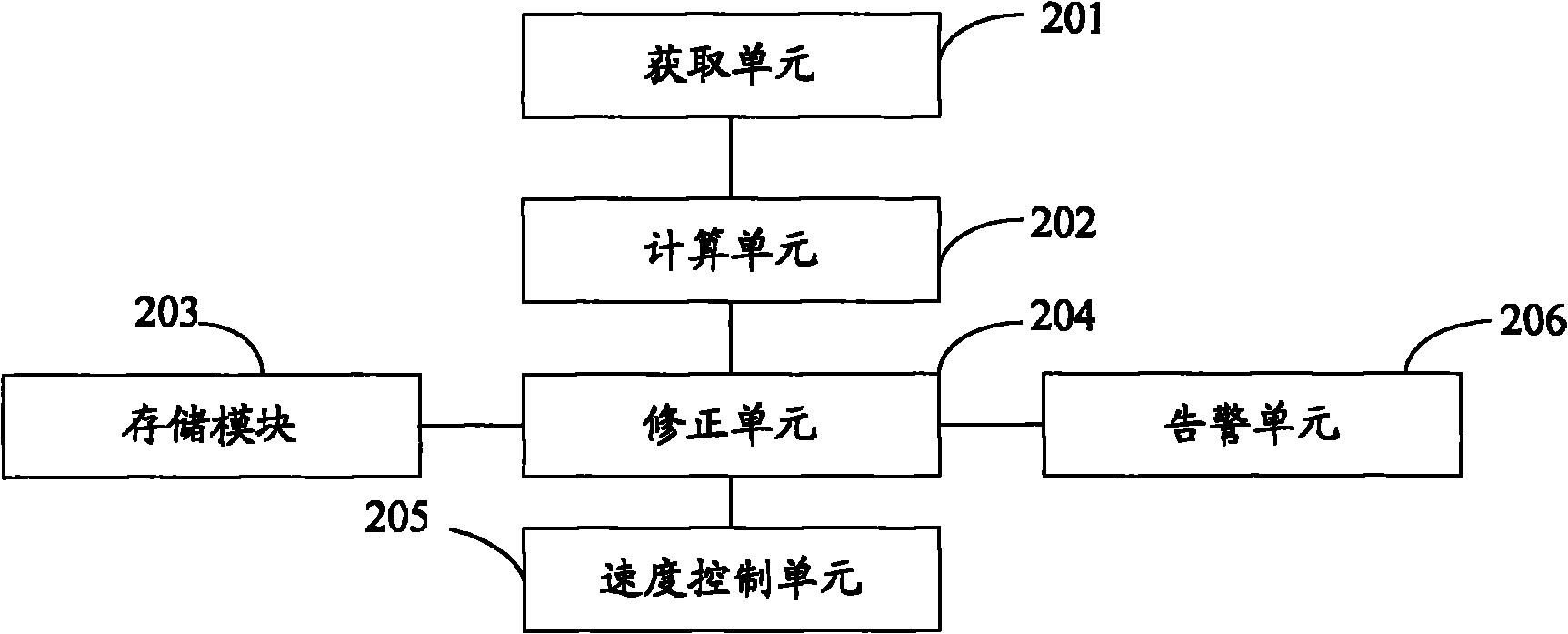

Method and device for regulating train speed

InactiveCN101875361AGuaranteed safe operationSmall amount of calculationSpeed controllerAutomatic systemsEngineeringSafe operation

The invention discloses a method for regulating train speed, comprising the steps of: acquiring target distance and line data; calculating the current external resistance by using the line data; modifying a predetermined target speed distance curve according to the external resistance and the target distance to obtain the current actual train control speed; and controlling the train speed according to the actual train control speed. The embodiment of the invention also provides a corresponding device. By prestoring an ideal train control curve which only takes the brake performance of the train into account without considering the external resistance, the actual train control speed can be obtained just by modifying the current train control speed in the ideal train control curve in each train control period, thereby reducing the calculated amount, shortening the train control period and ensuring the safe operation of the train.

Owner:HUAWEI TECH CO LTD

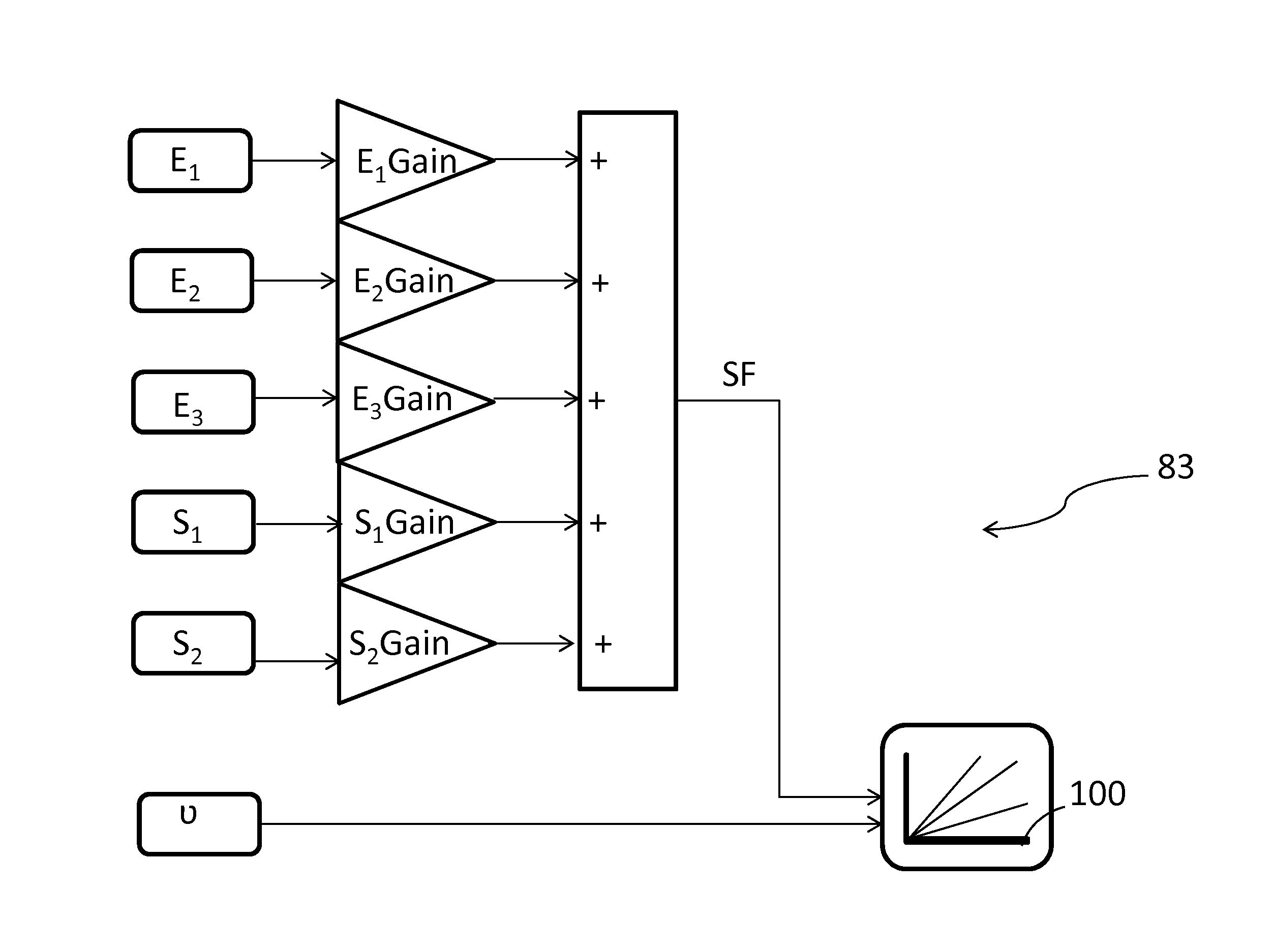

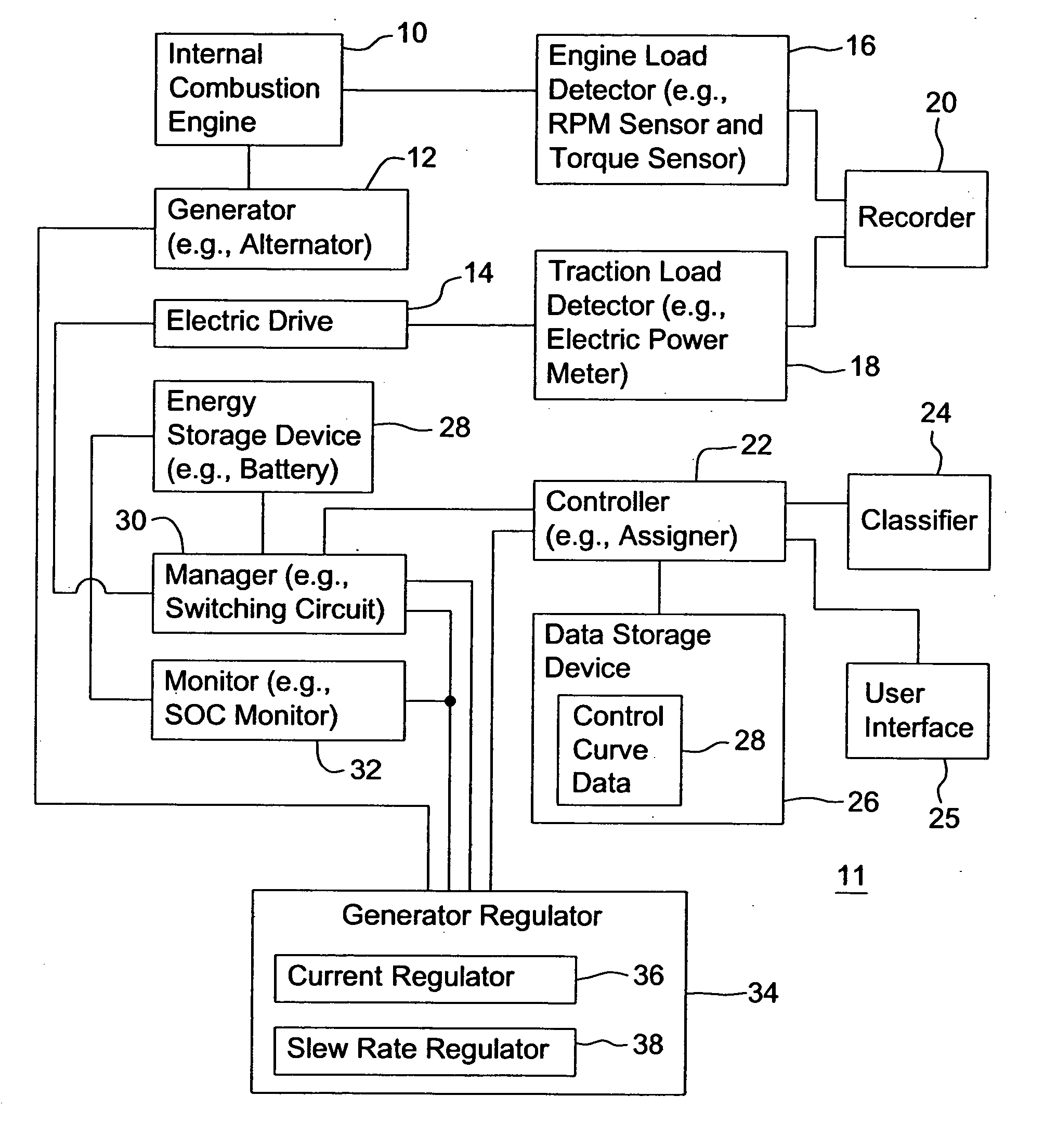

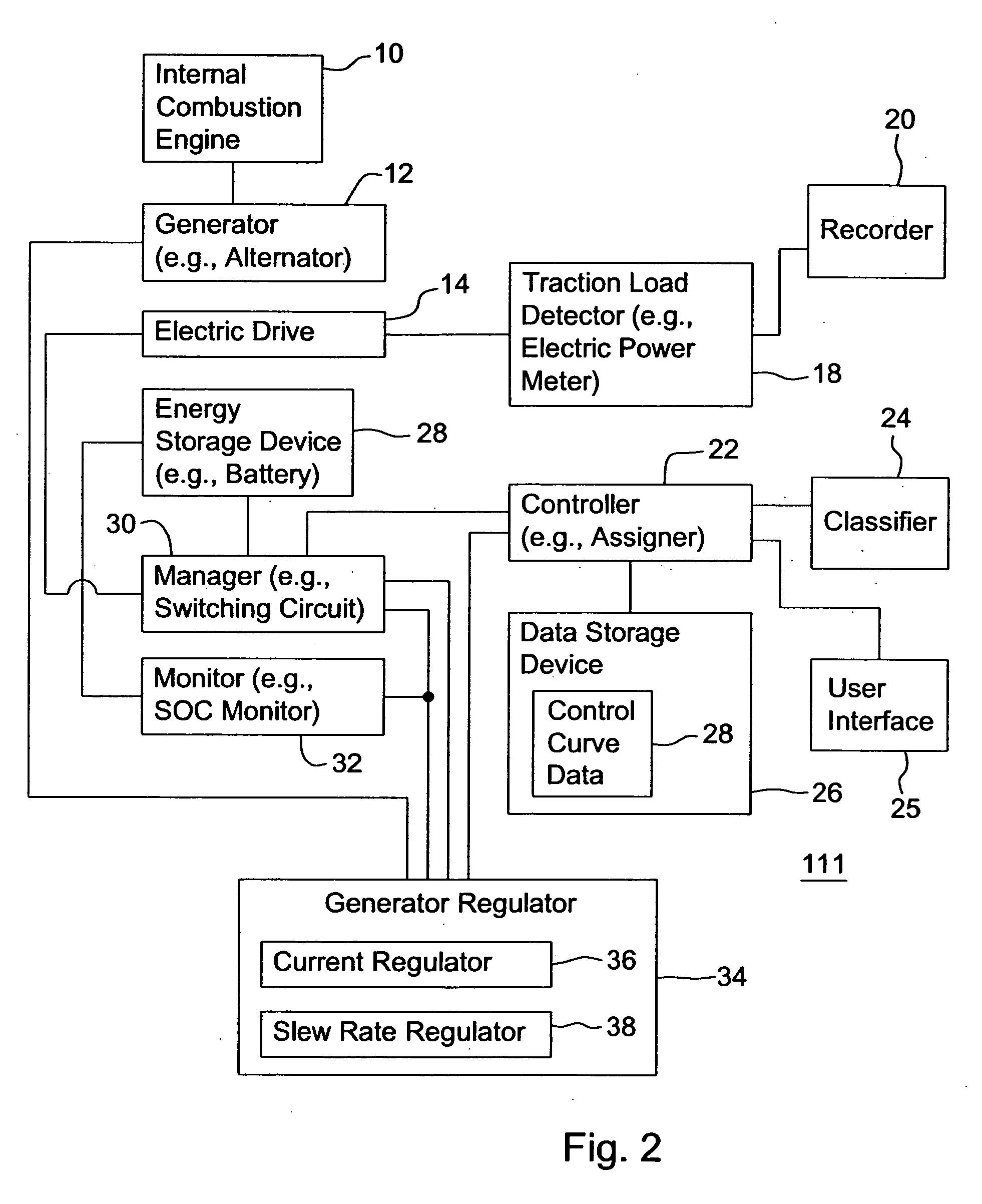

Method and system for adaptively controlling a hybrid vehicle

A method and system for adaptively controlling a hybrid vehicle comprises a recorder for recording a historical load or duty cycle of vehicle during or after operation of the vehicle. A classifier classifies the historical load in accordance with a load category. A controller assigns at least one of a current control curve and a slew rate control curve associated with the load category for a defined time period after the recording of the historical load or if the vehicle is presently operating generally consistent with the load category. At least one of the current control curve and the slew rate control curve, or data representative thereof, are used to control an operation of an electric drive motor of the vehicle for the defined time period.

Owner:DEERE & CO

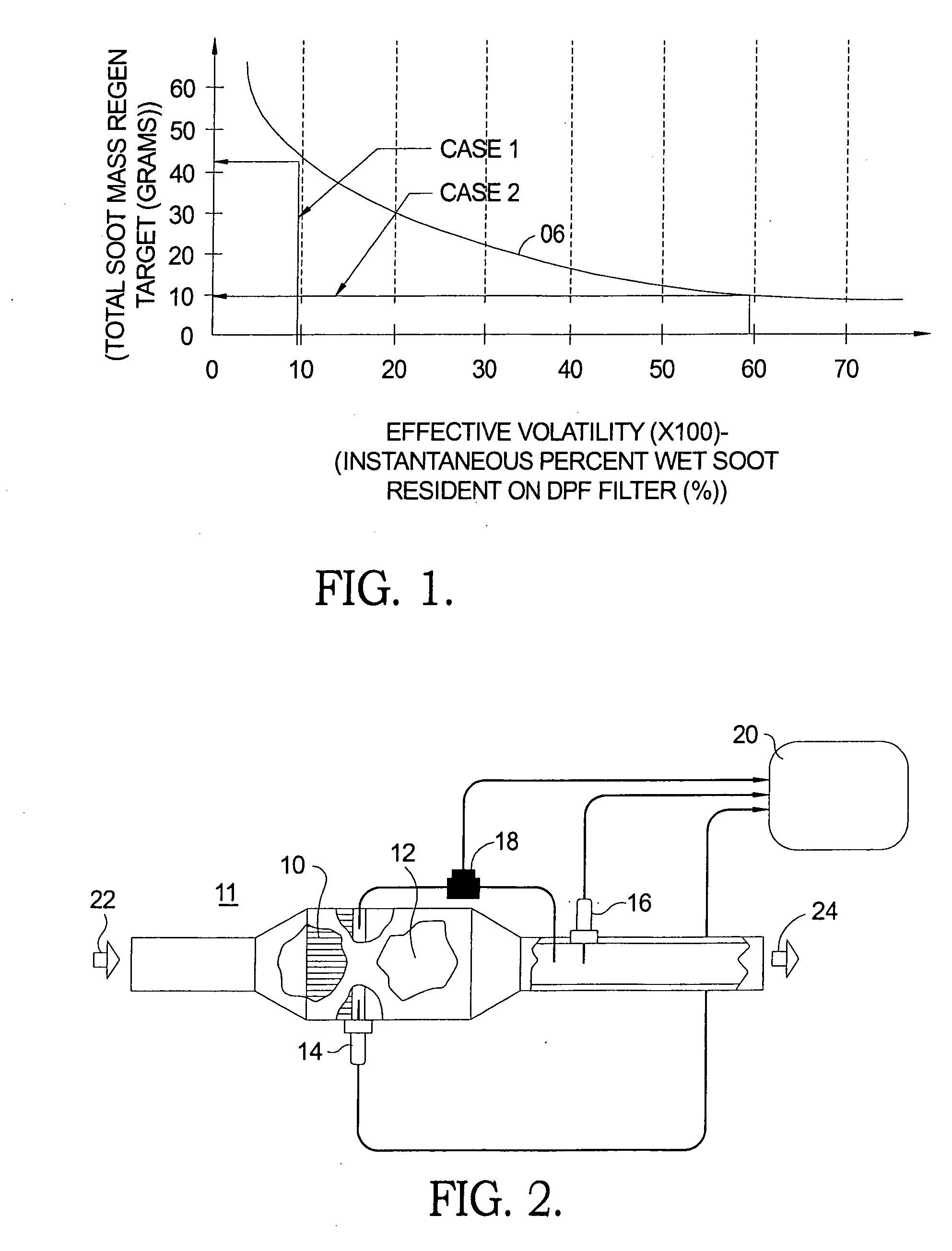

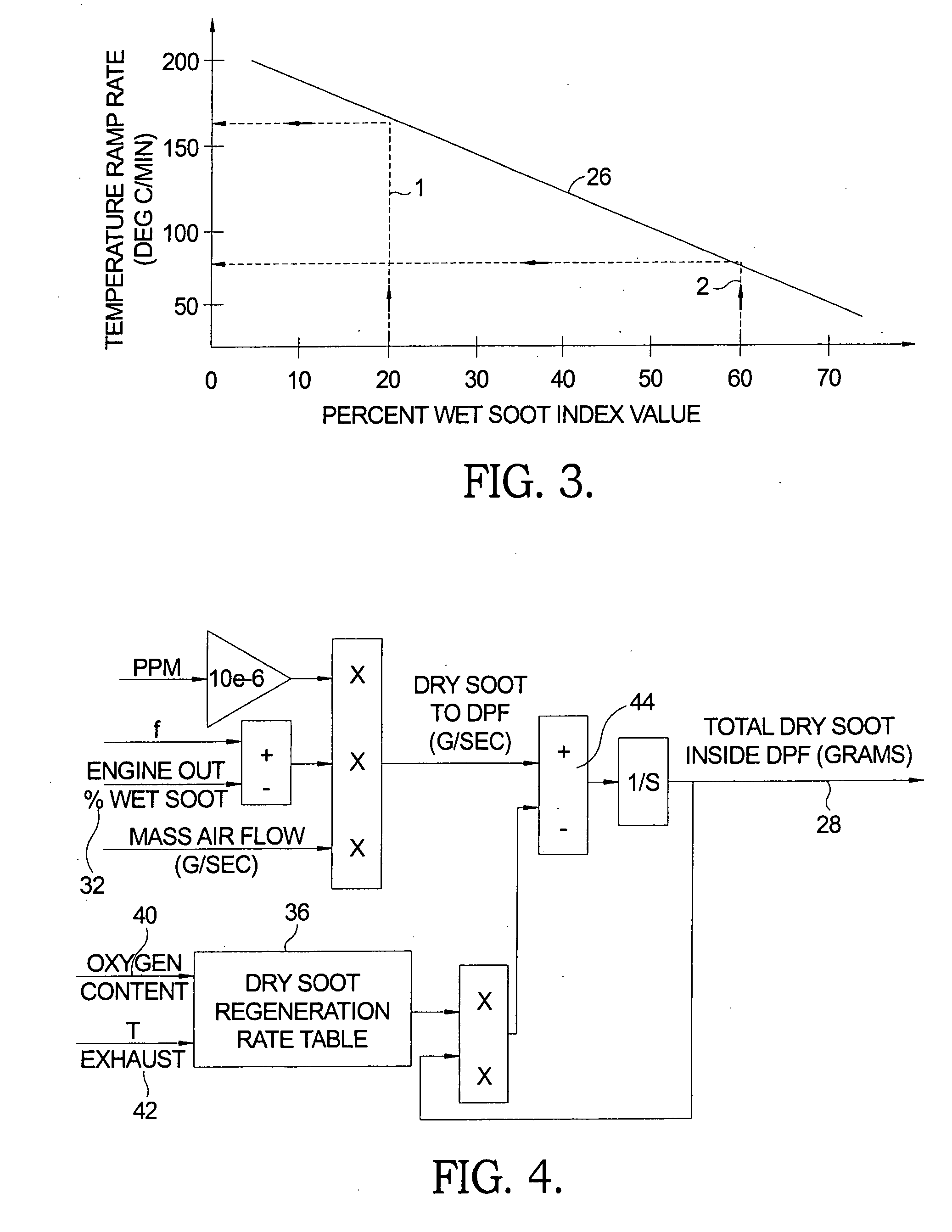

Method for controlling catalyst and filter temperatures in regeneration of a catalytic diesel particulate filter

InactiveUS20090188243A1Analogue computers for vehiclesInternal combustion piston enginesTemperature controlEngineering

A system for managing regeneration of a CDPF in a diesel engine. The system determines volatility of the accumulated soot by a weighting / indexing method to select a regeneration control strategy that protects the CDPF from thermal damage. The system determines the mass of wet soot and dry soot accumulated over the previous driving cycle and selects a management strategy to control the rate of temperature increase and the thermal gradient imposed upon the filter. The wet soot percent is an index for setting the regeneration temperature control profile for an allowable total accumulated soot mass as a function of the accumulated wet soot. The method also scales the soot mass regeneration threshold value based upon wet soot accumulation and accumulation rate and provides an indicator of combustibility of the soot accumulation. The method provides a temperature ramp rate, total regeneration time, and exhaust oxygen level required to control regeneration.

Owner:DELPHI TECH INC

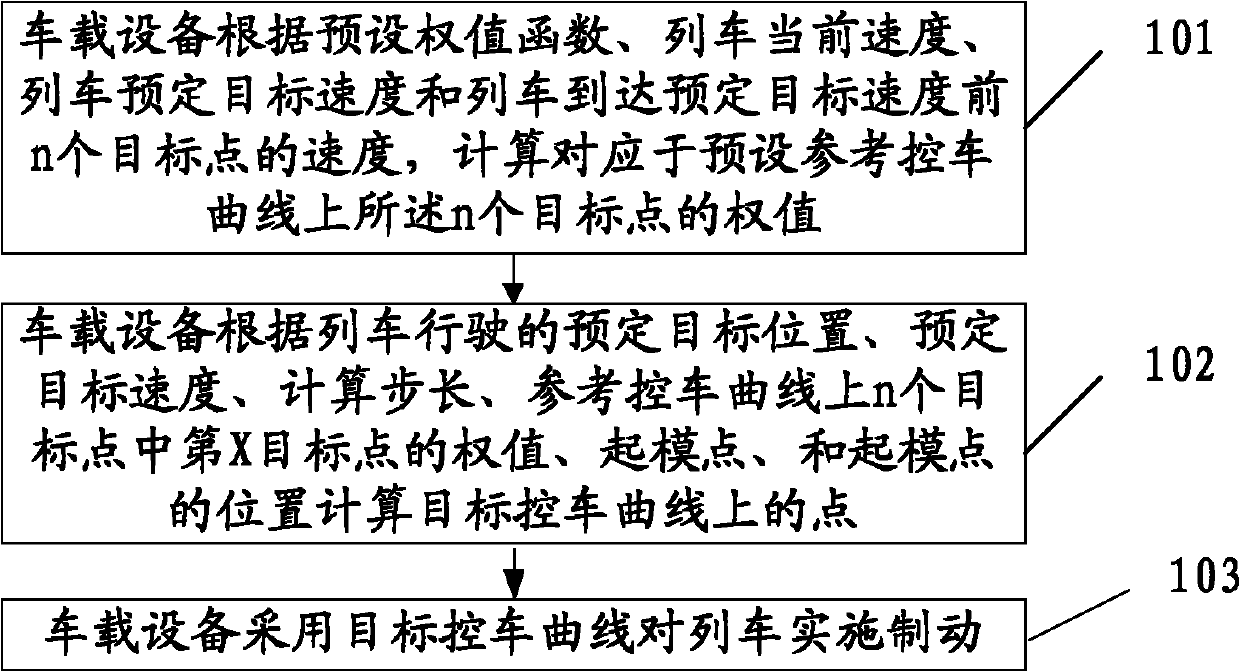

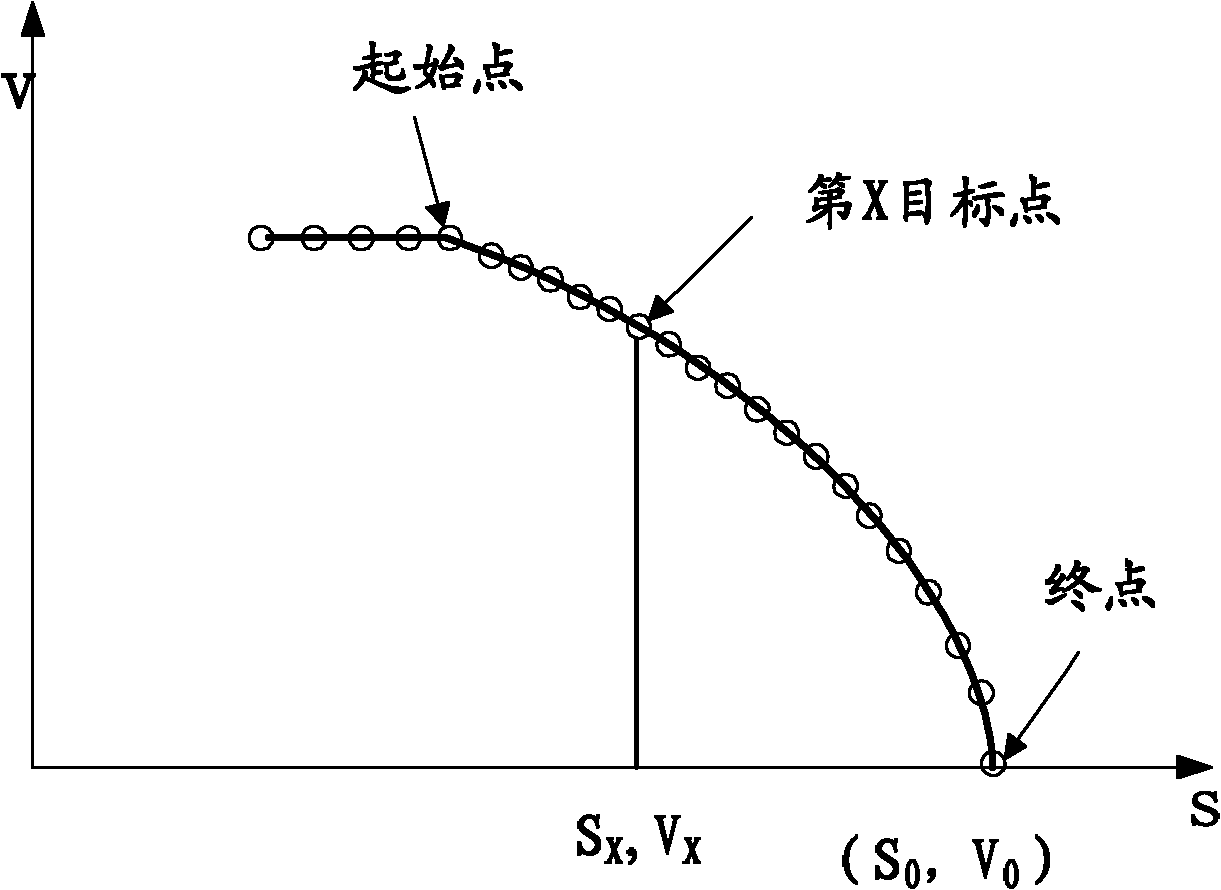

Train control method and automatic train protection equipment

ActiveCN102167066ASmall decelerationPrevent aggressivenessRailway traffic control systemsCurrent velocityAutomatic train protection

The embodiment of the invention discloses a train control method and automatic train protection equipment, relating to the field of train control and aiming to effectively prevent a train from going forward prematurely under the disturbance situation and enhance the safety of the train. The method comprises the following steps of: calculating weights corresponding to n target points on a reference train control curve according to a preset weight function, a current speed of the train, a preset target speed of the train and the speeds of n target points before the train reaches the preset target speed; calculating points on the target train control curve according to a preset traveling target position of the train, a preset target speed, a calculated step length, the weights of the n target points on the reference train control curve and the position of a train pattern drawing point; and braking the train by using the target train control curve. The method and equipment are mainly applied to train control.

Owner:HUAWEI TECH CO LTD

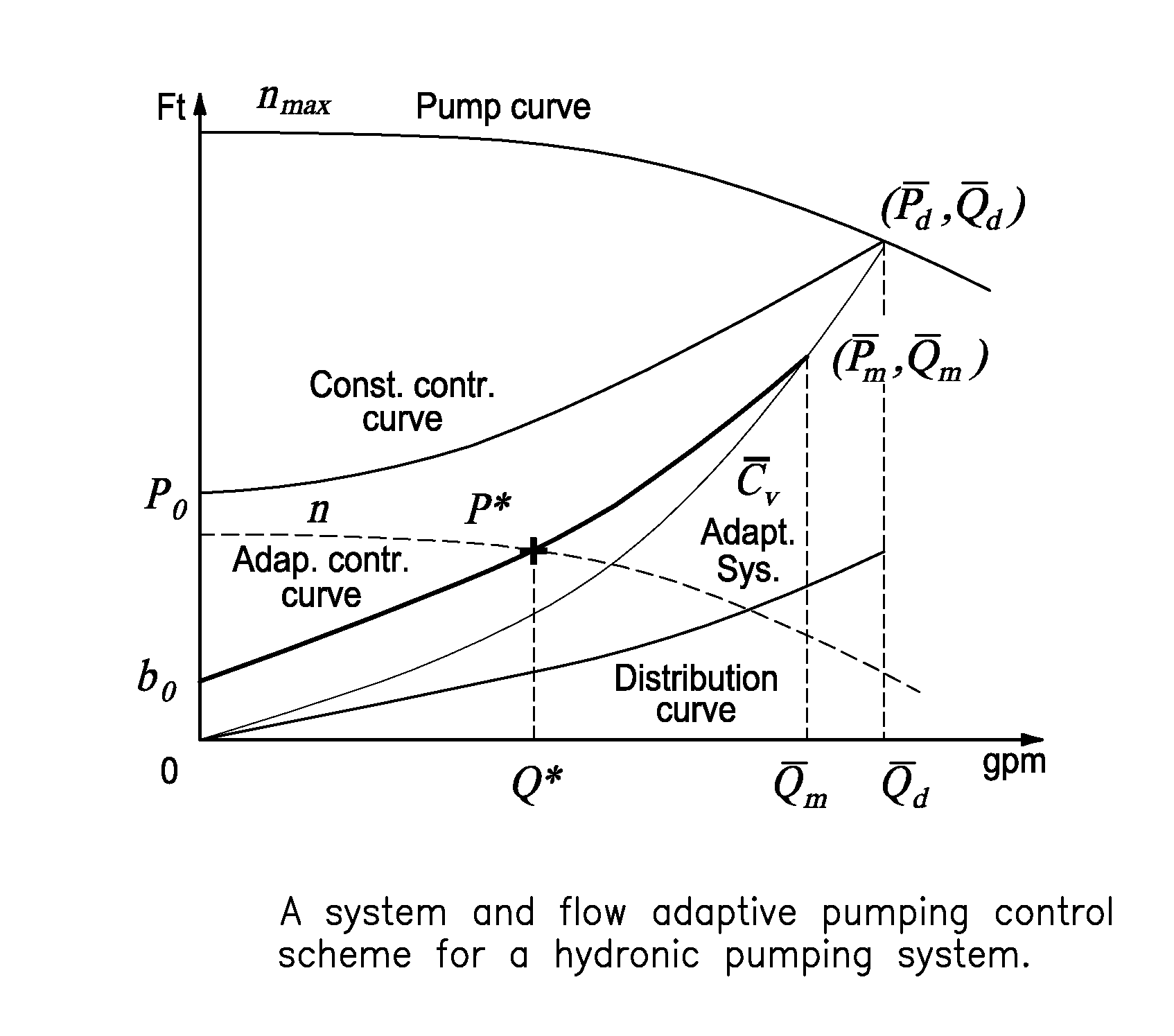

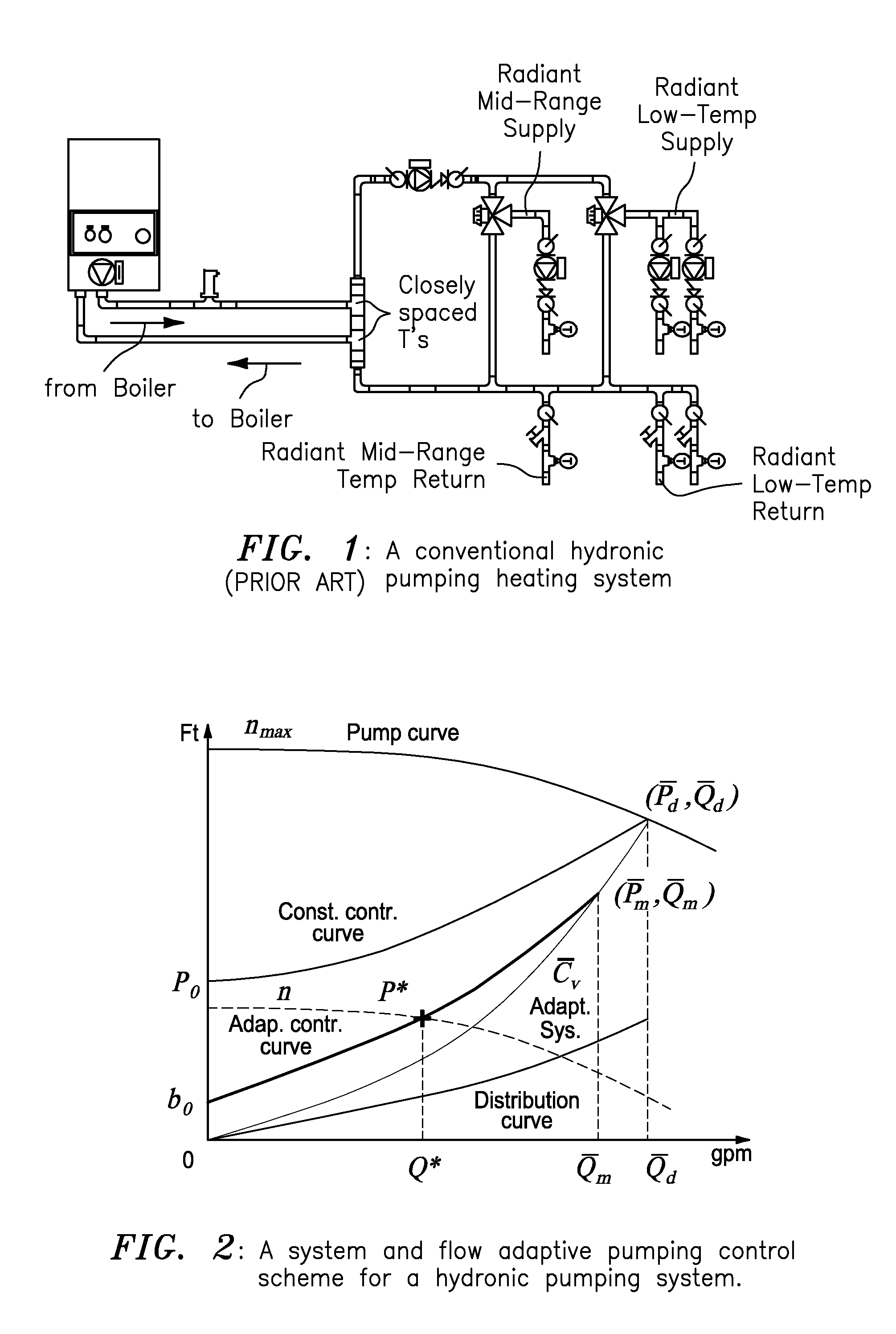

System and flow adaptive sensorless pumping control apparatus for energy saving pumping applications

ActiveUS20160017889A1Pumping energyEasy to storeSampled-variable control systemsSpace heating and ventilation safety systemsMaximum fluxEngineering

A signal processor receives signaling containing information about flow rates from sensorless converters in zone circulators in heating / cooling zones controlled by temperature sensors in a hydronic heating system in order to derive an adaptive pressure set point to meet the flow rates requested by the heating / cooling zones using an adaptive system and flow control curve equation, the signaling containing information about total flow rates requested by the zone circulators; determines desired pump speeds for the zone circulators to meet temperature requirements in heat zones; provides corresponding signaling containing information about the desired pump speeds; and / or determines the adaptive pump control curve equation based upon an adaptive system curve and as a moving maximum system flow rate depending on an adaptive pressure set point, a system flow rate requested by temperature loads, a minimum pressure at no flow, a control curve setting parameter, and an adaptive moving maximum flow and pressure.

Owner:FLUID HANDLING

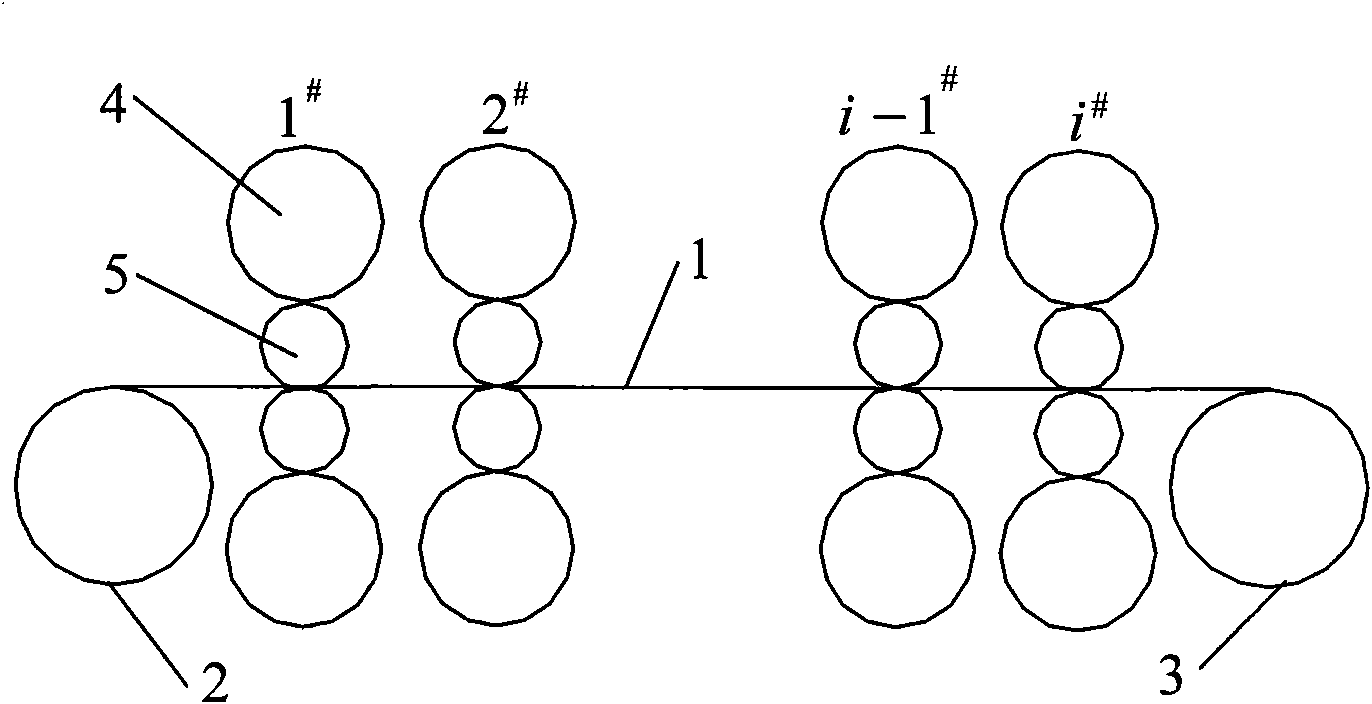

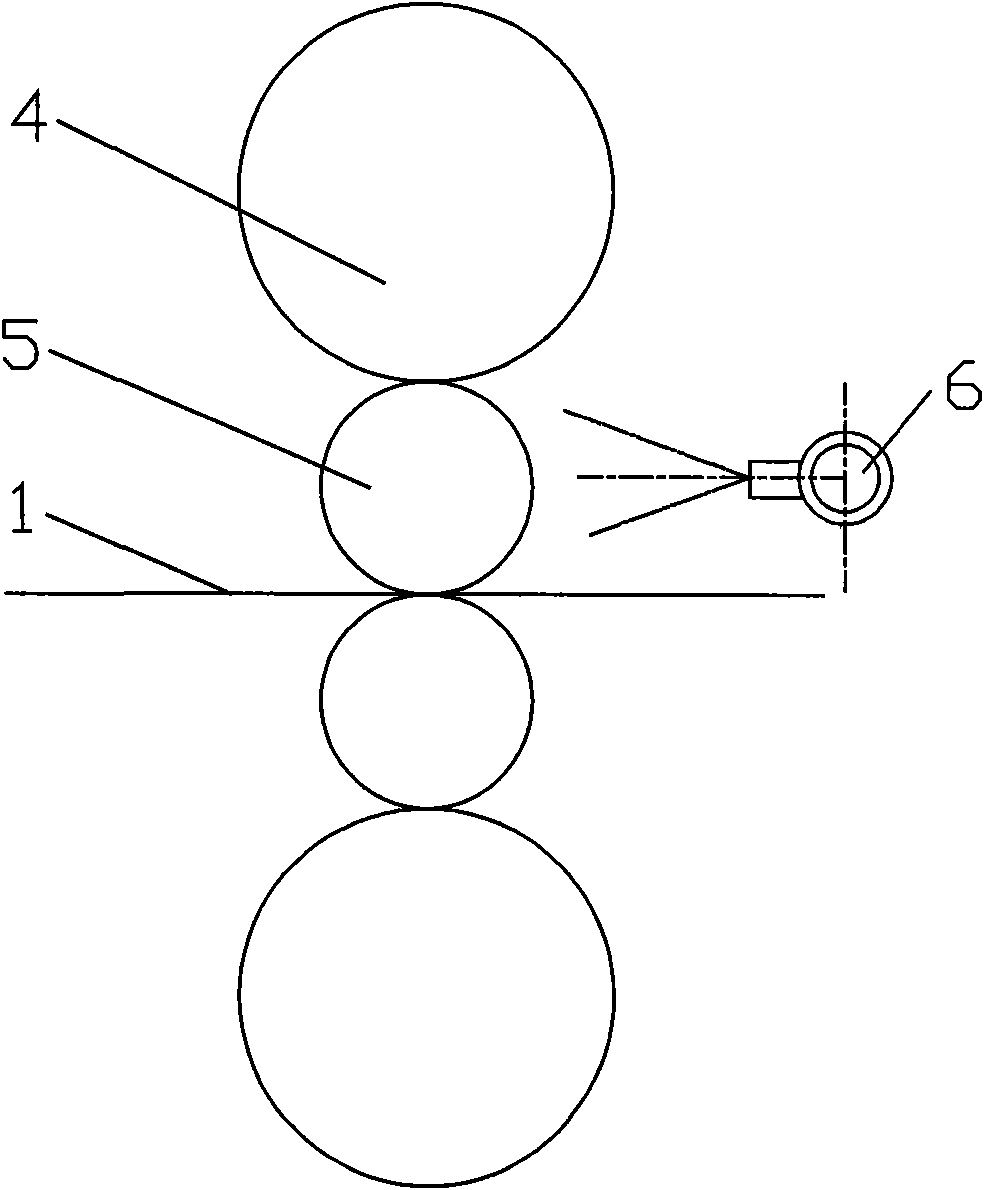

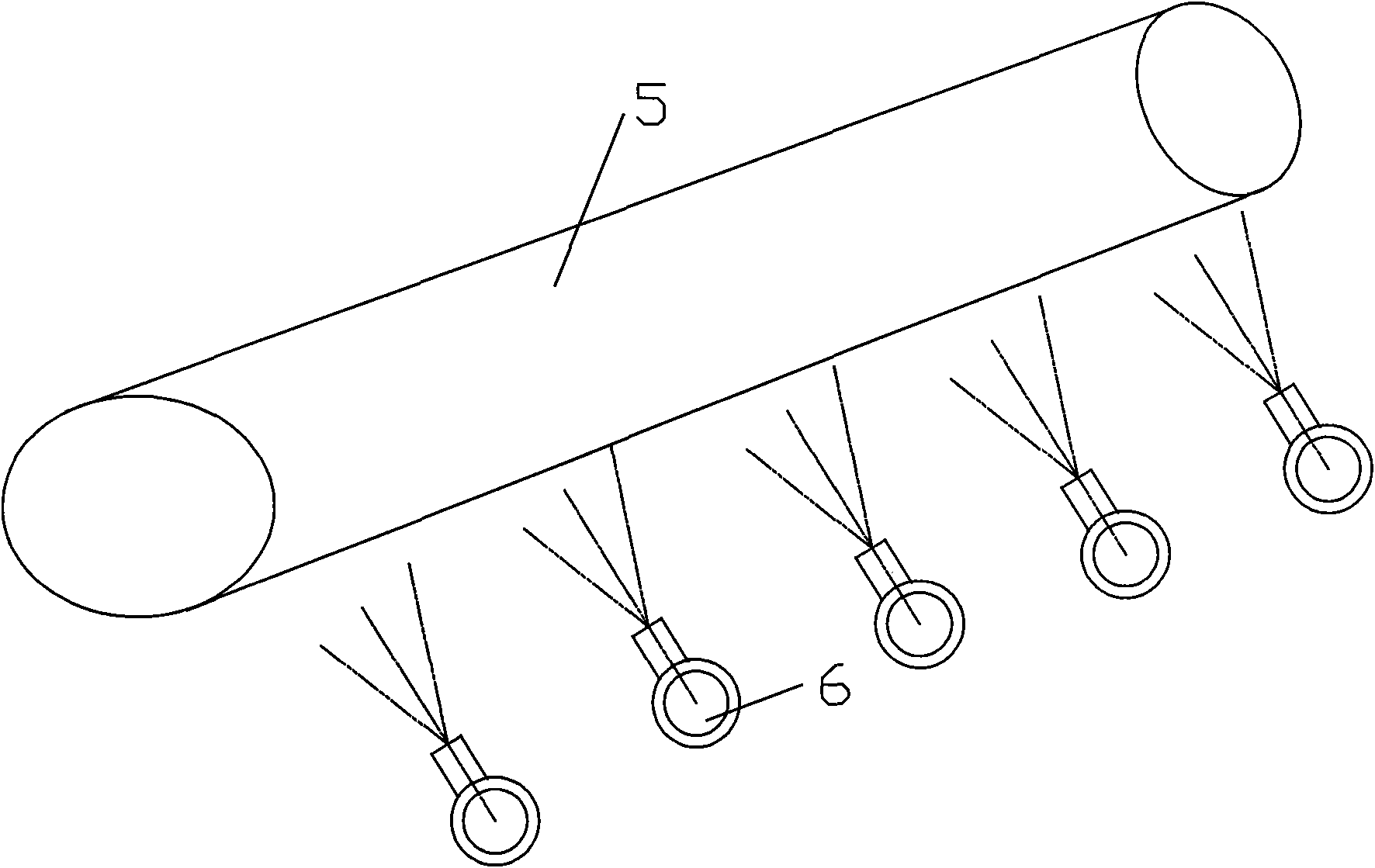

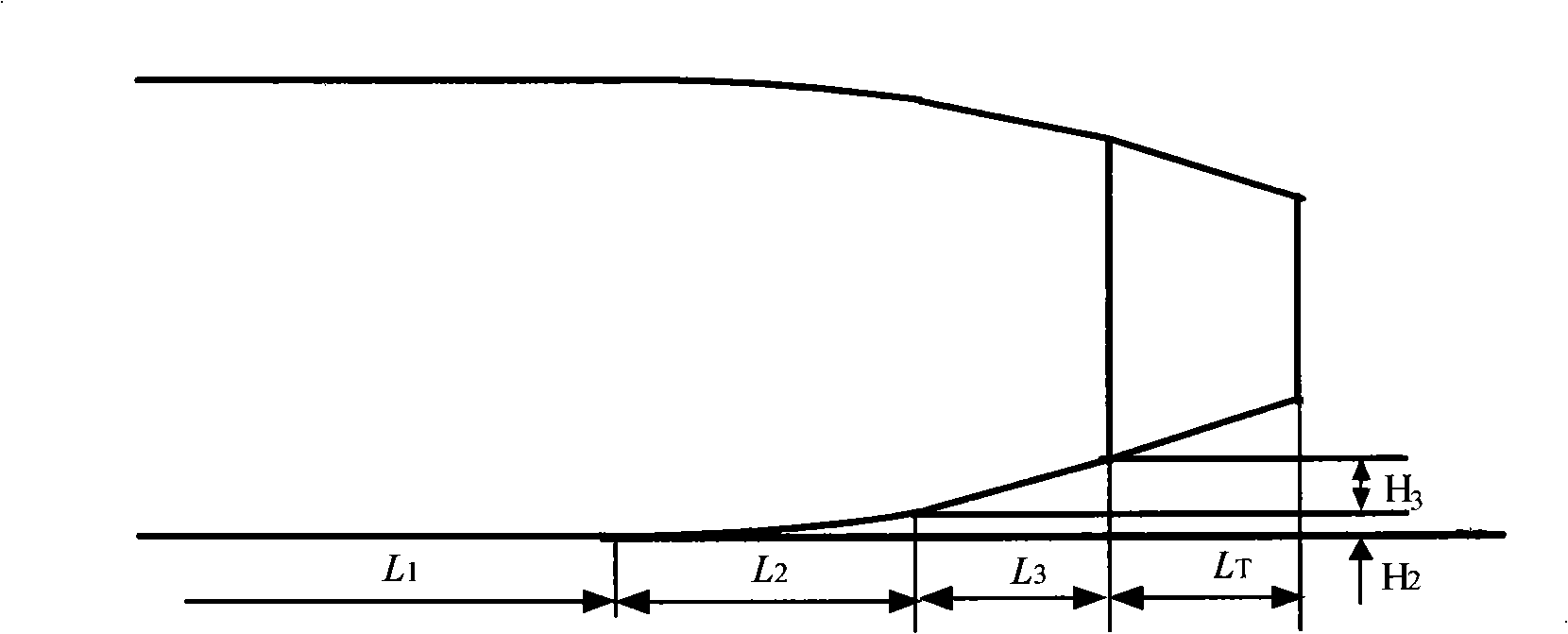

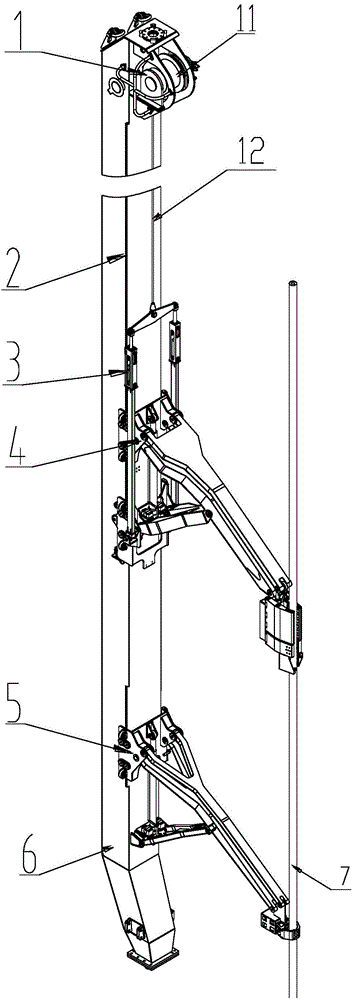

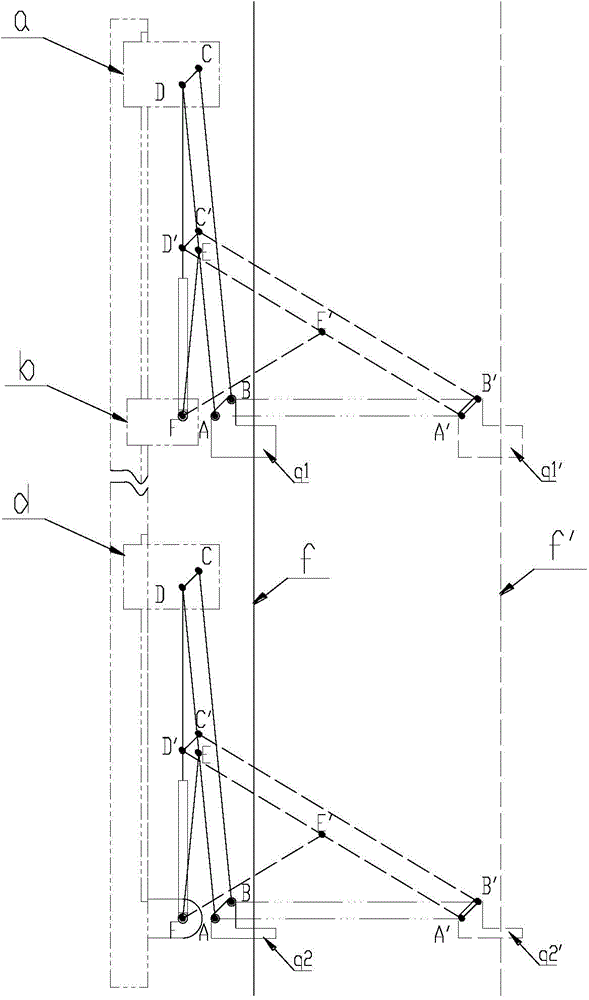

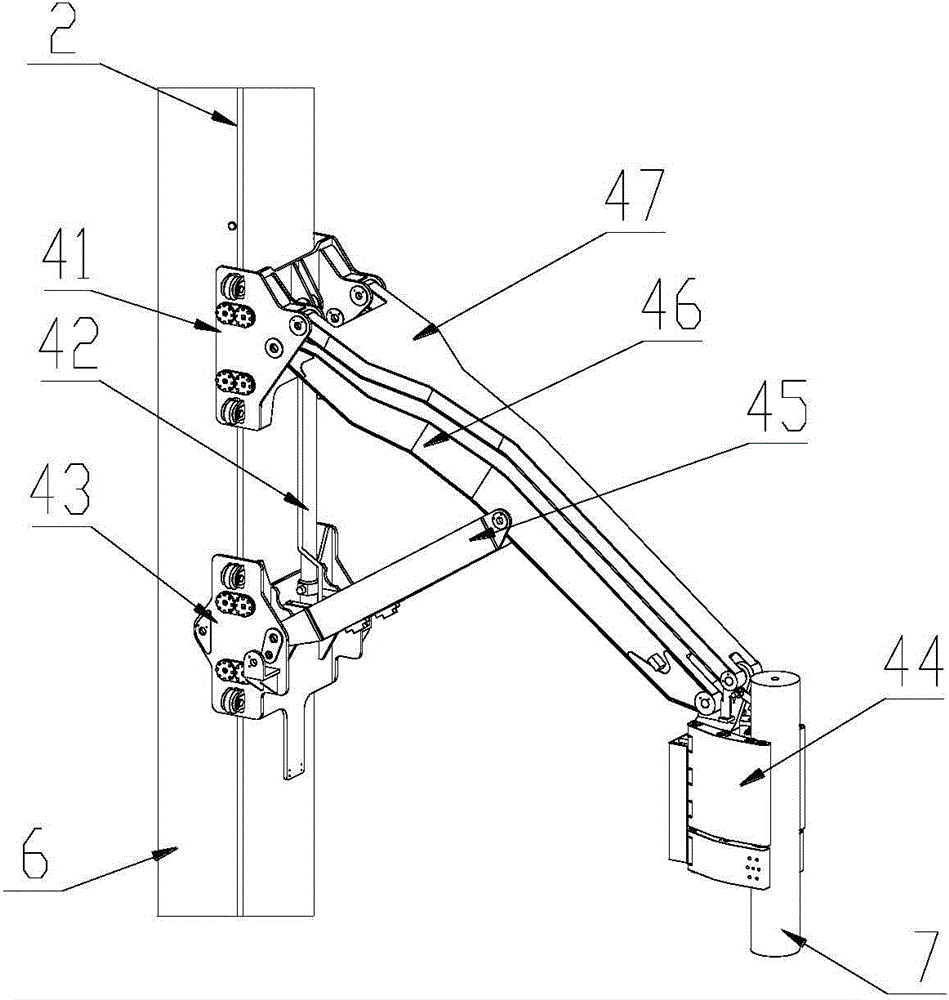

Pipe tool transportation mechanical arm

ActiveCN104389536AImprove work efficiencyEasy to controlDrilling rodsDrilling casingsControl systemHorizontal orientation

The invention discloses a pipe tool transportation mechanical arm, and belongs to the technical field of petroleum drill and exploitation equipment machinery. The pipe tool transportation mechanical arm comprises a guide rail, an upper mechanical arm and a lower mechanical arm, wherein the guide rail is installed on a girder of a tube draw bench, and the upper mechanical arm and the lower mechanical arm are installed on the guide rail. According to the pipe tool transportation mechanical arm, clamping pincers and righting pincers keep moving along the horizontal direction from beginning to end, displacement of a stand pipe is kept changeless in the vertical direction before and after a person grasps the stand pipe, and the person does not need to additionally regulate the vertical height of the stand pipe during the transportation process of the stand pipe. Furthermore, due to the fact that the upper mechanical arm and the lower mechanical arm adopt the same working principle, the person only needs to use the same control curve in control software for a first telescopic oil cylinder and a second telescopic oil cylinder under the condition that the first telescopic oil cylinder and the second telescopic oil cylinder are of the same specification, and then the purpose of respectively keeping stretching velocity and displacement of the upper mechanical arm and the lower mechanical arm synchronous is achieved. A control system of the pipe tool transportation mechanical arm is simple in programming and control, easy to implement and simple to debug, and therefore the pipe tool transportation mechanical arm is low in cost and simple to maintain.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

Train safety protective method for automatically adjusting braking force service factors of motor train unit

ActiveCN102582609AImprove operational safetyEasy to upgradeBrake safety systemsOperating speedBraking distance

The invention relates to a train safety protective method for automatically adjusting braking force service factors of motor train unit, which includes: firstly, arranging a train braking force state monitor on each vehicle of the motor train unit to monitor braking force state of each vehicle in real time; and secondly, using a vehicular subsystem of a train overspeed protective system to receive braking force state information monitored by each vehicle braking force state monitor in real time through an extended information receiving interface or information receiving interface arranged independently, automatically adjusting braking force service factors and train maximum permitted operating speed value according to the information, using a specific arithmetic formula to calculate a train braking distance, and adjusting generated train speed-distance safety protective curves such as a common braking control curve, an emergency braking control curve, a permitted operating speed control curve and the like in real time to automatically realize safety protection in running of the trains so as to improve running safety of the motor train unit.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

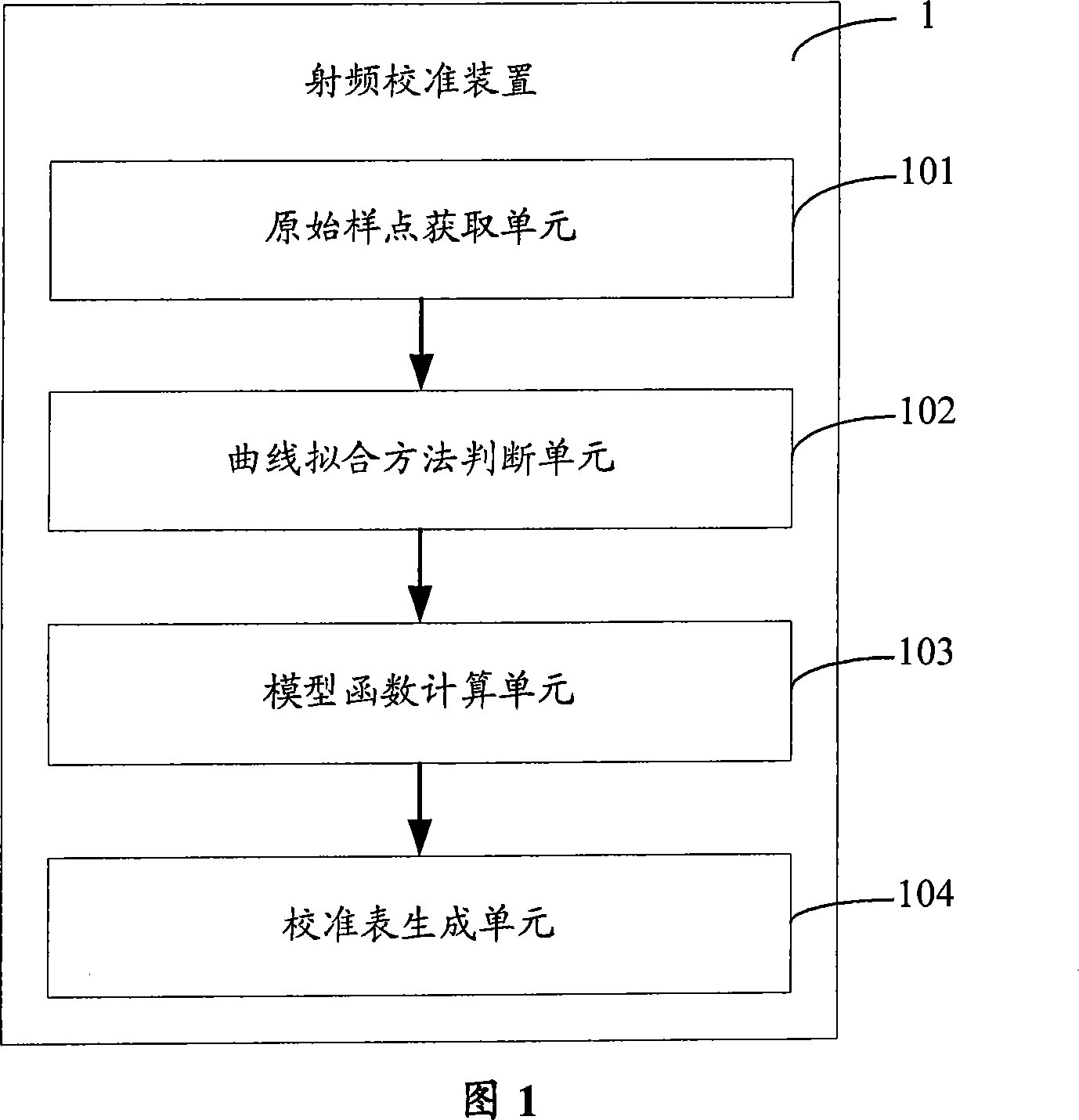

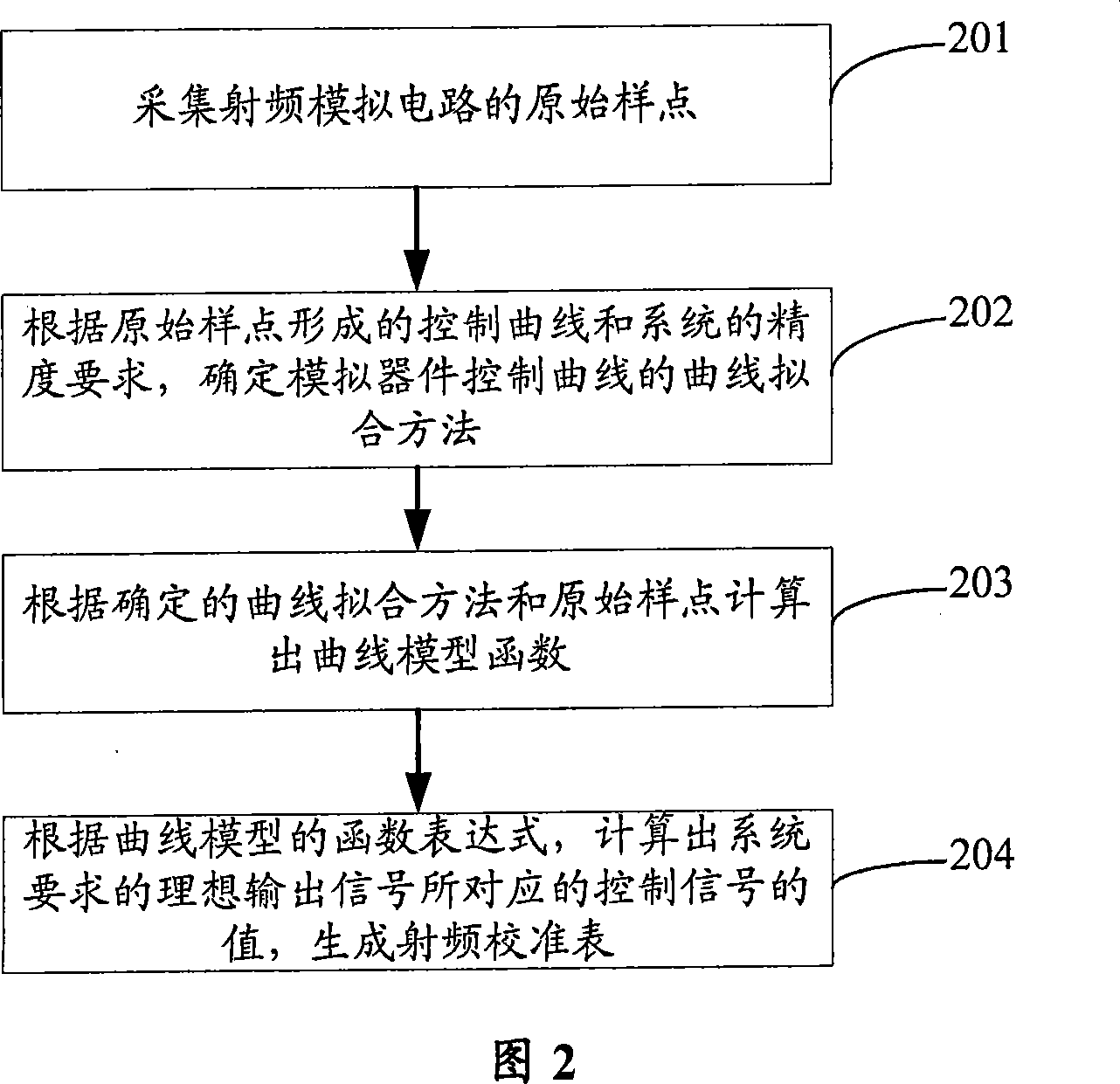

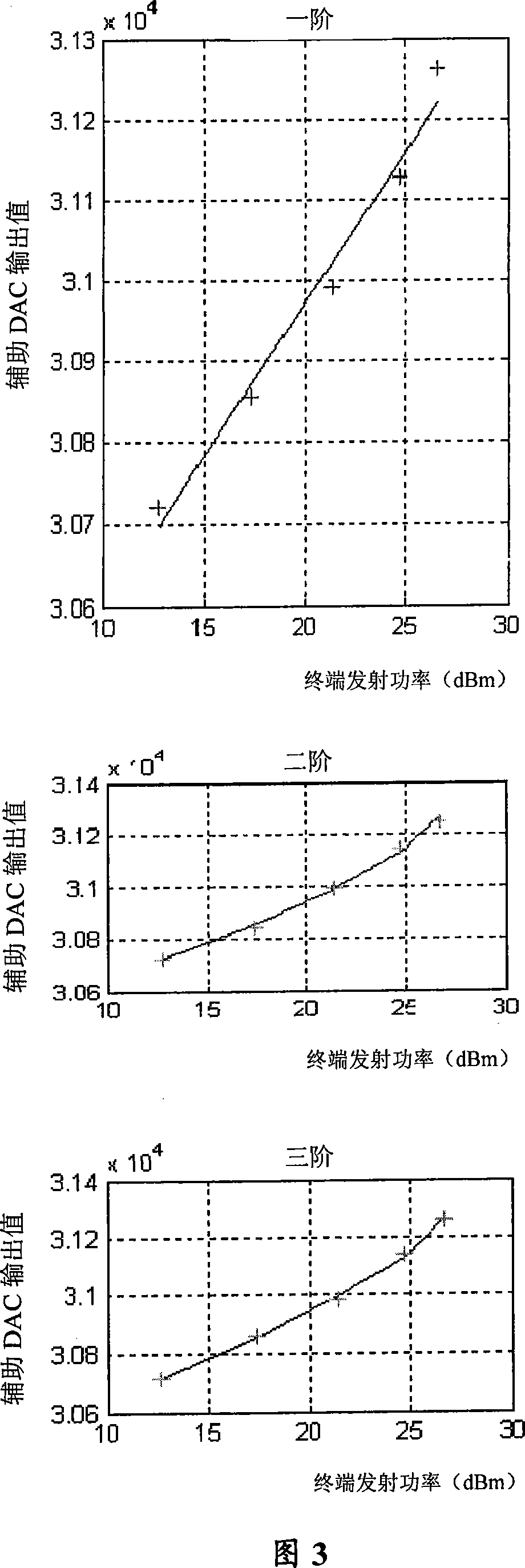

Radio frequency calibrating method and device

InactiveCN101068431AImprove accuracyImprove work performanceRadio/inductive link selection arrangementsTransmission monitoringCurve fittingRadio frequency

A method for calibrating radio frequency includes collecting original sample point of radio frequency analog circuit, confirming curve fitting means according to control curve formed by original sample point and accuracy requirement of system, calculating out expression of curve model function according to curve fitting means and original sample point then generating calibration table of radio frequency according to expression of curve model function. The device used for realizing said method is also disclosed.

Owner:ST ERICSSON SEMICON BEIJING

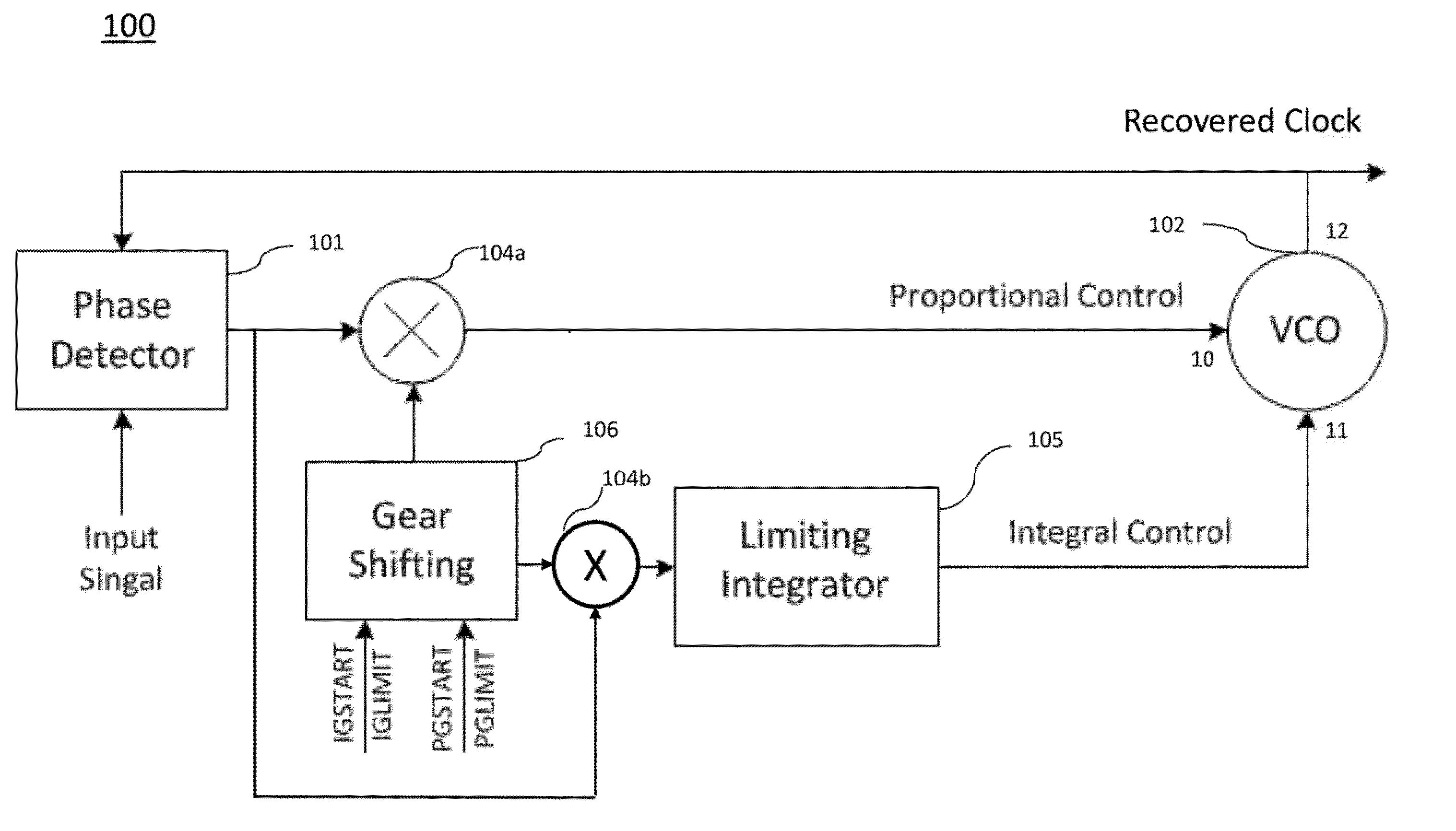

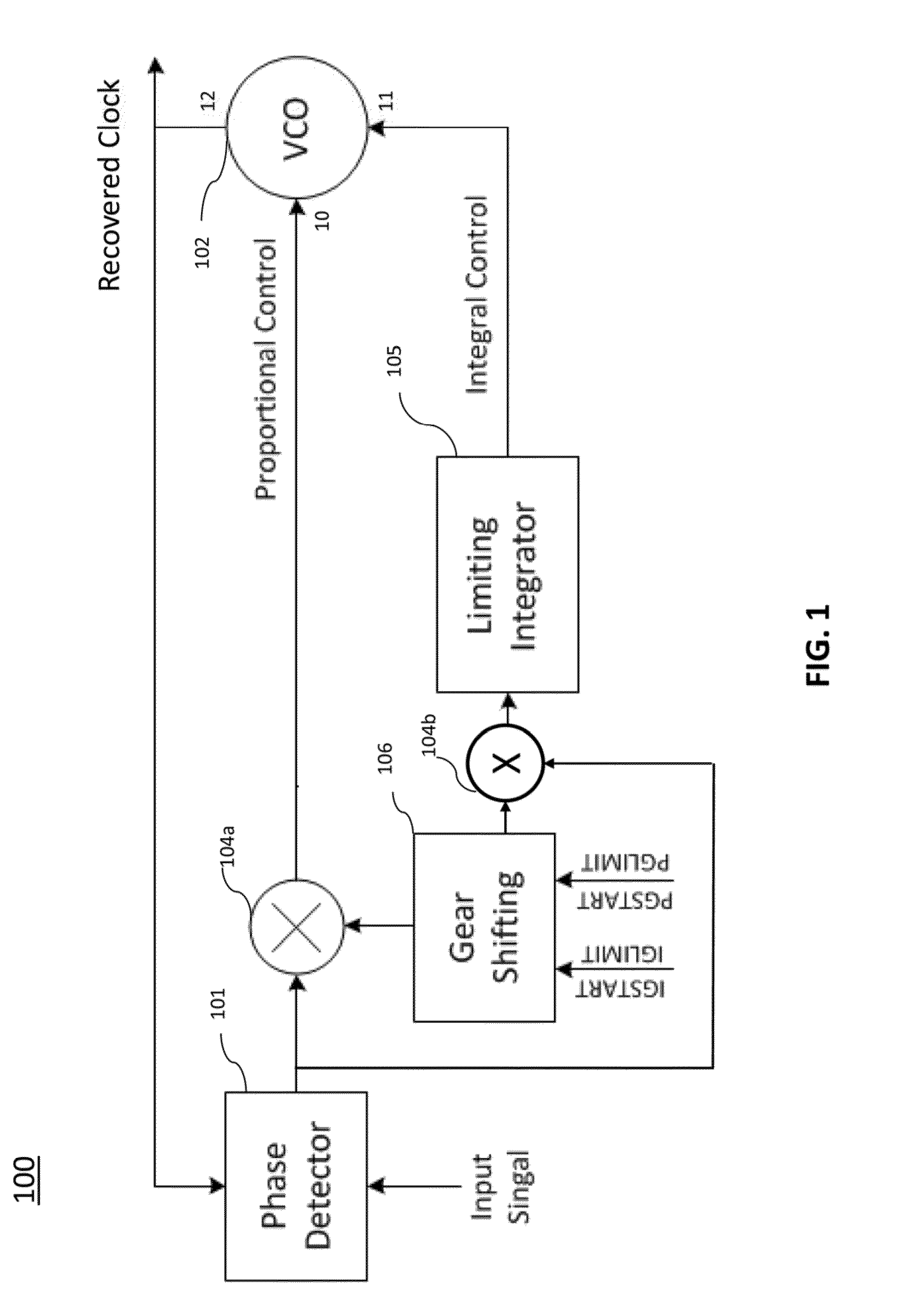

Serializer-deserializer clock and data recovery gain adjustment

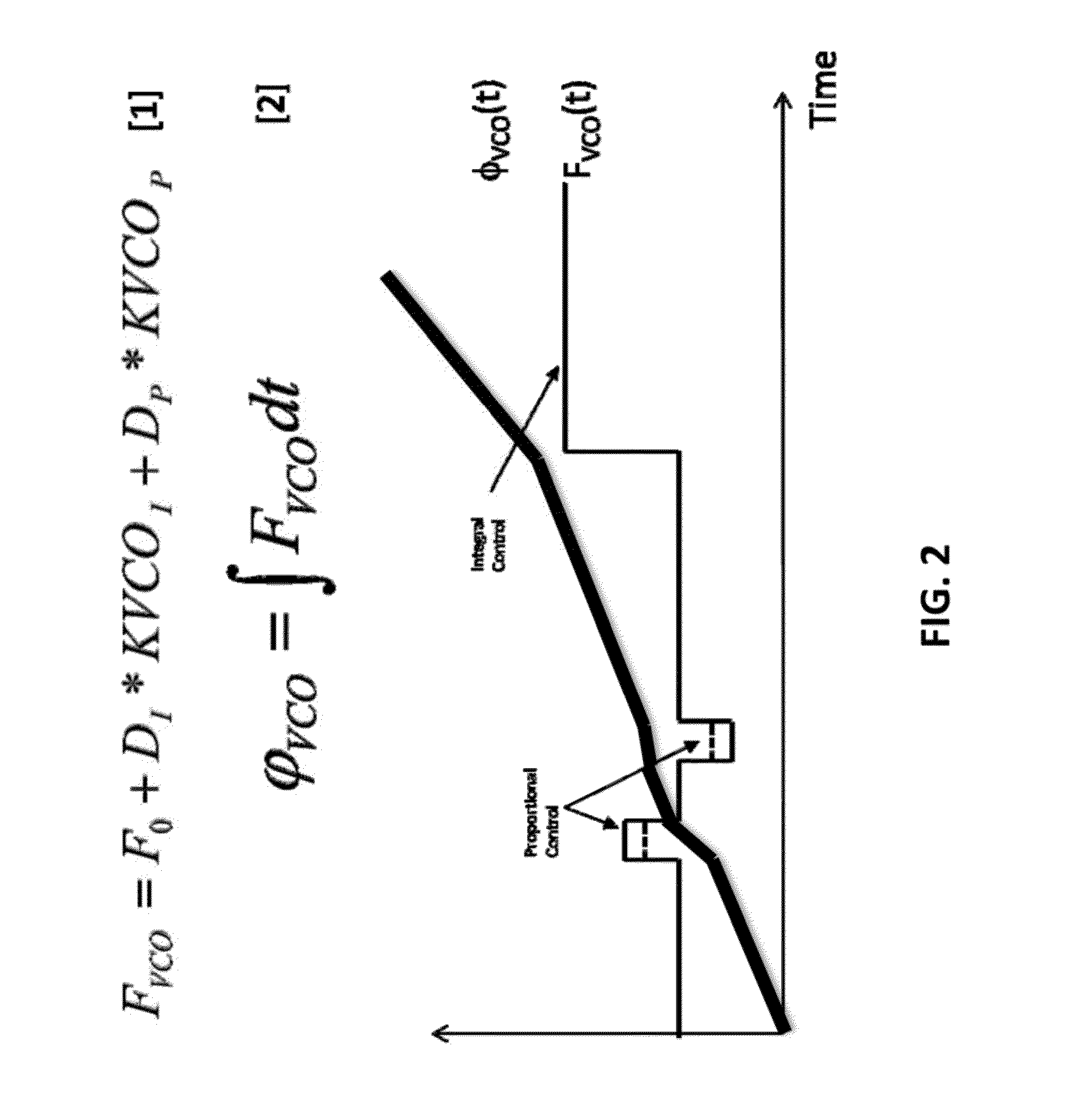

In described embodiments, a VCO based CDR for a SerDes device includes a phase detector, a VCO responsive to a first control signal and a second control signal and generating an output signal, a frequency calibration module configured to calibrate the frequency of the output signal by performing a coarse calibration and a subsequent fine calibration, a gear shifting control module controlling a gain, change of the first and second control signals in time, and a look-up table created by fine calibration values generated from the frequency calibration module, wherein the programmed variable gain of the gear shifting control module is calculated by a calculation circuit employing the fine calibration values stored in the look-up table, the calculation of the calculation circuit adjusts gear shifting down, and adjusts a gear shifting gain, and adjusting an overall CDR gain over a VCO control curve.

Owner:AVAGO TECH INT SALES PTE LTD

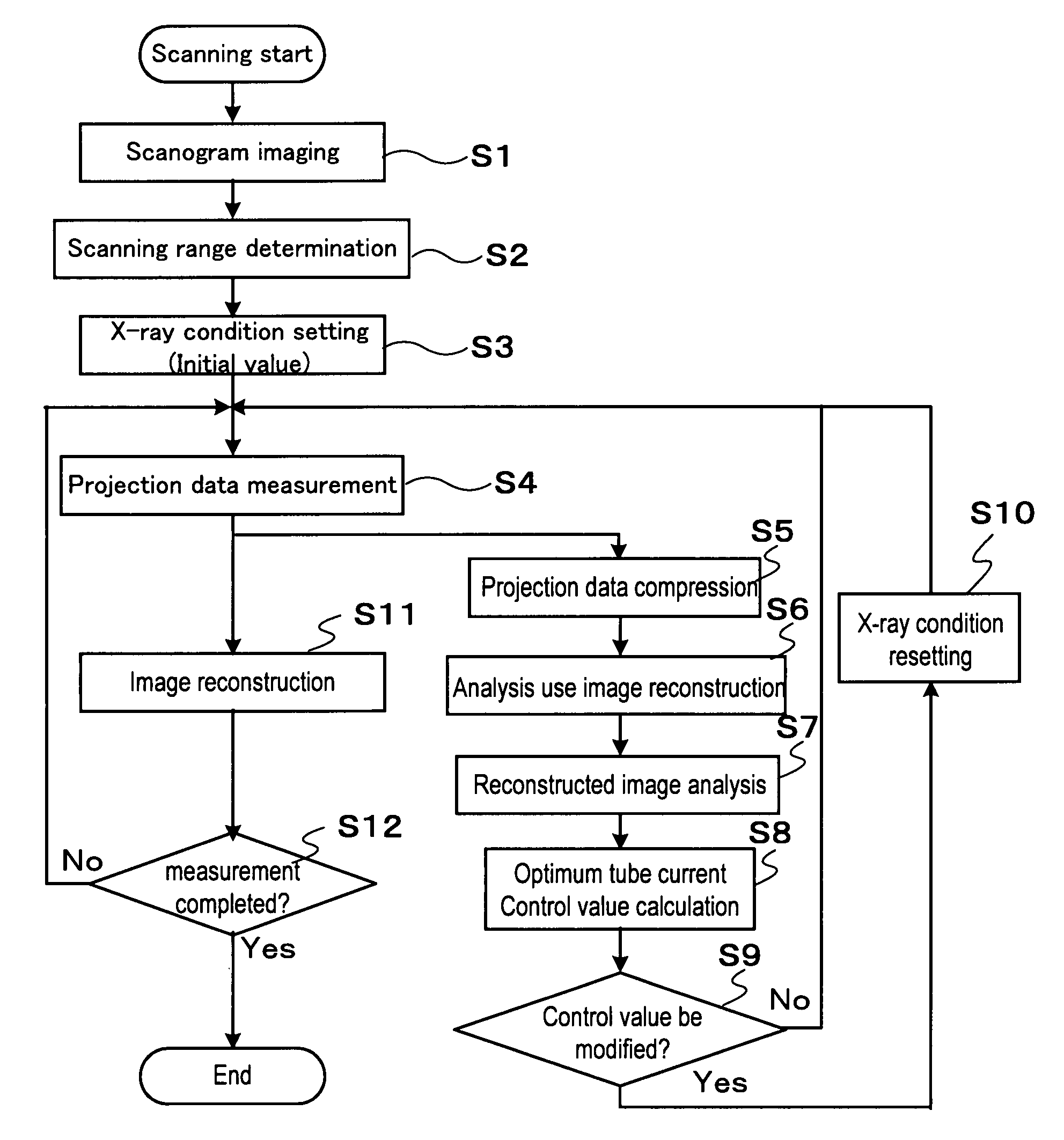

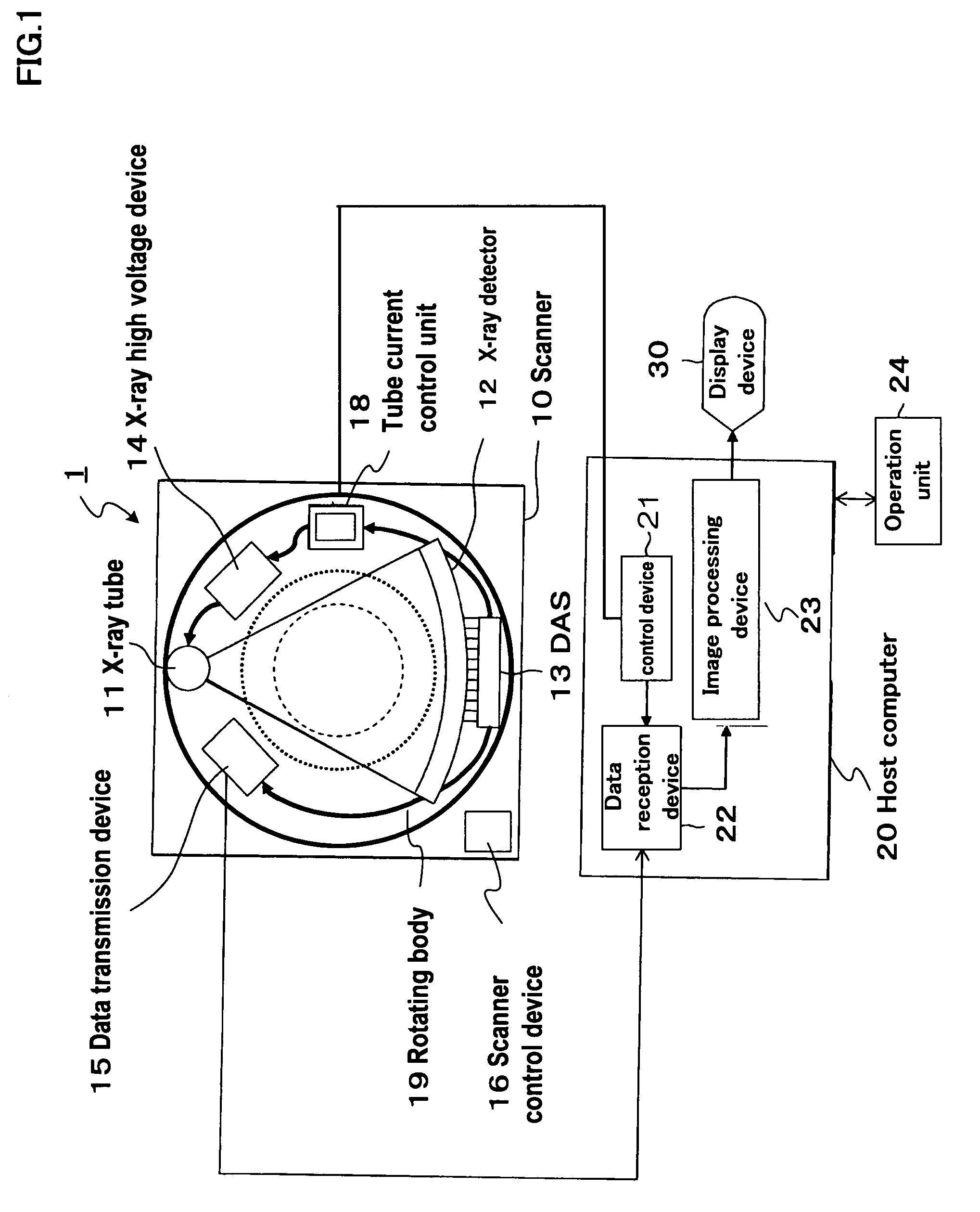

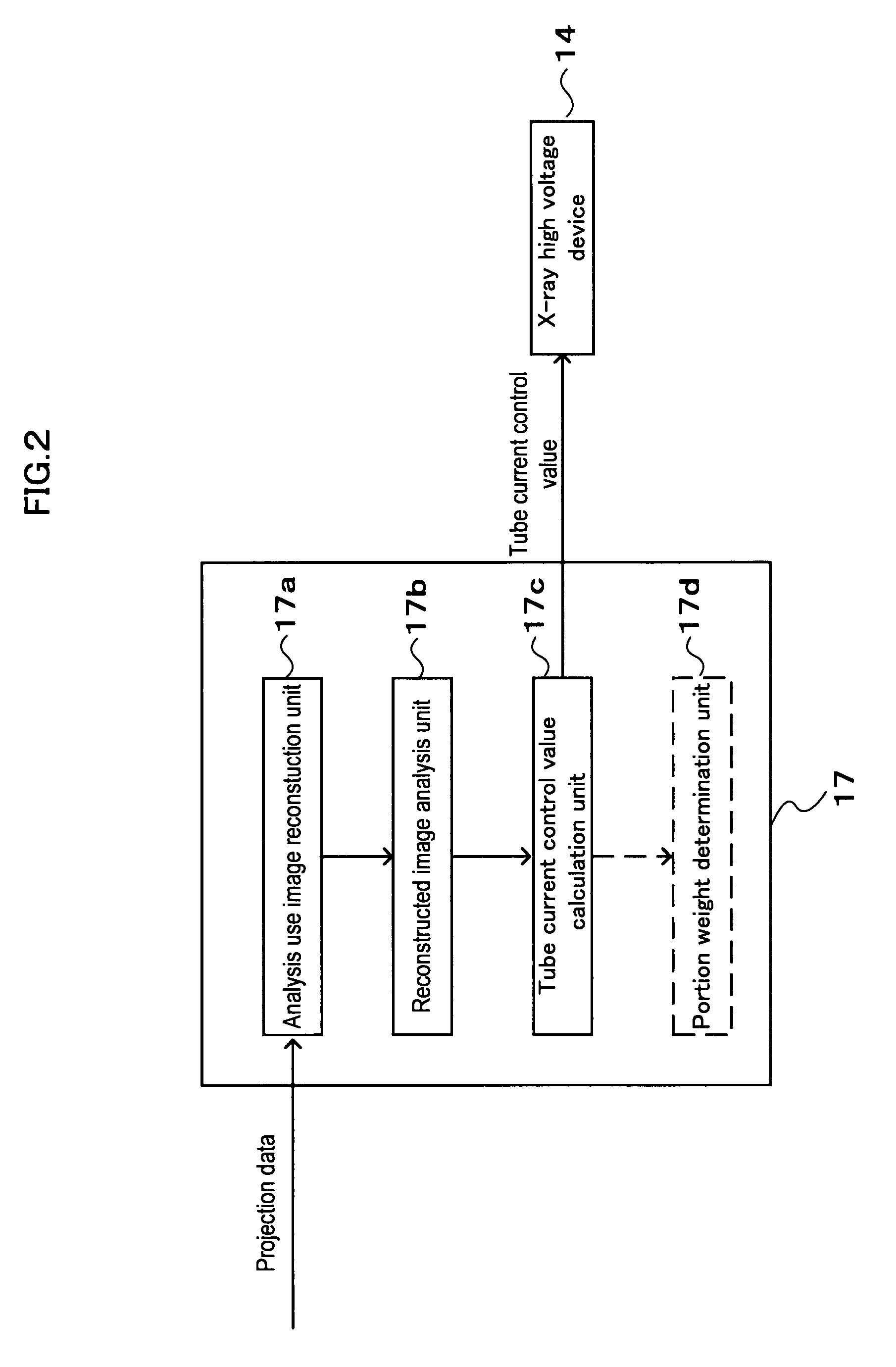

X-ray CT apparatus comprising a tube current control unit

InactiveUS7636416B2Quality improvementMaterial analysis using wave/particle radiationRadiation/particle handlingX-rayTomographic image

An X-ray CT apparatus includes a projection data analysis part that reconstructs a tomographic image at an imaging portion of the object used for analysis from the projection data and produces a control profile by reprojecting the reconstructed tomographic image, and a tube current control part that controls value of current to be fed to the X-ray tube based on the produced control profile.

Owner:HITACHI LTD

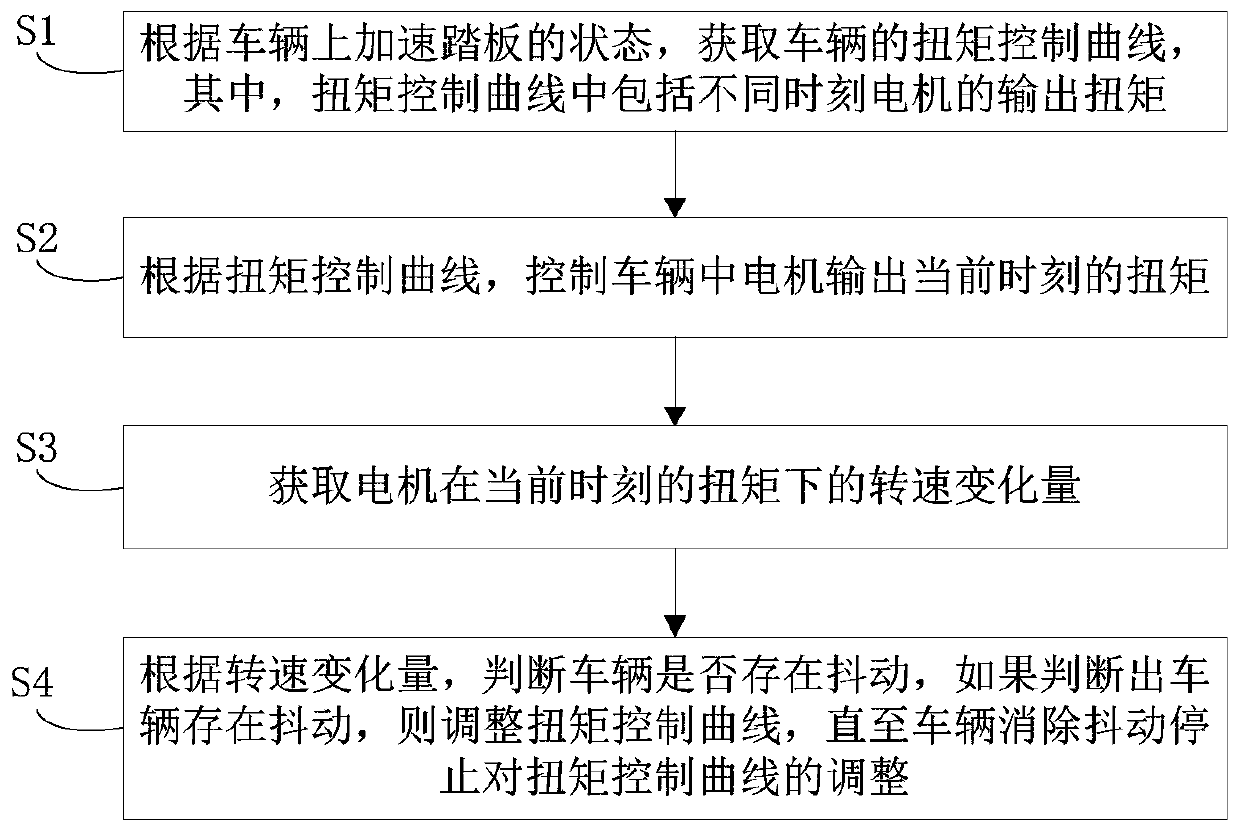

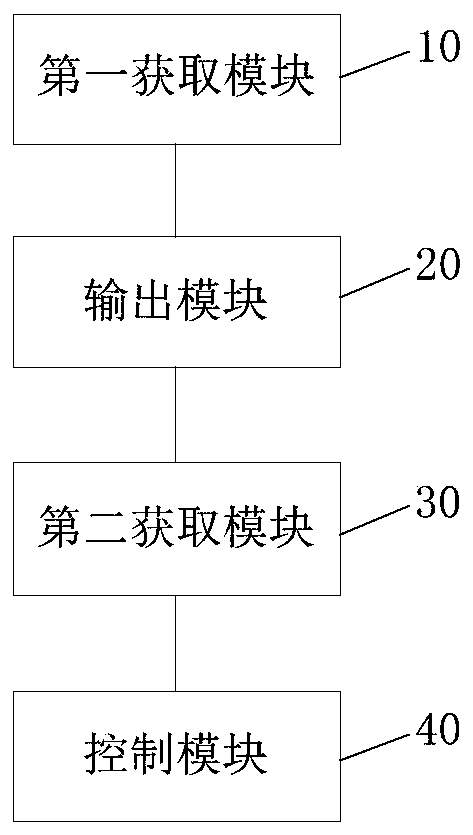

Vehicle and method and device for eliminating vehicle shake

ActiveCN109866625AEliminate jitterImprove comfortSpeed controllerElectric energy managementControl curveAcceleration Unit

The invention discloses a vehicle and a method and a device for eliminating vehicle shake. The method for eliminating vehicle shake comprises the following steps: acquiring a torque control curve of the vehicle according to a state of an acceleration pedal on the vehicle, wherein the torque control curve comprises output torques of a motor at different moments; controlling the output torque outputby the motor in the vehicle according to the torque control curve; acquiring a rotating speed variable amount under the output torque; and judging whether the vehicle shakes or not according to the rotating speed variable amount, if so, adjusting the torque control curve till eliminating the vehicle shake and stopping adjustment of the torque control curve. According to the method of eliminatingvehicle shake, a shake phenomenon of the motor switch between positive and negative torque at a zero crossing point is eliminated by adjusting the torque control curve, so that the comfort and power of the whole vehicle are improved.

Owner:BEIQI FOTON MOTOR CO LTD

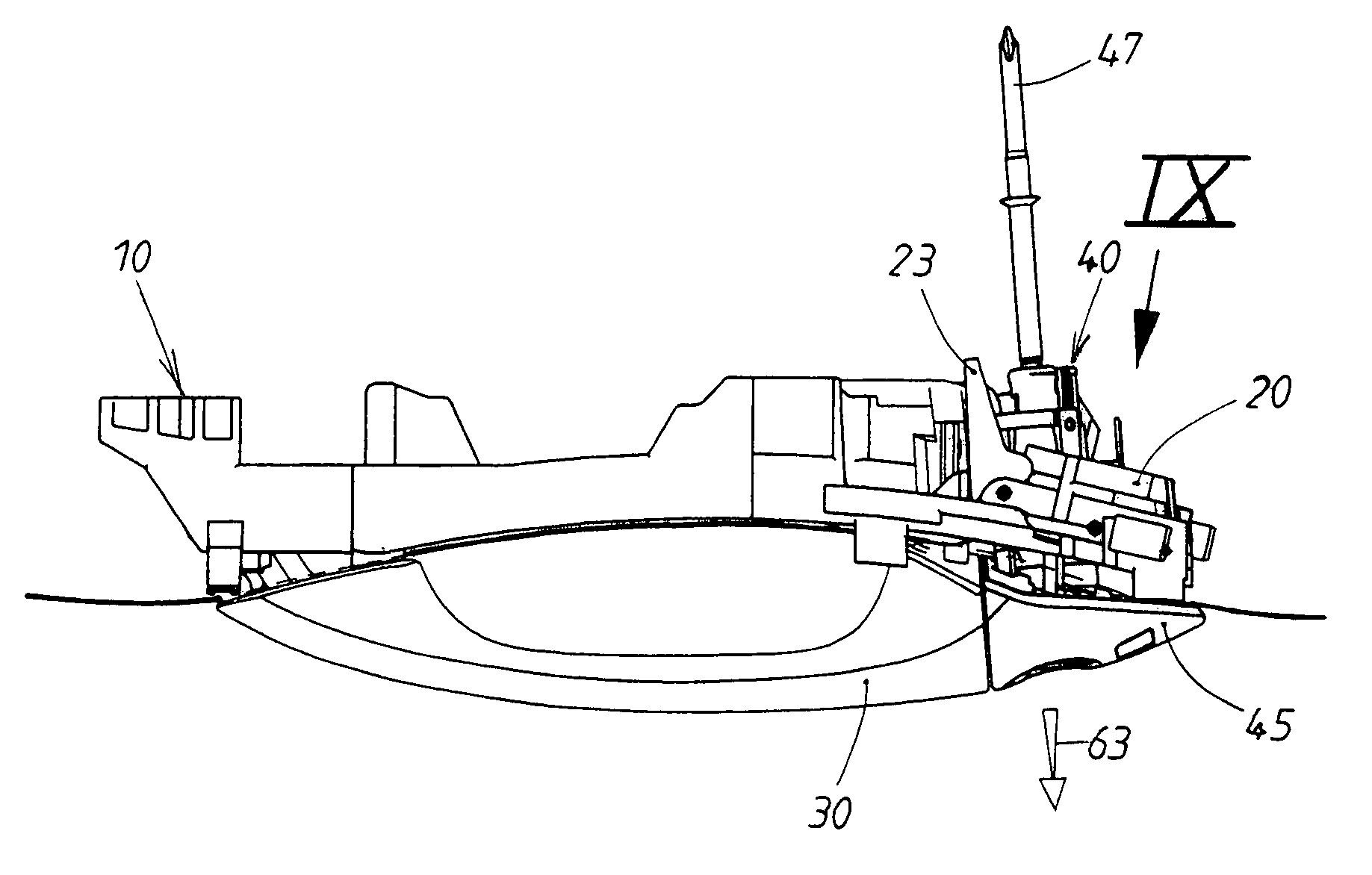

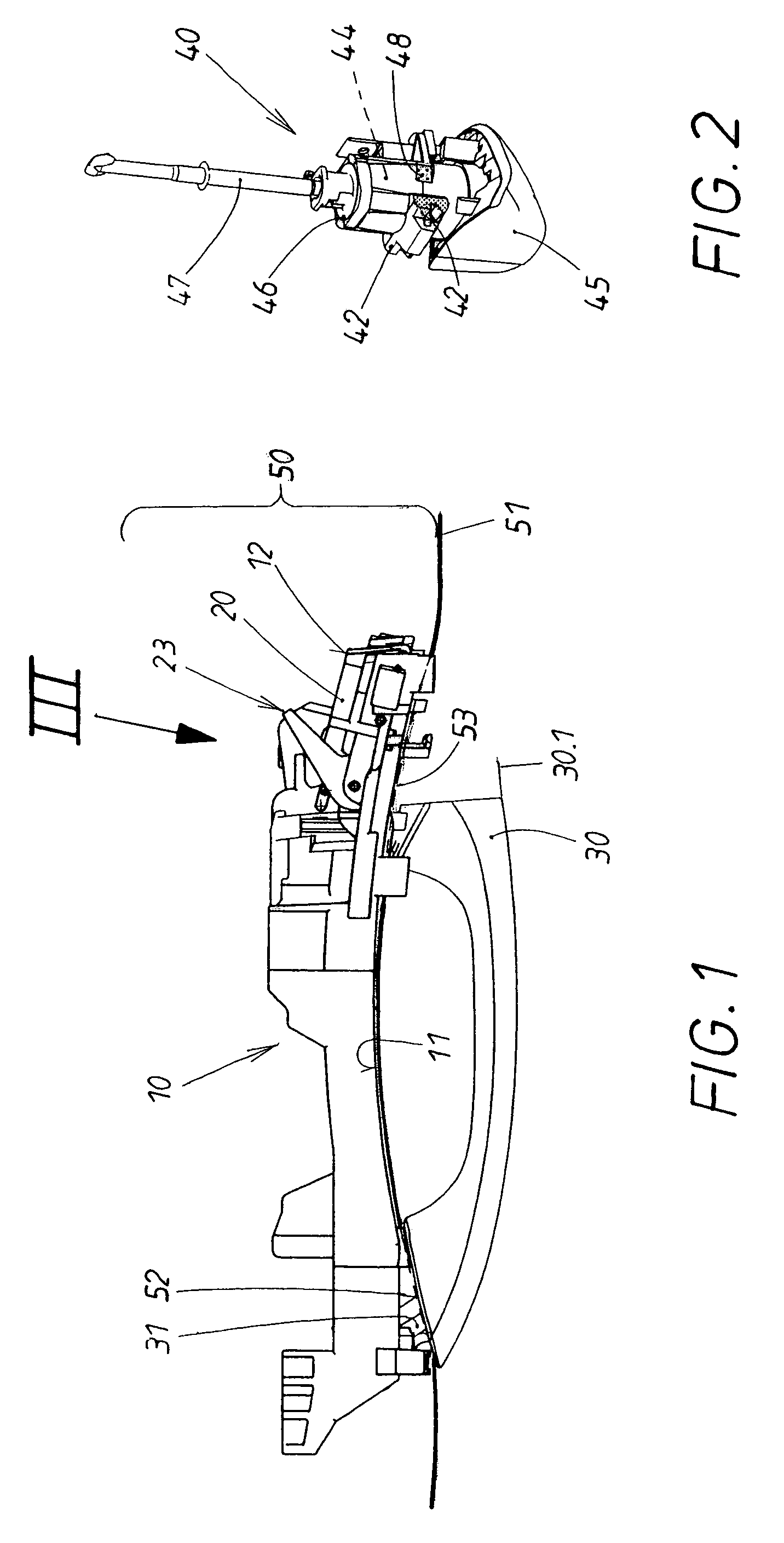

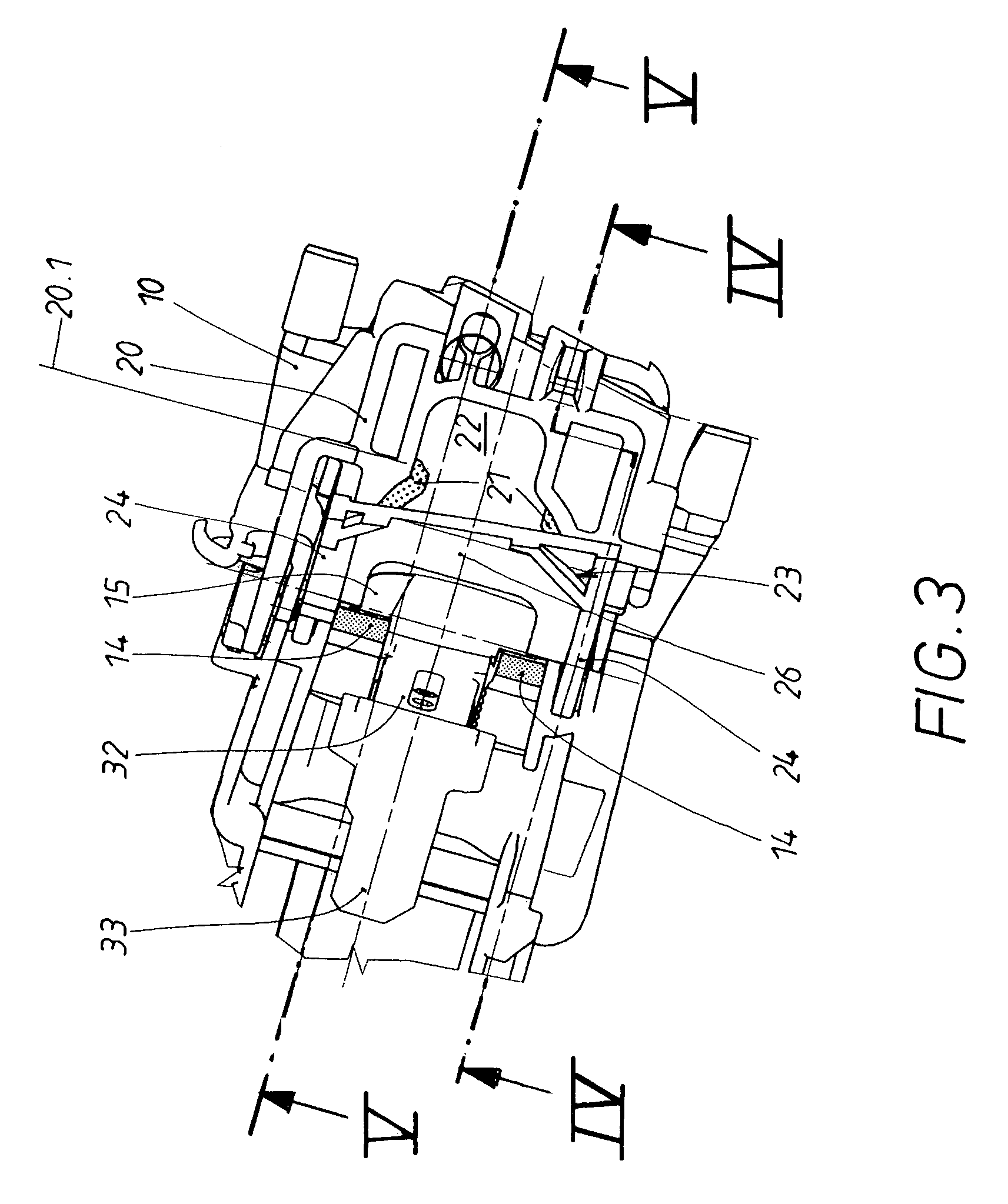

Actuating device for doors or hatches of vehicles

ActiveUS7146832B2Improve the immunityStrong resistanceAnti-theft cycle devicesVehicle locksEngineeringRocker arm

In an actuating device, the turret is installed in a carrier and removed from it by a setting movement. The setting movement comprises a plug-in phase and a shift phase during the installation procedure. Thus a shoulder on the turret arrives behind an opposing shoulder on the carrier. A locking screw secures the installed turret on the carrier. A rocker arm is supported pivotably on the carrier, which rocker arm has a control curve and a thrust surface and which can be pivoted between a starting position and an end position. In addition, the carrier is provided with a slide, which can also be shifted between a release position and locking position. Upon moving into the locking position, blocking surfaces on the slide arrive behind the opposing blocking surface on the turret. During the installation of the turret, the turret pushes against the thrust surface of the rocker arm and pivots the rocker arm toward its end position. During the removal of the turret, the thrust surface of the rocker arm ensures that the turret is pushed back in the carrier until the shoulder and the opposing shoulder release each other.

Owner:HUF HULSBECK & FURST GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com