Pipe tool transportation mechanical arm

A technology of manipulator and pipe tool, applied in the direction of drill pipe, casing, drilling equipment, etc., can solve the problems of pipe tool pushing off and dumping, complicated programming and control, and damage to the thread of drilling tool, so as to achieve the synchronization of extension speed and displacement. , simple programming and control, simple maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

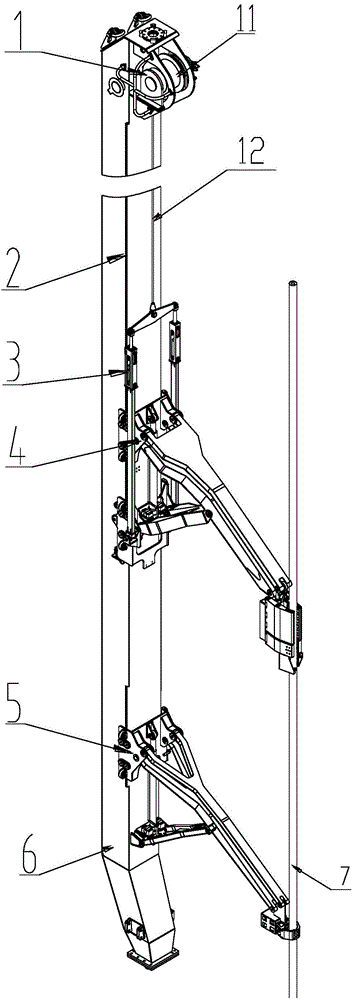

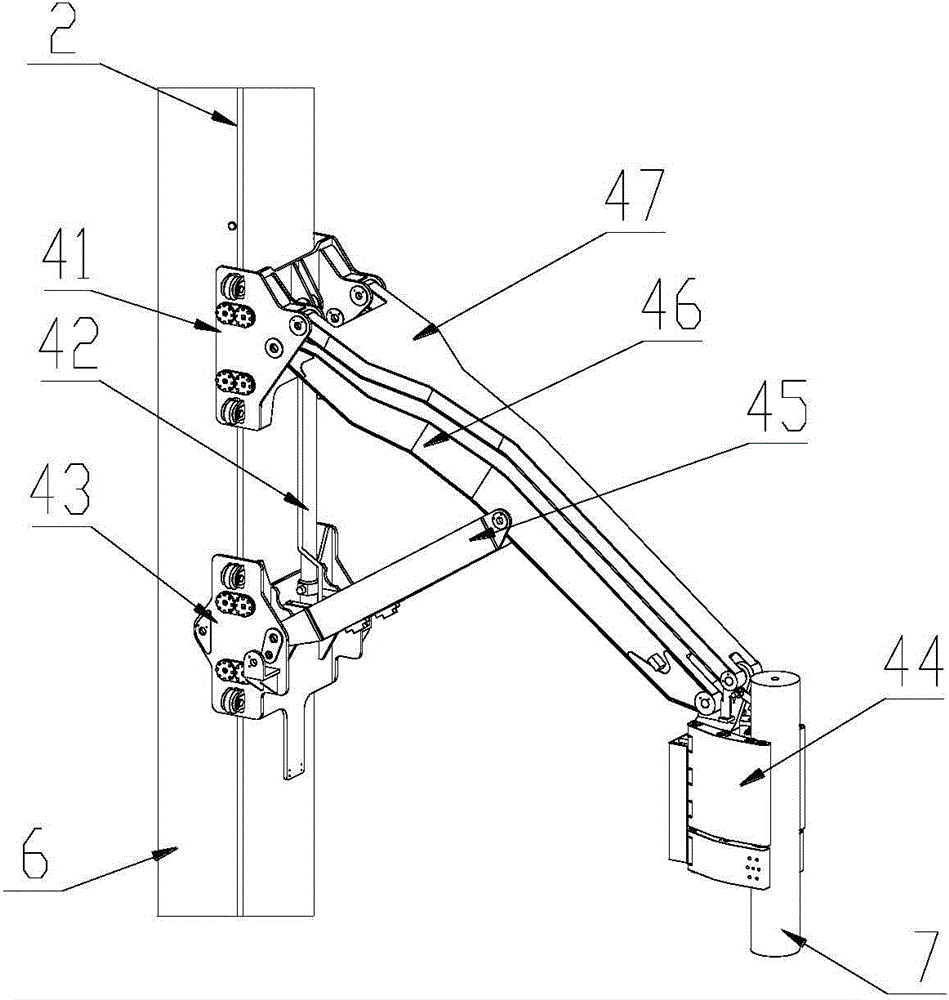

[0052] Figure 1 to Figure 4 The main beam 6 of the pipe arrangement machine shown in is the installation carrier of the pipe transfer manipulator in this embodiment. The upper and lower ends of the main beam 6 of the pipe arrangement machine are respectively hinged on the upper and lower traveling devices, which can realize the overall movement and rotation of the entire pipe transfer manipulator.

[0053] The pipe transfer manipulator of this embodiment is as follows: figure 1 As shown, it includes a lifting device 1, a guide rail 2, a counterweight device 3, an upper manipulator 4 and a lower manipulator 5. The guide rail 2 is fixed on both sides ahead of the main beam 6 of the pipe arrangement machine, and the upper manipulator 4 and the lower manipulator 5 are installed on the guide rail 2 by rollers, and the guide rail 2 provides moving lines for the sliding of the upper manipulator 4 and the lower manipulator 5. The lifting device 1 includes a winch 11 and a wire rop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com