Puller resetting device on shifting bearing block of twin-roll cast-rolling mill

A technology of a twin-roll casting mill and a moving bearing seat, which is applied in the field of twin-roll casting mills, can solve problems such as inability to respond quickly, and achieve the effect of convenient adjustment and guaranteed thickness requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

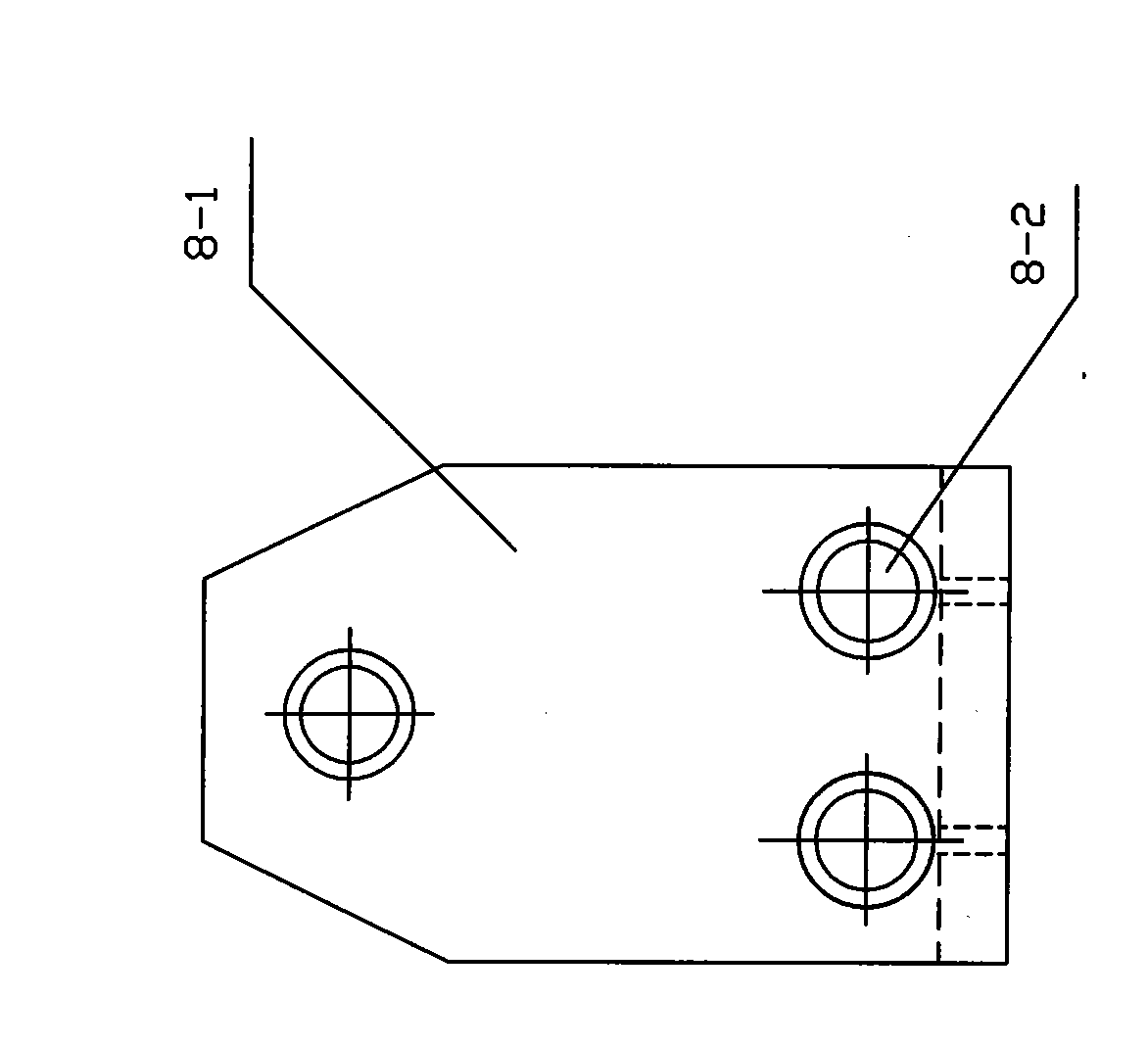

[0016] As shown in the accompanying drawings: a top-tightening reset device for a mobile bearing seat of a twin-roll casting mill, which includes a support seat 8-1 fixed on the bottom plate of the casting roll unit of the twin-roll cast-rolling mill by bolts, on the support seat 8-1 There are three shaft sleeve installation holes on the support plate, and a shaft sleeve 8-3 with internal thread is respectively arranged in the three shaft sleeve installation holes, and the shaft sleeve 8-3 is fixed on the support base 8-1 by the nut 8-4 On the supporting plate of each axle sleeve 8-3, an elastic jacking device 8-2 is threaded. The elastic jacking device 8-2 includes a sleeve 8-2-1 with one end closed and the other open. A disc spring 8-2-5 and a push rod 8-2 are arranged inside the sleeve 8-2-1. -3, the outer circle of the ejector rod 8-2-3 is processed with external threads, the outer thread of the ejector rod 8-2-3 is connected with the inner thread of the shaft sleeve 8-3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com