A Dispensing Shaping Inspection Line for Control Panels

A control panel and assembly line technology, applied in the field of automation, can solve problems such as insufficient insulation and isolation of components, and achieve the effect of ensuring quality, good market application value, and ensuring thickness requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

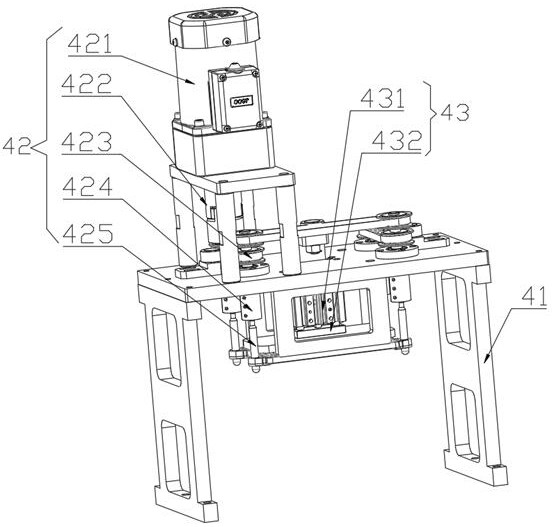

[0030] Embodiment one, such as figure 1 As shown, a dispensing and shaping detection line for control panels, including a worktable 1, is characterized in that a transmission line 2 is fixed on the workbench 1, and a dispensing part 3 and a shaping part 4 are sequentially arranged along the transmission line 2 And detection part 5, described dispensing part 3, shaping part 4 and detection part 5 all straddle on the described conveying line 2, described dispensing part 3, shaping part 4 and detecting part 5 are to the product on conveying line 2 8 Carry out dispensing operation, shaping operation and detection operation in sequence.

[0031] The dispensing part 3 adopts closed dispensing, and the dispensing part 3 forms a closed cavity with the product 8, and the dispensing head performs dispensing operation on the product 8 in the closed cavity;

[0032] The shaping part 4 is used for pressing and flattening the product 8;

[0033] The detection unit 5 is used to detect the ...

Embodiment 2

[0056]Embodiment 2. The difference from Embodiment 1 is that the inlet end and outlet end of the transmission line 2, the rear side of the dispensing mechanism, the rear side of the shaping part 4 and the rear side of the detection part 5 are all provided with the partitions. Blocking mechanism 6, the blocking mechanism 6 is used to block the product 8, so that the product 8 stops at the corresponding position, which is convenient for the operator to take and place and operate at the corresponding position.

[0057] Such as Image 6 As shown, the third embodiment is different from the above embodiments in that the transmission line 2 includes a transmission support 21, a transmission side plate 22, a transmission belt 23, a driving wheel, a driven wheel 24 and a transmission motor 25, and the transmission support 21 Fixed on the workbench 1, the two transmission side plates 22 are fixed on the transmission bracket 21, a driven wheel 24 is respectively fixed at both ends of the...

Embodiment 4

[0058] Embodiment 4. On the basis of Embodiment 3, the following improvements are made. A photoelectric switch is also fixed on the transmission side plate 22. The photoelectric switch is fixed on the transmission side plate 22 through a switch bracket. The photoelectric switch The sensing end is downward, facing the product 8 passing in the conveying line 2, and the photoelectric switch is used to sense whether the product 8 has reached a designated position on the conveying line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com