A processing method for copper-plating hole filling in core board layer through-holes

A hole processing method and core layer technology are applied in the direction of printed circuits, electrical components, and the formation of electrical connections of printed components. The effects of immersion in the liquid medicine, ensuring the filling degree and ensuring the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

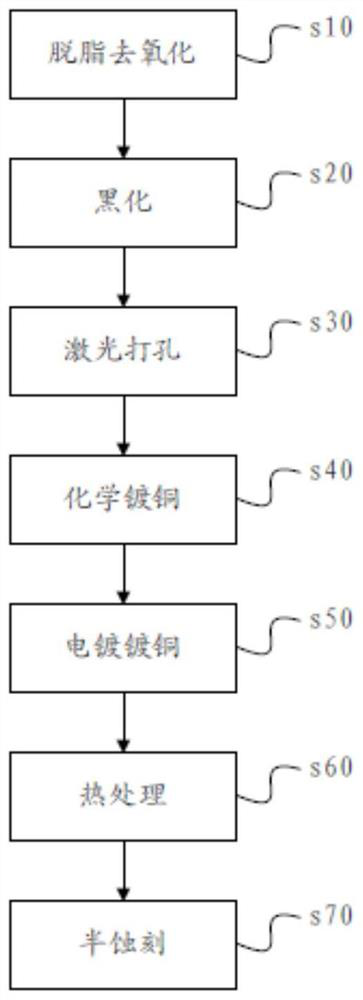

[0051] Such as figure 1 Shown is the process flow of an embodiment of the method for processing through-hole copper plating on the core board layer of the present application, including the following steps:

[0052] s10, degreasing and deoxidizing, the substrate of the core board is subjected to alkaline degreasing treatment and then put into pickling solution for weak etching treatment;

[0053] s20, blackening, the substrate after the weak etching treatment is put into a blackening agent for blackening treatment, so that the substrate forms a needle crystal surface;

[0054] s30. Laser drilling, using laser drilling equipment to perform several times of laser drilling on the front and back sides of the blackened substrate to form through holes, each time the depth of the laser drilling is 1 / 2 to 3 of the thickness of the substrate / 5;

[0055] s40. Electroless copper plating, after desmearing the punched substrate, performing electroless copper plating to deposit a uniform...

Embodiment 2

[0092] On the basis of Embodiment 1, adopt proprietary laser drilling equipment to implement step s30 laser drilling in this embodiment; as Figure 7 and Figure 8 As shown, the laser drilling equipment is provided with a workbench 100; the middle part of the workbench 100 is provided with a processing opening 110; the upper surface of the workbench 100 is provided with a pair of A clamping block 120 for clamping the substrate; a laser generator 200 is provided above and below the processing port 110;

[0093] A pair of clamping grooves 121 for clamping the substrate are provided on opposite surfaces of a pair of clamping blocks 120; the clamping grooves 121 are used to clamp the substrate that needs to be punched in this application; both sides of the substrate are inserted into the clamping The upper surface of the workbench 100 is respectively provided with an upper processing receiving mechanism 300 and a The lower processing undertaking mechanism 400;

[0094] A pair o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com