Ceramic chip antenna and preparation method thereof

A ceramic antenna and chip technology, applied in the field of ceramic antennas, can solve the problems of lack of interface bonding and separation, achieve excellent interface bonding, avoid air oxidation, and ensure antenna performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] A method for preparing the above-mentioned chip ceramic antenna includes the following steps:

[0053] S1) According to the material and size requirements of the ceramic base, the blank of the ceramic base is prepared by tape casting, punching and cutting processes;

[0054] S2) According to the material and thickness requirements of the first metal circuit, the first metal circuit is printed on the blank of S1 by a screen printing process, and sintered, to obtain the first metal circuit attached The ceramic base;

[0055] S3) According to the material and thickness requirements of the second metal circuit, any one of chemical vapor deposition, magnetron sputtering, electron beam evaporation deposition, electroplating, and electroless plating is used on the surface of the first metal circuit in S2 Preparing the second metal circuit;

[0056] S4) According to the material of the third metal circuit, the third metal circuit is prepared on the surface of the second metal circuit ...

Embodiment 1

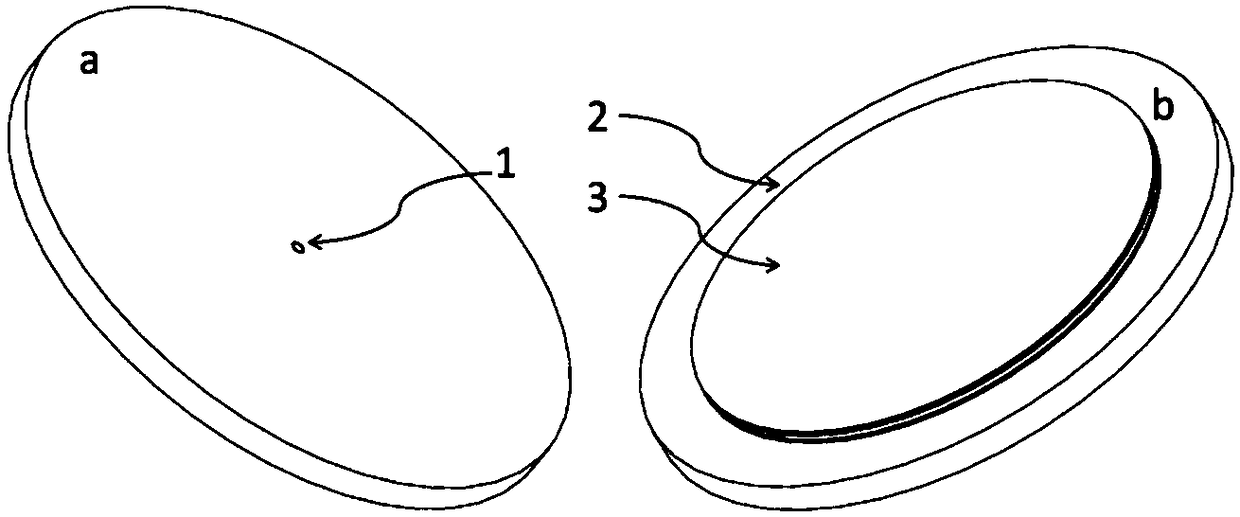

[0062] A structure design of a chip ceramic antenna, such as figure 1 , figure 2 Shown, including ceramic base and metal circuit:

[0063] among them,

[0064] The material of the ceramic base 2 is preferably alumina;

[0065] The metal circuit 3 is attached to the outer surface of the ceramic base 2 and the position of the via hole 1, wherein the metal circuit layer on the outer surface serves as the main body of the ceramic antenna, and the metal circuit located in the via hole serves as a circuit conduction function;

[0066] The metal circuit 3 has a multi-layer structure. According to the distance from the ceramic base, they are sequentially labeled as the first metal circuit 31, the second metal circuit 32, the third metal circuit 33, the fourth metal circuit 34, and the fifth metal circuit. 35;

[0067] The material of the first metal circuit 31 is preferably tungsten, and the thickness of the first metal circuit is preferably 1.5um;

[0068] The material of the second metal ci...

Embodiment 2

[0073] A method for preparing the chip ceramic antenna described in Example 1. It includes the following steps:

[0074] S1) According to the material of the ceramic base is preferably alumina and the size requirements, the green body of the ceramic base is prepared by casting, punching and cutting processes;

[0075] S2) According to the requirements that the material of the first metal circuit is preferably tungsten and the thickness is 1.5um, the first metal circuit is printed on the blank of the ceramic base described in S1 by a screen printing process, and high-temperature sintering is performed in an air environment , Sintering temperature is 1650℃, holding time is 2h;

[0076] S3) According to the requirement that the material of the second metal circuit is preferably chromium and the thickness is 0.5um, the second metal circuit is prepared on the surface of the first metal circuit in S2 by using a magnetron sputtering process;

[0077] S4) According to the requirement that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com