Electroplating manufacturing process of circuit board with back-drilled blind hole

A manufacturing process and circuit board technology, applied in the direction of the electrical connection of printed components, etc., can solve the problems of poor resin removal effect, voids, thin copper thickness in holes, etc., to achieve good deglue effect and solve the effect of inexhaustible glue removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] The invention provides a circuit board back-drilled blind hole electroplating process, which is mainly used to solve the problem of poor resin removal effect in blind holes and copper thickness in holes caused by chemical deglue in the current circuit board back-drilled blind hole electroplating process. Thin, after electroplating, it is easy to form defects such as voids in the hole, broken copper or open circuits, and the thickness of the copper layer in the blind hole cannot meet the requirements of 18UM in the end.

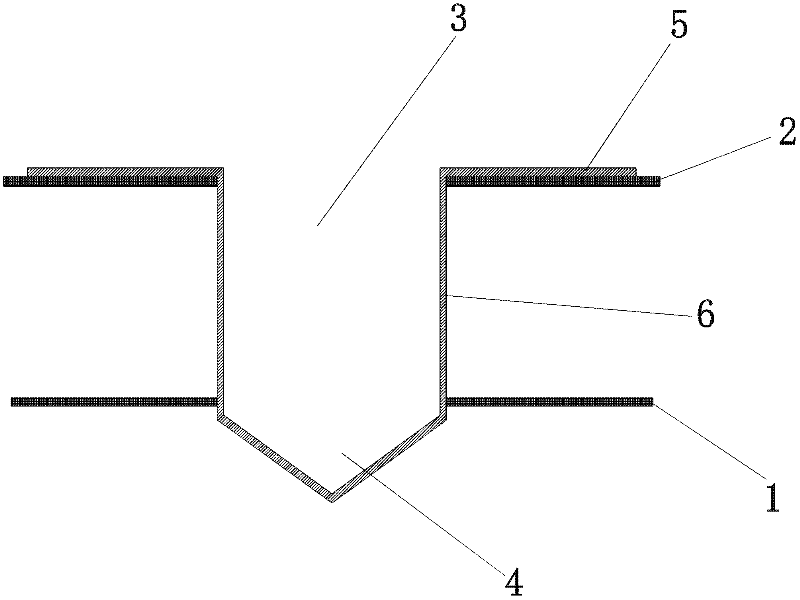

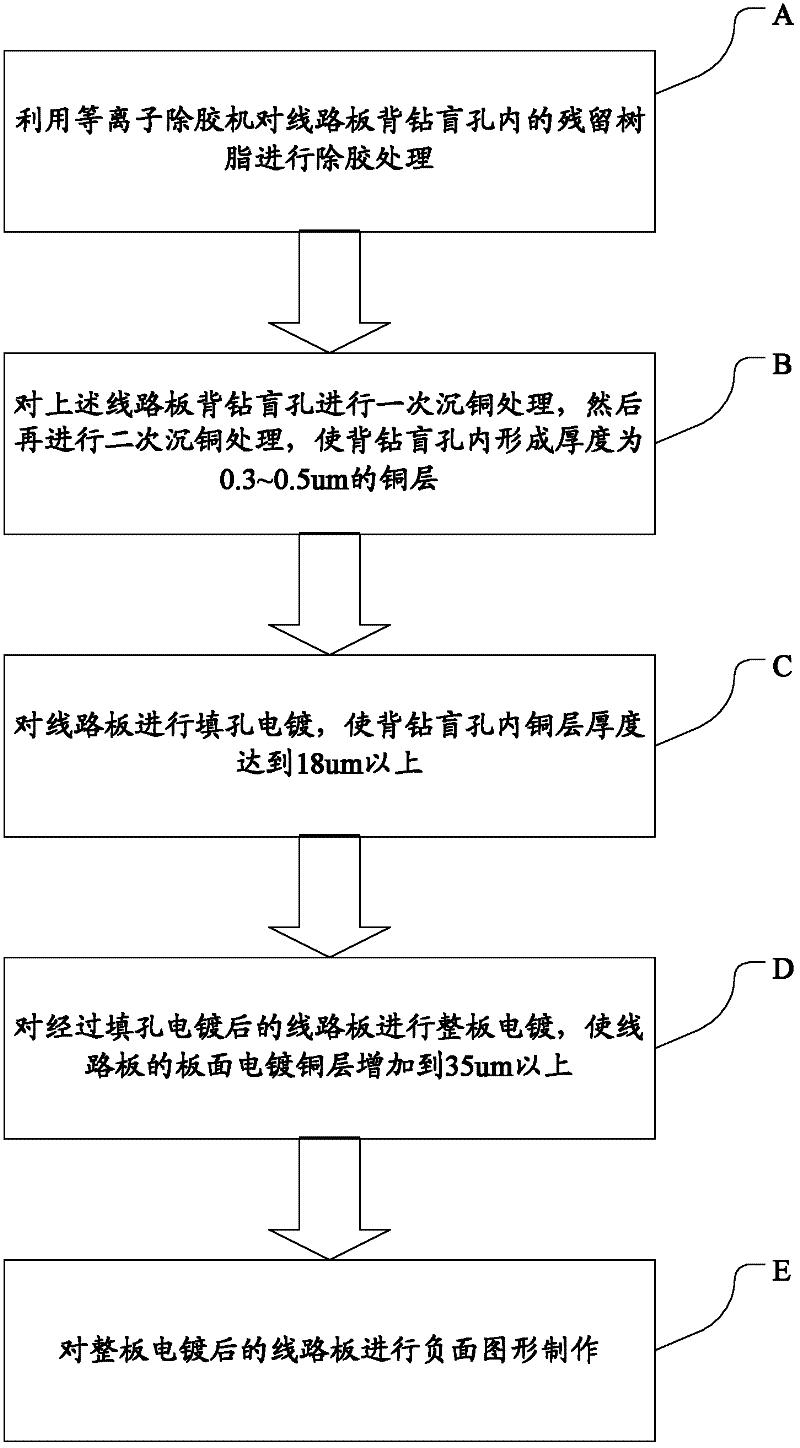

[0028] See figure 1 , figure 2 as shown, figure 1 Schematic diagram of the slicing structure for back-drilling blind holes on the circuit board; figure 2 It is a flow chart of the electroplating manufacturing process for back-drilling blind holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com