A printed circuit board and its manufacturing method

A technology for printed circuit boards and manufacturing methods, which is applied to printed circuits, printed circuit manufacturing, printed circuit components, etc., can solve problems such as etching difficulties, and achieve the effect of ensuring thickness uniformity and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

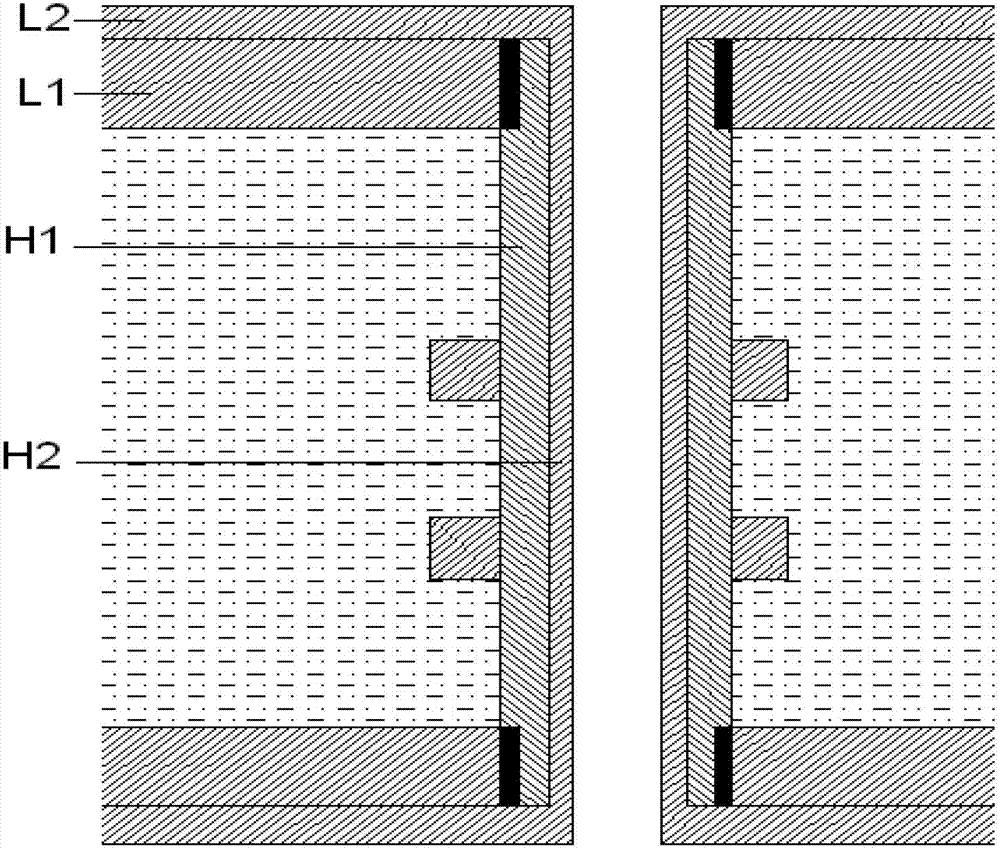

[0038] In the present invention, by adjusting the surface copper composition structure of the printed circuit board, the thickness of the surface copper is reduced on the basis of meeting the requirements of the hole copper, so that the thickness of the hole copper and the surface copper are accurately controlled. The technical scheme of the present invention comprises: setting surface copper copper foil thickness L1, plating surface copper thickness L2, plating hole copper thickness H1, H2; surface copper thickness L=L1+L2, hole copper thickness H=H1+H2, wherein, copper The layer thicknesses L2 and H2 are obtained by electroplating at the same time, and the thicknesses of the copper layers L1 and H1 can be produced and controlled separately; during the production process, the differences in the thicknesses of the copper layers L2 and H2 in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com