Hollowed-out lattice sandwich layer with gradient functionality and manufacturing method of hollowed-out lattice sandwich layer

A functional and dot-matrix technology, applied in additive manufacturing, improving energy efficiency, improving process efficiency, etc., can solve problems such as lack of overall strength and functionality, inability to realize gradient functionality, and high quality of hollowed-out dot-matrix interlayers. To achieve the effect of avoiding strength, reducing risk, avoiding complex multi-process flow, and avoiding performance mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method for preparing a hollow lattice interlayer with gradient functionality, characterized in that it comprises the following steps:

[0036] Step 1, convert the drawn 3D data model of the hollow lattice sandwich structure into STL format data and export it;

[0037] Step 2, import the STL format data obtained in step 1 into the commercial model segmentation software, and determine the placement position of the parts during the laser selective melting process, use the commercial model segmentation software to divide the model into slices and import the data into commercial 3D printing equipment;

[0038] Step 3, formulate the forming process of the laser selective melting process, set the laser selective melting parameters, and obtain a hollow lattice interlayer structure with gradient functionality for one overall forming, where the specific laser selective melting parameters are: laser power 300-400KW, The scanning speed is 500-1500mm / s, the overlap rate is 30-60%...

Embodiment 1

[0040] Forming preparation of titanium alloy hollow lattice interlayer with gradient functionality

[0041] (1) Design and draw the 3D model of titanium alloy hollow lattice interlayer

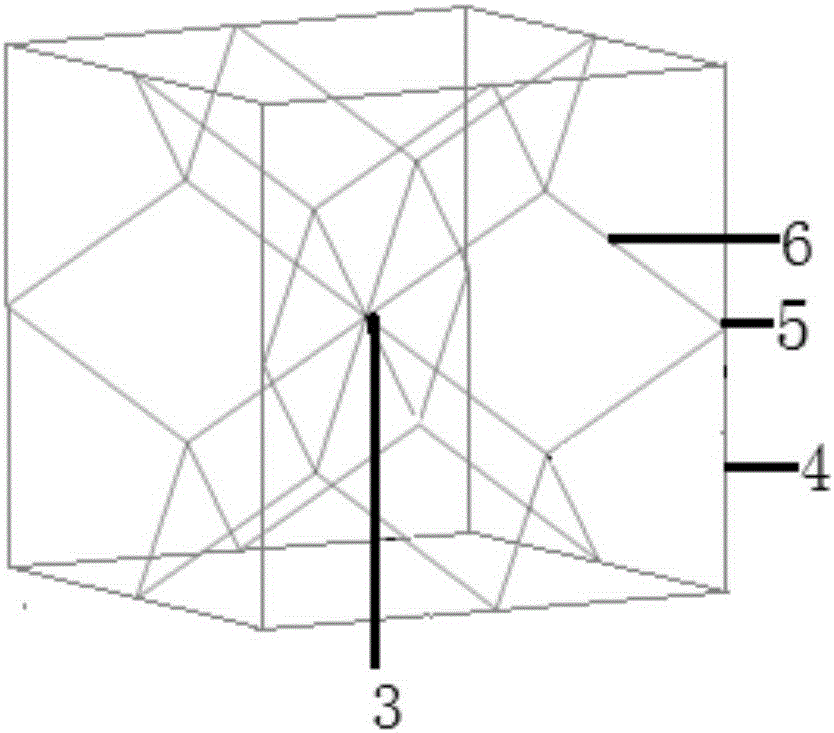

[0042] like Figure 2-3 As shown, a rhombus-shaped hollow cell structure is designed, and the side length of the outer contour body of the cube is 5mm; 12 nodes 5 are determined on the outer contour body 4, and the specific distribution is: one node is determined on each side length of the outer contour body 4 Nodes, a total of 12 nodes 5; 9 nodes 5 are determined inside the outer contour body 4, and the overall hollow lattice filling unit 3 has a total of 21 nodes 5, and all nodes 5 are determined to follow the law, the rule is that each node When the point 5 is connected according to the law: the angle between the round rod 6 and the surface of the outer contour body 4 is 35°.

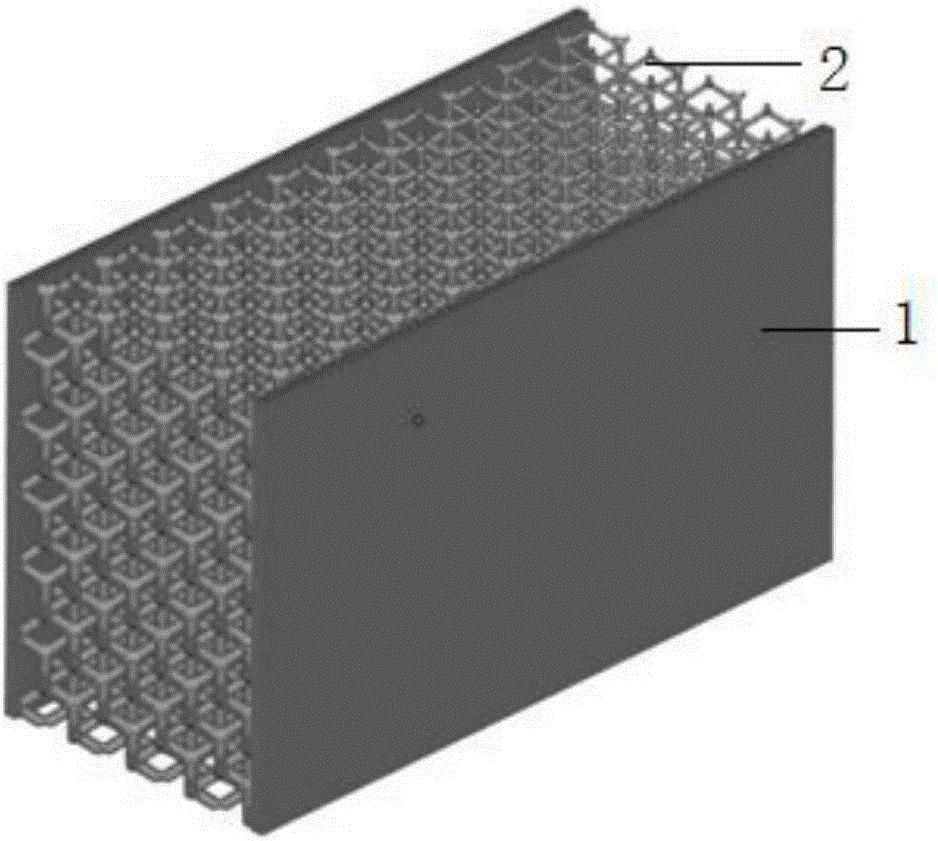

[0043] Draw the designed hollow lattice sandwich structure, and design the dimensions of the cladding plate 1 an...

Embodiment 2

[0048] Forming preparation of aluminum alloy hollow lattice interlayer with gradient functionality

[0049] (1) Design and draw the 3D model of aluminum alloy hollow lattice interlayer

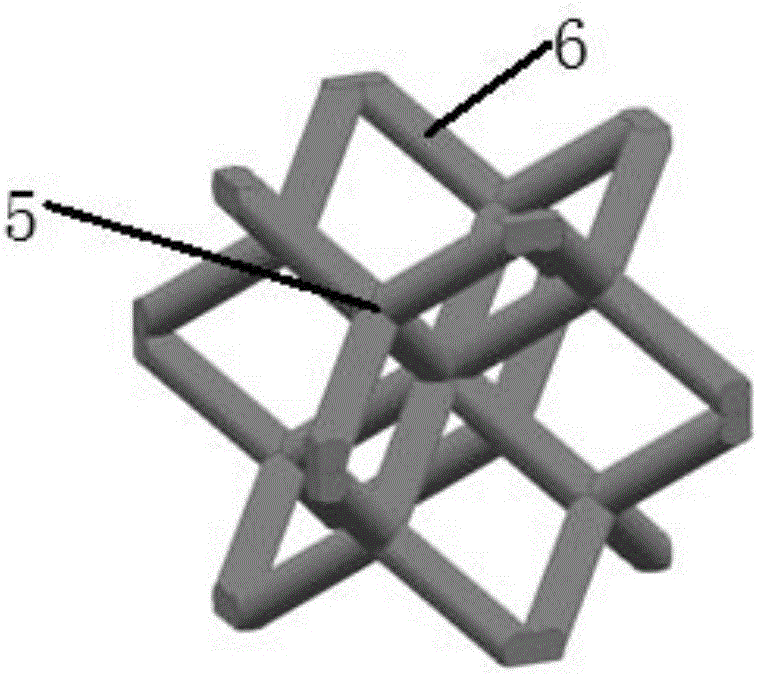

[0050] like Figure 5-6 As shown, a cubic branch-shaped hollow cell structure is designed, and the side length of the outer outline of the cube is 3mm; 20 nodes 5 are determined on the outer outline 4, and the specific distribution is: each vertex of the outer outline 4 determines one There are 8 nodes 5 in total, 1 node is determined on each side length, 12 nodes in total; 9 nodes 5 are determined inside the outer contour body 4, and the overall hollow lattice filling unit 3 has a total of 29 nodes 5, all The node 5 is determined to follow the law, and the rule is that when the nodes 5 are connected according to the law: the angle between the round rod 6 and the surface of the outer contour body 4 is 40°.

[0051] Draw the designed hollow lattice sandwich structure, and design the dimension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com