Method for manufacturing high-strength 7055 aluminum alloy forge piece formed by spraying

A technology of spray forming and manufacturing method, which is applied in the field of aluminum alloy manufacturing to achieve the effects of stable quality, no component segregation, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

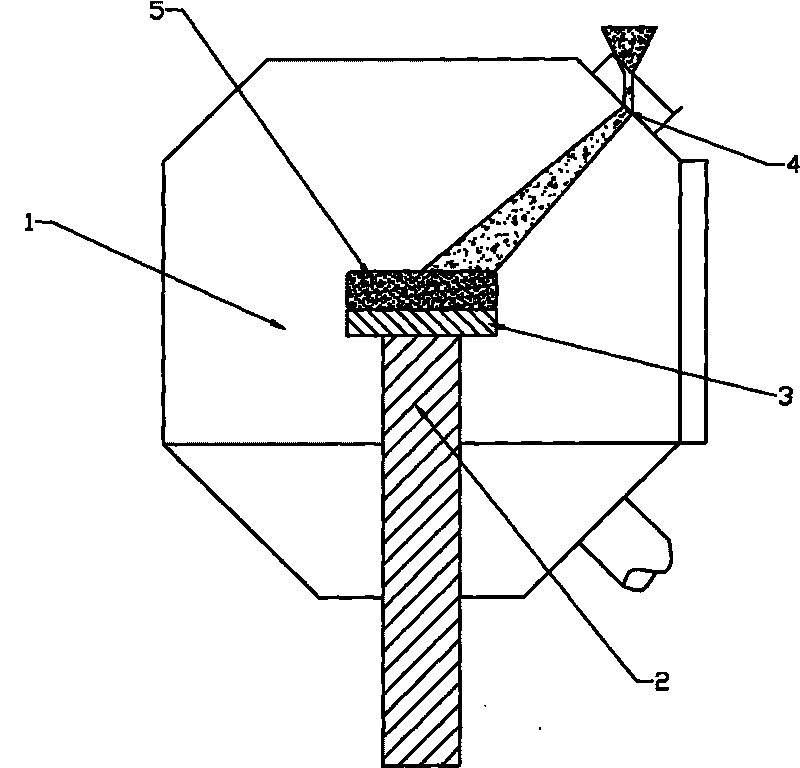

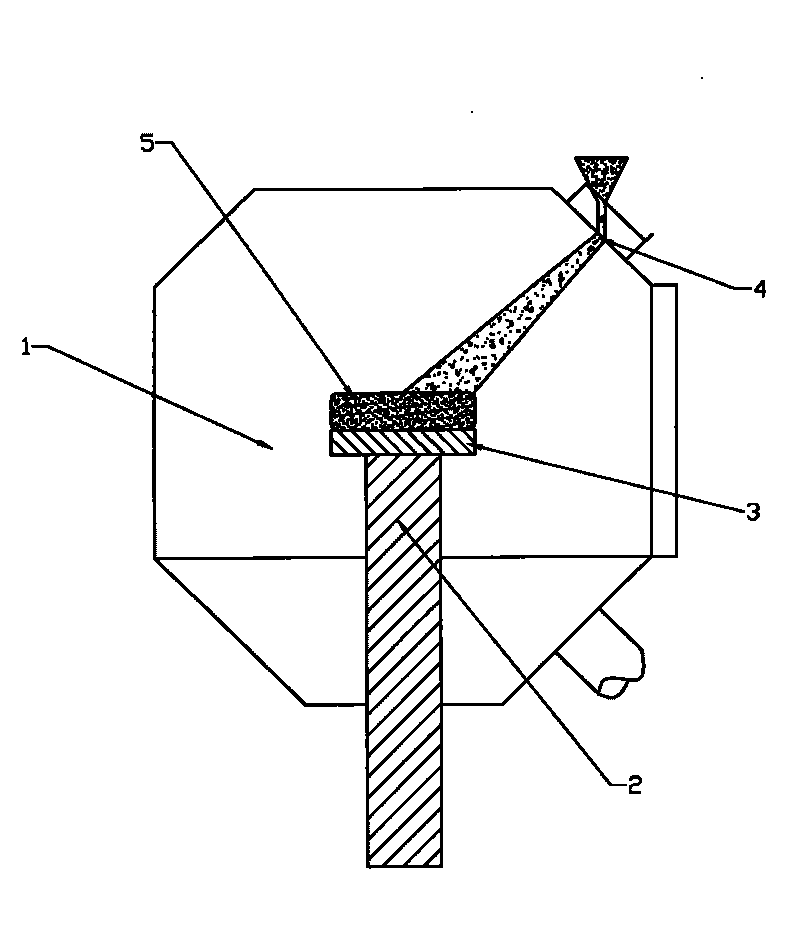

Image

Examples

Embodiment 1

[0029] Example 1: A 7055 aluminum alloy aircraft hub blank was prepared by using the method of the present invention.

[0030] 1) Weight percent of each alloy composition: Si: 0.06%, Fe: 0.1%, Cu: 2.41%, Mn: 0.03%, Mg: 2.18%, Zn: 8.0%, Ti: 0.006%, Zr: 0.12%, Ni: 0.009%, Al balance. The alloy is melted in an intermediate frequency furnace with a melting temperature of 750°C.

[0031] 2) Adding a slag removal agent, degassing and deslagging the aluminum alloy melt, transferring the melt to a tundish, refining with a powder refining agent, and then standing for 15 minutes before filtering.

[0032] 3) Spray forming equipment and technology are used to spray the filtered melt. The spray deposition process parameters are: spray angle 20°, atomization pressure 0.8MPa, atomization temperature 750°C, receiving pan rotation speed 35rpm, receiving pan descending speed 2.8mm / s, receiving distance 530mm. Finally, a cylindrical aluminum alloy ingot of Φ370×1200 mm is obtained.

[0033]...

Embodiment 2

[0038] Example 2: A 7055 aluminum alloy aircraft cylinder block blank was prepared by using the method of the present invention.

[0039] 1) Weight percentage of each alloy composition: Si: 0.06%, Fe: 0.13%, Cu: 2.3%, Mn: 0.03%, Mg: 2.18%, Zn: 7.9%, Ti: 0.006%, Zr: 0.12%, Ni: 0.009%, Al balance. The alloy is melted in an intermediate frequency furnace at a melting temperature of 750°C.

[0040] 2) Adding a slag removal agent, degassing and deslagging the aluminum alloy melt, transferring the melt to a tundish, refining with a powdery refining agent, standing for 10 minutes, and then filtering.

[0041] 3) Using the self-developed spray forming equipment and process, the filtered melt is spray formed. The spray deposition process parameters are: spray angle 25°, atomization pressure 1.0MPa, atomization temperature 800°C, receiving pan rotation speed 40rpm, receiving pan descending speed 3.2mm / s, receiving distance 580mm. Finally, a cylindrical aluminum alloy ingot of Φ430×12...

Embodiment 3

[0047] Example 3: A 7055 aluminum alloy rocket engine nozzle casing forging was prepared using the method of the present invention.

[0048] 1) Weight percentage of each alloy composition: Si: 0.06%, Fe: 0.1%, Cu: 2.41%, Mn: 0.03%, Mg: 2.3%, Zn: 8.1%, Ti: 0.006%, Zr: 0.12%, Ni: 0.009%, Al balance. The melting temperature is 750°C.

[0049] 2) Add a slag removal agent to degas and remove slag from the aluminum alloy melt, transfer the melt to a tundish, refine it with a powder refining agent, then let it stand for 20 minutes, and then filter it.

[0050] 3) Using the self-developed spray forming equipment and process, the filtered melt is spray formed. The spray deposition process parameters are: spray angle 15°, atomization pressure 0.7MPa, atomization temperature 800°C, receiving pan rotation speed 30rpm, receiving pan descending speed 2.5mm / s, receiving distance 500mm. Finally, a cylindrical aluminum alloy ingot of Φ370×1200mm is obtained.

[0051] 4) The spray-formed al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com