Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "No component segregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing high-strength 7055 aluminum alloy forge piece formed by spraying

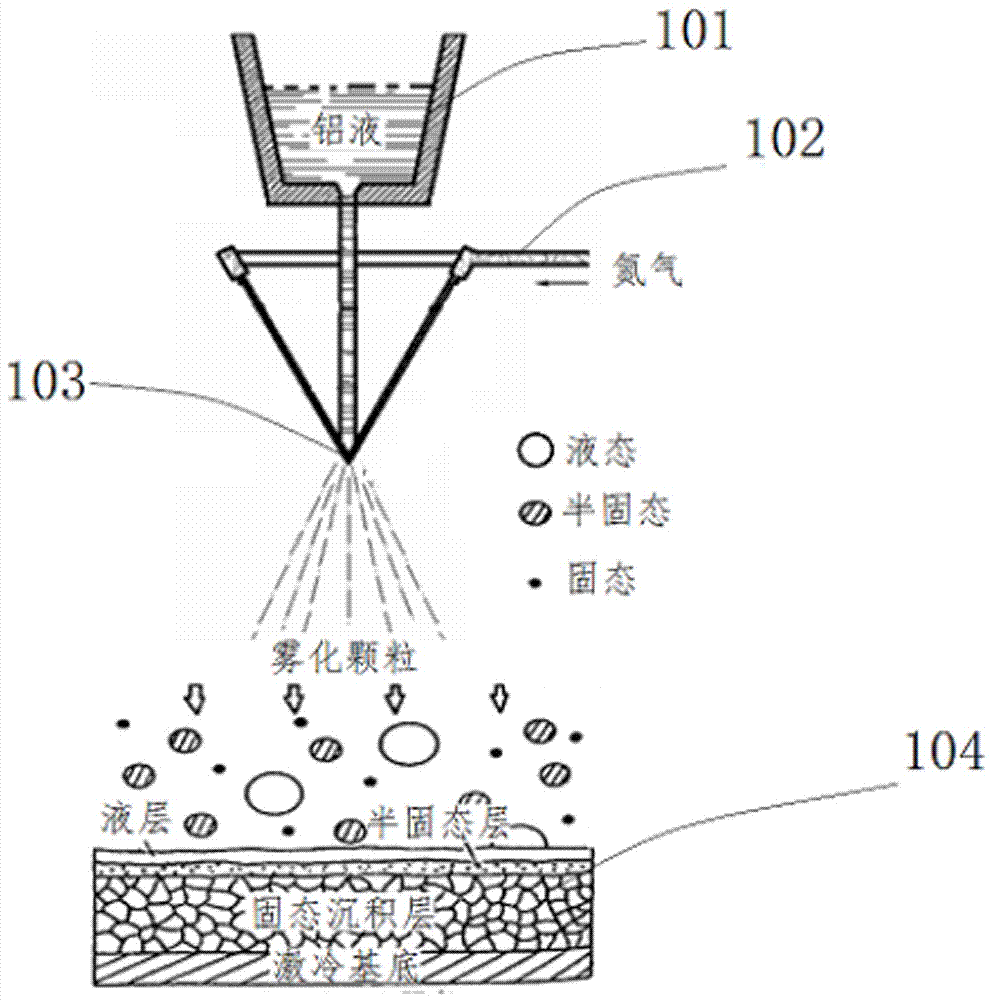

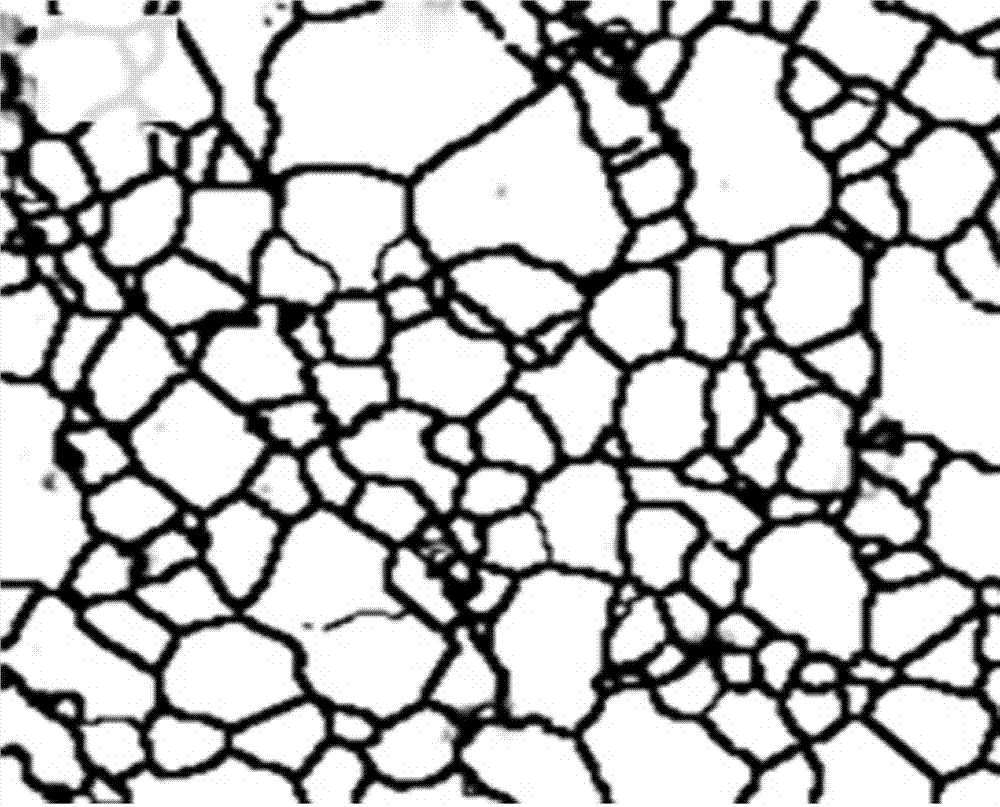

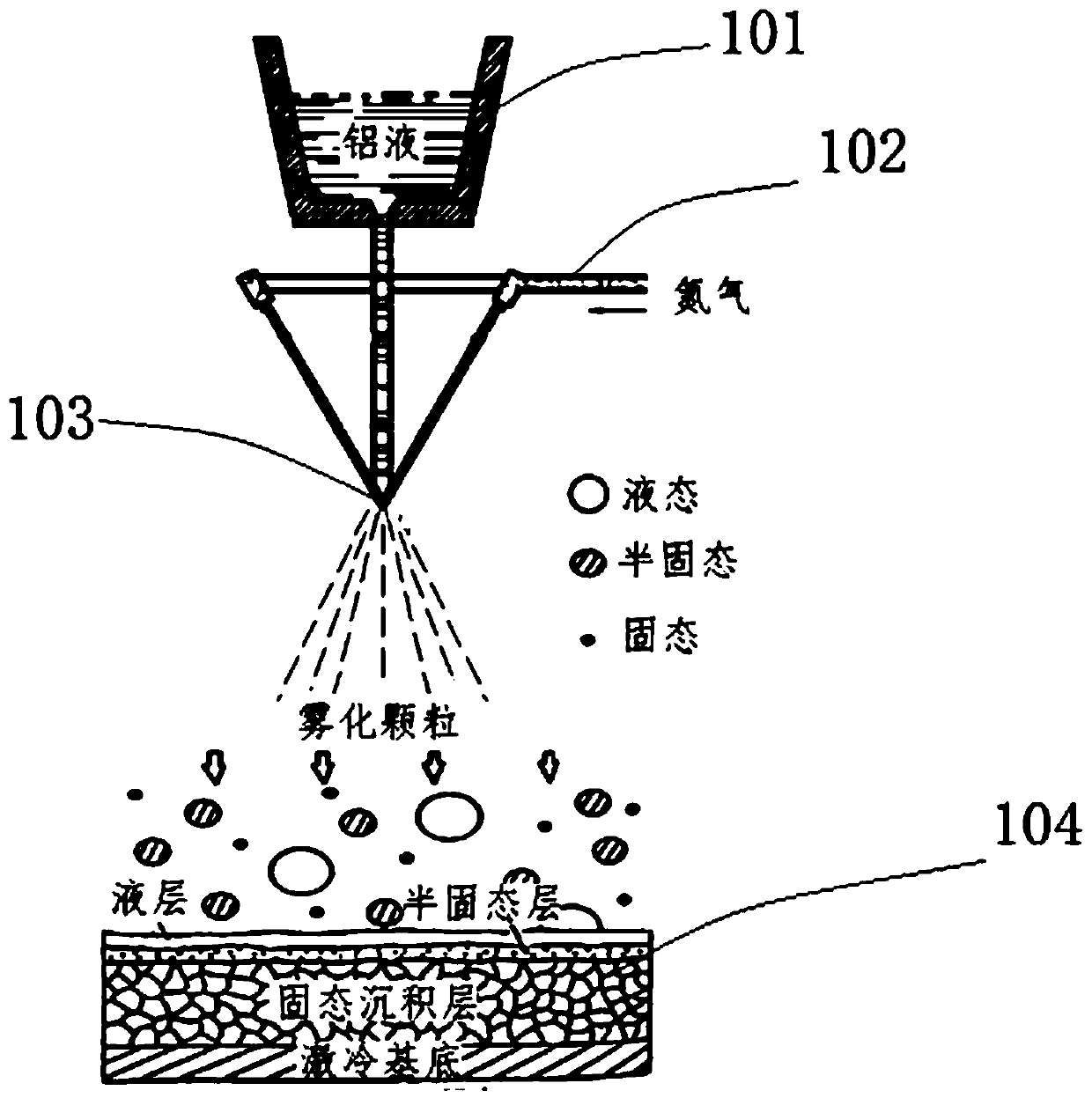

The invention belongs to a manufacturing technology of aluminum alloy and relates to a method for manufacturing a high-strength 7055 aluminum alloy forge piece formed by spraying. The method sequentially comprises the following steps: (a) melting components of 7055 alloy in an intermediate frequency furnace; (b) degassing, deslagging, refining and filtering an aluminum alloy fusant; (c) forming the filtered fusant by spraying to obtain a columnar aluminum alloy ingot blank; (e) carrying out hot extrusion on the aluminum alloy ingot blank formed by spraying; (f) constantly cutting the extrusion ingot as required and then carrying out free forging; (g) carrying out blocker-type forging and / or stamp forging on the blank after the free forging to obtain a stamp forging piece; and (h) carrying out T6 heat treatment on the stamp forging piece. A large-specification and high-property 7055 product can be obtained by using the method which is suitable for industrial production.

Owner:JIANGSU HAORAN SPRAY FORMING ALLOY

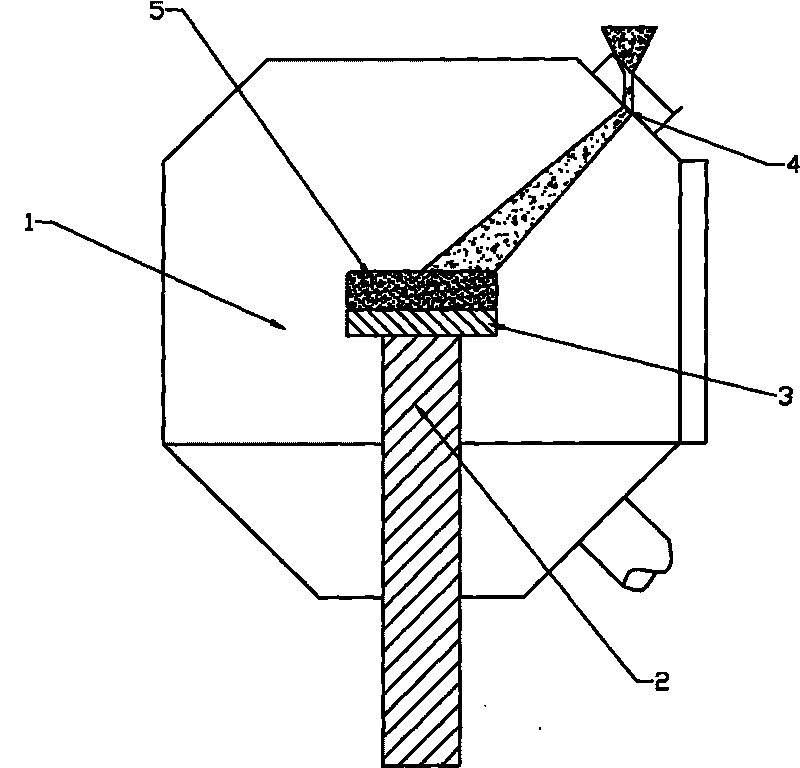

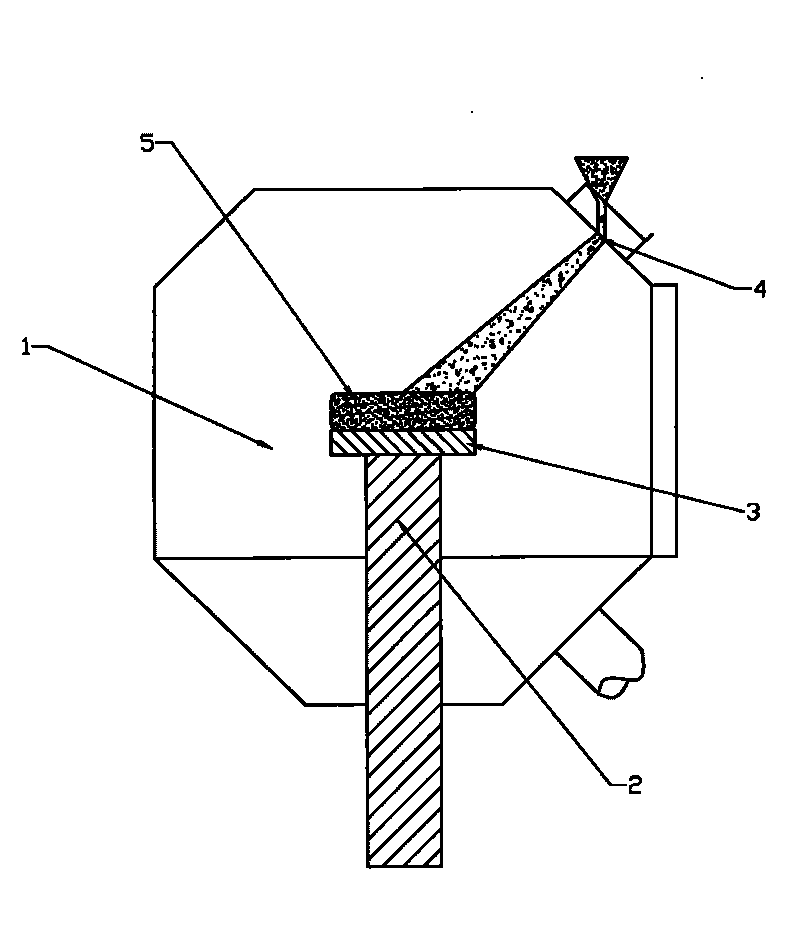

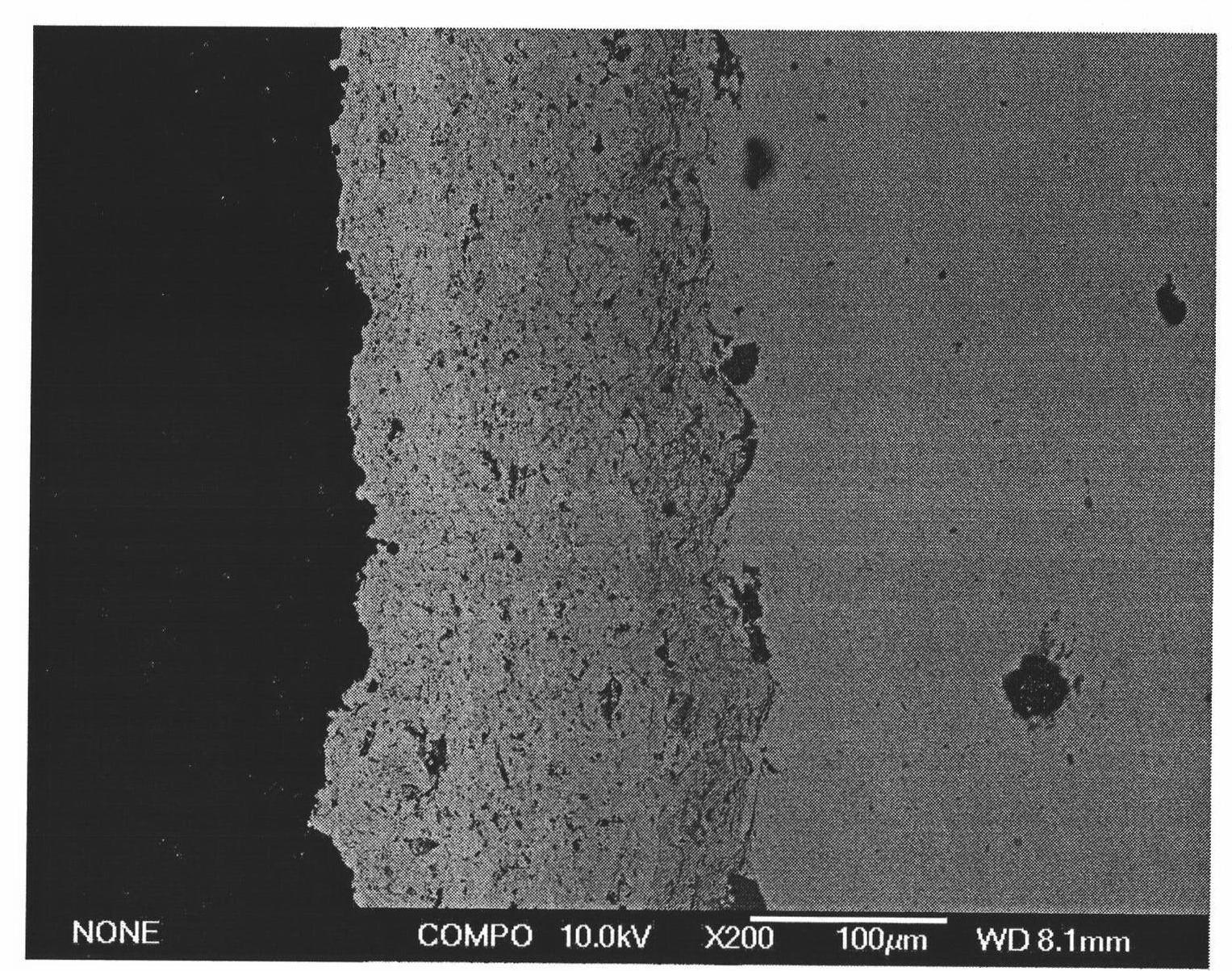

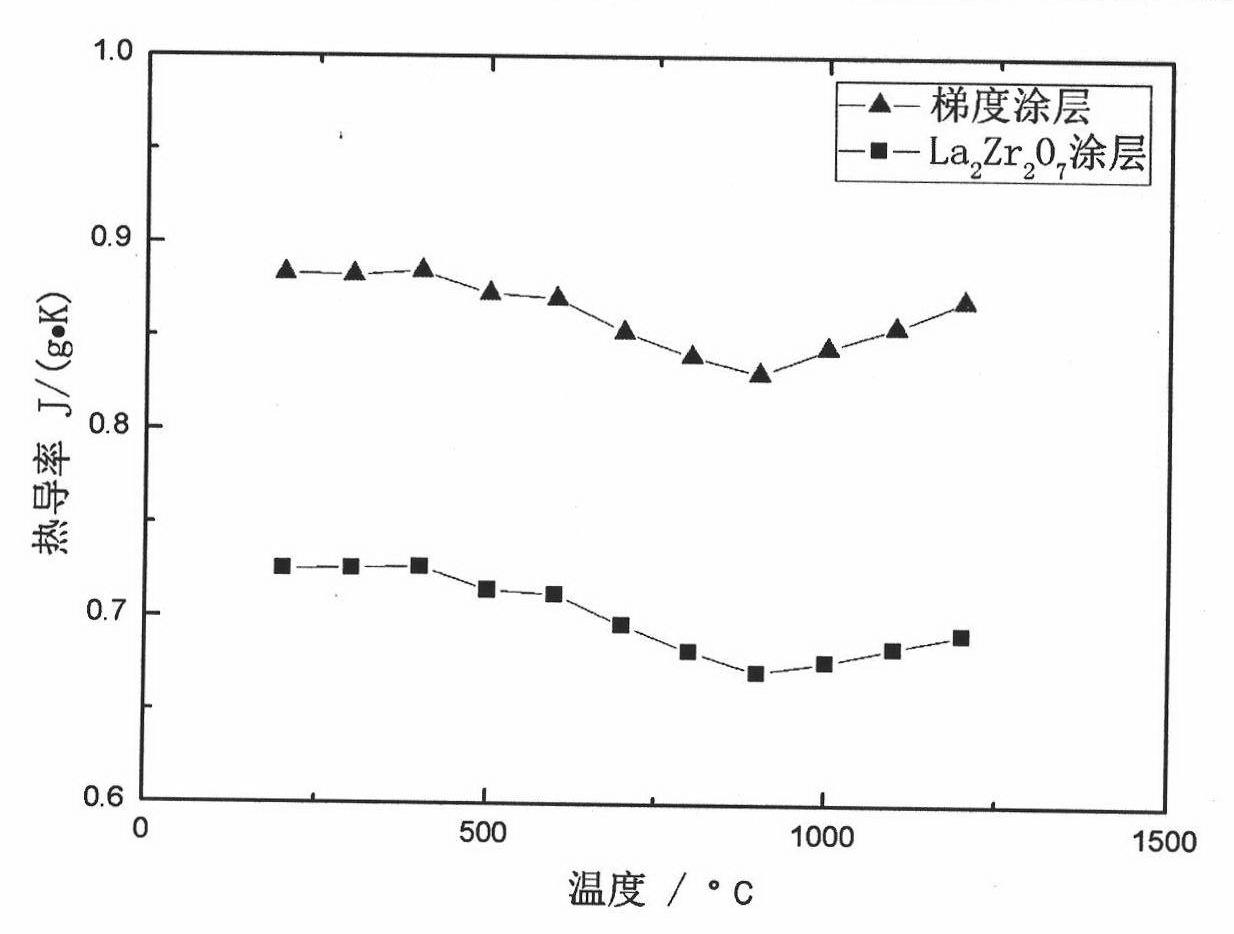

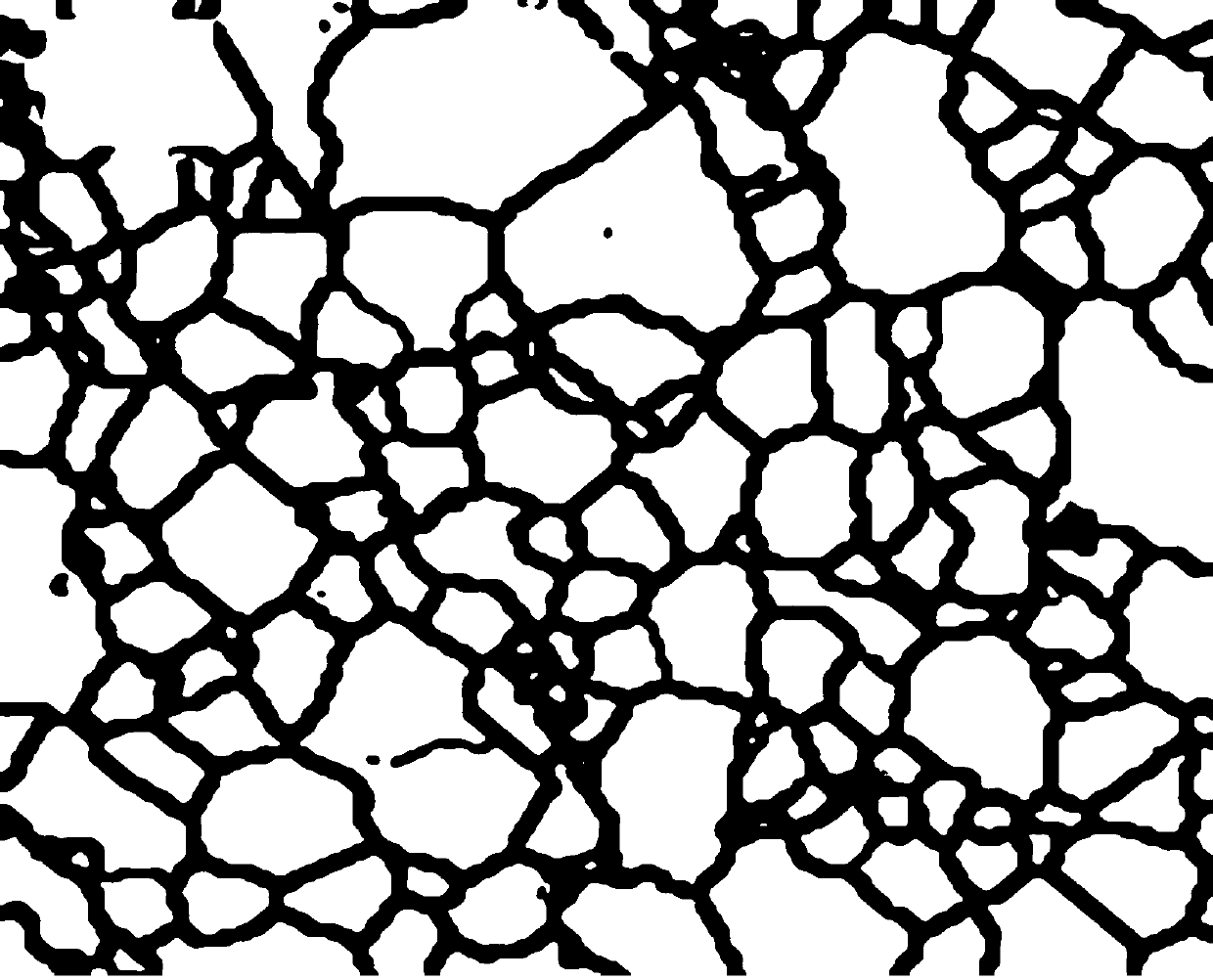

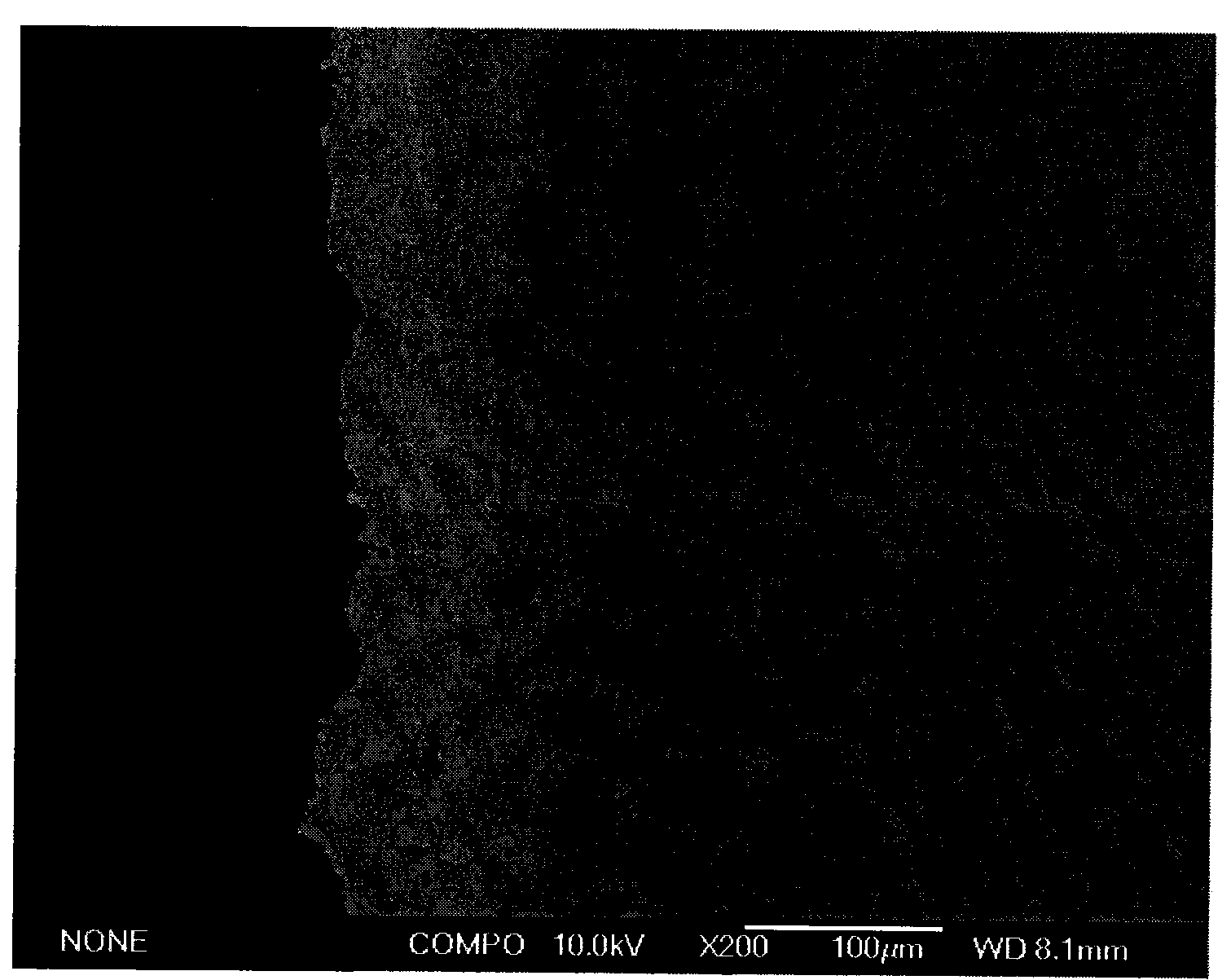

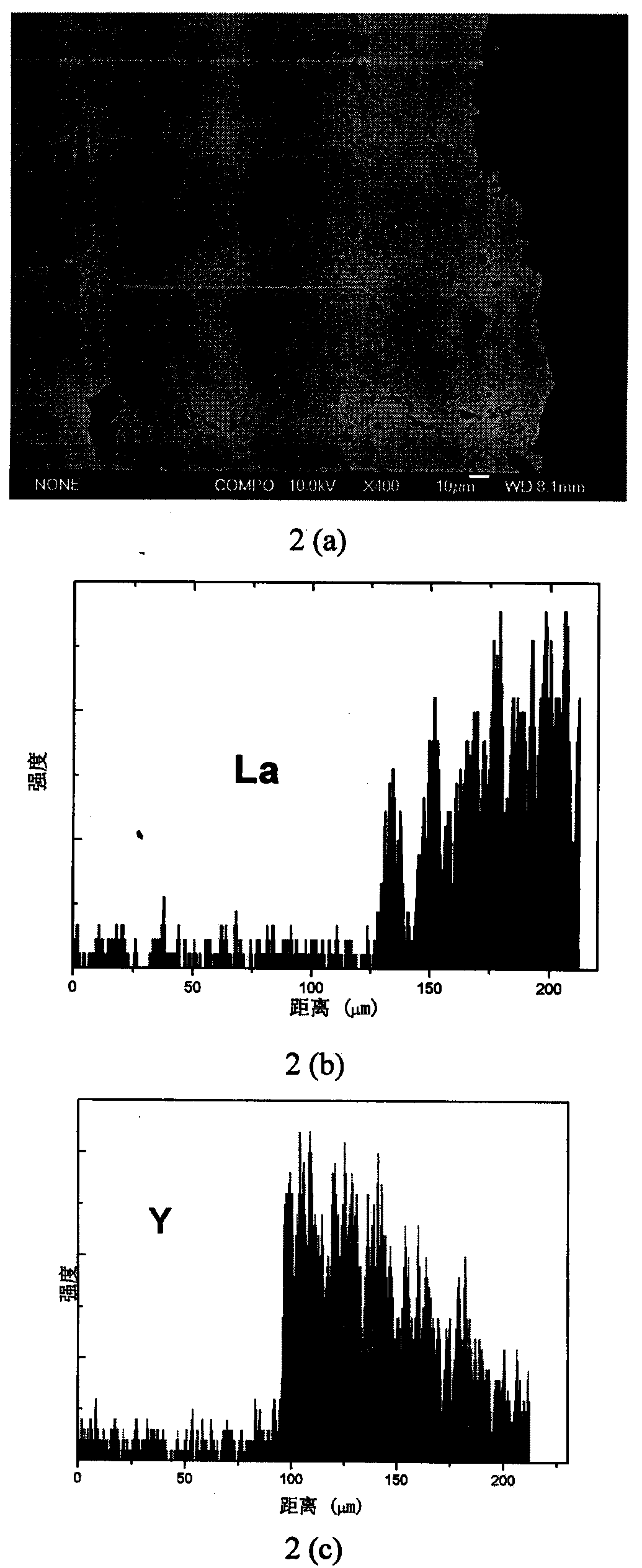

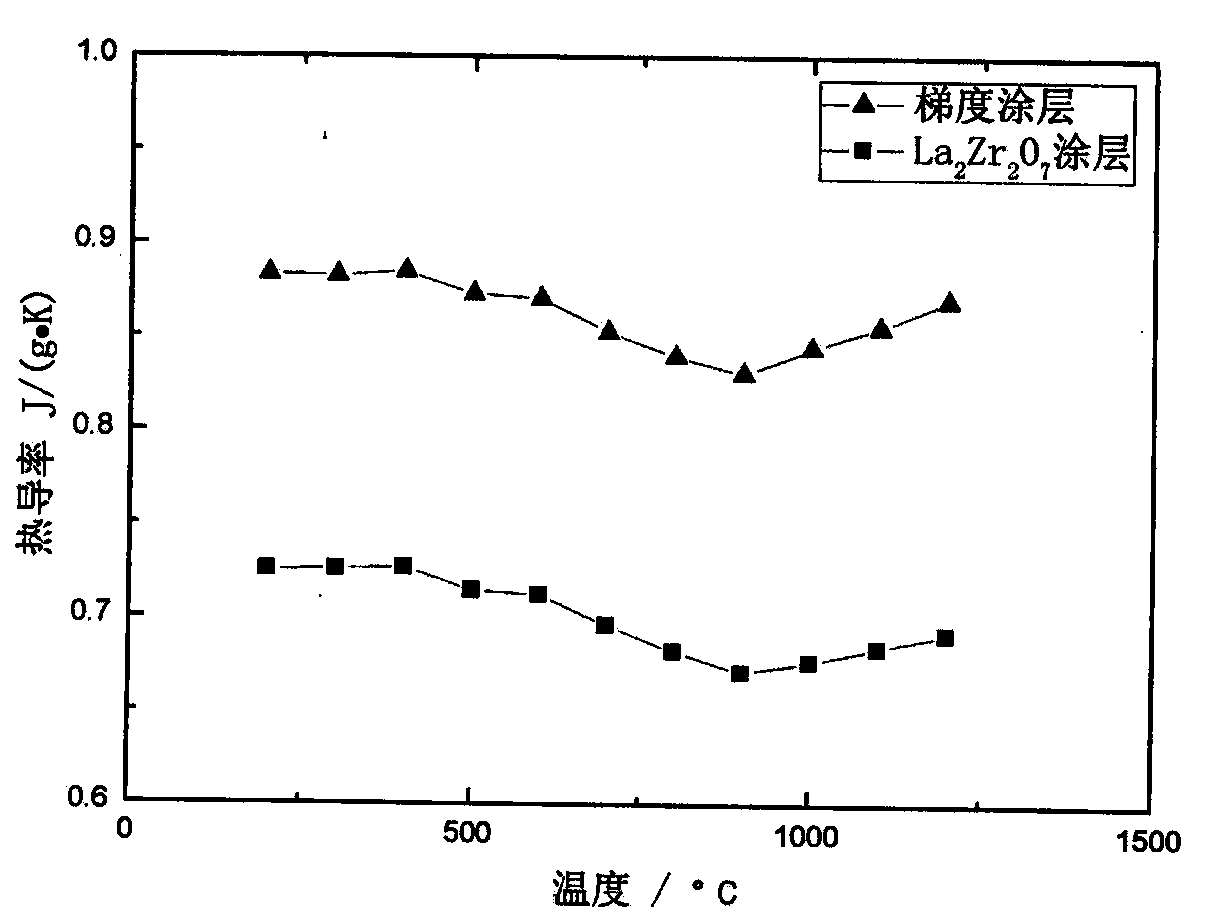

Thermal protection coating with component gradient change and preparation method

InactiveCN101768380AReduce heat stress concentrationImprove thermal shock resistanceMolten spray coatingRare-earth elementLanthanum aluminate

The invention belongs to the field of inorganic materials, particularly relates to a thermal protection coating with component gradient change and a preparation method. The thermal protection coating comprises two components of M1 and M2, wherein the M1 is selected from one of YSZ, lanthanum aluminate, mulite or BSAS, the M2 is selected from one of Ln2Zr2O7, Ln2Ce2O7, Ln2SiO5, Ln2Si2O7 or MoSi2, and Ln is selected from rare earth elements the atom coefficients of which are 57-71, Y or Sc. The thermal protection coating has the characteristics of good coating compactness, high bonding strength with a substrate, low thermal conductivity and the like and has favorable thermal shock resistance.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

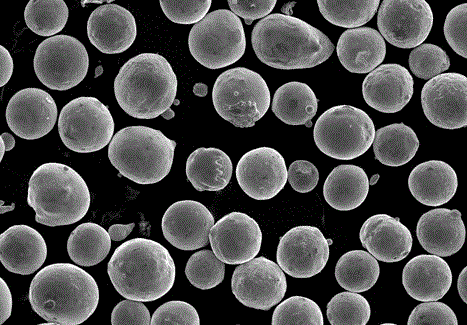

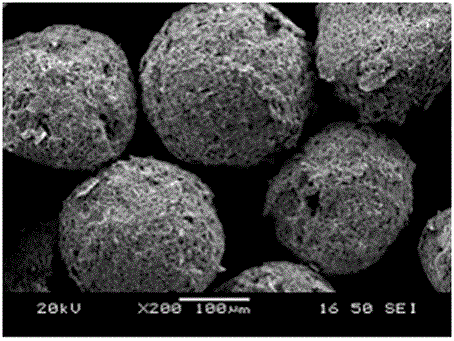

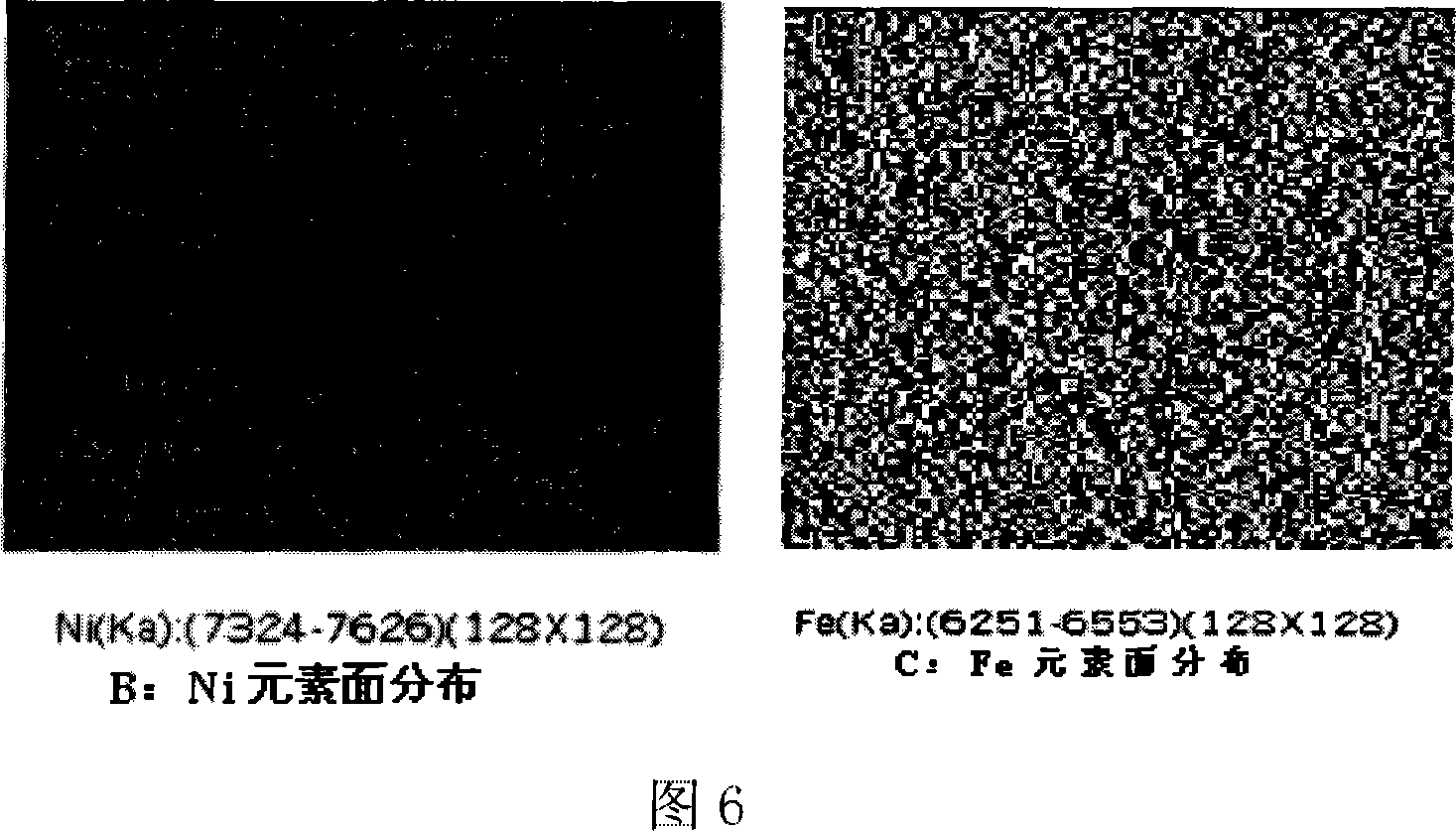

Spherical nickel-rhenium alloy powder and preparation method and application thereof

InactiveCN107008916AGood composition uniformitySpeed up evaporationTransportation and packagingMetal-working apparatusRheniumSpray Granulation

The invention discloses a preparation method of spherical nickel-rhenium alloy powder. The preparation method comprises the following steps that dissolving and mixing are carried out; reducing is carried out after atomizing or dynamic drying is carried out, and precursor powder is obtained; and reducing, slurry preparation, spray granulation and balling forming are carried out. According to the aim, the preparation method of the spherical nickel-rhenium alloy powder is provided, the problems that an existing low-rhenium alloy is uneven in ingredient, rhenium-containing elements can hardly be introduced into a base material, multicomponent ingredient controllability is poor, and the preparation process is complex are solved, a balling process is creatively used two times, and the spherical powder is obtained well and fast in a saving manner. The powder obtained through the method can be directly applied to wear-resisting anti-corrosive coatings, thermal spraying, 3D printing and powder metallurgy parts, and powder raw materials do not need to be additionally matched.

Owner:湖南元极新材料有限公司

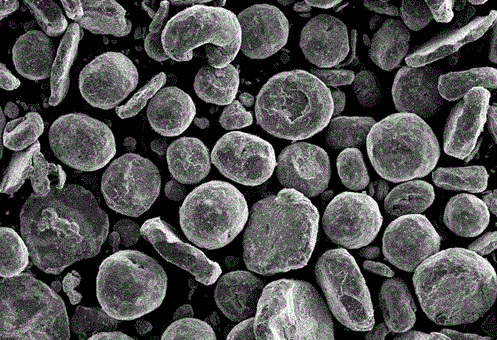

Preparation method for tin-coated copper composite powder

The invention relates to a preparation method for tin-coated copper composite powder. The composite powder comprises primary particles and secondary particles, wherein the primary particles mainly comprise copper powder; and the secondary particles mainly comprise small particle tin powder. The preparation method comprises the steps as follows: weighing a certain amount of the copper powder and the tin powder respectively; placing the weighed powder in a ball mill, and preprocessing for a period of time to prepare sheet powder; annealing the preprocessed powder under a protective atmosphere; and adding the annealed powder into spheroidizing equipment, and compounding and spheroidizing to prepare the tin-coated copper composite powder. According to the tin-coated copper composite powder, the copper powder can be uniformly coated with tin, the particle size of the powder is uniform, and the flowability is good. The preparation process is simple, the cost is lower, and the prepared oil bearing powder is good in flowability and easy to press.

Owner:JIANGSU YINGQIU GRP CO LTD

Preparation method of molybdenum titanium alloy material with high density, large size and high homogeneity

ActiveCN103740979AUniform microstructureSmall particle sizeVacuum evaporation coatingSputtering coatingSolventSpray nozzle

The invention discloses a preparation method of a molybdenum titanium alloy material with high density, large size and high homogeneity. The method comprises the following steps: 1) adding a solvent and a binder to Mo powder and Ti powder and grinding into slurry; 2) atomizing and pelletizing the slurry by using a spraying machine, wherein the inlet temperature is 250-300 DEG C, and the rotating speed of a spray nozzle is 8000-12000rpm, so as to obtain Mo-Ti composite powder; pressing the composite powder into blanks with regular sizes; 3) loading a plurality of blanks into a sheath, filling the Mo-Ti composite powder of 50-250 microns into the adjacent blanks to form a uniform composite powder layer, wherein the thickness of the composite powder layer is 0.5-1mm, and the condition that a gap between the inner wall of the sheath at any side and the outer wall of the adjacent blank is smaller than or equal to 0.5mm is ensured; and 4) welding and degassing the sheath and then carrying out hot isostatic pressing treatment at 750-900 DEG C and 120-160MPa and removing the sheath, wherein the heat-preserving and pressure-maintaining time is 4-6 hours. The target material fabricated by the method can be used as a cathode material of a magnetron sputtering technique.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

High-strength and high-toughness multi-element Al-Cu alloy and preparation method and application thereof

The invention discloses a preparation method of a high-strength and high-toughness multi-element Al-Cu alloy. The preparation method comprises the following steps: raw materials is heated into a molten state, spray forming process is carried out through spray forming equipment, so that the multi-element Al-Cu alloy is formed, and the multi-element Al-Cu alloy is composed of Al, Cu, Mn, Ni, V, Sc, impurity Si and Fe. According to the preparation method, the high-strength and high-toughness multi-element Al-Cu alloy material for a lightweight cartridge case is prepared through the proportion of the raw material components, based on the micro-alloying component design of a Al-Cu alloy system and by combining 3d spraying forming-rapid solidification technology; the high-strength high-toughness multi-element Al-Cu alloy material has the advantages that crystal grains are fine, the structure is uniform, and the high-strength and high-toughness performance is achieved; according to the structure and the performance of the multi-element Al-Cu alloy, a reasonable cartridge case preparation technology is selected so that the use requirements of various lightweight cartridge cases can be met, and the Al-Cu alloy material can also be applied to a shell and a launching component of a short-range, medium-range and even a remote missile; and the Al-Cu alloy material has huge economic benefits.

Owner:安徽建业科技有限公司

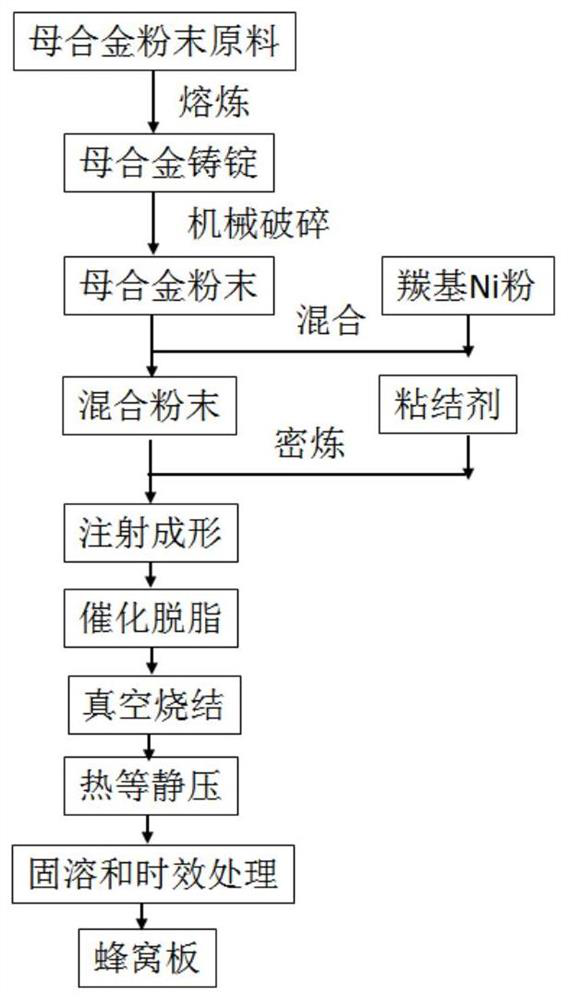

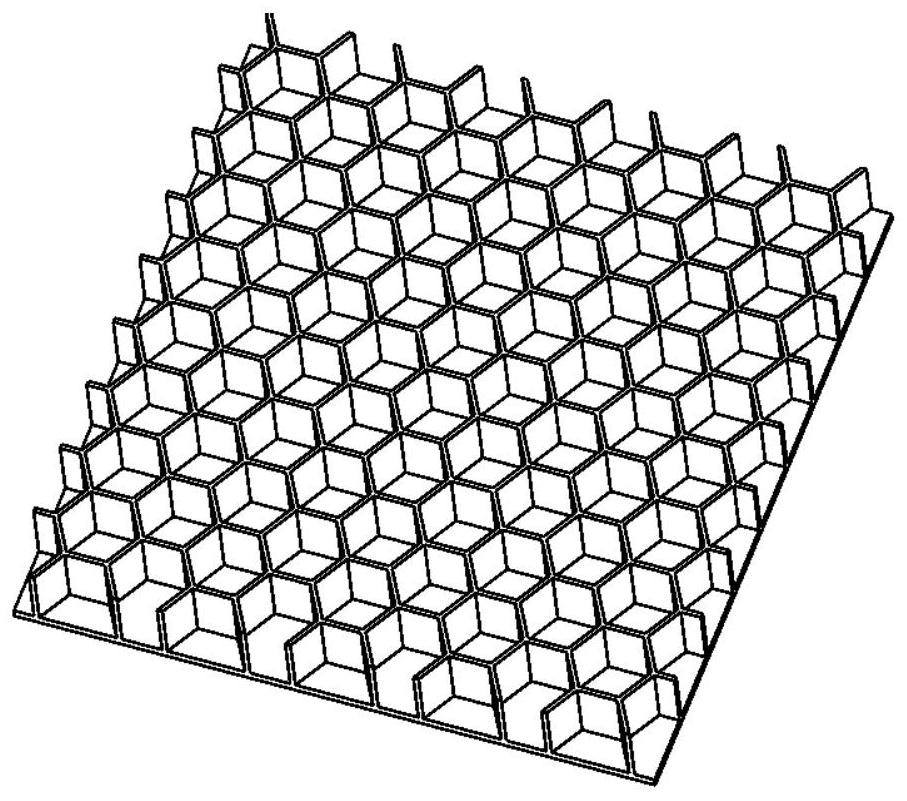

Method for preparing high-temperature alloy honeycomb insulation board based on injection forming

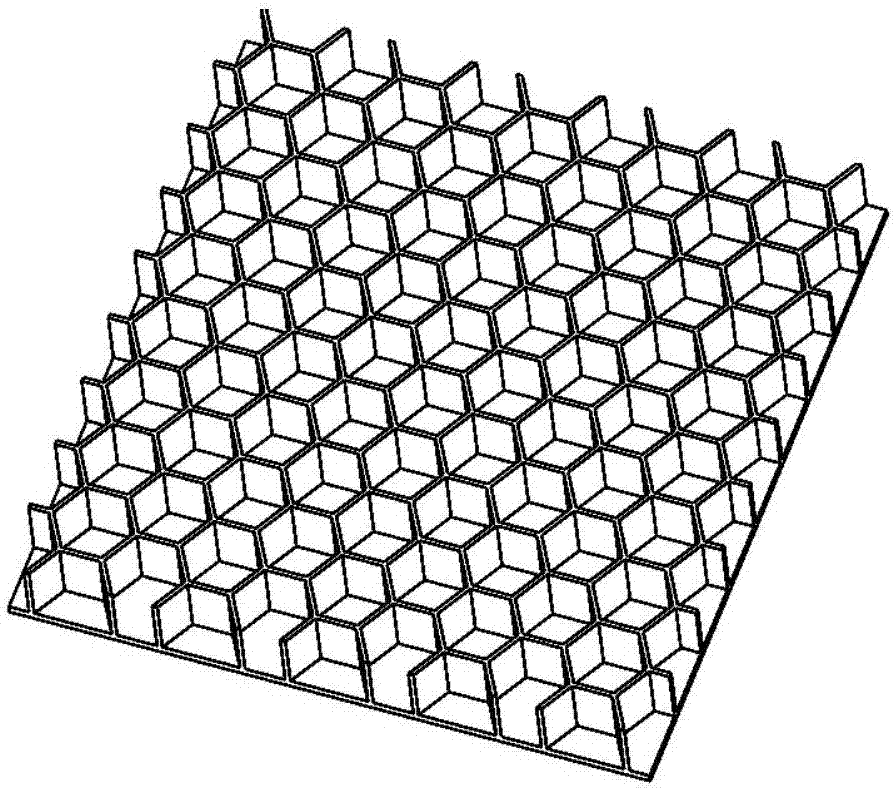

ActiveCN107999756AImprove mechanical propertiesLow costTransportation and packagingMetal-working apparatusHoneycombSuperalloy

The invention relates to the technical field of metal injection forming, and particularly relates to a method for preparing a high-temperature alloy honeycomb insulation board based on injection forming. The method comprises the steps of S1, preparation of mother alloy powder, S2, feeding and pelleting, S3, injection forming, S4, degreasing, S5, sintering, S6, hot isostatic pressing, S7, solid solution and aging treatment and other steps. By adopting the method for preparing the high-temperature alloy honeycomb insulation board, the defects that traditional brazing processes are complex in machining process, high in manufacturing cost and low in size precision can be effectively overcome, and the comprehensive mechanical properties of the prepared high-temperature alloy honeycomb insulation board are better than those of honeycomb boards prepared through brazing methods.

Owner:SHENZHEN ELEMENT TECH CO LTD

Preparation method of oxide dispersion strengthened (ODS) titanium and titanium alloy

The invention discloses a preparation method of oxide dispersion strengthened (ODS) titanium and titanium alloy, and belongs to the field of powder metallurgy titanium. Calcium-aluminum alloy (CaAl) powder and titanium powder are mixed in proportion, then cold isostatic pressing forming and vacuum pressureless sintering are conducted, and oxide dispersion strengthened titanium and titanium alloy are obtained. The preparation method has the advantages that Ca and Al elements are introduced into the titanium alloy by adding CaAl alloy powder, Ca is uniformly distributed in a matrix, and dispersedly distributed fine Ca-Ti-O oxide second-phase particles are generated in situ in the sintering process, and meanwhile, the Al element is subjected to solid solution in the titanium matrix to form aTiAl solid solution, so that the mechanical property of the titanium alloy is greatly improved. The method is a new thought for improving oxygen control and performance regulation and control of preparation of high-performance titanium and titanium alloy, the requirement for the oxygen content of titanium and titanium alloy powder raw materials is lowered, and the method has the advantages of being low in cost, simple in process, easy to operate, suitable for industrial production and the like.

Owner:UNIV OF SCI & TECH BEIJING

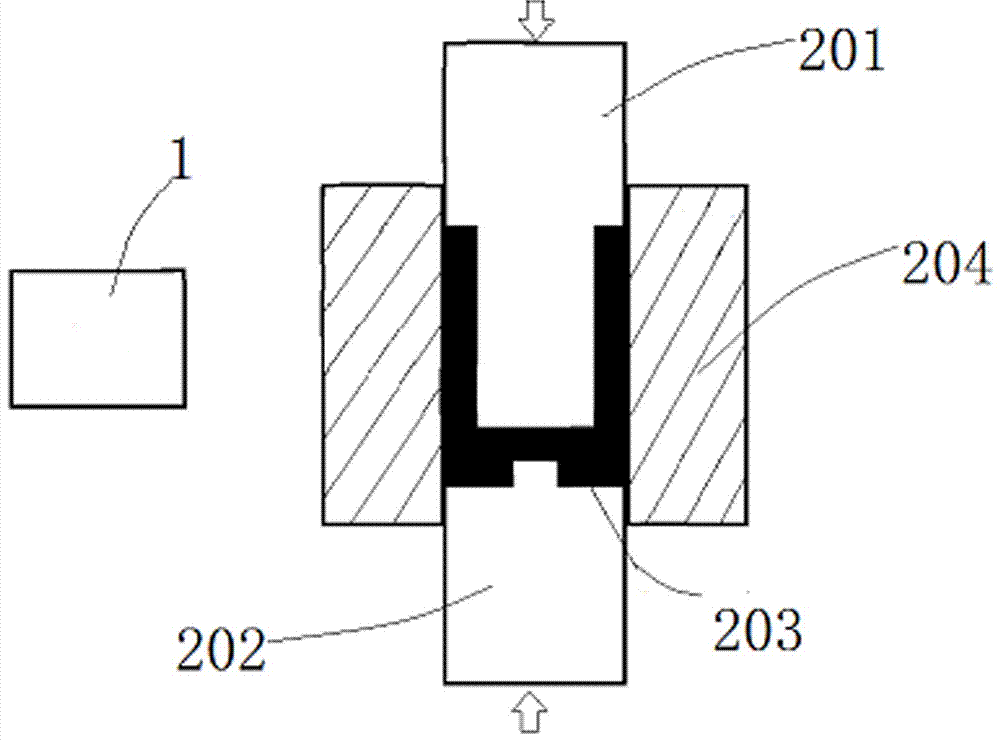

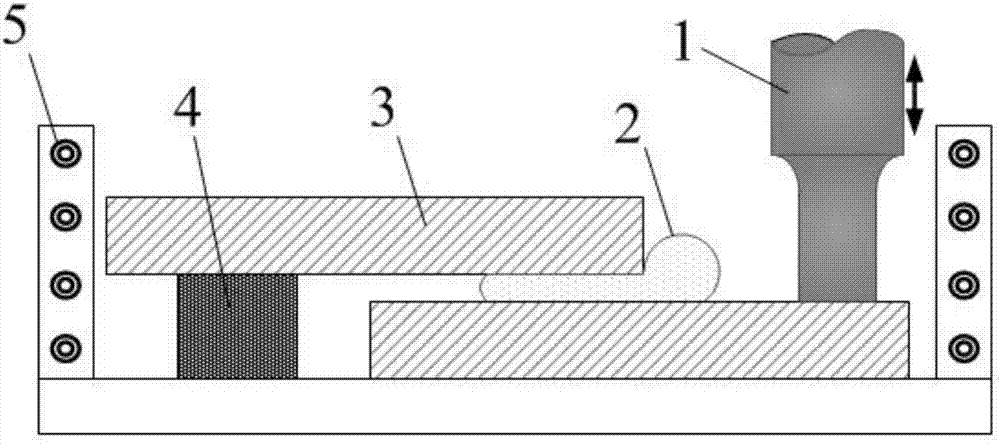

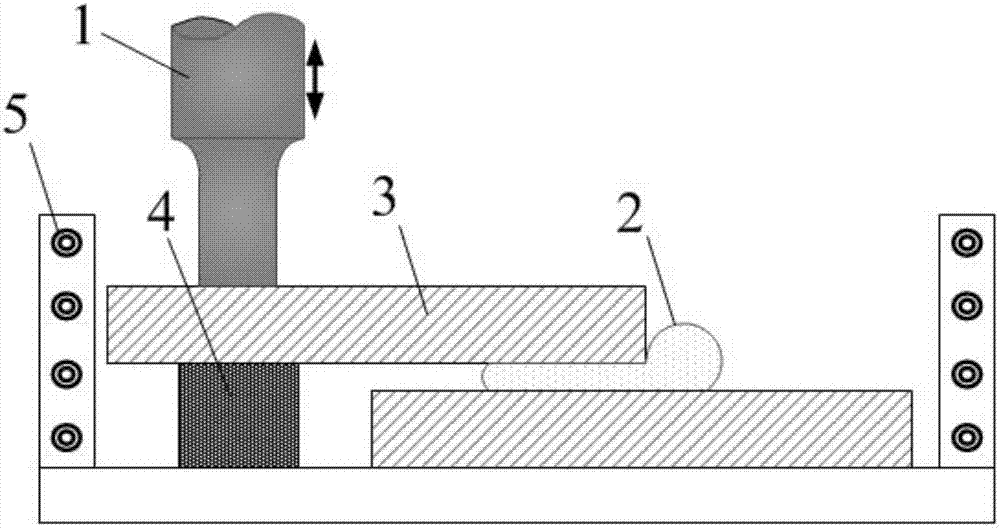

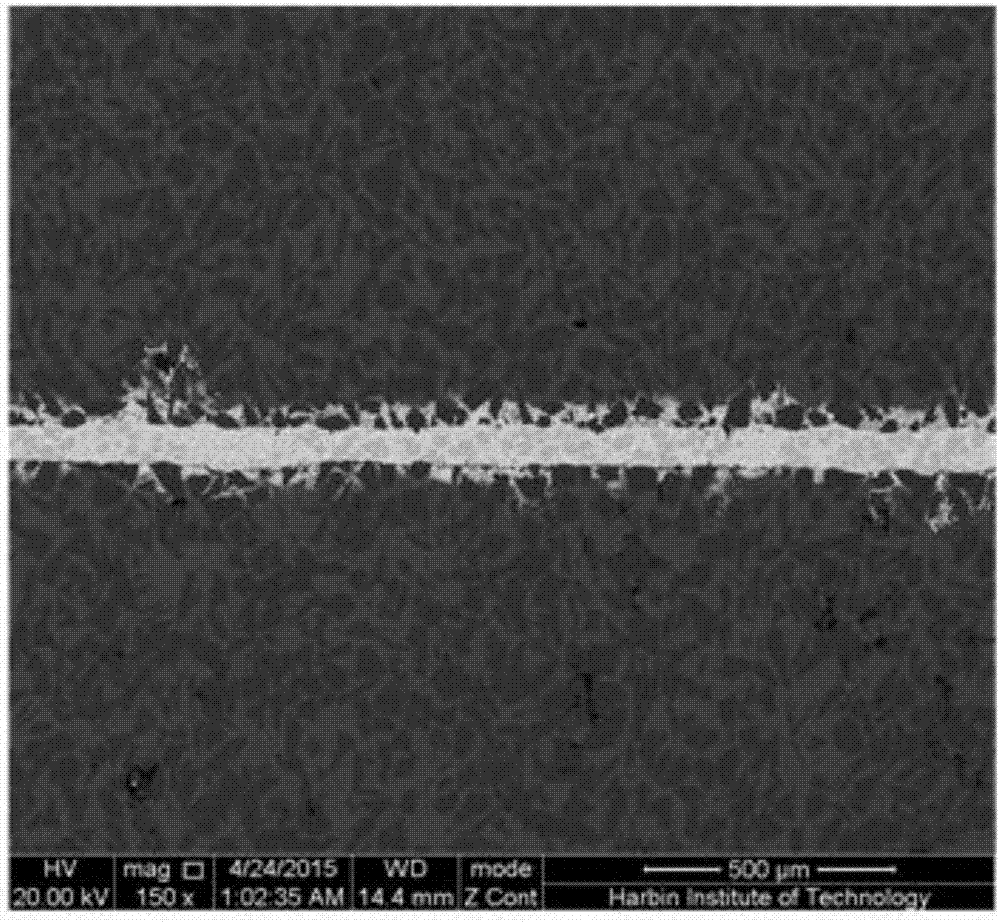

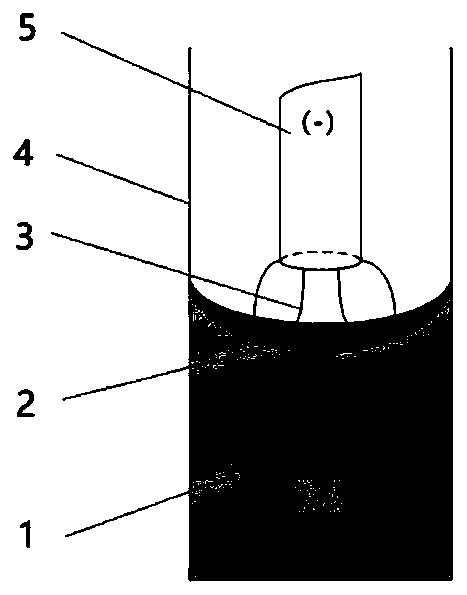

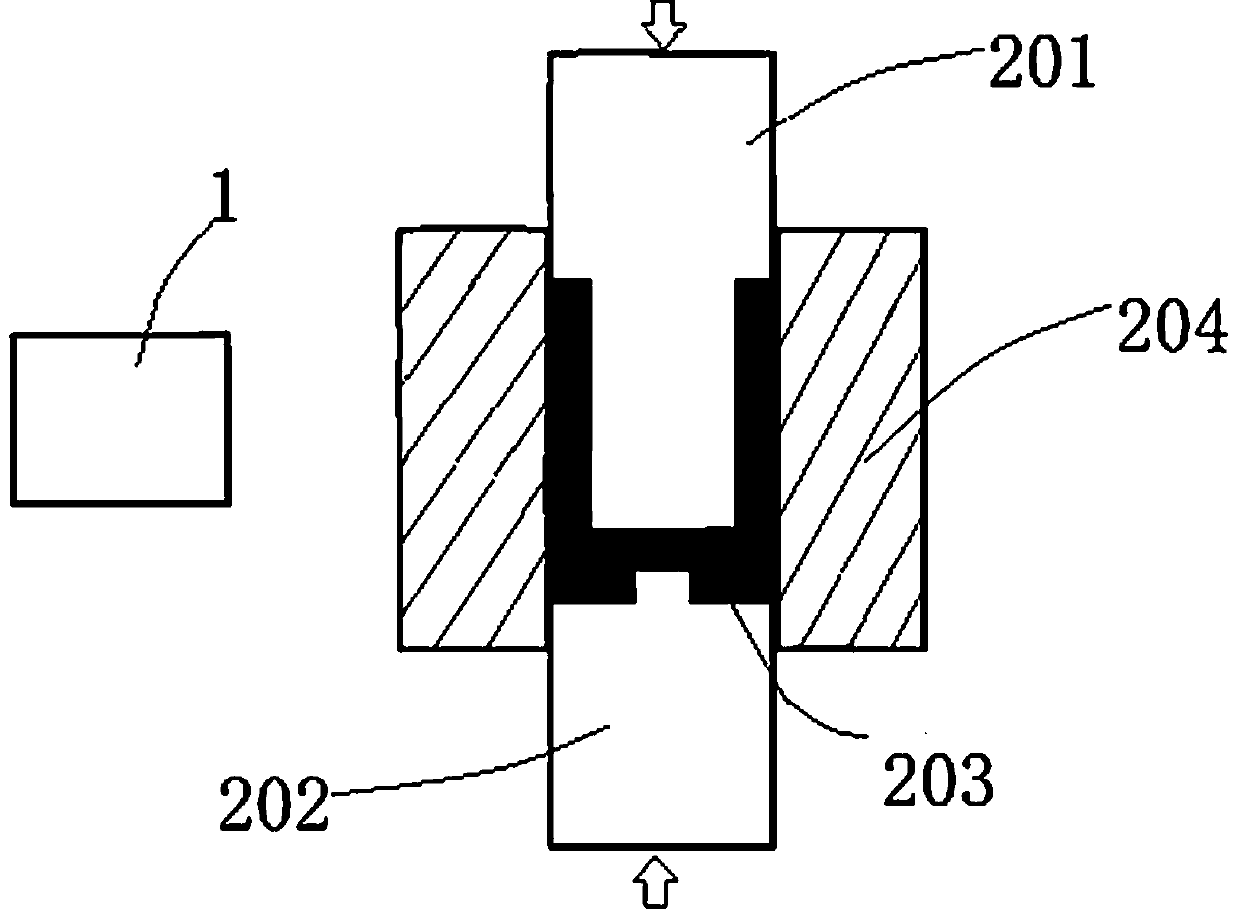

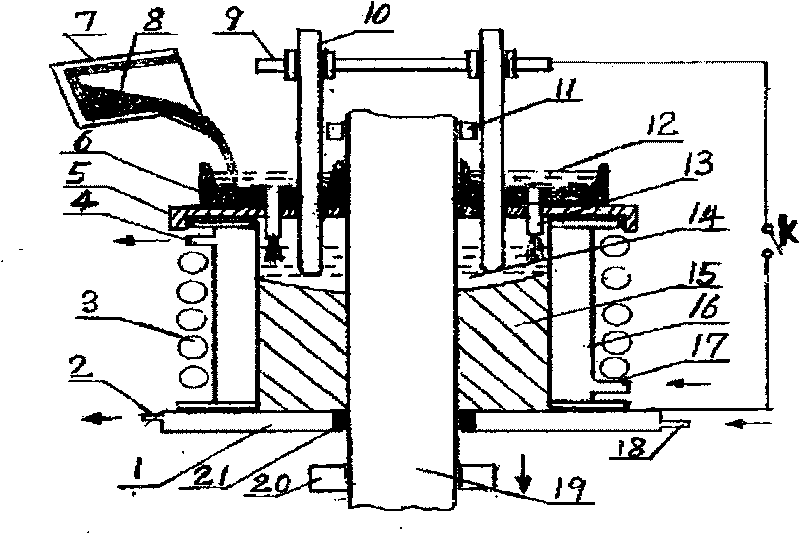

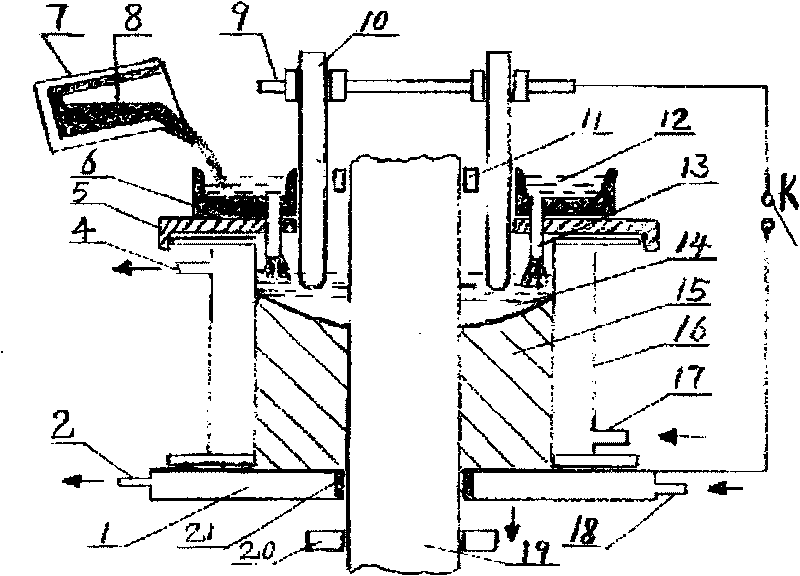

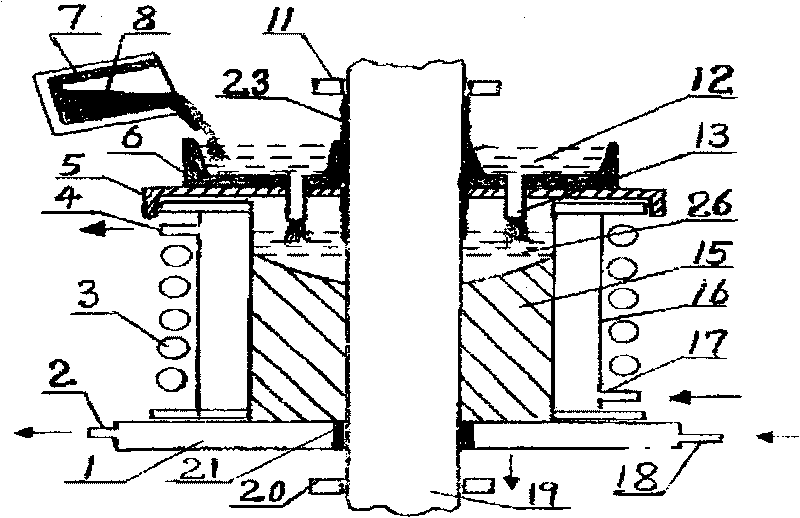

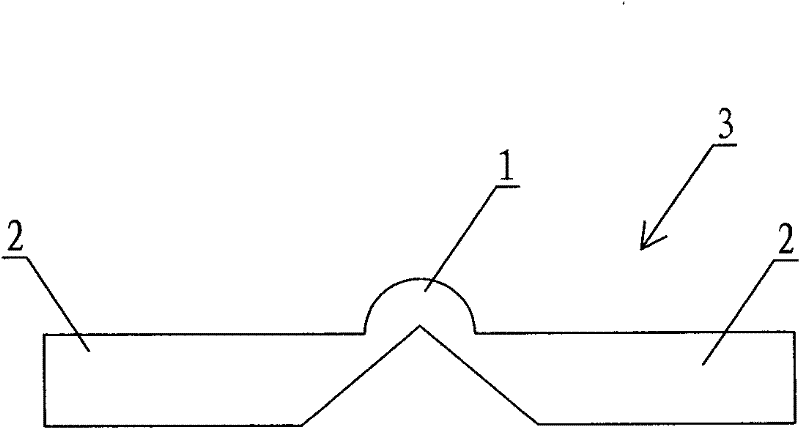

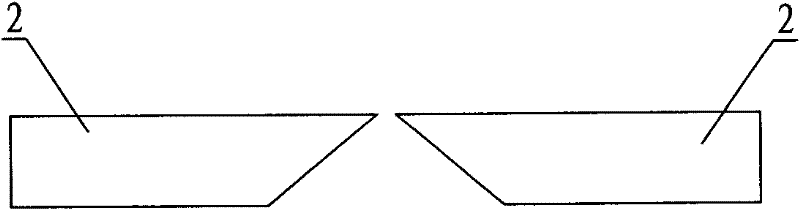

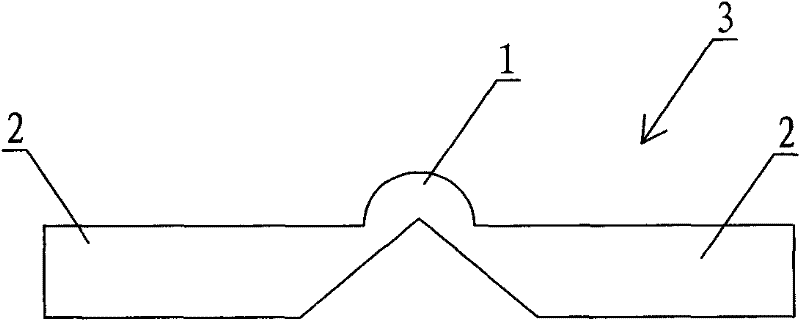

Method for improving strength of soldered seams on basis of thin-melt ultrasonic fine crystallization treatment in narrow gaps

ActiveCN107096974AEnhanced ultrasonic acoustic cavitation effectSolve the problem that the ultrasonic energy distribution is not uniform enoughSoldering auxillary devicesMaterials scienceAluminum matrix composites

The invention provides a method for improving strength of soldered seams on the basis of thin-melt ultrasonic fine crystallization treatment in narrow gaps, and relates to the technical field of material welding. The invention aims at solving the problems that for an existing soldering connection method, due to the fact that the welding cycle is long and the welding temperature is high, soldered seam metal is large in crystal size and nonuniform in texture, and the soldered seams are low in strength. The method comprises the steps that 1, soldering materials and parent metal are assembled into a to-be-soldered part, and parent metal lapping gaps are adjusted and controlled; 2, preliminary soldering is conducted; and 3, thin-melt ultrasonic fine crystallization treatment is conducted. After soldering is conducted through the method, the crystal size of the soldered seams is obviously refined, and toughness of the soldered seams is greatly improved. According to the method, the technology is simple, the operation cost is low, fine crystal strengthening of the soldered seams of aluminum-alloy, copper-alloy, magnesium-alloy and aluminum-matrix composite materials and ceramic and ceramic-matrix composite materials can be achieved, and the method can be used for the engineering application field of complex structural components.

Owner:HARBIN INST OF TECH

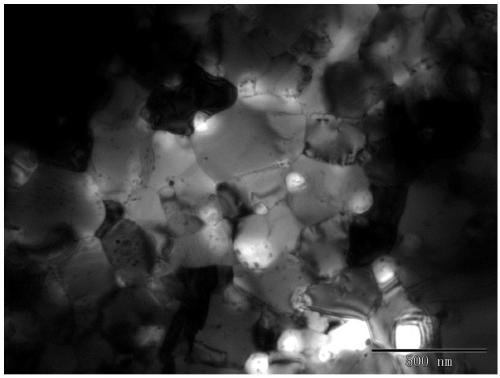

Preparation method of high-strength iron-cobalt-nickel alloy

The invention provides a preparation method of a high-strength iron-cobalt-nickel alloy and relates to the field of preparation of a high-strength alloy material. The preparation method comprises thesteps of firstly, weighing iron powder, cobalt powder and nickel powder according to a certain mass ratio; secondly, mixing the above powder and conducting ball milling under inert gas shielding to realize alloying; thirdly, conducting sintering molding on the alloyed powder through spark plasma sintering or hot isostatic sintering and conducting hot rolling or hot extrusion on sintered samples; and finally, removing stress through heat treatment and homogenizing the structure to obtain the high-strength iron-cobalt-nickel alloy. The iron-cobalt-nickel alloy prepared through the method is uniform in structure, has the average grain diameter being about 300 nm and the strength higher than 700 Mpa and is superior to an iron-cobalt-nickel alloy prepared through a smelting method.

Owner:UNIV OF SCI & TECH BEIJING

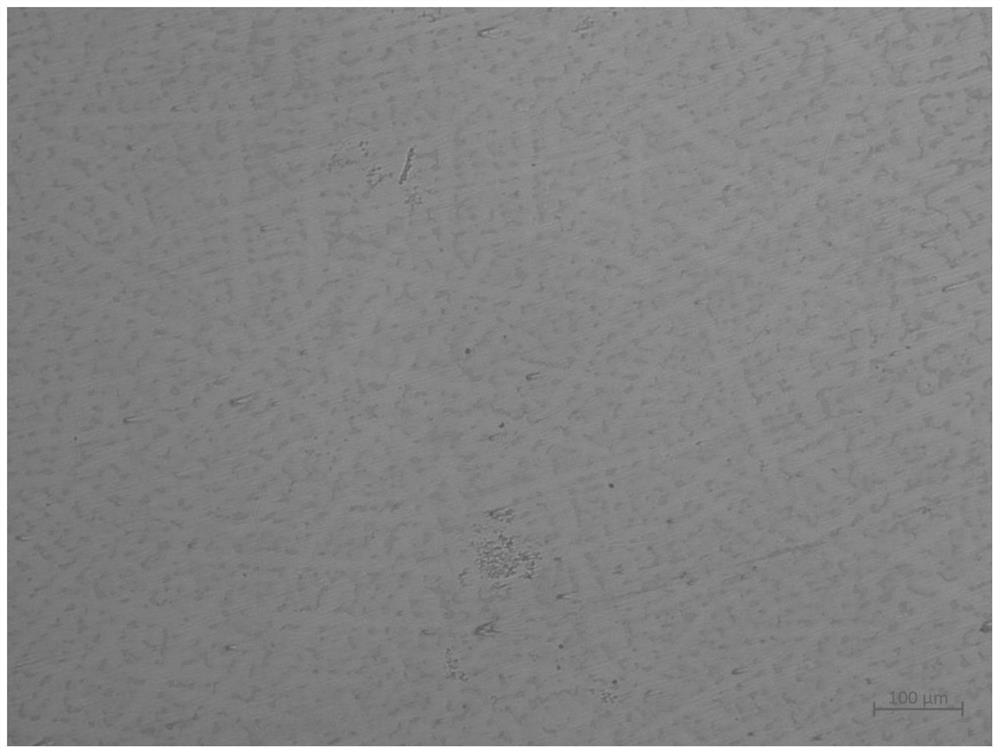

Preparation method of Ti-25Nb alloy sheet

The invention provides a preparation method of a Ti-25Nb alloy sheet, which comprises the following steps: 1. carrying out vacuum consumable arc-melting on raw materials sponge titanium and Ti-47Nb interalloy to obtain a Ti-25Nb alloy cast ingot; 2. carrying out cogging and forging; 3. forging a sheet blank; 4. carrying out hot rolling; 5. sequentially carrying out quenching, shot blasting and pickling treatment; and 6. carrying out cold rolling to obtain the Ti-25Nb alloy sheet of which the thickness is 0.3-1mm. The Ti-25Nb alloy sheet prepared by the method provided by the invention has the advantages of no inclusion, no composition segregation, more uniform structural composition, high flatness, smooth surface and no defects, such as cracking, peeling, stratifying, folding and the like.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Preparation method for smelting copper-titanium series alloy material by adopting vacuum self-consuming electric arc

The invention discloses a preparation method for smelting a copper-titanium series alloy material by adopting vacuum self-consuming electric arc, and relates to the technical field of copper-titanium alloy preparation. The preparation method comprises the following steps of, S1, raw material proportioning, specifically, the material comprises the following components of, in percentage by mass: 0.5-99.5% of copper powder and 99.5-0.5% of sponge titanium; s2, mixing the raw materials, specifically, weighing the required raw materials according to the proportion, and mixing the raw materials in a mixer; s3, pressing, specifically, putting the mixture into a mold for powder upsetting, and putting the mold subjected to powder upsetting into a cold isostatic press for blank pressing; s4, sintering: putting the pressed green body into a vacuum sintering furnace for sintering; and S5, smelting, specifically, taking the sintered blank as a consumable electrode to be loaded into a vacuum consumable electric arc smelting furnace to be smelted. The alloy material prepared through the method has the advantages of being low in gas content, few in inclusion, uniform in structure and free of copper, titanium enrichment and other microdefects.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Preparation method of prealloying powder

The invention discloses a preparation method of prealloying powder, which belongs to the technical field of prealloying power preparation. The method comprises the following steps of: uniformly mixing powder comprising two or more than two components; applying a current; taking powder as a heating element, and heating the powder; bonding the powder with different components; preparing to be massive prealloying power; crushing and sieving; and preparing to be the prealloying powder. According to the method, the powder is used as a heating element to be heated directly, so that the heat efficiency is greatly improved, compared with a high temperature furnace, the diffusion technology is reduced by 5-70 percent, and the production efficiency is high.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

Liquid forging process for main reduction gear used for automobile transmission

InactiveCN106086619AImprove corrosion resistanceImprove forging efficiencyFoundry mouldsSolid state diffusion coatingHardnessAutomotive transmission

The invention provides a liquid forging process for a main reduction gear of an automobile transmission. The process comprises the steps of (1) smelting; (2) mould designing; (3) liquid forging; (4) normalizing; (5) turning; (6) carburizing and quenching; (7) tempering; (8) grinding; (9) shot blasting and flaw detecting; and (10) phosphorus saponification treatment, cleaning, polishing and anti-rust oil coating. According to the process, the liquid forging method is adopted for conducting gear machining and forging, labor and energy are saved, the material utilizing ratio is high, a blank is approximate to a final machined gear of the main reduction gear, the forging quality is high, the obtained gear hardness is high, the abrasion resistance is good, the corrosion resistance is high, the forging cost is low, and the forging process is environmentally friendly.

Owner:JIANGSU BAOJIE FORGING

Ni-Cr-based alloy welding wire and preparation method thereof

InactiveCN110153590AIncrease melting rateEvenly dispersedWelding/cutting media/materialsSoldering mediaWeld seamAlloy

The invention relates to a Ni-Cr-based alloy welding wire and a preparation method thereof. The welding wire consists of the following components in percentage by weight: 30-80wt% of Ni, 5-40wt% of Cr, one or more of 0-35wt% of Al, Cu, Fe, Mn, Co, Ti, Zr and Hf and one or two or three of 0-8wt% of B, C and O. The welding wire preparation process comprises the following steps: mixing, link blank extrusion-forming and degreasing-sintering, wherein the diameter of the extruded welding wire is smaller than or equal to 2 mm. The prepared alloy welding wire is great in component range, and is suitable for multi-variety small-batch production. Compared with a wire obtained by a conventional drawing method, the prepared alloy welding wire is better in structure component consistency, is free of component segregation, is free of processing hardening, is high in yield, has a welding melting point lower than that of a welding wire produced by a drawing method by 100-200 DEG C, is high in weldingstrength; and after being polished, a welding seam is attractive and uniform, and is good in associativity with a base material.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Hafnium lead titanate-based anti-ferroelectric ceramic material and preparation method thereof

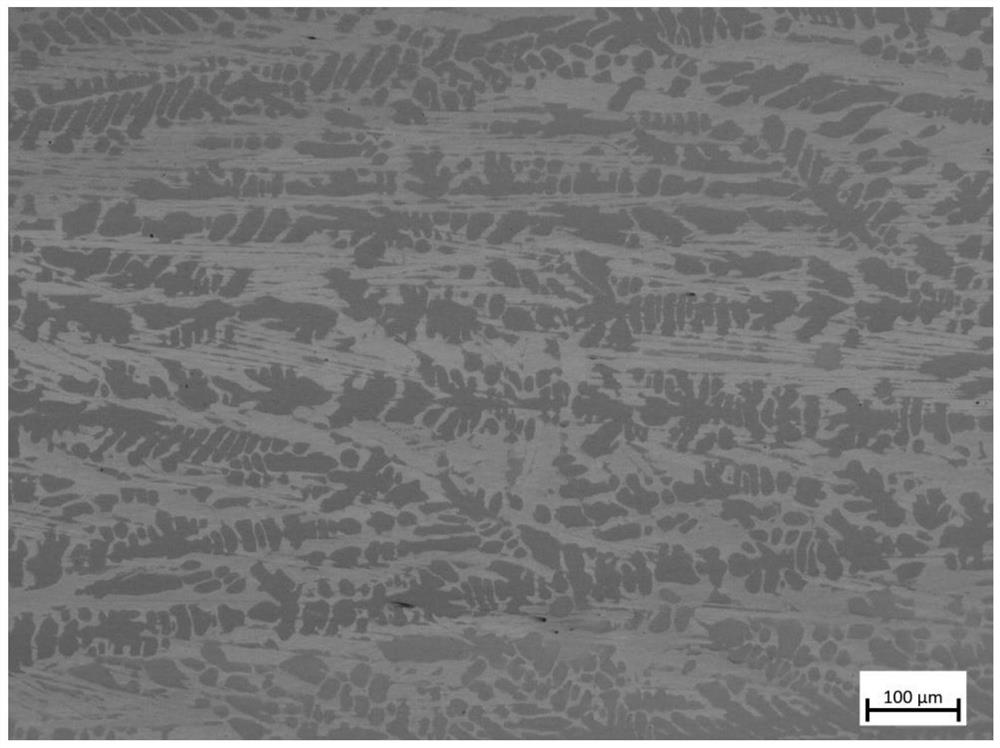

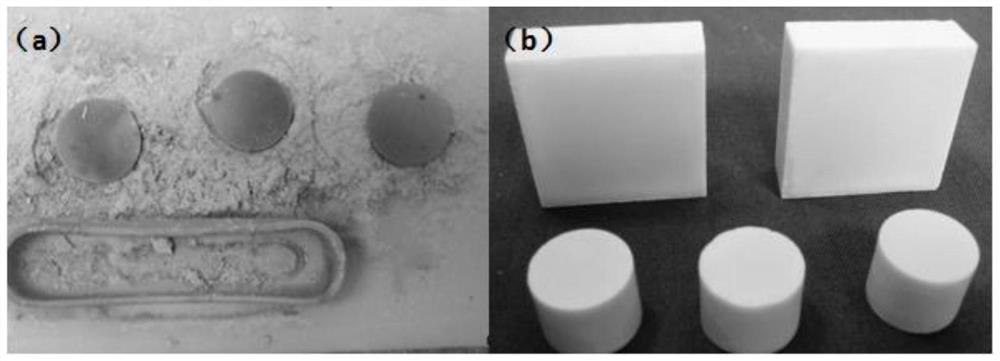

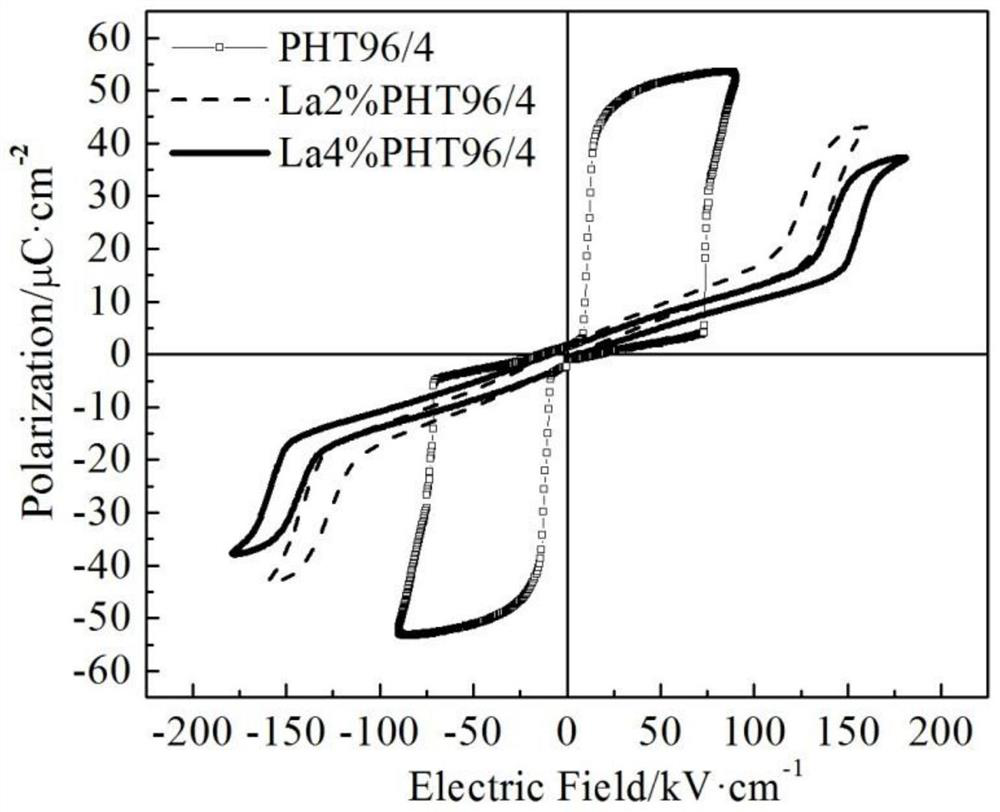

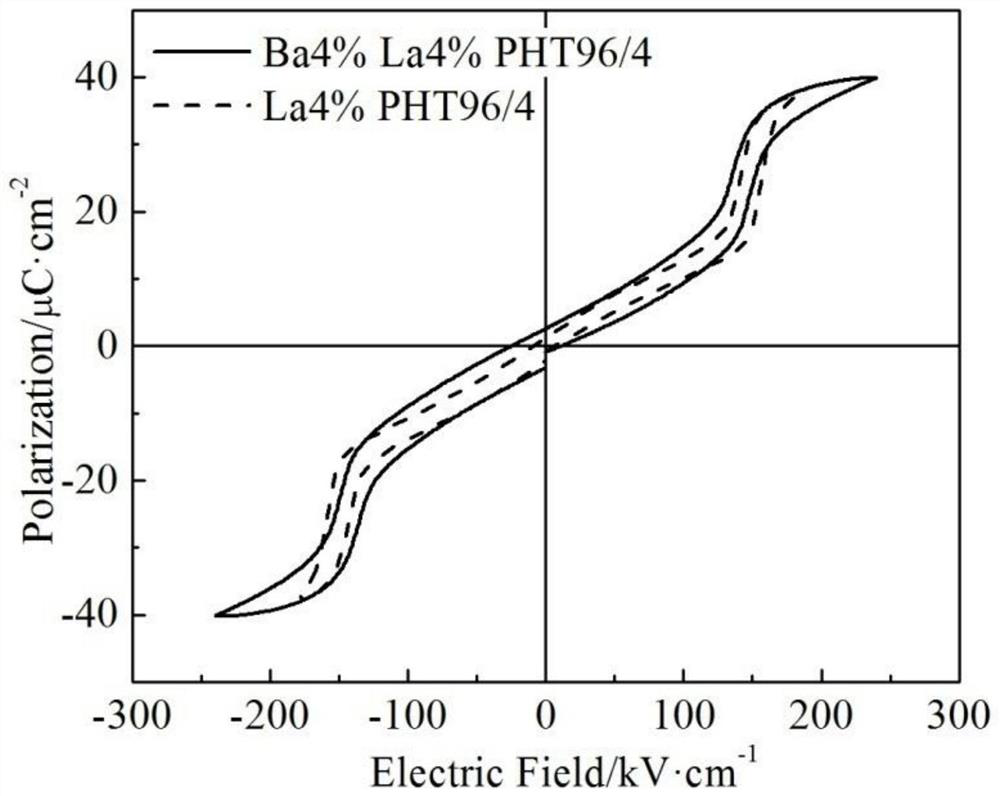

A hafnium lead titanate-based anti-ferroelectric ceramic material is characterized in that lead (Pb) in hafnium lead titanate is partially replaced by metal element lanthanum A (La), hafnium (Hf) is partially replaced by tin (Sn), then lead is partially replaced by element B, the chemical formula of the material is [(Pb[1-w]B[w])[1-3z / 2]La[z]][(Hf[1-y]Sn[y])[1-x]Ti[x]]O[3], wherein B is at least one of barium (Ba) and strontium (Sr). The prepared hafnium lead titanate-based anti-ferroelectric ceramic block material has the advantages of compact microstructure, few defects, uniform component distribution, no component segregation, excellent energy storage density (up to 5 J / cm<3>), discharge pulse power (up to 1 MW / cm<3>), high breakdown electric field (up to 250-300 kV / cm), small dielectric loss and stable material performance.

Owner:CHONGQING UNIV OF ARTS & SCI

Preparation method of copper-niobium superconducting composite material

PendingCN111041250AUniform compositionNo component segregationSuperconductors/hyperconductorsSuperconductor devicesElectric arc furnaceNiobium

The invention discloses a preparation method of a copper-niobium superconducting composite material. The method comprises the following steps that (1), copper powder and niobium powder are uniformly mixed; (2), the uniformly mixed copper-niobium powder is poured into a mold, then a copper-niobium consumable electrode bar is pressed on a press machine; (3) the pressed copper-niobium consumable electrode bar is loaded into a vacuum sintering furnace, sintering is carried out, a copper-niobium consumable electrode is obtained; and (4) the copper-niobium consumable electrode is welded on an auxiliary electrode in protective gas, smelting in a vacuum arc furnace is carried out, and the copper-niobium superconducting composite material is obtained. According to the preparation method of the copper-niobium superconducting composite material, the copper-niobium superconducting composite material is uniform in component, free of the component segregation phenomenon and free of generated inclusions.

Owner:JIANGSU UNIV OF SCI & TECH

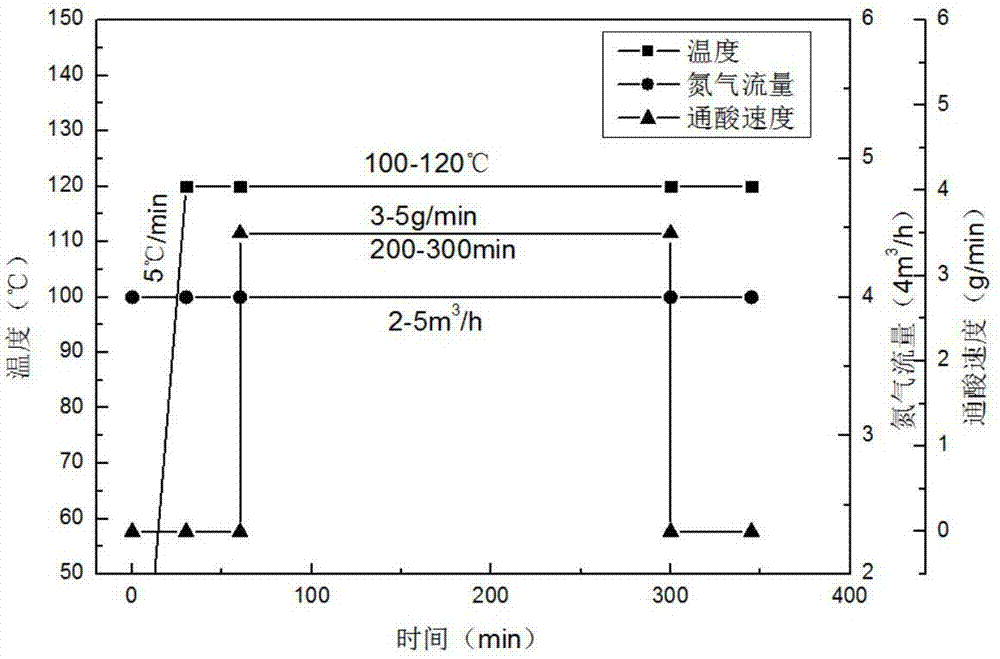

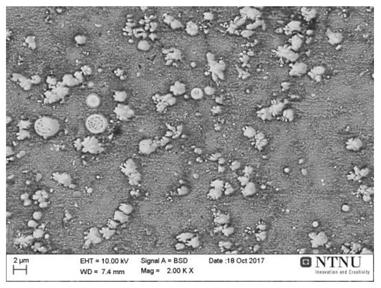

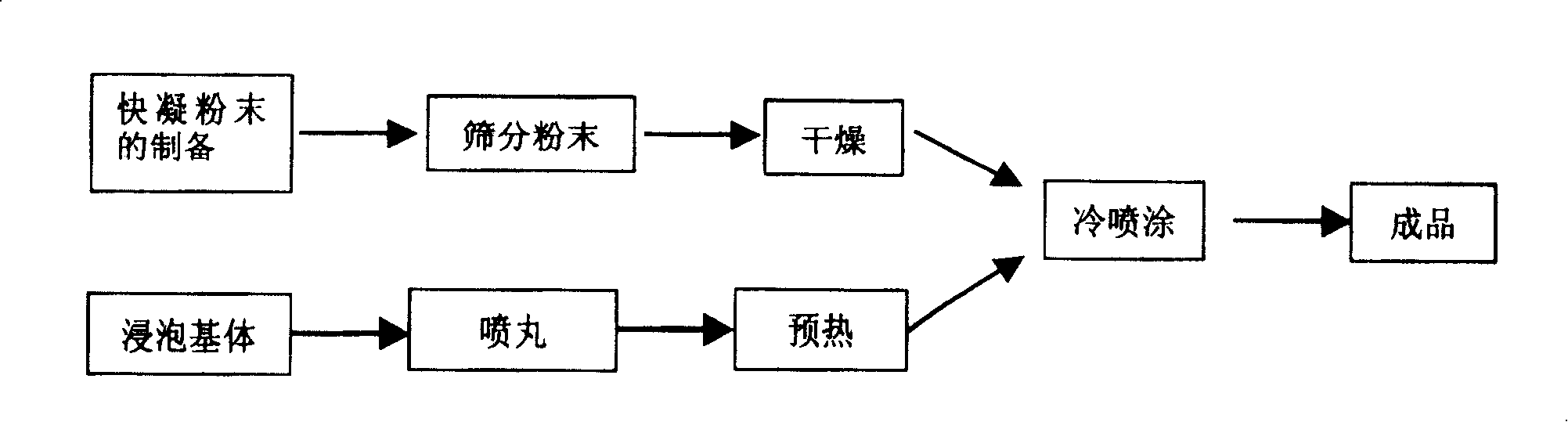

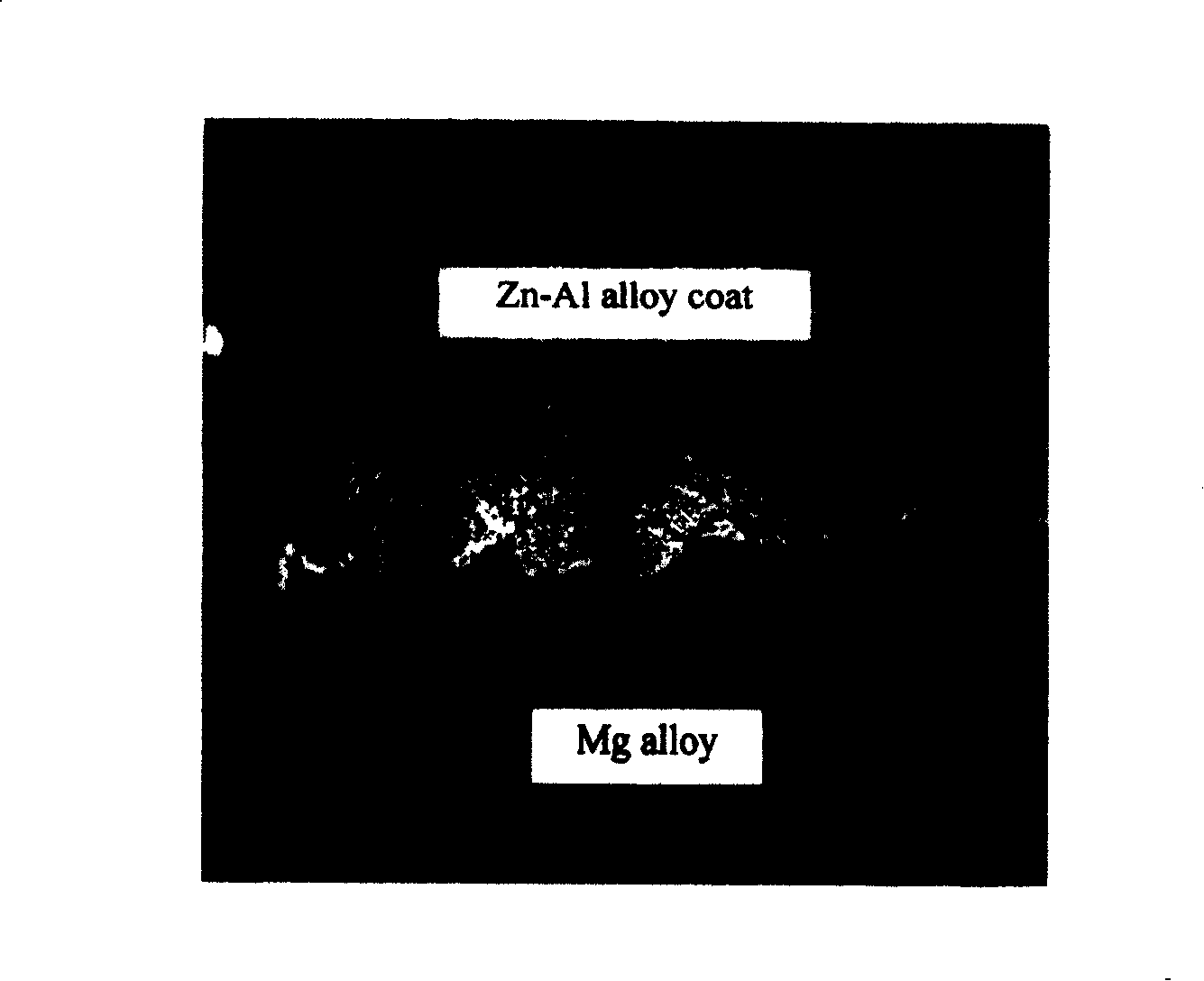

Spray coating technology of magnesium alloy surface protective layer

InactiveCN100406614CStrong anti-corrosion and wear resistancePerformance unchangedHeat inorganic powder coatingSpray coatingZinc

Owner:SHENYANG POLYTECHNIC UNIV

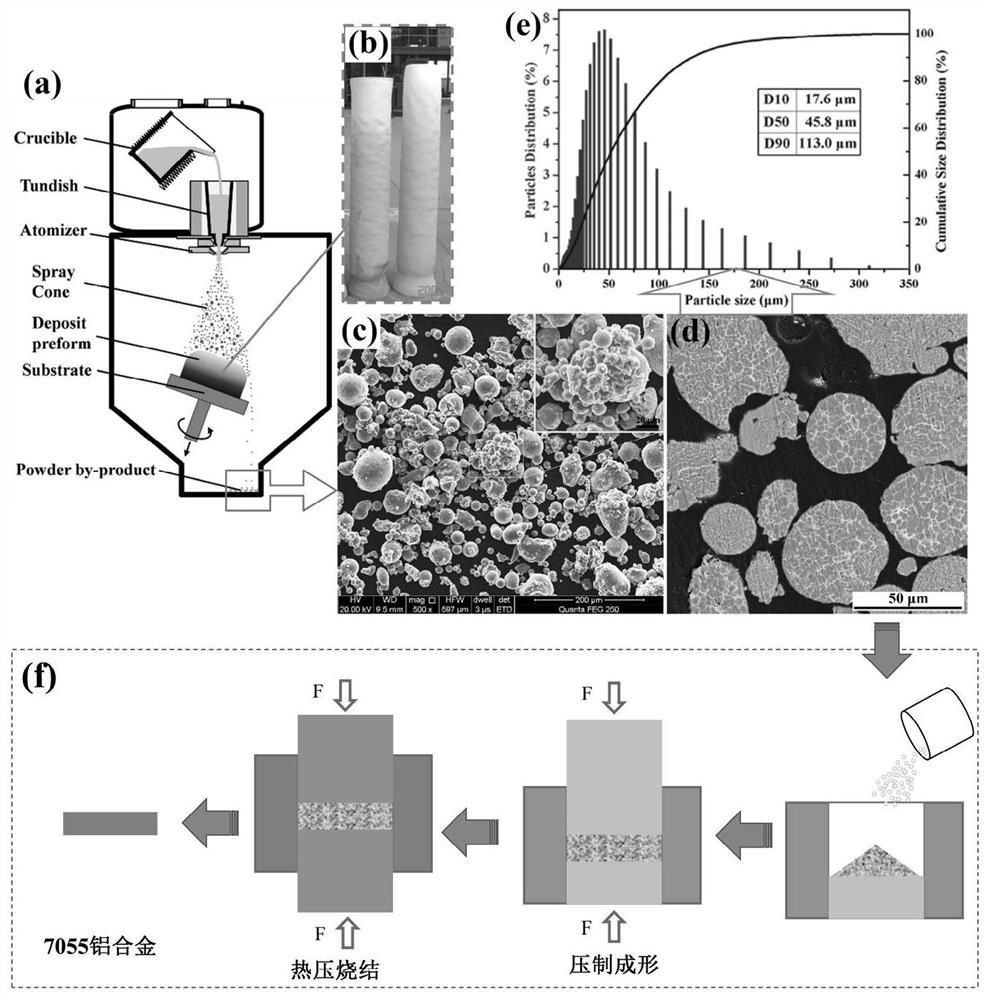

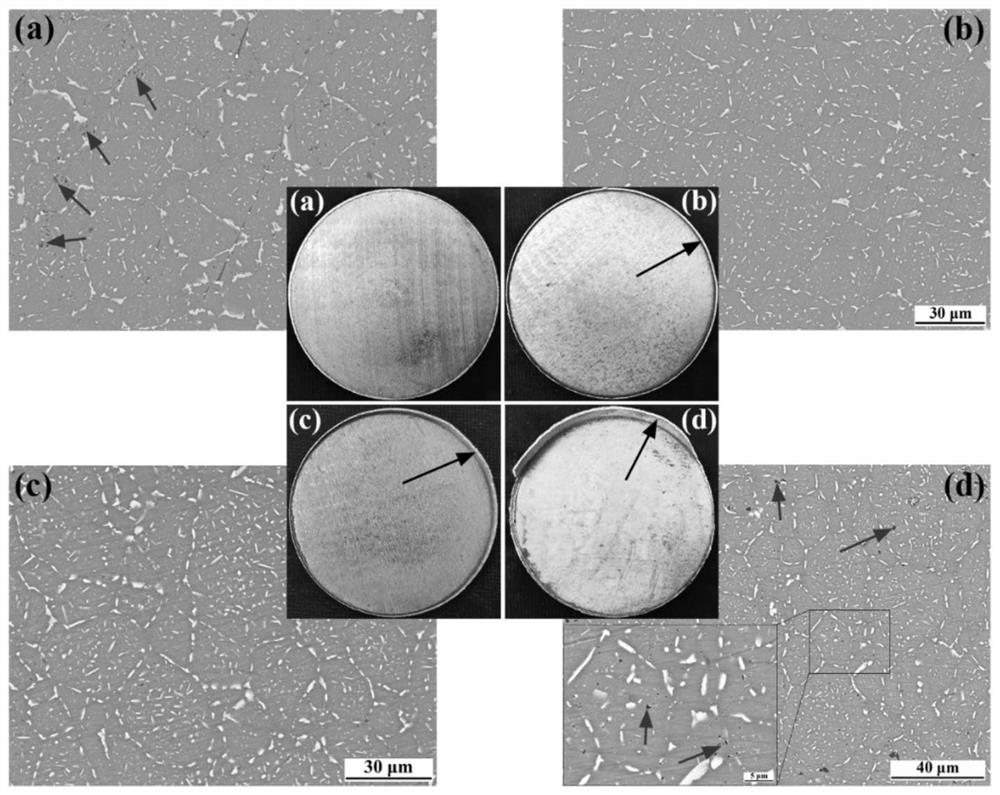

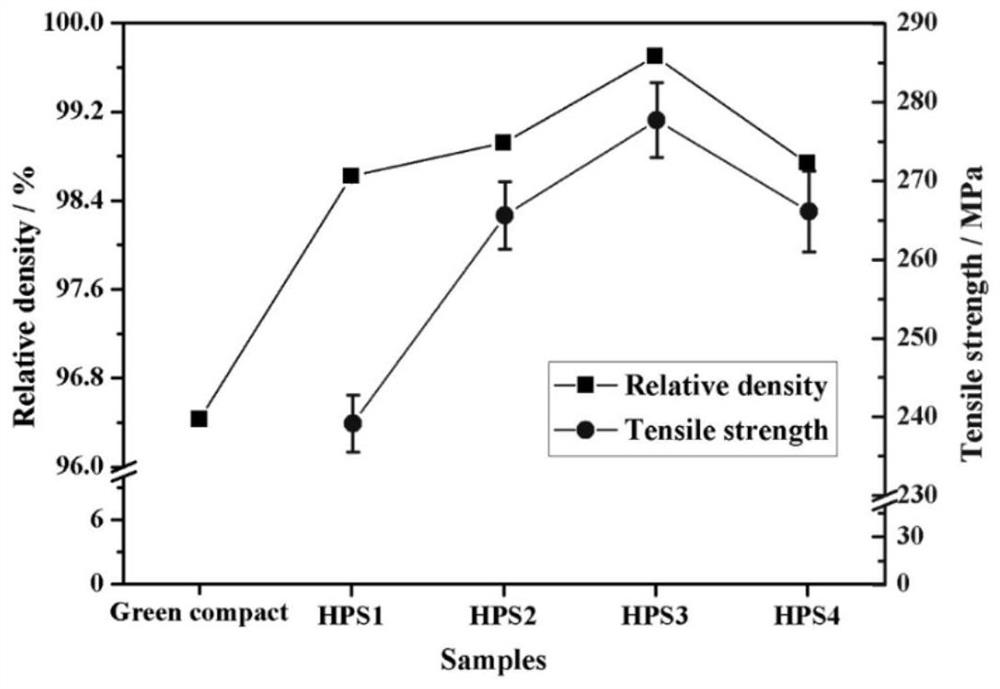

Comprehensive utilization method of powder by-products generated in spray forming process and product application

The invention provides a comprehensive utilization method of powder by-products generated in the spray forming process. The method comprises the steps that powder by-products are pressed, formed and sintered directly; the powder by-products mainly from extra powder generated in the spray forming green part preparation process, and are named as powder by-products in order to differ from a spray forming green part; according to the pressing forming, a hydraulic single column press or a four-column hydraulic press is adopted for loading the powder by-products into a steel mold to be formed, and agreen body is prepared; according to sintering, a vacuum hot pressing furnace is adopted for performing sintering densification, an alloy is prepared, and therefore the powder by-products are comprehensively utilized. According to the comprehensive utilization method of powder by-products generated in the spray forming process, the preparation technological process is short, the cost is low, operation is easy, convenient and flexible, the prepared materials have the structure and performance advantages of being fine in grain, uniform in structure, free of segregation and high in strength. Themethod can effectively achieve comprehensive utilization of powder by-products, the material utilization rate is increased, and the certain economic benefits are obtained.

Owner:CENT SOUTH UNIV

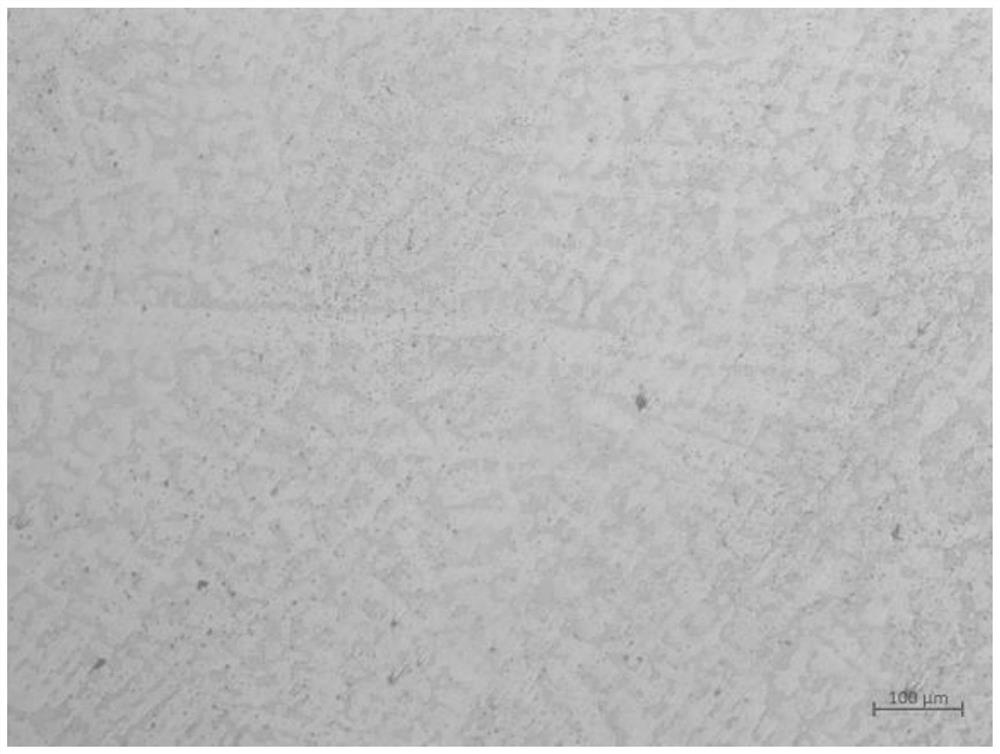

A kind of high-strength and high-toughness multi-element Al-cu alloy and its preparation method and application

The invention discloses a preparation method of a high-strength and high-toughness multi-element Al-Cu alloy. The preparation method comprises the following steps: raw materials is heated into a molten state, spray forming process is carried out through spray forming equipment, so that the multi-element Al-Cu alloy is formed, and the multi-element Al-Cu alloy is composed of Al, Cu, Mn, Ni, V, Sc, impurity Si and Fe. According to the preparation method, the high-strength and high-toughness multi-element Al-Cu alloy material for a lightweight cartridge case is prepared through the proportion of the raw material components, based on the micro-alloying component design of a Al-Cu alloy system and by combining 3d spraying forming-rapid solidification technology; the high-strength high-toughness multi-element Al-Cu alloy material has the advantages that crystal grains are fine, the structure is uniform, and the high-strength and high-toughness performance is achieved; according to the structure and the performance of the multi-element Al-Cu alloy, a reasonable cartridge case preparation technology is selected so that the use requirements of various lightweight cartridge cases can be met, and the Al-Cu alloy material can also be applied to a shell and a launching component of a short-range, medium-range and even a remote missile; and the Al-Cu alloy material has huge economic benefits.

Owner:安徽建业科技有限公司

A kind of preparation method of oxide dispersion strengthened (ods) titanium and titanium alloy

The invention discloses a preparation method of oxide dispersion strengthened (ODS) titanium and titanium alloy, and belongs to the field of powder metallurgy titanium. Calcium-aluminum alloy (CaAl) powder and titanium powder are mixed in proportion, then cold isostatic pressing forming and vacuum pressureless sintering are conducted, and oxide dispersion strengthened titanium and titanium alloy are obtained. The preparation method has the advantages that Ca and Al elements are introduced into the titanium alloy by adding CaAl alloy powder, Ca is uniformly distributed in a matrix, and dispersedly distributed fine Ca-Ti-O oxide second-phase particles are generated in situ in the sintering process, and meanwhile, the Al element is subjected to solid solution in the titanium matrix to form aTiAl solid solution, so that the mechanical property of the titanium alloy is greatly improved. The method is a new thought for improving oxygen control and performance regulation and control of preparation of high-performance titanium and titanium alloy, the requirement for the oxygen content of titanium and titanium alloy powder raw materials is lowered, and the method has the advantages of being low in cost, simple in process, easy to operate, suitable for industrial production and the like.

Owner:UNIV OF SCI & TECH BEIJING

Thermal protection coating with component gradient change and preparation method

InactiveCN101768380BLow thermal conductivityUniform microstructureMolten spray coatingRare-earth elementInorganic materials

The invention belongs to the field of inorganic materials, particularly relates to a thermal protection coating with component gradient change and a preparation method. The thermal protection coating comprises two components of M1 and M2, wherein the M1 is selected from one of YSZ, lanthanum aluminate, mulite or BSAS, the M2 is selected from one of Ln2Zr2O7, Ln2Ce2O7, Ln2SiO5, Ln2Si2O7 or MoSi2, and Ln is selected from rare earth elements the atom coefficients of which are 57-71, Y or Sc. The thermal protection coating has the characteristics of good coating compactness, high bonding strength with a substrate, low thermal conductivity and the like and has favorable thermal shock resistance.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

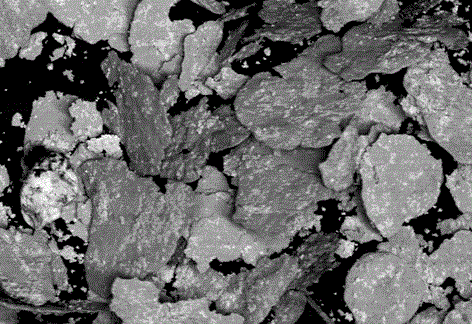

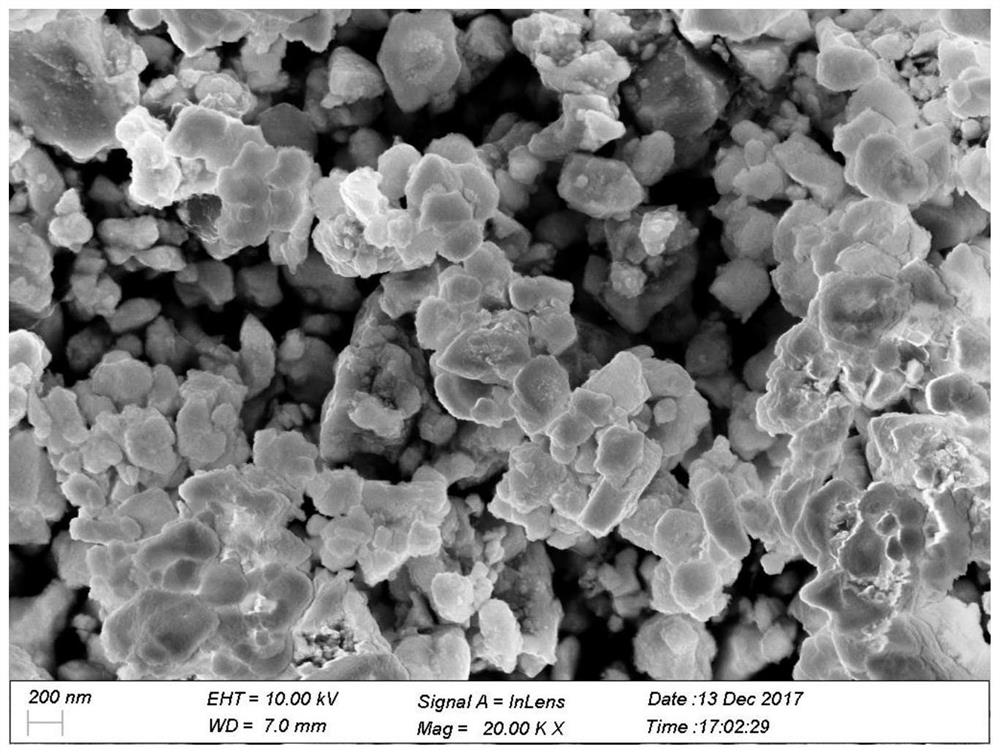

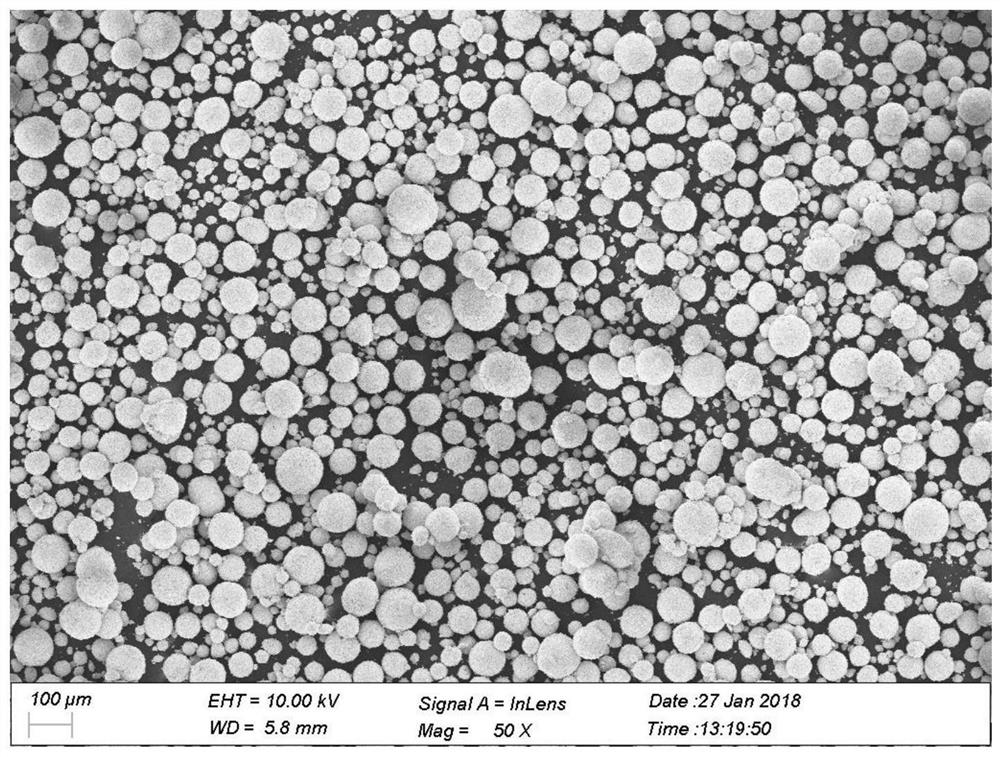

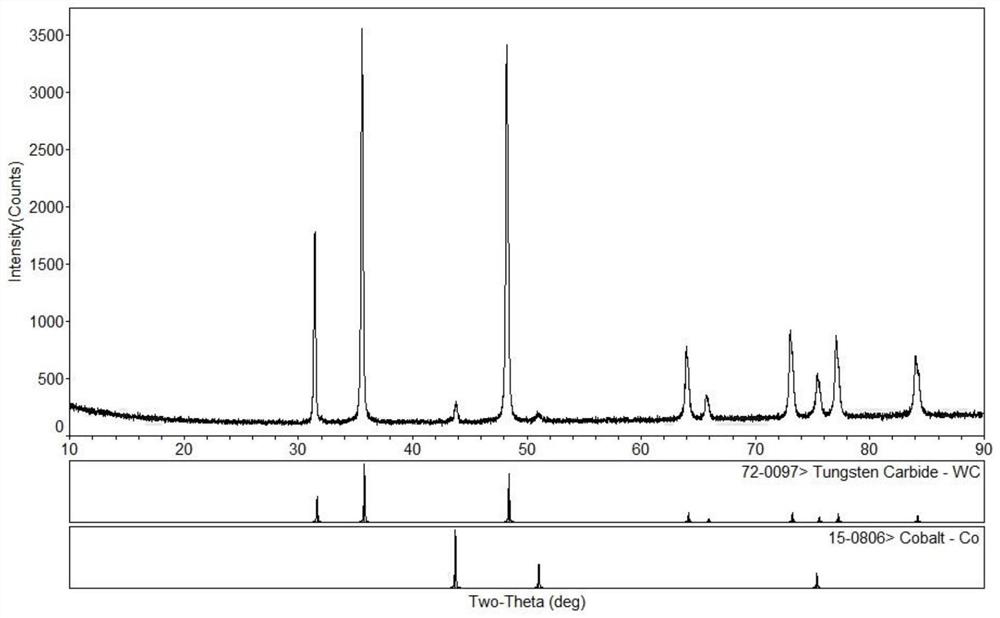

A kind of preparation method of granulated wc-co thermal spray powder

ActiveCN108326319BLarge specific surface areaEvenly distributedMolten spray coatingTransportation and packagingSpray GranulationWet grinding

The invention discloses a preparation method of granulated WC-Co thermal spray powder, which uses carburized nano-WC-Co composite powder as raw material, undergoes alcohol wet grinding, pressure spray granulation, vacuum degreasing and sintering to obtain the target product. The granulated WC-Co thermal spray powder obtained in the present invention has high sphericity, pure phase, good fluidity, high bulk density and excellent performance.

Owner:HEFEI UNIV OF TECH

A method for preparing superalloy honeycomb insulation board based on injection molding

ActiveCN107999756BImprove mechanical propertiesLow costTransportation and packagingMetal-working apparatusSuperalloyMachining process

Owner:SHENZHEN ELEMENT TECH CO LTD

Preparation method of high-silicon alloy for combustor

The invention discloses a preparation method of a high-silicon aluminum alloy for a burner. The silicon carbide aluminum alloy and solid silicon are mixed in proportion by weight, and the silicon carbide aluminum alloy is 10-20%, of which silicon carbide is about 50-70%, and aluminum is about 30%. ~50%; solid silicon 80-90%, and then put the mixture in a medium frequency induction furnace for remelting. After remelting is completed, silicon carbide is dissolved in the lower part of the silicon liquid, aluminum is dissolved in the upper part, and then the bottom and upper solutions are separated. Add copper, aluminum titanium, aluminum manganese, aluminum nickel, magnesium, iron, zinc, bismuth and other alloying elements to the obtained aluminum and silicon liquid mixture, then refine, remove slag, and cast to prepare high silicon aluminum alloy.

Owner:QINGDAO TIANDI CASTING CO LTD

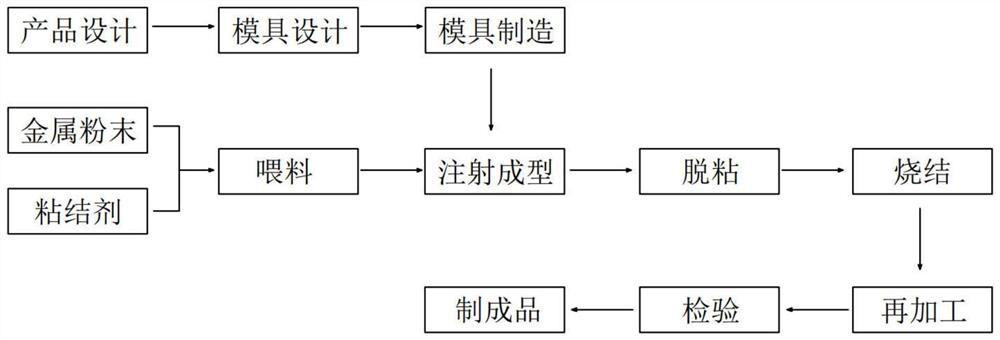

Injection molding process for metal handles of medical forceps

PendingCN113500193AFlat surfaceImprove compactnessOther manufacturing equipments/toolsForcepsInjection molding process

The invention discloses an injection molding process for metal handles of medical forceps. The injection molding process specifically comprises the following steps of (1) product designing; (2) mold manufacturing; (3) material mixing; (4) feeding; (5) injection molding; (6) debonding; (7) sintering; (8) re-machining; and (9) inspecting. The invention relates to the technical field of medical instrument machining, in particular to an injection molding process for metal handles of medical forceps. Compared with a traditional injection molding process for metal handles of medical forceps, the injection molding process for the metal handles of the medical forceps has the following advantages that 1, parts with complex geometrical shapes are directly formed; 2, the product is high in size precision and smooth in surface; 3, the product is good in internal compactness and high in density; 4, the internal structure is uniform, and no component segregation phenomenon exists for the alloy; 5, the production efficiency is high, and the production cost is greatly reduced under the condition of mass production; and 6, the application range of the materials is wide, and the materials comprise materials which are difficult to melt, cast and machine.

Owner:湖南博睿特新材料科技有限公司

A method for preparing a high-density, large-size, high-uniformity molybdenum-titanium alloy target

ActiveCN103740979BHigh densityUniform densityVacuum evaporation coatingSputtering coatingSlurrySolvent

The invention discloses a preparation method of a molybdenum titanium alloy material with high density, large size and high homogeneity. The method comprises the following steps: 1) adding a solvent and a binder to Mo powder and Ti powder and grinding into slurry; 2) atomizing and pelletizing the slurry by using a spraying machine, wherein the inlet temperature is 250-300 DEG C, and the rotating speed of a spray nozzle is 8000-12000rpm, so as to obtain Mo-Ti composite powder; pressing the composite powder into blanks with regular sizes; 3) loading a plurality of blanks into a sheath, filling the Mo-Ti composite powder of 50-250 microns into the adjacent blanks to form a uniform composite powder layer, wherein the thickness of the composite powder layer is 0.5-1mm, and the condition that a gap between the inner wall of the sheath at any side and the outer wall of the adjacent blank is smaller than or equal to 0.5mm is ensured; and 4) welding and degassing the sheath and then carrying out hot isostatic pressing treatment at 750-900 DEG C and 120-160MPa and removing the sheath, wherein the heat-preserving and pressure-maintaining time is 4-6 hours. The target material fabricated by the method can be used as a cathode material of a magnetron sputtering technique.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Surface treatment process for electroplating iron-nickel alloy and electroplating solution thereof

Owner:湖南纳菲尔新材料科技股份有限公司

Layered metal composite material manufacturing technology and equipment

The present invention relates to a technique for producing laminated and composite metal material, belonging to manufactural technique of composite metal material. The present technique for producinglaminated and composite metal material is characterized by simple process, high production efficiency, low production cost, simple facility and small investment. In the method, metal liquid is directcast into a crystallizer with an induction heater on the external part. The metal liquid is refined by electroslag in the crystallizer and is simultaneously combined with metal mandril installed in the crystallizer to achieve the aim of metallurgical combination. The interface of compound layer can be easily controlled with no composition segregation in product. With highly structural density, high product quality and wide selectivity about both the madril and the material of the compound layer, the prevent invention is free from limitation of facility and technique to achieve producing laminated and multilayer composite product in large volume by small equipment.

Owner:丁刚 +1

Method for preparing pliers of butted cutting edges

The invention discloses a method for preparing pliers of butted cutting edges, comprising the following steps: (1) preparing an all-in-one mould of the butted cutting edges, wherein the mould comprises the left mould cavity of cutting edge and the right cavity of cutting edge which are opposite to each other, and the wedge-shaped ends of the mould cavities of cutting edges are opposite to each other, and a connecting part of mould cavity is installed between the mould cavities of cutting edges; (2) loading the mould obtained in step (1) into the metal powder injection molding machine, and preparing an integration of butted cutting edges and connecting part by injecting and forming in metal powder, degreasing, sintering and heat treating, wherein the integration of butted cutting edges comprises a left cutting edge and a right cutting edge which are opposite to each other, and the connecting part is used for connecting the two end faces of the wedge-shaped ends of the cutting edges; (3) mounting the integration of butted cutting edges obtained in step (2) on the pliers so as to prepare the blank of pliers; (4) removing the connecting part of the integration of butted cutting edges in the blank of pliers which is obtained in step (3) by grinding wheel so as to prepare the pliers of butted cutting edges. The pliers of butted cutting edges prepared by the invention have good property, sharpness and durability and high finished product ratio, and the pliers are not easy to misplace.

Owner:洪殿

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com