Preparation method of high-strength iron-cobalt-nickel alloy

An iron-cobalt-nickel alloy and high-strength technology, which is applied in the field of preparation of high-strength iron-cobalt-nickel alloys, can solve the problems of small output and high preparation cost, and achieve the effects of high density, uniform grain size and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

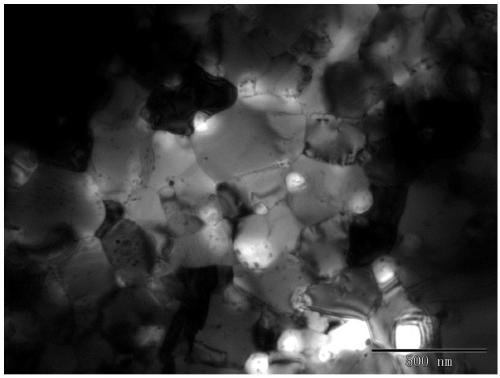

Image

Examples

Embodiment 1

[0023] 1. Weigh 54g of iron powder, 58.8g of cobalt powder, and 58.2g of nickel powder, then mix the powder and add 9g of n-heptane for ball milling. The ball milling parameters were set as ball-to-material ratio 12:1, the ball mill speed was 300rpm, the ball milling time was 60h, and the ball milling was carried out under high-purity argon atmosphere.

[0024] 2. Put the ball-milled alloy powder into a high-temperature hydrogen reduction furnace for reduction at 800°C for 2 hours, and the reduced powder is quickly vacuum-packaged.

[0025] 3. Perform SPS sintering on the reduced powder, the sintering temperature is 1100°C, the pressure is 50MPa, and the holding time is 6min

[0026] 4. Cover the sintered sample with a stainless steel sheath, heat the sample to 900°C and start hot rolling, the final rolling temperature is 750°C, and the rolling deformation is 80%.

[0027] 5. The hot-rolled alloy was heat-treated at 950° C. for 12 hours under the protection of high-purity arg...

Embodiment 2

[0030] 1. Weigh 60g iron powder, 55.5g cobalt powder, 55.5g nickel powder, then mix the powder and add 15g n-heptane for ball milling. The ball milling parameters were set as ball-to-material ratio 10:1, ball mill speed 350rpm, ball milling time 72h, and ball milling was carried out under high-purity argon atmosphere.

[0031] 2. Put the ball-milled alloy powder into a high-temperature hydrogen reduction furnace for reduction at 700°C for 2.5 hours, and the reduced powder is quickly vacuum-packaged.

[0032] 3. Perform SPS sintering on the reduced powder, the sintering temperature is 1000°C, the pressure is 60MPa, and the holding time is 8min

[0033] 4. Cover the sintered sample with a stainless steel sheath, heat the sample to 1000°C and start hot rolling, the final rolling temperature is 750°C, and the rolling deformation is 70%.

[0034] 5. The hot-rolled alloy was heat-treated at 900° C. for 24 hours under the protection of high-purity argon, and then air-cooled to room ...

Embodiment 3

[0037] 1. Weigh 60g of iron powder, 52.3g of cobalt powder, and 59g of nickel powder, then mix the powder and add 1.8g of stearic acid for ball milling. The ball milling parameters were set as a ball-to-material ratio of 15:1, a ball mill speed of 350 rpm, and a ball milling time of 48 hours. The ball milling was carried out under a high-purity argon atmosphere.

[0038] 2. Put the ball-milled alloy powder into a high-temperature hydrogen reduction furnace for reduction at 900°C for 1.5 hours, and the reduced powder is quickly vacuum-packaged.

[0039] 3. The reduced powder is sintered by hot isostatic pressing at a temperature of 1200° C. and a pressure of 100 MPa for 3 hours.

[0040] 4. Cover the sintered sample with a stainless steel sheath, heat the sample to 900°C and start hot rolling, the final rolling temperature is 750°C, and the rolling deformation is 80%.

[0041] 5. The hot-rolled alloy was heat-treated at 1050° C. for 18 hours under the protection of high-purity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com