Spray coating technology of magnesium alloy surface protective layer

A protective layer and magnesium alloy technology, applied in the field of new surface spraying of magnesium alloy protective layer, can solve problems such as wear, magnesium alloy surface corrosion, environmental pollution, etc., and achieve the effect of low spraying temperature, compact structure and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

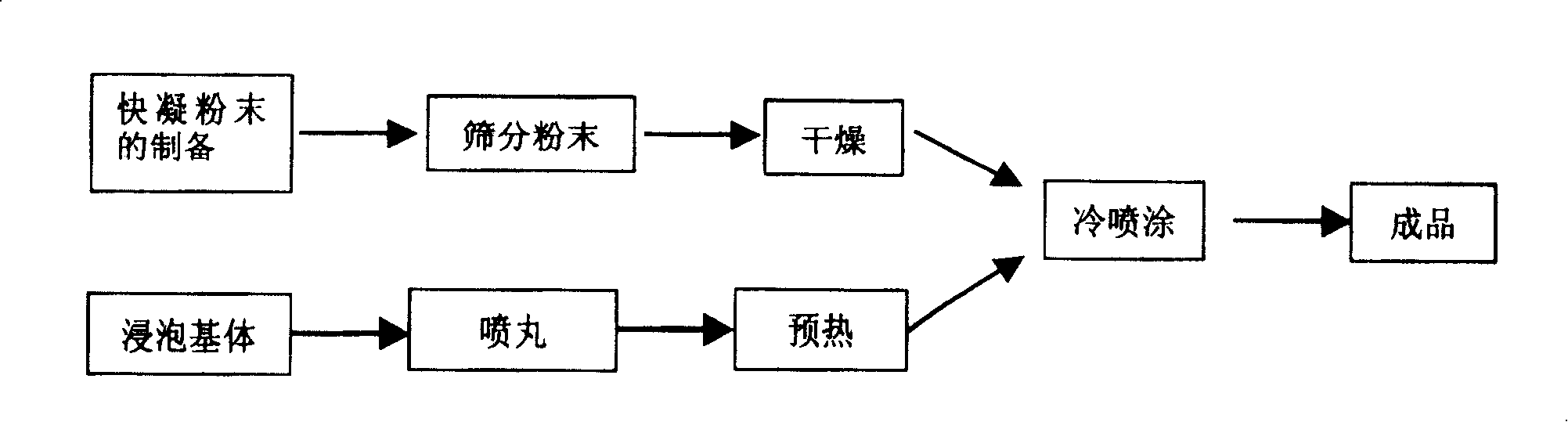

[0021] Coating process of the present invention divides following three steps:

[0022] (1) Preparation of powder. The 5wt% Al-95wt% Zn alloy is sprayed into fine powder with a particle size of 25-75 microns by supersonic atomization device, collected and sieved before being bottled;

[0023] (2) Treatment before spraying.

[0024] A. Take the zinc-aluminum alloy powder with a particle size of 25-75 microns, place it in a vacuum drying oven and dry it to remove moisture;

[0025] B. Soak the magnesium alloy base material in acetone to degrease, roughen the surface by shot peening, and then preheat the base material;

[0026] (3) Spray the protective layer. Put the dried zinc-aluminum alloy powder into the powder feeder, and fix the substrate parts at a certain distance (usually 5-40mm) from the nozzle, first turn on the gas heater, and the high-pressure gas is heated and sprayed onto the substrate surface, preheat the substrate. The temperature is about 150°C; then the po...

Embodiment 2

[0028] (1) Preparation of powder. The 30wt% Al-70wt% Zn alloy is made into fine powder with a particle size of 25-75 microns by laser evaporation method, collected and sieved before being bottled;

[0029] (2) Treatment before spraying.

[0030] A. Take the zinc-aluminum alloy powder with a particle size of 25-75 microns, place it in a vacuum drying oven and dry it to remove moisture;

[0031] B. Soak the magnesium alloy parts in alcohol to degrease, sandblast and roughen the surface, and then preheat the base material;

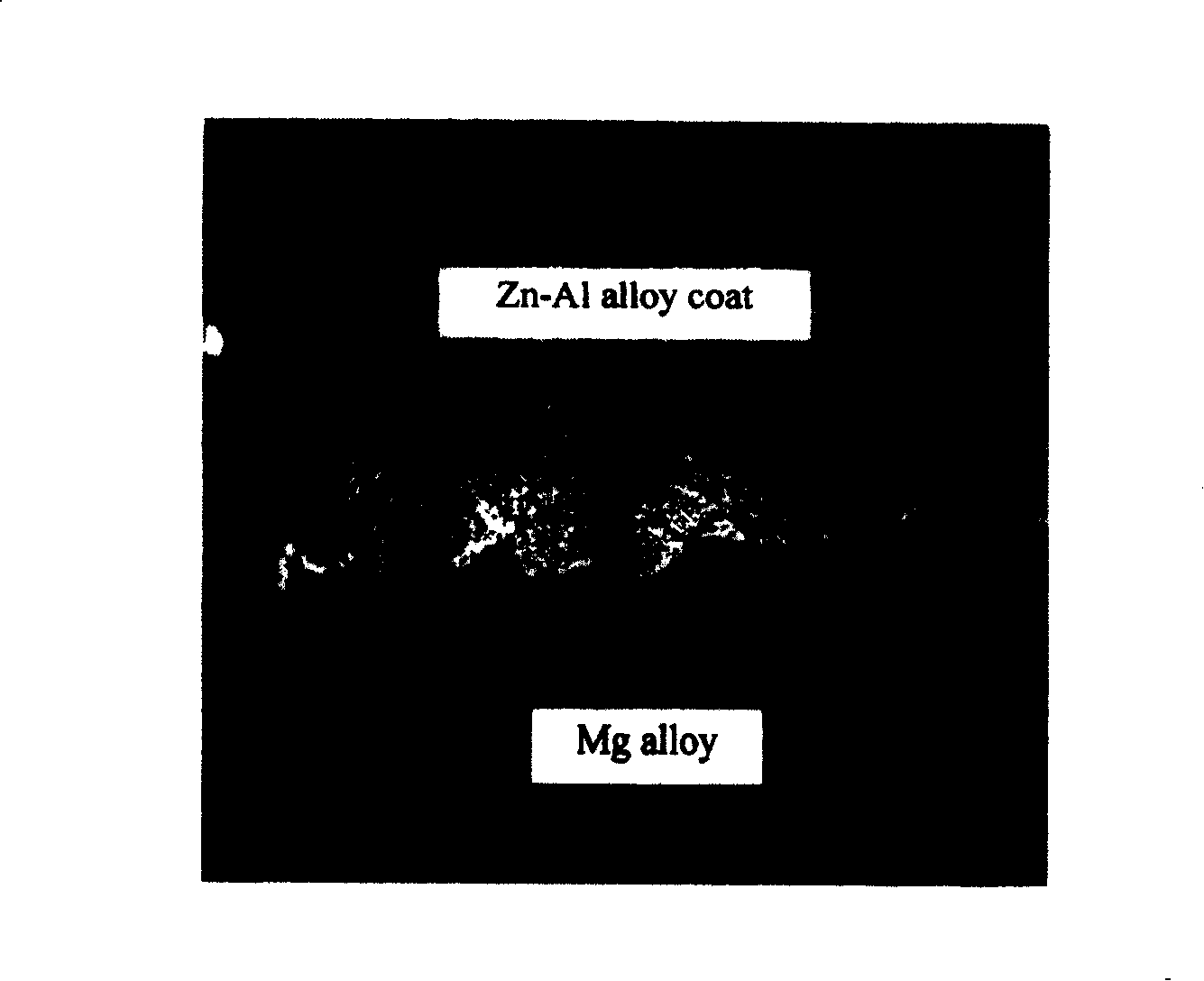

[0032] (3), spray protective layer. Put the dried zinc-aluminum alloy powder into the powder feeder, and fix the parts at a distance of 10mm from the nozzle. First turn on the gas heater to preheat the parts, and then turn on the powder feeder. At this time, the supersonic nozzle The jet effect will spray the powder on the surface of the substrate of the component at a high speed under a pressure of 2.5MPa, and form a zinc-aluminum alloy protective coating...

Embodiment 3

[0034] (1) Preparation of powder. Using a supersonic atomization device to make 15wt% Al-85wt% Zn alloy into fine powder with a particle size of 25-75 microns, collect and sieve it and bottle it;

[0035] (2) Treatment before spraying.

[0036] A. Take the zinc-aluminum alloy powder with a particle size of 25-75 microns, and dry it in a vacuum drying oven to remove moisture;

[0037] B. Soak the magnesium alloy parts in acetone or alcohol to degrease, and the surface is shot peened and roughened.

[0038] (3) Spray the protective layer. Put the dried zinc-aluminum alloy micro-powder into the powder feeder, and fix the substrate parts at a distance of 30mm from the nozzle, first turn on the gas heater to preheat the parts to 150°C, and then turn on the powder feeder And the nozzle switch, at this time, under the pressure of 2.0MPa, the supersonic nozzle will spray the micro powder on the surface of the parts by means of the jet effect. On the surface, a zinc-aluminum alloy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com