Preparation method of copper-niobium superconducting composite material

A composite material and superconducting technology, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problem of high content of impurity elements in copper-niobium alloy, and achieve no component segregation and no inclusions. The effect of material and composition uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Put 17kg of copper powder with a particle size of 200 meshes and 3kg of niobium powder with a particle size of 200 meshes into a roller ball mill and mix for 2h, then pour the uniformly mixed copper-niobium powder into a mold and press on the press to form copper with a size of Φ50×300mm -Niobium consumable electrode bar material, the pressure is 300MPa during pressing, and the pressure holding time is 10min. The pressed copper-niobium consumable electrode bar material is put into a vacuum sintering furnace for sintering. The sintering temperature is 900°C, and the holding time is 10min. Time is 10h, vacuum degree is 1×10 -4 Pa, the copper-niobium consumable electrode is obtained, which is welded on the auxiliary electrode by argon tungsten arc welding, and is smelted in a vacuum arc furnace of model ZH-200.

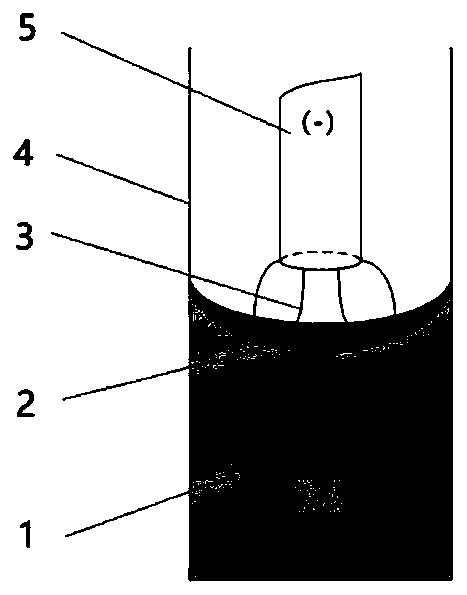

[0018] The melting process is like figure 1 As shown, the copper-niobium consumable electrode 5 is placed in a water-cooled crucible 4 with a diameter of 150mm. The a...

Embodiment 2

[0021] Put 16kg of copper powder with a particle size of 200 mesh and 4kg of niobium powder with a particle size of 200 mesh into a roller ball mill and mix for 2 hours, then pour the uniformly mixed copper-niobium powder into a mold and press on the press to form copper with a size of Φ50×300mm -Niobium consumable electrode bar material, the pressure is 300MPa during pressing, and the pressure holding time is 10min. The pressed copper-niobium consumable electrode bar material is put into a vacuum sintering furnace for sintering. The sintering temperature is 900°C, and the holding time is 10min. Time is 10h, vacuum degree is 1×10 -4 Pa, the copper-niobium consumable electrode is obtained, which is welded on the auxiliary electrode by argon tungsten arc welding, and is smelted in a vacuum arc furnace of model ZH-200 to obtain a copper-niobium superconducting composite material. The length is 25-30mm, the melting voltage is 25V, the melting current is 5000A, and the furnace pressu...

Embodiment 3

[0023] Put 15kg of copper powder with a particle size of 200 meshes and 5kg of niobium powder with a particle size of 200 meshes into a roller ball mill and mix for 2 hours, then pour the uniformly mixed copper-niobium powder into a mold and press on the press to form copper with a size of Φ50×300mm -Niobium consumable electrode bar material, the pressure is 300MPa during pressing, and the pressure holding time is 10min. The pressed copper-niobium consumable electrode bar material is put into a vacuum sintering furnace for sintering. The sintering temperature is 900°C, and the holding time is 10min. Time is 10h, vacuum degree is 1×10 -4 Pa, the copper-niobium consumable electrode is obtained, which is welded on the auxiliary electrode by argon tungsten arc welding, and is smelted in a vacuum arc furnace of model ZH-200 to obtain a copper-niobium superconducting composite material. The length is 25-30mm, the melting voltage is 25V, the melting current is 5000A, and the furnace pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com