Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

148results about How to "Low content of impurity elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cu-Fe in-situ composite with boron, silver and rare earth elements added and preparation method thereof

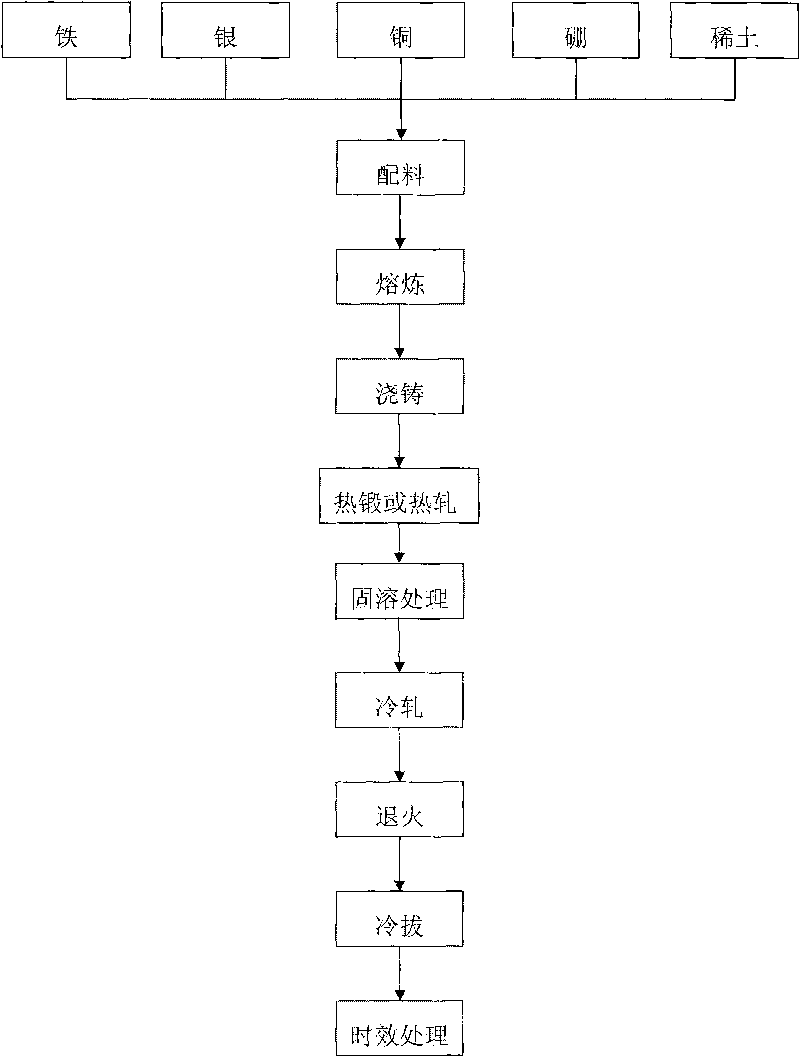

The invention discloses a Cu-Fe in-situ composite with boron, silver and rare earth elements added and a preparation method thereof. The invention is characterized by adopting multimode comprehensive strengthening technology such as multi-micro alloying, solid solution strengthening, aging strengthening, fine grain strengthening, distortion strengthening, fiber strengthening and the like, using Cu as the base and adding a little Fe and trace Ag and B, rare earth or rare earth compounds to prepare the high strength and high conductivity copper alloy material through smelting, casting, hot forging or hot rolling, solid solution treatment, cold rolling or cold drawing, aging and the like. The prepared material has the advantages of high strength, good electric and thermal conductivity, simple preparation process and low cost, thus realizing wide application in the fields such as electronics, information, transportation, energy, metallurgy, electromechanics and the like.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

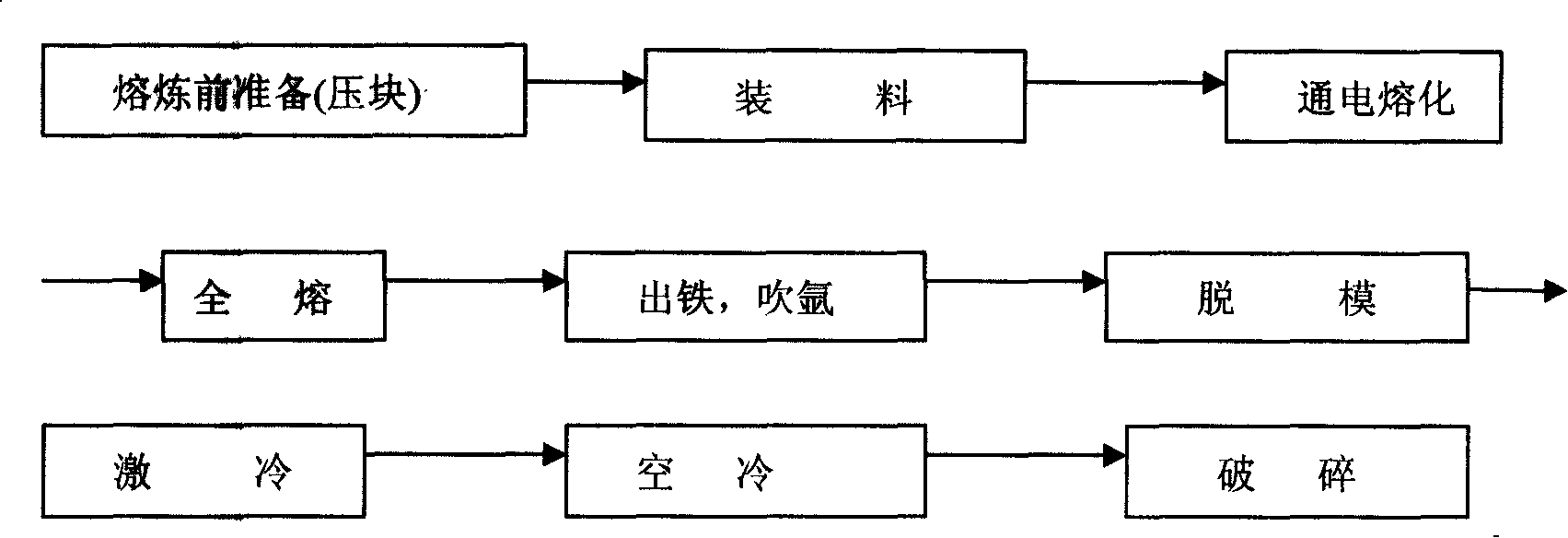

Low-nitrogen low-aluminum ferrotitanium, manufacturing method thereof and core-spun yarn

The invention relates to low nitrogen, low-aluminum ferrotitanium and a manufacture method and an alloy cored wire thereof. The low nitrogen and low-aluminum ferrotitanium is 70Fe-Ti alloy, comprising the impurity elements such as nitrogen, aluminum, silicon, carbon, phosphorus, and sulfur and so on, the content of nitrogen is less than or equal to 0.08 percent and the content of aluminum is less than or equal to 0.5 percent. The content of titanium is 60 percent to 80 percent, the content of silicon is less than or equal to 0.5 percent, the content of carbon is less than or equal to 0.1 percent, the content of phosphorus is less than or equal to 0.04 percent, and the content of sulfur is less than or equal to 0.03 percent, the rest is ferrum. The manufacture method is as follows: in a common smelting method, the industrial salt is used as slagging constituents during the smelting; the sponge titanium, waste titanium, high quality steel scraps or ferroferrite comprising the impurity elements, such as nitrogen, aluminum, silicon, carbon, phosphorus, and sulfur, etc. with low content are used as alloy raw materials, the raw materials are briquetted before smelting; the smelting is carried out in an argon smelting furnace or a consumable electrode vacuum furnace. The low nitrogen and low-aluminum ferrotitanium used as the alloy raw material is applied in manufacturing the high grade steel such as stainless steel, which requires titanium to be used as stabilization alloy element or alloy strengthening element to obtain good combination property in strength, plasticity, ductility, and inoxidability, etc. and which also requires low content of the impurity elements such as nitrogen, aluminum, silicon, carbon, phosphorus, sulfur, etc.

Owner:上海马腾新型材料厂

Total-converting steelmaking method of electric furnace

ActiveCN102534112AReduce noise and radiation pollutionReduce smelting costProcess efficiency improvementElectric furnaceDeoxidizationScrap

The invention discloses a total-converting steelmaking method of an electric furnace. The method achieves the purposes of energy saving and consumption reducing through the working procedures containing adjustment for ratio of raw materials and strict control for the converting process. The method specifically comprises the following steps of: controlling the proportion of molten iron to be 71-79 percent; adding steel scraps through a furnace mouth for one time, and adding the molten iron through an iron exchanging mouth for two times; preheating, warming and decarburizing the steel scraps and molten steel in a furnace through a nozzle of an oxygen-burning system 3 installed on a furnace wall; during converting, regulating a corresponding gear according to demands, meanwhile converting with a furnace door oxygen gun, and making the converting efficiency to be maximized; adding slag making materials such as lime into the electric furnace to make slag; and when the molten steel achieves the temperature and components needed by steel grades, carrying out ladle deoxidization for steel tapping. Compared with the general steelmaking method of the electric furnace, the total-converting steelmaking method of the electric furnace has the advantages that electrode heating is cancelled, the consumptions of the electric energy, electrode and steel scrap are greatly reduced, the smelting cost per ton of steel is greatly reduced, the pollution is decreased, meanwhile the contents of harmful elements in the steel are reduced, and the product quality is increased.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

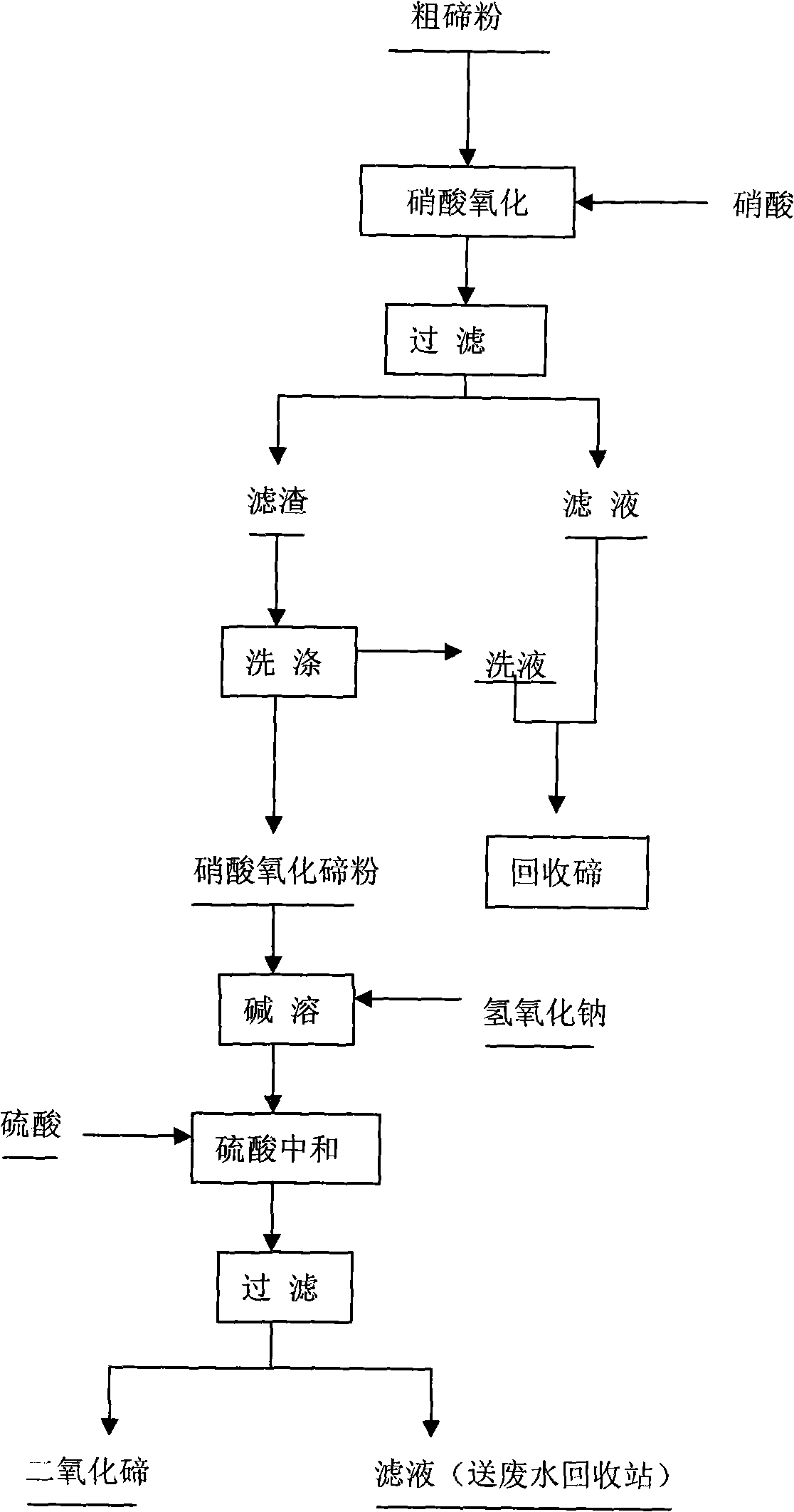

Deep impurity-removing method for crude tellurium powder

InactiveCN101259956ASimple processReduce labor intensityElemental selenium/telluriumNitrateTe element

The invention provides a method for removing deep impurities of coarse tellurium powders, relating to a method for removing deep impurities in the coarse tellurium powders which are recovered from copper anode slimes. The invention is characterized in that in the process of impurity removal, coarse tellurium powders react with nitric acids, which makes the tellurium in the coarse tellurium powders oxidized into the tellurium dioxide and makes impurity elements in the coarse tellurium powders form nitrates to be dissolved into the solution, and after filtering and separation, impurity nitrates are removed; after being washed, filter slimes are dissolved by sodium hydroxide, and solid impurities are obtained by filtering and separation; and the filtrate is added with sulphuric acids for neutralization, and tellurium dioxide powders are obtained after filtering. The method of the invention adopts the nitric acid oxidation impurity removal process, thereby major impurity elements in the coarse tellurium powders can be removed; moreover, the purity of tellurium dioxide powders obtained by the method is more than 99.9 percent.

Owner:JINCHUAN GROUP LIMITED

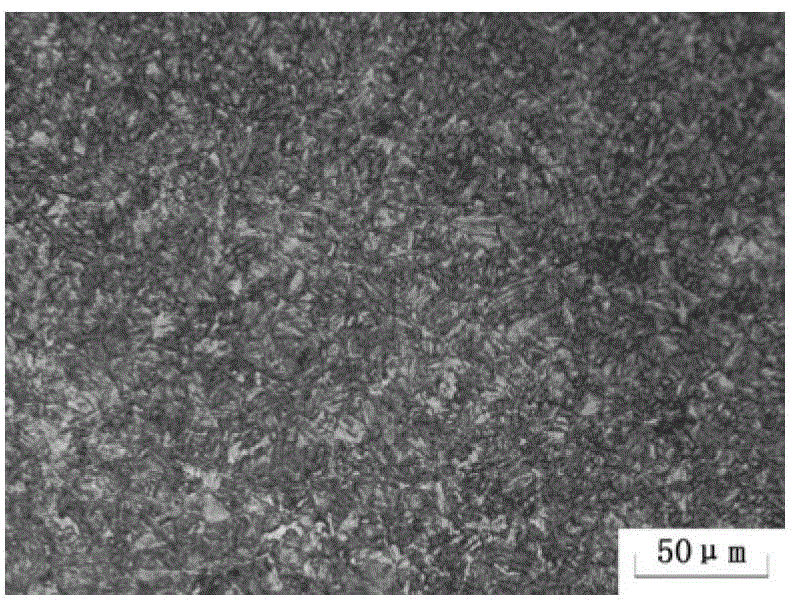

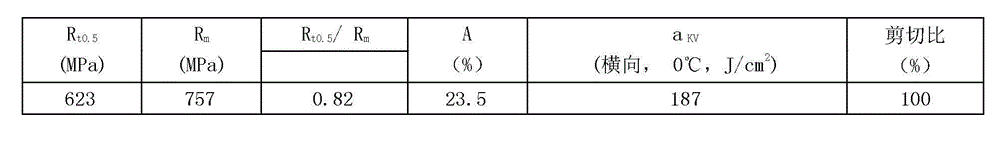

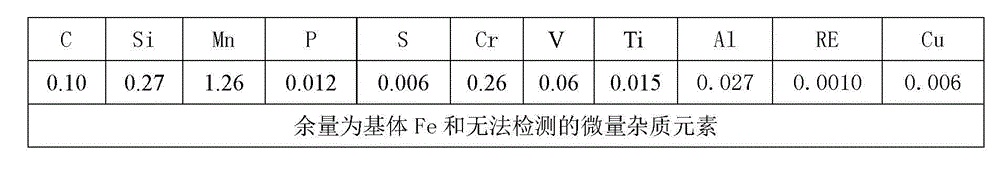

Rare earth containing, high-strength and high-toughness seamless steel pipe for L555Q pipeline and production method thereof

The invention relates to a rare earth containing, high-strength and high-toughness seamless steel pipe for the L555Q pipeline and a production method thereof. The seamless steel pipe is composed of 90 wt% of blast furnace molten iron and 10 wt% of high-quality waste steel in percentage by weight. The pipe blank comprises the following chemical components in percentage by weight: 0.06 to 0.13 wt% of C, 0.15 to 0.35 wt% of Si, 1.10 to 1.40 wt% of Mn, not more than 0.020 wt% of P, not more than 0.010 wt% of S, 0.10 to 0.30 wt% of Cr, 0.03 to 0.09 wt% of V, 0.01 to 0.03 wt% of Ti, 0.01 to 0.04 wt% of Al, 0.0005 to 0.0100 wt% of rare earth (RE), not more than 0.10 wt% of Cu, and the balance being substrate Fe and undetectable trace impurity elements. The mechanical properties of the seamless steel pipe are as follows: the yield strength is 600 to 680 MPa, the residual stress is smaller than or equal to 30 MPa, the impact value is more than or equal to 160 J / cm<2>, and the grain size is more than or equal to 8.5 grade. The technology process can be simplified as the following steps: molten iron pre-treating, smelting in a top-bottom combined blowing converter, refining in a LE furnace, VD vacuum processing, round continuous casting, cutting, heating the pipe blank, perforating, continuous rolling, sizing (stretch reducing), cooling, sawing, heat treating, straightening, flaw detecting, and chamfering. The product has the advantages of low impurity element content, high roughness matching degree, uniform and fine tissue, and good welding performance.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Method for producing using aluminum gray and coal gangue composite castoff

InactiveCN101270412AOvercome limitationsLow content of impurity elementsProcess efficiency improvementBriquetteCoal gangue

The invention discloses a production method of Aluminum-Silicon alloy in the field of metallurgy technology by utilizing a composite waste including aluminum ash and coal gangue, which has the procedures as follows: the first step is the material preparation and the pretreatment of raw material, i.e. iron removal by magnetic separation pretreatment for aluminum ash, optimal selection and milling to the granularity of smaller than 40 meshes and iron removal by magnetic separation pretreatment on coal gangue; the second step is proportioning and briquetting, i.e. proportioning according to the following weight percent including 5 to 25 percent of aluminum ash, 60 to 95 percent of coal gangue and 0 to 15 percent of petroleum coke, adding 15 to 20 percent by the weight of raw material of waste pulp with as binder, mixing the material to briquette and baking to moisture of below 2 percent; the third step is preparation of Aluminum-Silicon alloy by using electrothermal method. The invention overcomes the component limitation of one solid waste, not only decreases the cost of Aluminum-Silicon alloy and but also consumes the wastes which easily cause the environmental pollution.

Owner:SHANGHAI JIAO TONG UNIV +1

High-performance wrought magnesium alloy material

The invention relates to a high-purity high-performance magnesium alloy material, which consists of the following components in percentage by mass: 6.2 to 6.4 percent of Zn, 0.5 to 0.6 percent of Zr, 0.007 to 0.011 percent of inevitable Fe, Si, Cu, Ni and other impurities, and the balance magnesium. The material is prepared by the following steps: selecting raw magnesium with higher purity as a raw material; melting the raw magnesium by using the semicontinuous casting technology; properly increasing the melt standing time to ensure that compound particles containing Fe, Si and other impurity elements can be sufficiently deposited and a high-purity alloy cast blank can be prepared; and preparing the Mg-Zn-Zr wrought magnesium alloy by adopting the conventional extruding technology. The wrought magnesium alloy can maintain the high strength of traditional commercial ZK60 magnesium alloy to ensure that the plasticity and forming performance of the alloy can be greatly improved and the application potential of the material is sufficiently developed. Furthermore, the technical equipment used in the invention is conventional universal equipment, and the preparation process is simple.

Owner:CHONGQING UNIV

Method for preparing industrial pure zirconium ingot

The invention relates to a method for preparing industrial pure zirconium ingot, used in the field of nuclear power, metallurgy, petrochemical engineering and the like. The method includes the steps that industrial sponge zirconium of required weight is weighed to prepare an electrode block by pressing; the pressed electrode block is welded into an electrode; and then electric beam melting on vacuum consumable electro-arc furnace combining electric beam melting is carried out for at least once, so as to obtain industrial pure zirconium ingot. The zirconium ingot produced by the invention has uniform and stable chemical components and low content of impurity elements of Fe, Cr, O, H and the like, is better than the ingot melted by vacuum consumable electric arc, and is not mixed with high or low density of ZrO2 and WC; and the invention is applicable to producing pure zirconium ingot with high metallurgy quality.

Owner:BAOJI TITANIUM IND CO LTD

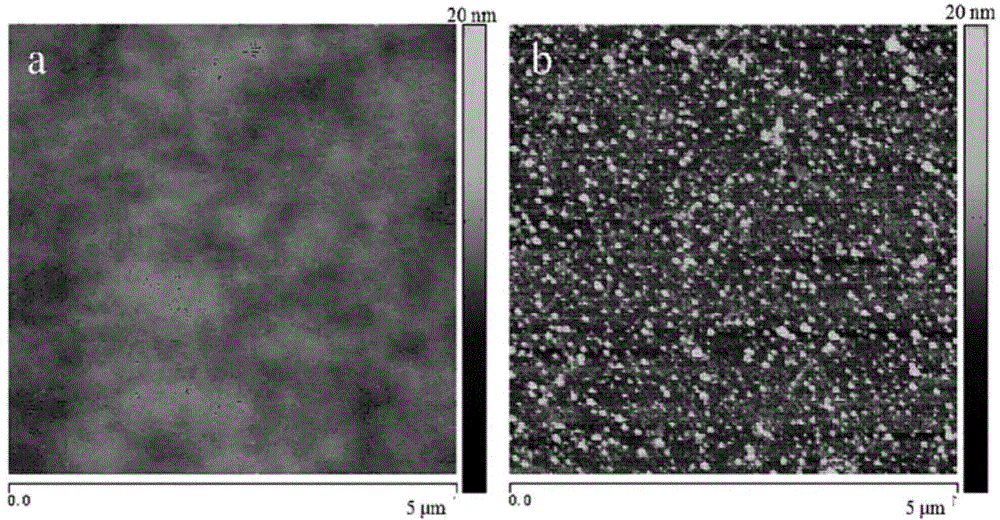

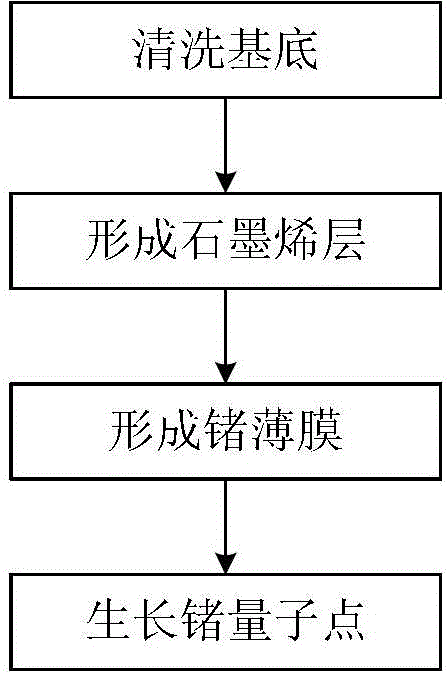

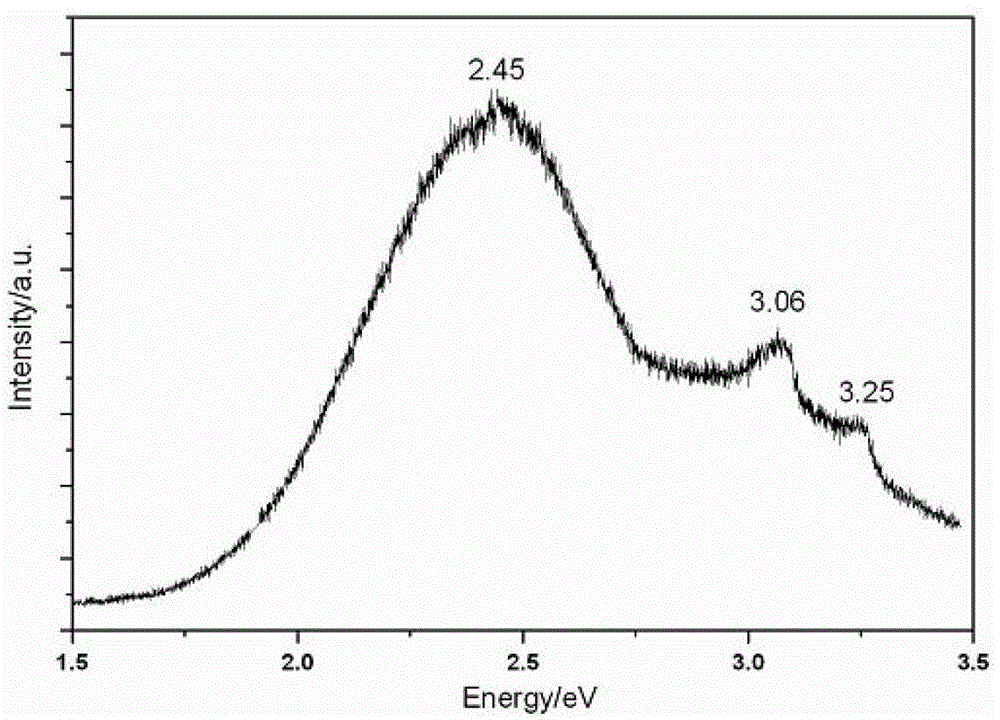

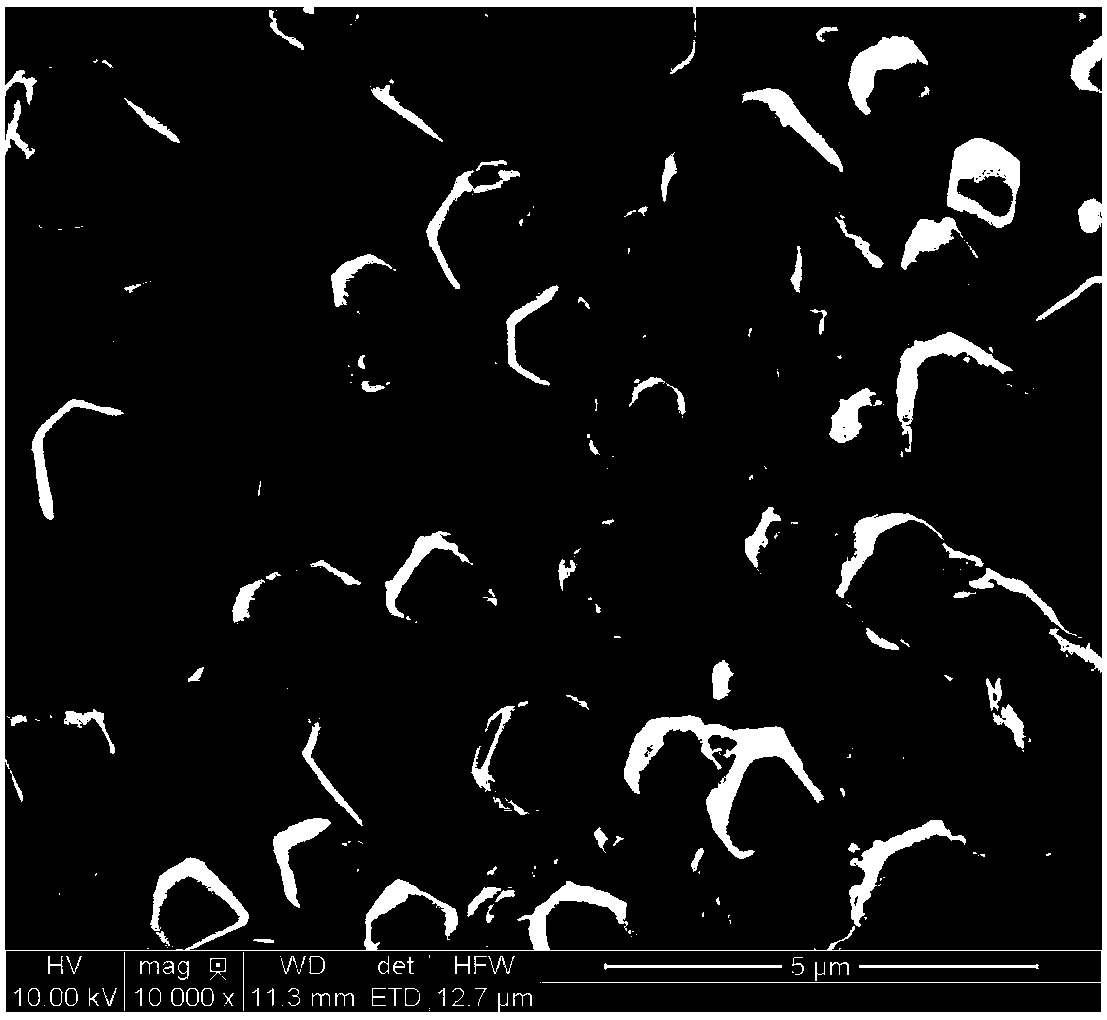

Germanium quantum dot growing method, germanium quantum dot composite material and application of germanium quantum dot composite material

ActiveCN104377114AAchieve growthAvoid complicated cleaning proceduresSemiconductor/solid-state device manufacturingPhotovoltaic energy generationQuantum dotCvd graphene

The present invention relates to a method for growth of germanium quantum dots. In the method, germanium quantum dots are grown on graphene interfaces with different quantities of layers. In the present invention, ultra-high uniformity graphene interfaces are introduced on a conventional substrate surface, Ge quantum dots are grown on the interfaces, and complicated cleaning processes for obtaining high-quality interfaces are avoided, and process flows are simplified; in addition, the low-matrix element content and the low defect rate of the germanium quantum dots are ensured, a self-organization growth process of the germanium quantum dots is ensured, and germanium quantum dots with good shape and uniformity are formed.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Cu-Cr in-situ composite with boron, silver and rare earth elements added and preparation method thereof

The invention discloses a Cu-Cr in-situ composite with boron, silver and rare earth elements added and a preparation method thereof. The invention is characterized by adopting multimode comprehensive strengthening technology such as multi-micro alloying, solid solution strengthening, aging strengthening, fine grain strengthening, distortion strengthening, fiber strengthening and the like, using Cu as the base and adding a little Cr and trace Ag and B, rare earth or rare earth compounds to prepare the high performance copper alloy in-situ composite through smelting, casting, hot forging or hot rolling, solid solution treatment, cold rolling or cold drawing, aging and the like. The prepared material has the advantages of high strength, good electric and thermal conductivity, simple preparation process and low cost, thus realizing industrial application in the aspects such as electrician switches, contact materials, resistance electrodes, rotor conductors of large electrical high speed turbine generators, overhead conductors of electric cars and electric trains, lead frames of very large scale integrated circuits and the like.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

Process for preparing Nb and/or Ta powder

A process for preparing Nb and / or Ta powder features that under the action of reducer chosen from alkali metal plus at least one of the halides of Mg, Ca, Sr, Ba, Li and Ce, the alkali-metal fluonidobium and / or tantalate is reduced at 300-1050 deg.C to obtain said products. Its advantages are high recovery rate for reduction, and large specific surface area, high porosity and low oxygen content of product.

Owner:NINGXIA ORIENT TANTALUM IND

Method for recovering noble metal platinum

InactiveCN103014353ALow content of impurity elementsHigh purityProcess efficiency improvementAmmonium chloride mixturePrecious metal

The invention provides a high-recovery-rate method for recovering noble metal platinum with low impurity element content and high purity, which comprises the following steps: 1) putting a noble metal platinum sample into a container, firing and cooling; 2) preparing a dissolution agent by using 36-38 wt% hydrochloric acid and 66-68 wt% nitric acid in a volume ratio of (1-4):1 a dissolution reagent; 3) adding the prepared dissolution reagent into the cooled container, and heating until the metal platinum is completely dissolved; 4) evaporating the solution by heating to the nearly dry state, adding hydrochloric acid, and evaporating the solution by heating to the nearly dry state; 5) dropwisely adding an ammonium chloride solution into the container, and filtering to obtain an ammonium chloroplatinate precipitate; and 6) putting the ammonium chloroplatinate precipitate into the container, firing and cooling. The metal platinum recovered from the noble metal platinum sample has the advantages of low impurity element content and high purity; and the method provided by the invention enhances the recovery rate of platinum, has the advantages of simple technical process, low cost and high recovery value, and is beneficial to energy saving, emission reduction and environmental protection.

Owner:CDGM OPTICAL GLASS

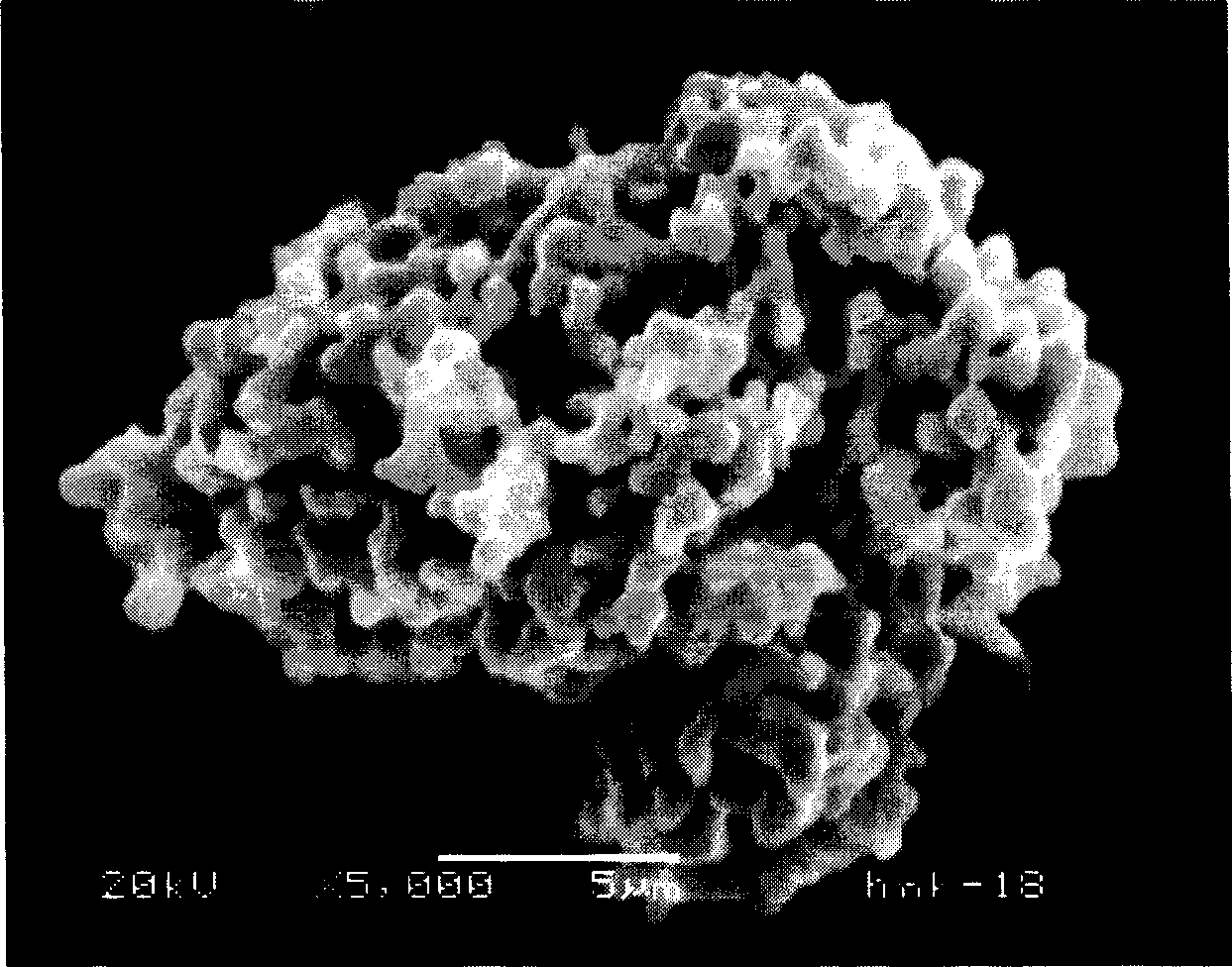

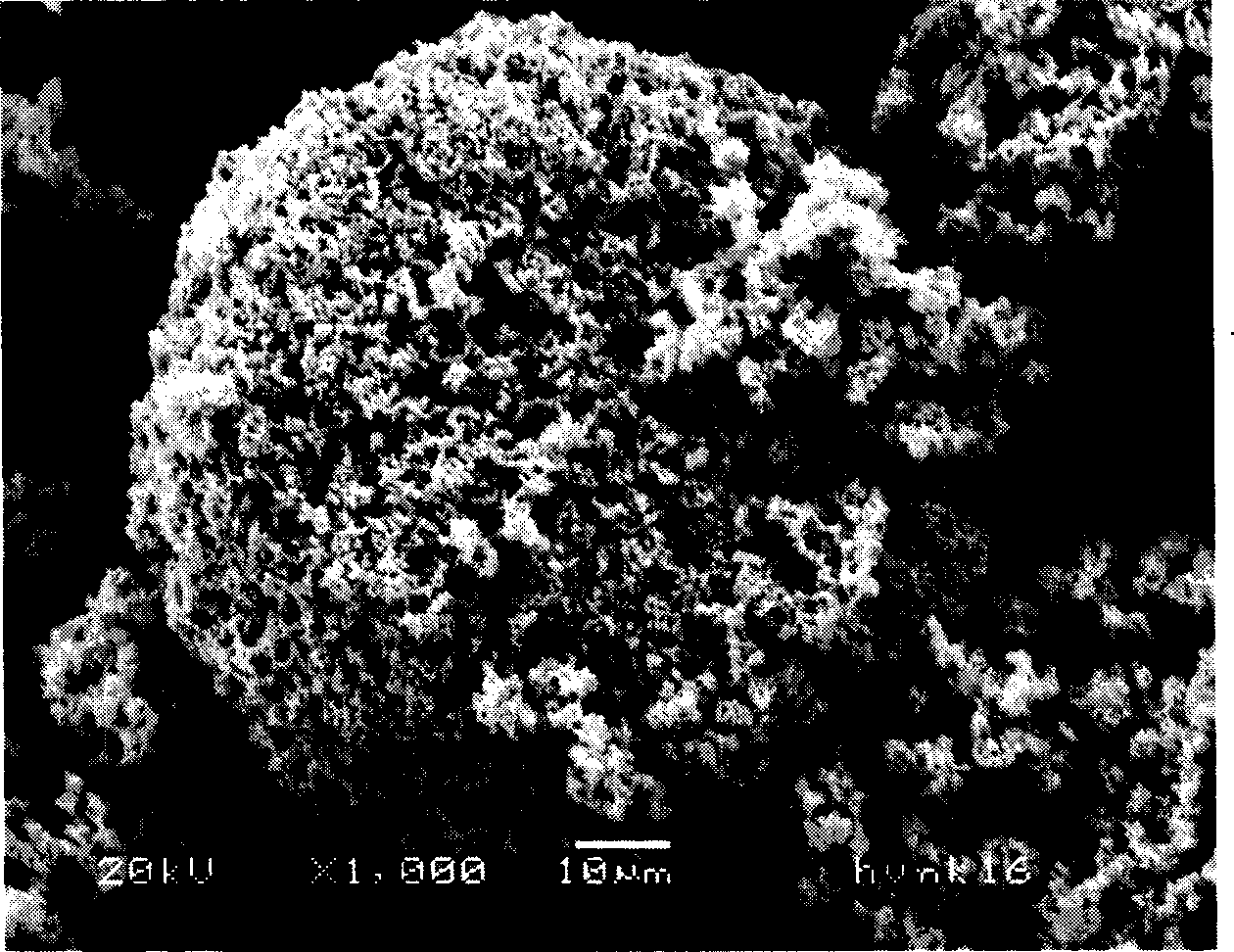

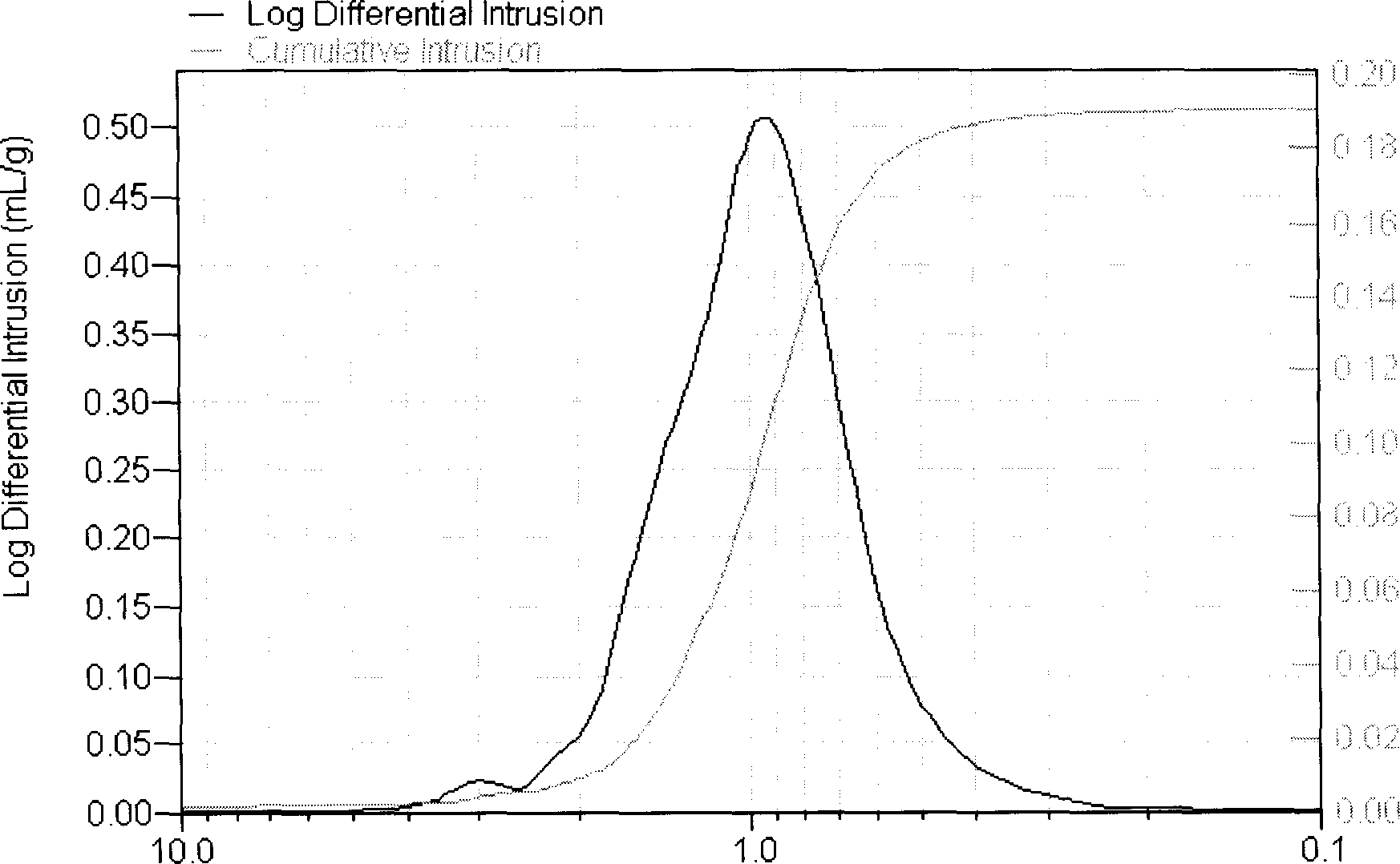

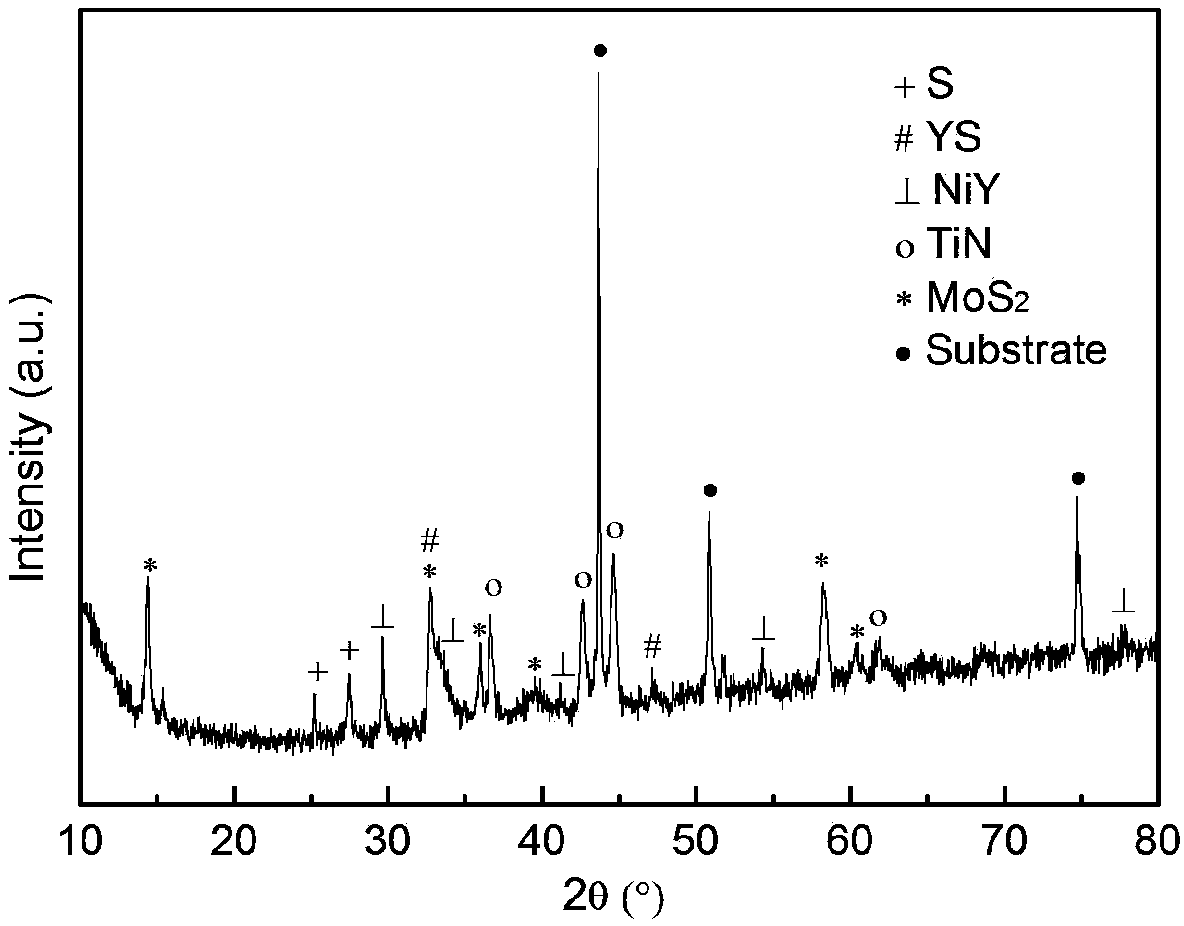

Rare earth yttrium doped molybdenum disulfide self-lubricating composite coating and preparation method thereof

ActiveCN108149220AHigh purityLow content of impurity elementsChemical vapor deposition coatingCalcium Chloride HexahydrateGas phase

The invention provides a rare earth yttrium doped molybdenum disulfide self-lubricating composite coating and a preparation method thereof. Specifically, the molybdenum disulfide self-lubricating composite coating is doped with rare earth yttrium, wherein the molar content of yttrium in the composite coating is 0.1%-5% according to the total molar content of the composite coating. According to themolybdenum disulfide self-lubricating composite coating, sublimed sulfur, yttrium chloride hexahydrate and molybdenum trioxide are adopted as raw materials, and the rare earth yttrium doped molybdenum disulfide self-lubricating composite coating is prepared through the chemical vapor deposition method. The molybdenum disulfide self-lubricating composite coating has good wear resistance and self-lubrication and excellent winding plating property. Coating deposition can be conducted on large-size complex workpieces of a complex shape.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Reinforced and toughened metastable beta titanium alloy and preparation method thereof

InactiveCN108342616ALow content of impurity elementsReduce the content of elementsChemical compositionHigh density

The invention discloses a reinforced and toughened metastable beta titanium alloy. The reinforced and toughened metastable beta titanium alloy comprises the following elements in percentage by weight:3.6-6.0% of Al, 3.0-5.0% of Mo, 3.0-5.0% of V, 2.0-5.9% of Cr, 1.0-4.0% of Nb, 0.4-2.0% of Fe, 0.05-0.3% of O, and the balance of Ti and inevitable impurities; the total quantity of impurity elementsis not higher than 0.15%; and the weight percentage sum of all the components is 100%. The invention further discloses a preparation method of the titanium alloy. Through changing of the adding formof Nb element, formation of the high-density inclusion defect of Nb-enriched non-melted blocks is prevented. Step variable-power smelting process parameters are adopted, so that the ingot chemical component uniformity is improved, and the component uniformity and the performance stability of the WSTi544432 metastable beta titanium alloy are guaranteed.

Owner:西部超导材料科技股份有限公司

Method for preparing NbZr10 alloy cast ingots

The invention relates to a method for preparing NbZr10 alloy cast ingots, which comprises the following steps of: (a), preparing niobium ingots; (b), preparing zirconium strips; (c), preparing electrodes; (d), performing primary smelting in a vacuum consumable electric-arc furnace; (e), performing secondary smelting in the vacuum consumable electric-arc furnace; (f), scalping zirconium niobium alloy cast ingots obtained by the two times of smelting till the surface is smooth and bright without any defects that can be seen by bare eyes; making samples and analyzing if these ingots are qualified; and obtaining NbZr 10alloy cast ingots, namely qualified ingots. The two times of smelting in the high-vacuum, high-current-intensity and high-power vacuum consumable electric-arc furnace ensure that the components of the finished NbZr10alloy cast ingots are distributed uniformly, and dramatically reduce impurity content. The diameter of the finished cast ingots is big enough to meet the current quality and use requirements on NbZr10alloy cast ingots.

Owner:BAOJI HENGXIN RARE METALS

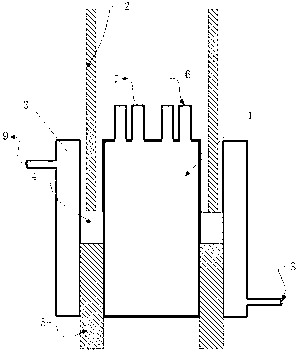

Electroslag remelting slag system of super duplex stainless steel

The invention relates to an electroslag remelting slag system of super duplex stainless steel. The electroslag remelting slag system comprises the following ingredients by weight percentage: 55-74% ofCaF2, 5-20% of CaO, 5-20% of Al2O3, 5-15% of MgO and 1-15% of SiO2. According to the electroslag remelting slag system, optimal slag alkalinity is achieved by adjusting contents of basic oxides, namely CaO and MgO, and acidic oxides, namely SiO2 and Al2O3; and the electroslag remelting slag system is particularly applicable to electroslag remelting of the super duplex stainless steel, improves purity of the super duplex stainless steel, reduces a content of harmful impurity elements, optimizes an ingot structure, greatly improves processability of the stainless steel increases a hot processing yield and contributes to achieving excellent mechanical properties and corrosion resistance.

Owner:CHONGQING MATERIALS RES INST

Large-size fine grain molybdenum rod and preparation method thereof

ActiveCN110722152AImprove pass rateSimple processTransportation and packagingMetal-working apparatusUltimate tensile strengthFine grain

The invention discloses a preparation method of a large-size fine grain molybdenum rod. The method comprises the steps of forming treatment, wherein forming treatment is carried out on molybdenum powder to obtain a formed blank; sintering treatment, wherein sintering treatment is carried out on the formed blank to obtain a sintered blank; forging deformation treatment, wherein forging deformationtreatment is carried out on the sintered blank to obtain a forging rod blank; and heat treatment, wherein annealing heat treatment is carried out on the forging rod blank to obtain a molybdenum rod. The production specifications of the pure molybdenum rod prepared with the preparation method of the large-size fine grain molybdenum rod can be enlarged, the diameter can range from 90 millimeters to150 millimeters, and the length can reach 3,000 millimeters; and according to the material, crystalline grains are fine and uniform, the room temperature tensile strength is higher than or equal to 550 MPa while the percentage elongation after fracture is larger than or equal to 15% at the room temperature, and at 1,000 DEG C, the high-temperature strength is higher than or equal to 200 MPa, and the percentage elongation after fracture is larger than or equal to 20%.

Owner:安泰天龙钨钼科技有限公司 +1

Method for preparing high-speed steel composite roll for hot rolling

The invention discloses a method for preparing a high-speed steel composite roll for hot rolling. The method is characterized by comprising the following steps of: firstly, manufacturing a regenerated high-speed steel composite roll collar by adopting an electroslag hollow stripping method; melting low-cost nodular cast iron or plain carbon steel by utilizing an intermediate frequency furnace or an electric arc furnace; manufacturing a roll core by a casting method; and fusing the roll outer collar and the roll core together in the manner of casting to prepare the composite roll for the hot rolling, wherein the working roll collar of the composite roll for the hot rolling is made of high-speed steel, and the roll core is made of the nodular cast iron or the plain carbon steel. The high-speed steel composite roll prepared by the method disclosed by the invention has the characteristics that the outer layer thickness is even, the tissue is fine and compact, and the nodular cast iron or the plain carbon steel is adopted to serve as the material of the roll core. The quality of the working face of the roll is comprehensively improved by utilizing the dual action of rare earth treatment and electroslag refining during a process of manufacturing the roll collar, and the service life is long. A roll body and the roll core are respectively made of the nodular cast iron or plain carbon steel, so that the integrated cost is low. The method disclosed by the invention is suitable for manufacturing the high-speed steel composite roll for the hot rolling and can be widely applied in metallurgical industry and renewable resource industry.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

Novel high-strength heat-resistant aluminium-alloy conductor

InactiveCN103820680AImprove performanceImprove heat resistanceSingle bars/rods/wires/strips conductorsMetal/alloy conductorsHeat resistanceManganese

The invention discloses a novel high-strength heat-resistant aluminium-alloy conductor. According to the invention, commercial-purity aluminium is used as a raw material, and traces of boron, antimony, manganese, copper and zirconium elements are added at 800+ / -10 DEG C. the novel high-strength heat-resistant aluminium-alloy conductor comprises components of, by weight, 0.01-0.30% of boron, 0.05-0.60% of antimony, 0.02-0.80% of manganese, 0.05-2.30% of copper, 0.05-0.90% of zirconium and the balance pure aluminium and unavoidable impurities. The novel high-strength heat-resistant aluminium-alloy conductor is manufactured by a conventional alloy smelting technology. The prepared aluminium-alloy conductor has high strength, good heat resistance and excellent conductivity. Comprehensive performance of the conductor is raised effectively. The aluminium-alloy conductor can be widely applied in national electric transmission lines, especially a long-span long-distance transmission and transformation project.

Owner:GUANGXI DONGXING DINGKANG PLASTIC IND

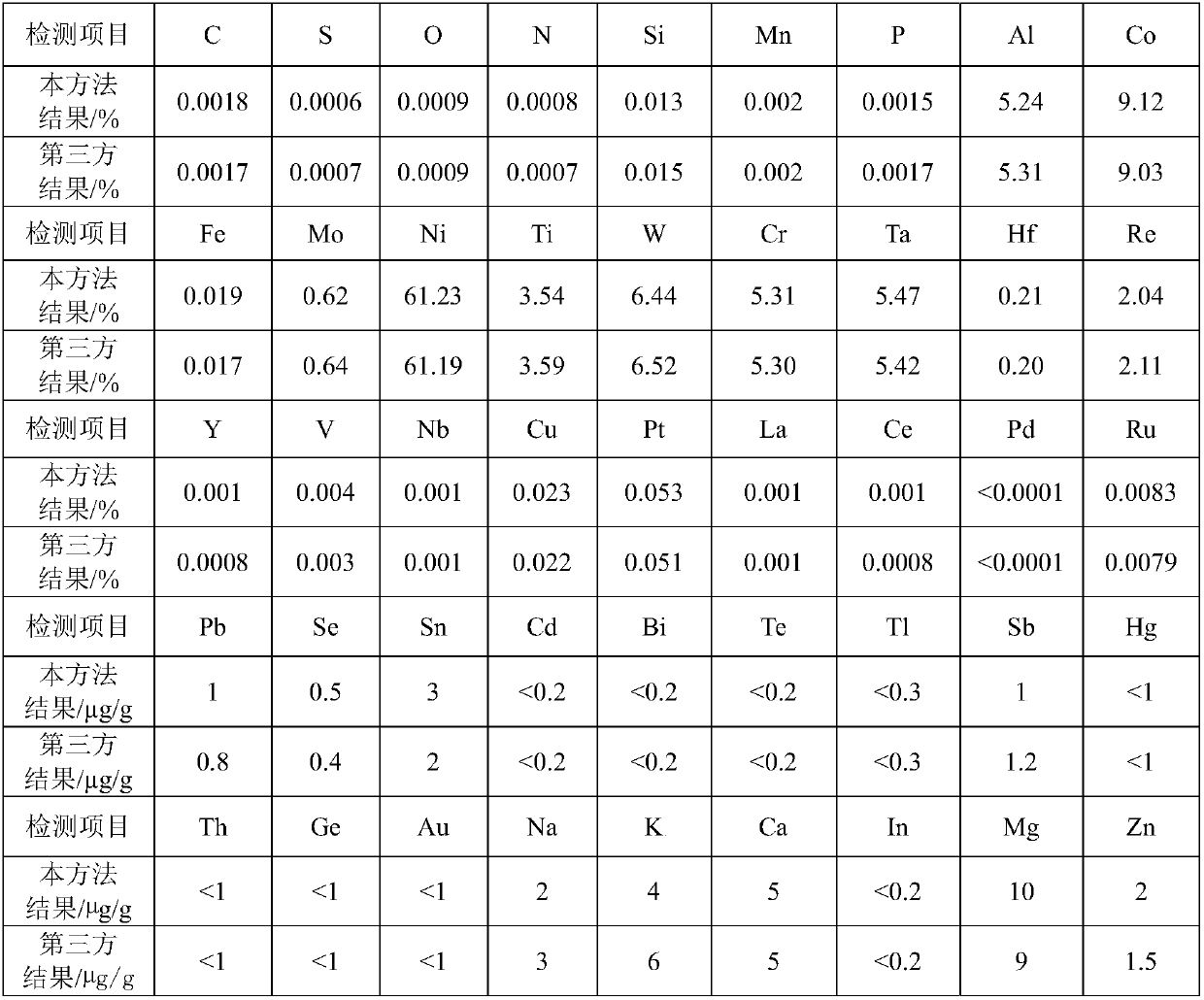

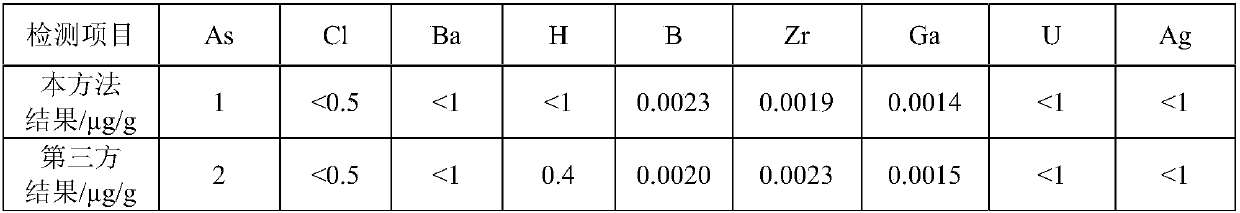

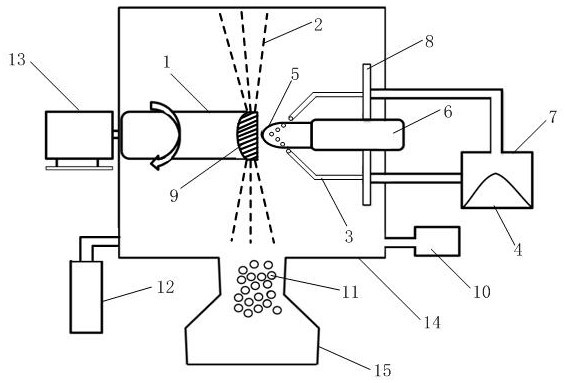

On-the-spot sample quick analysis method for major elements and trace elements in monocrystal high-temperature master alloy

InactiveCN108051495ALow content of impurity elementsRaise the level of purityPreparing sample for investigationMaterial analysis by electric/magnetic meansSingle crystalOxygen

The invention relates to an on-the-spot sample quick analysis method for major elements and trace elements in monocrystal high-temperature master alloy. The on-the-spot sample quick analysis method comprises the following steps: firstly, taking monocrystal master alloy melt in a vacuum induction furnace by using a fireproof cup and adopting a secondary immersion method, quickly cooling after solidifying, and completing sampling; secondly, cutting the tail part of a test sample into a first test sample of which the thickness is 8 to 15 mm, cutting a second test sample of which the thickness is3 to 6 mm from the remained test sample, pelletizing, and using the remained part as a third test sample; finally, respectively testing the major elements and the trace elements in the monocrystal master alloy by adopting a carbon-sulfur detector, an oxygen-nitrogen detector, an X-ray fluorescence spectrometer, a direct-reading spectrometer and a glow discharge mass spectrometer, and quickly transmitting detection results to a smelting control room by utilizing an LSAM (Lower Sampling Room) database. According to the on-the-spot sample quick analysis method disclosed by the invention, on-the-spot sample quick analysis on 50 or more major elements and trace elements in the monocrystal master alloy can be completed within 15 to 20 minutes, the on-the-spot sample analysis time of high-temperature alloy is shortened, and accurate data can be provided for effectively controlling the major elements and purified harmful impurity elements for smelting of monocrystal alloy.

Owner:JIANGSU LONGDA SUPERALLOY MATERIAL CO LTD

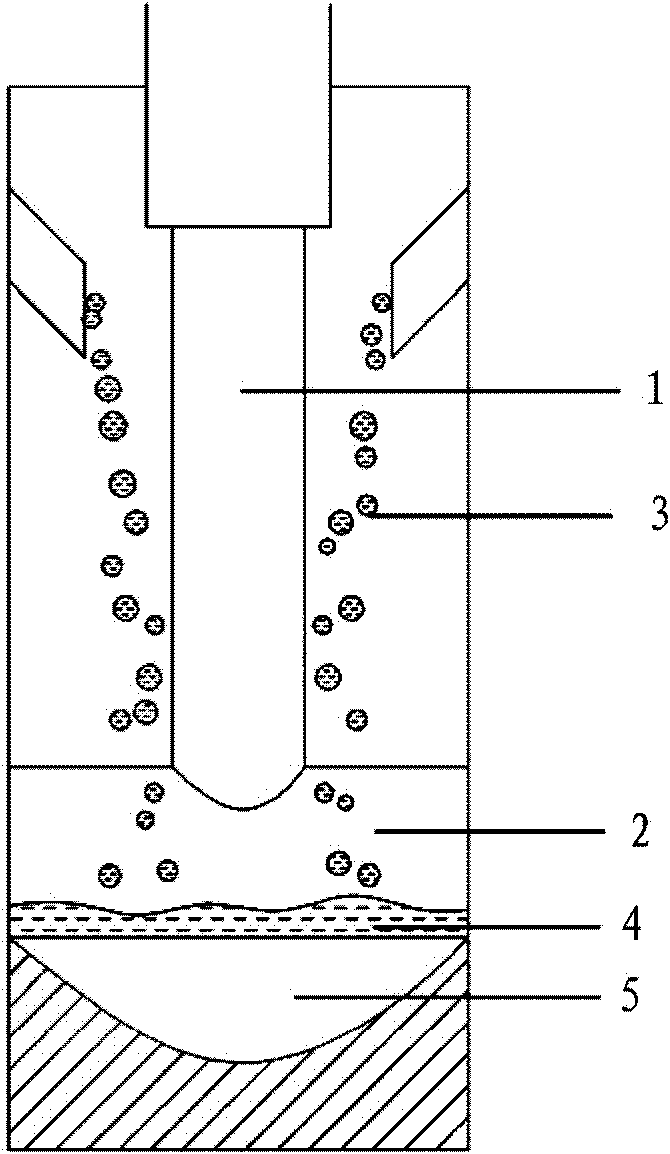

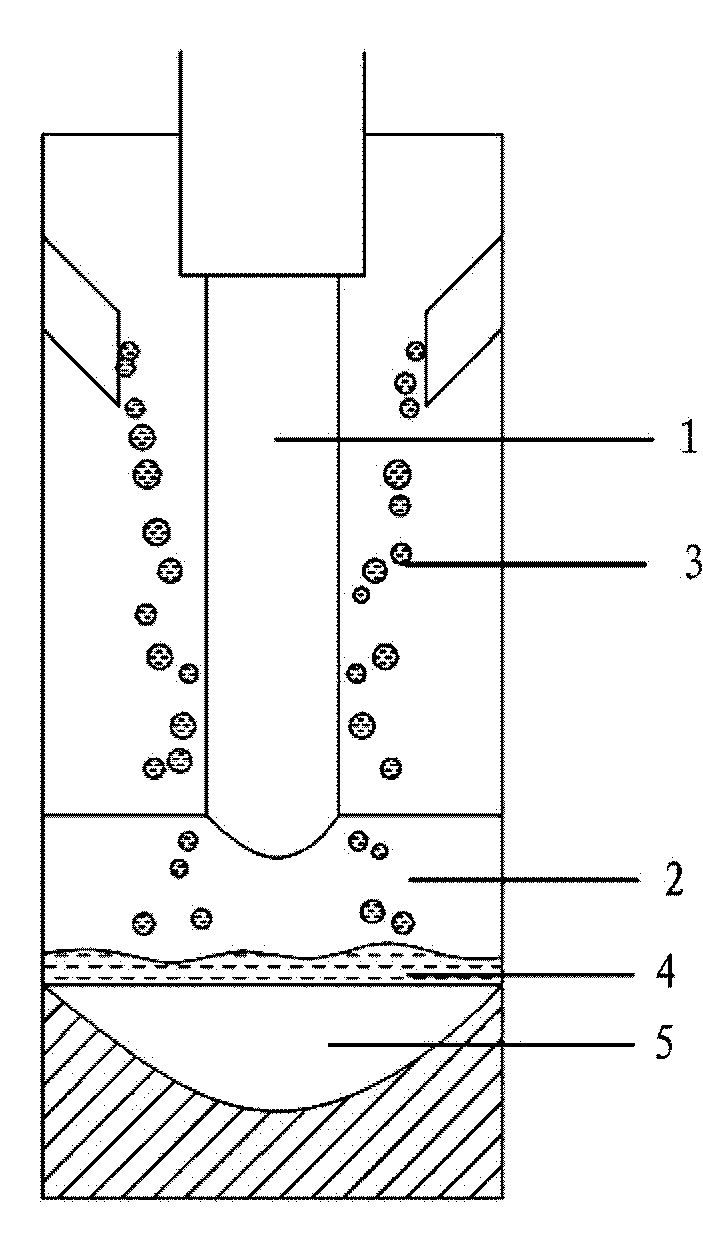

Method for promoting cryptomere congealing of continuously casting molten steel

The invention relates to a method for accelerating the solidification of casting steel water, wherein it adds micro powder smaller than 20micrometer into steel water while the consumption is 0.05-5% of steel water, while said micro powder can be same material of steel water, or / and electrolyte iron powder. The corn shaper of said invention will not affect the components of steel water.

Owner:WUHAN IRON & STEEL ENG TECH GROUP

Method for manufacturing molybdenum plate blank through sintering

The invention discloses a method for manufacturing a molybdenum plate blank through sintering. The method includes the steps that firstly, raw materials are weighed, and the weighed raw materials are evenly mixed, and mixed molybdenum powder is obtained; secondly, the mixed molybdenum powder is pressed into a plate blank in a cold isostatic pressing manner; and thirdly, under the hydrogen atmosphere, the plate blank is heated and sintered, and the molybdenum plate blank is obtained after being naturally cooled. Heating and sintering include the specific steps that firstly, the plate blank is firstly heated to 900 DEG C and sintered for 1 hour to 2 hours at the temperature of 900 DEG C, then the plate blank is heated to 1,500 DEG C and sintered for 2 hours to 4 hours at the temperature of 1,500 DEG C, and then the plate blank is heated to 750 DEG C to 1,780 DEG C and sintered for 6 hours to 10 hours at the temperature of 750 DEG C to 1,780 DEG C. According to the method, molybdenum powder used in the method is common brands of molybdenum powder in the market, cost is controllable, and purchase is easy; the apparent density of the mixed molybdenum powder is increased, fluidity is improved, a rubber sleeve is filled with the molybdenum powder more easily in the powder filling process, and the plate profile of the pressed blank is improved; and the maximum sintering temperature is lowered, and the loss of equipment and the like and energy consumption are reduced.

Owner:XIAN REFRA TUNGSTEN & MOLYBDENUM

Refining agent for atmosphere protected electro-slag re-melting

The invention provides a refining agent for atmosphere protected electro-slag re-melting. The refining agent comprises aluminum metal, calcium metal and electro-slag, wherein the specific gravity of the refining agent is greater than that of molten slag and smaller than that of molten alloy. The refining agent for the atmosphere protected electro-slag re-melting can be used for refining various products suitable for electro-slag re-melting process treatment such as carbon steel, alloy constructional steel, bearing steel, die steel, high-speed steel, stainless steel, heat resistant steel, ultrahigh-strength steel, high-temperature alloy, precision alloy, anticorrosive alloy, electric heating alloy and the like. The refining agent can effectively reduce the content of impurity elements such as O, S, P and the like of an alloy product on the premise that the conventional atmosphere protected electro-slag re-melting production process is not affected, can reduce nonmetallic inclusion content of the alloy and does not introduce new impurity elements, so as to improve the metallurgical quality of the alloy product.

Owner:CENT IRON & STEEL RES INST

High-performance arc spraying Zn-Al powder core wire and preparation method thereof

InactiveCN102839344AImprove mechanical propertiesHinder dislocation movementMolten spray coatingOceanic climateCorrosion

The invention discloses a high-performance arc spraying Zn-Al powder core wire and a preparation method thereof, belonging to the technical field of metal surface protection. The wire is mainly composed of an outer cladding and a powder core, wherein the outer cladding is a Zn-Al alloy strip; the powder core is mainly composed of the following components in percentage by weight: 60-70% of nano Al2O3 powder, 10-20% of nano TiO2 powder and the balance of nano Y2O3 powder; and the nano powder core accounts for 5-20% of the total weight of the wire. The novel Zn-Al nano powder core wire can be prepared into a Zn-Al nano composite coating through an arc spraying method; and the ocean climate corrosion resistance and the hardness of the coating are far higher than those of the common arc spraying Zn-Al coating.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

High-specific-gravity tungsten-based alloy formation method based on pre-alloyed powder

ActiveCN110315076APromote meltingNot easy to melt and formAdditive manufacturing apparatusIncreasing energy efficiencyManufactured formSolid solution

The invention discloses a high-specific-gravity tungsten-based alloy formation method based on pre-alloyed powder. The high-specific-gravity tungsten-based alloy formation method based on the pre-alloyed powder comprises the steps that firstly, according to the designed ingredients and proportion of the high-specific-gravity tungsten-based alloy, material mixing, pressing, vacuum sintering and forging machining are sequentially conducted, then a tungsten-based alloy rod is obtained, and pre-alloyed powder is obtained through a plasma-rotating electrode powder manufacturing method; secondly, athree-dimensional model of the high-specific-gravity tungsten-based alloy is established, slicing and designing are conducted, and then slice layers and scanning data are obtained; thirdly, with the pre-alloyed powder as the raw material, according to the slice layers and the scanning data, a powder bed type electron beam additive manufacturing forming device is adopted to form the high-specific-gravity tungsten-based alloy. According to the high-specific-gravity tungsten-based alloy formation method based on the pre-alloyed powder, by utilizing the different melting points between tungsten and other elements in the high-specific-gravity tungsten-based alloy, the pre-alloyed powder with tungsten powder particles being wrapped inside low-melting-point element solid solution is prepared, sothat the shells of the pre-alloyed powder are easy to melt and adhere to one another for formation, and therefore the formation difficulty of the pre-alloyed powder is lowered; and with the pre-alloyed powder as the raw material, preparation of the high-specific-gravity tungsten-based alloy is achieved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Preparation method of pentaerythritol tetrabasic acid ester

ActiveCN106631782AGood high temperature performanceLow content of impurity elementsOrganic compound preparationCarboxylic acid esters preparationIodo fatty acidPentaerythritol

The invention provides a preparation method of pentaerythritol tetrabasic acid ester. The method includes the steps of: a) mixing pentaerythritol, fatty acid and a catalyst to perform an esterification reaction to prepare a pentaerythritol tetrabasic acid ester crude product; and b) mixing the pentaerythritol tetrabasic acid ester crude product with a solid adsorbent to purify the crude product to obtain the pentaerythritol tetrabasic acid ester. Compared with the prior art, the preparation method can effectively remove impurities in the reaction system, so that the pentaerythritol tetrabasic acid ester has excellent high temperature performance. A test result proves that the content of impurity elements in the pentaerythritol tetrabasic acid ester prepared through the method is lower than 1 ppm. In addition, the pentaerythritol tetrabasic acid ester has better oxidizing performance, wherein the initial oxidization temperature thereof is increased by more than 10 DEG C in the same base oil.

Owner:CHINA PETROLEUM & CHEM CORP

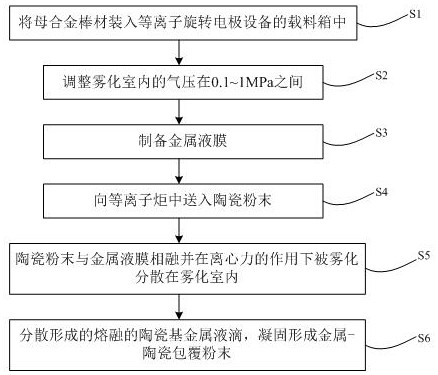

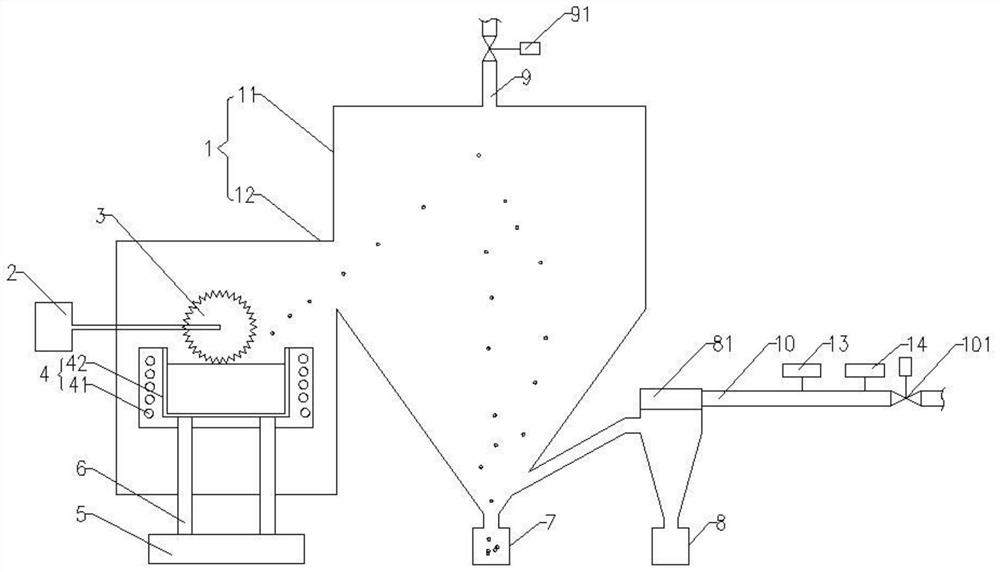

Device and method for preparing metal-ceramic coated powder

ActiveCN113245544AResolve the breakHigh sphericityTransportation and packagingMetal-working apparatusMolten metalHigh heat

The invention belongs to the technical field of preparation of composite powder materials, and particularly relates to a device and method for preparing metal-ceramic coated powder. By the adoption of the device, the problems that a metal-ceramic bar is difficult to smelt and the bar is fractured due to insufficient metal-ceramic bonding strength are solved. In the process of preparing metal spherical powder by PREP, ceramic powder sprayers are started to enable ceramic powder to enter a high-temperature plasma torch at an incident angle of 10-60 degrees, the surface of the ceramic powder is instantly liquefied under the high-temperature action of the plasma torch, but the core part of the ceramic powder is still kept in a solid state, and the ceramic powder is brought into metal liquid film on the end face of a bar through the plasma torch to be fused with the metal liquid film; the surface-liquefied ceramic powder and the molten metal are fused under the action of thermal capillary force, the molten metal wraps the surface-liquefied ceramic powder; and molten ceramic-based metal liquid drops are dispersed into an atomizing chamber under the action of centrifugal force and are solidified to form metal-ceramic coated powder which is high in sphericity degree, low in impurity content and uniform in coating.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

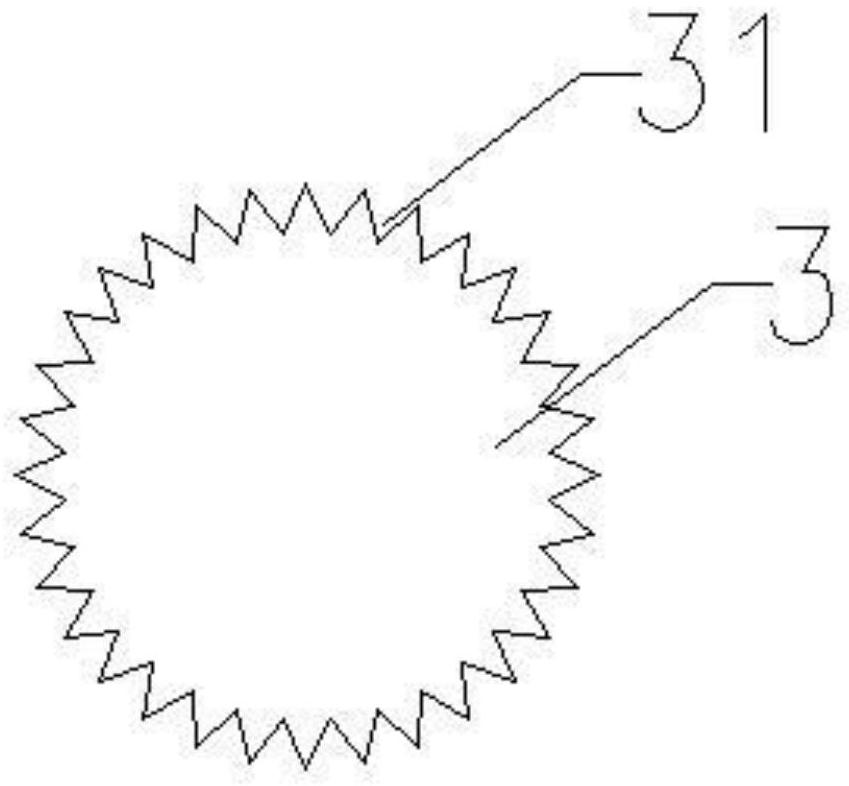

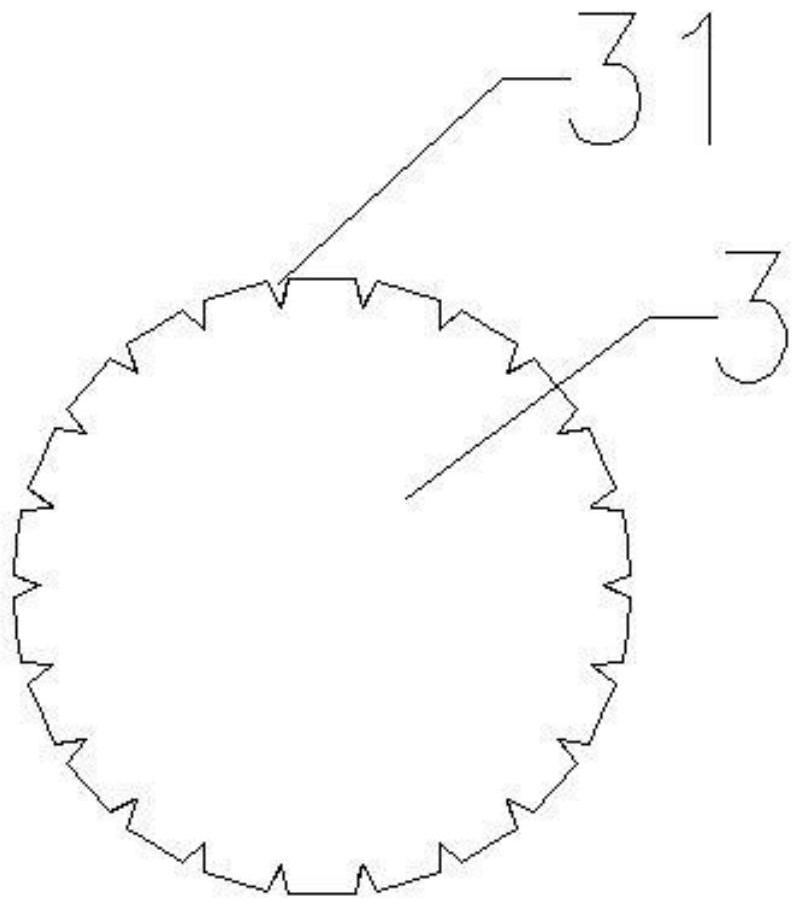

Device and method for preparing spherical titanium and titanium alloy powder

PendingCN114192790AGood sphericityFine sphericityAdditive manufacturing apparatusIncreasing energy efficiencyIngotTitanium

The invention relates to a spherical titanium and titanium alloy powder preparation device and method. The device comprises a smelting chamber (12), an atomizing chamber (11), a rotating wheel (3), a smelting unit (4), a lifting device (5) and a primary powder collecting tank (7), the rotating wheel (3) is rotationally arranged in the smelting chamber (12) and located above the smelting unit (4), the smelting unit (4) moves through the lifting device (5), the smelting chamber (12) is communicated with the atomizing chamber (11), a communication port is located on the tangent line of the rotating wheel (3), and the primary powder collecting tank (7) is communicated with the atomizing chamber (11). The method comprises the following steps: a, alloy ingot smelting; b, atomizing molten drops; c, collecting powder; and d, screening the powder. And a rotating wheel is adopted to throw out the melt for heat exchange to prepare the spherical titanium or titanium alloy powder which is fine in granularity, low in hollow rate, high in sphericity degree and low in oxygen content. The problems that according to an existing spherical titanium and titanium alloy preparation method, the oxygen content, the hollow rate and the impurity content of powder are high are solved.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

Process for preparing Nb and/or Ta powder

Owner:NINGXIA ORIENT TANTALUM IND

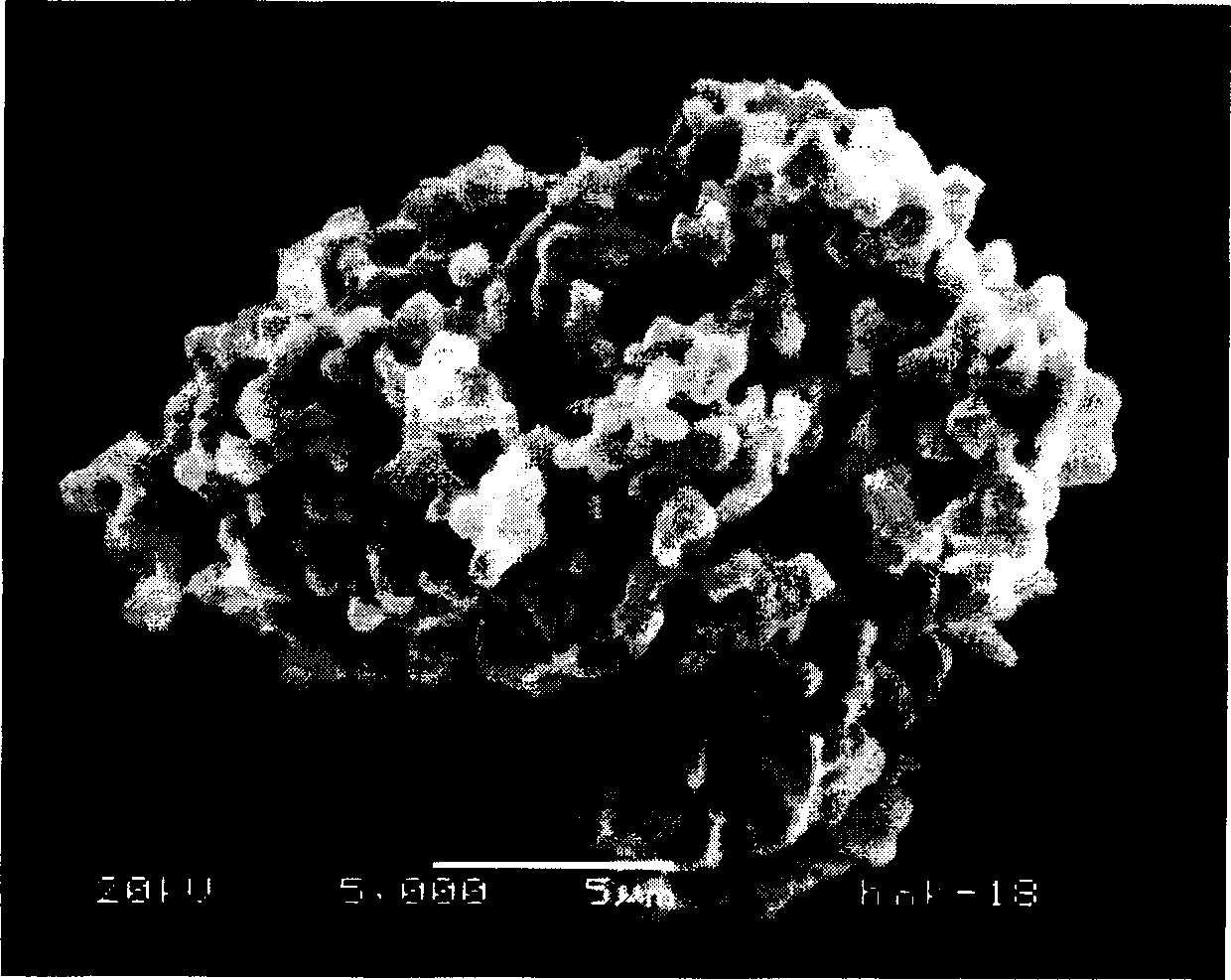

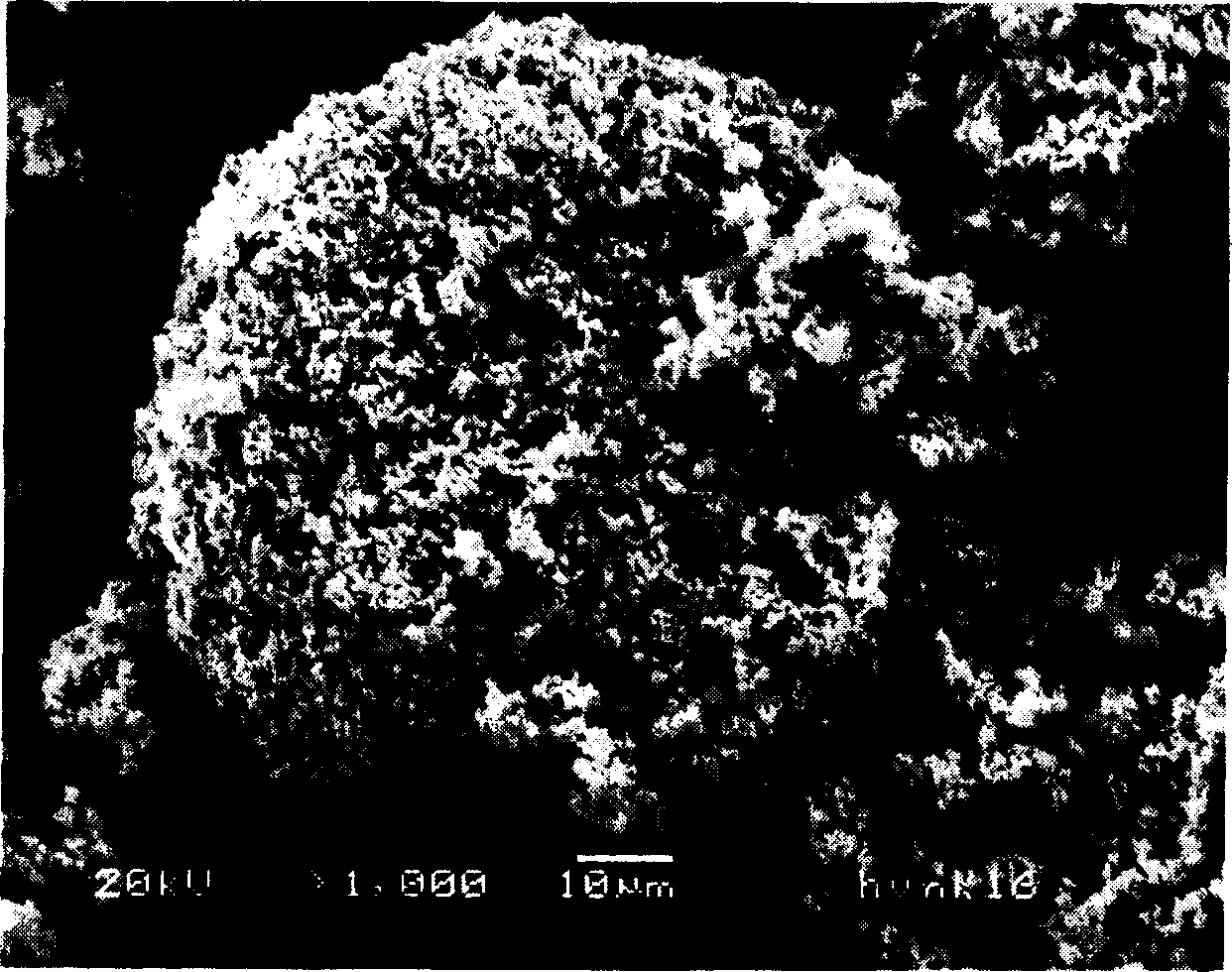

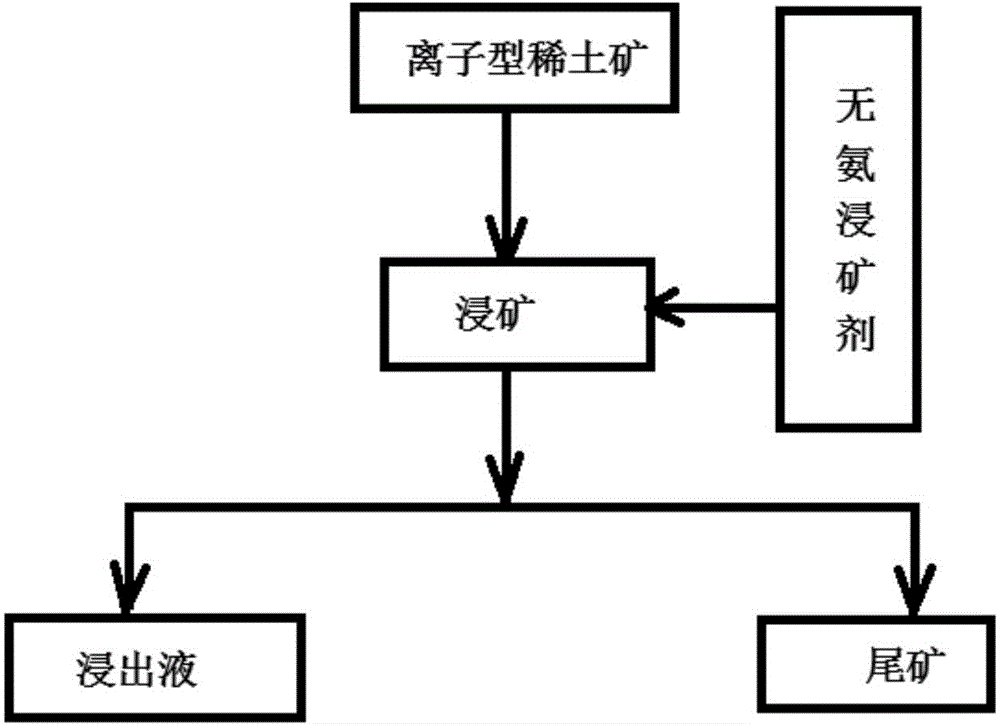

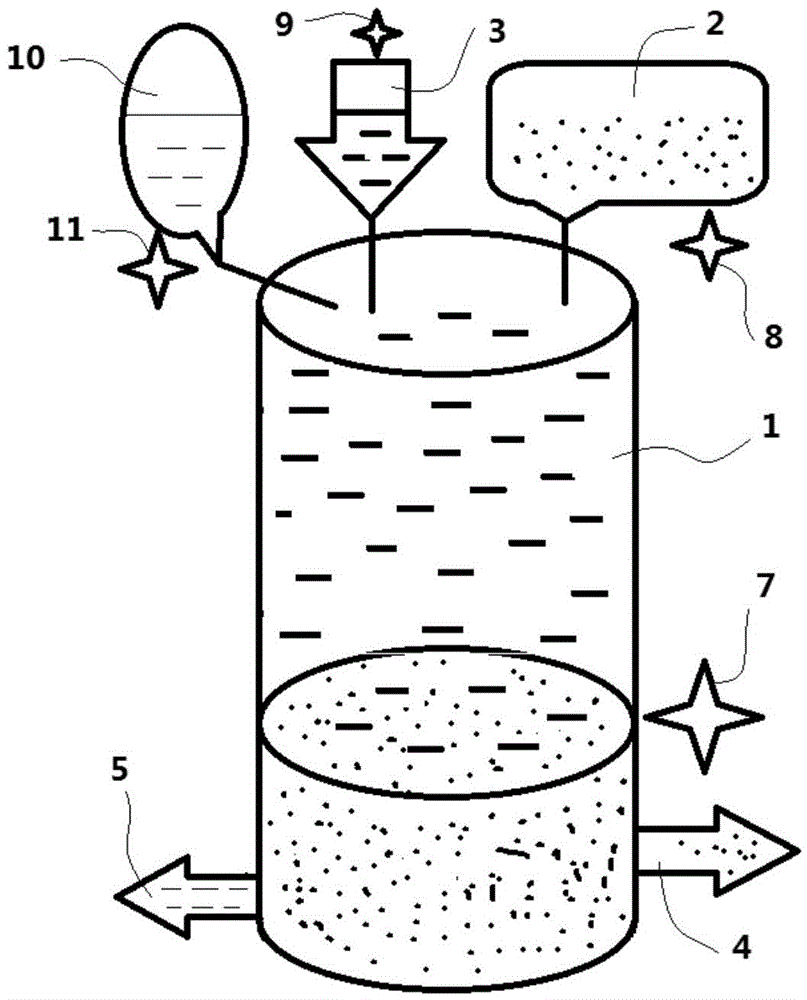

Mineral leaching method and mineral leaching system for ionic rare earth mine

InactiveCN103555939AImprove leaching effectImprove rare earth leaching rateProcess efficiency improvementRare earthMaceral

The invention relates to a mineral leaching method for an ionic rare earth mine. The mineral leaching method is characterized by comprising the following steps: carrying out percolation leaching on the mine by taking ammonia-free electrolyte as a mineral leaching agent, so that positive ions in the mineral leaching agent and ion-phase rare earth adsorbed on the surface of a carrier mine exchange to form a soluble rare earth compound entering the solution; loading the ionic rear earth mine in a mineral leaching exchange column, and adding the ammonia-free mineral leaching agent with the concentration of 2-5% according to the proportion of the mineral leaching agent (liters) to the mine (kilograms) being 0.6-0.8; after the surface of the mine is exposed out, adding top water according to the proportion of the top water (liters) to the mine (kilograms) being about 0.2; and draining away a residual solution in the mineral leaching exchange column fundamentally, namely ending mineral leaching work. The mineral leaching method is high in mineral leaching efficiency, and can prevent the pollution of ammonia nitrogen to the environment.

Owner:GANZHOU NONFERROUS METALLURGICAL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com