On-the-spot sample quick analysis method for major elements and trace elements in monocrystal high-temperature master alloy

A high-temperature master alloy and trace element technology, which is applied in the field of chemical analysis, can solve the problems of harsh service conditions of single crystal superalloys, achieve the effect of reducing smelting time, reducing burning loss and energy consumption, and improving the level of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

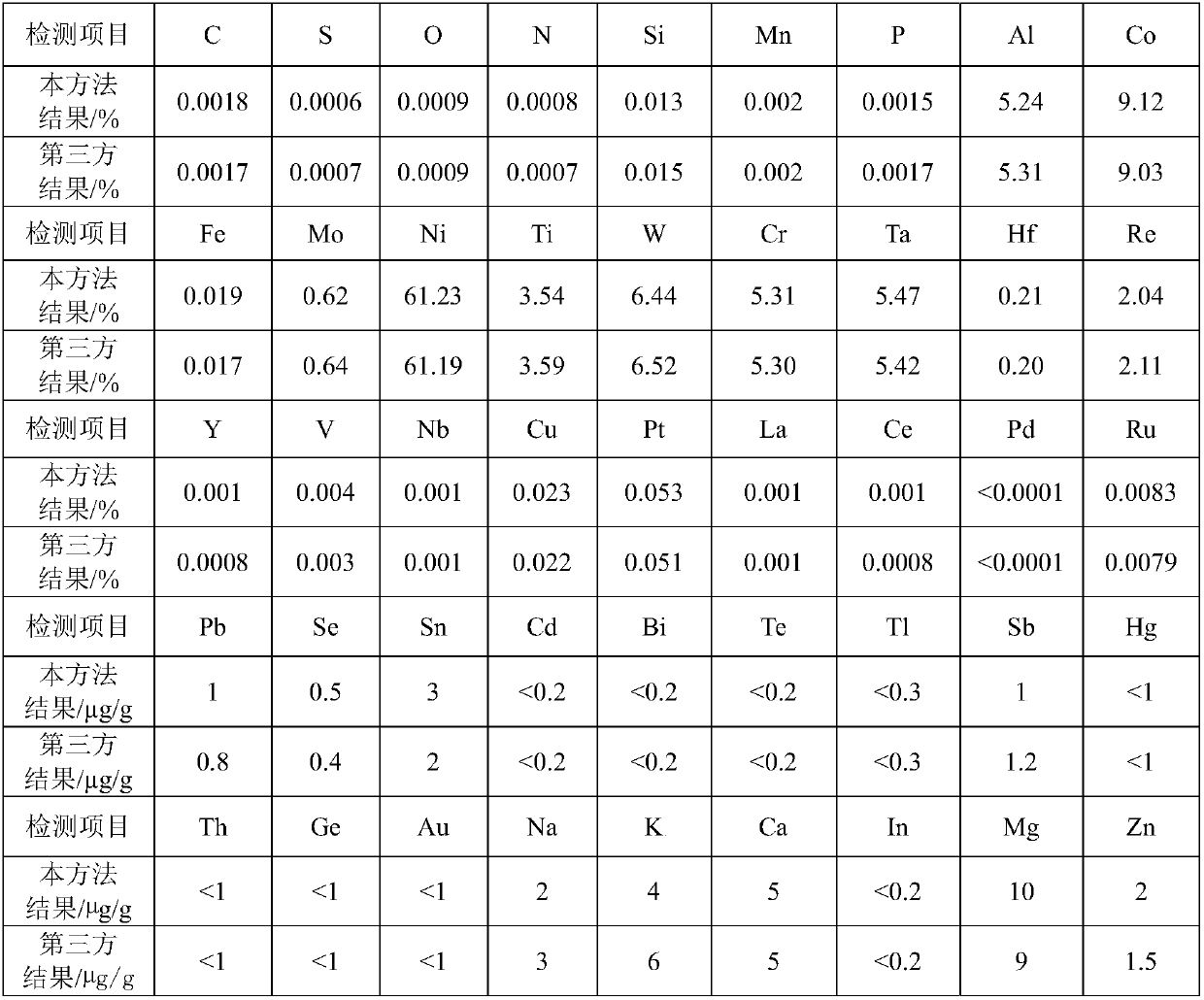

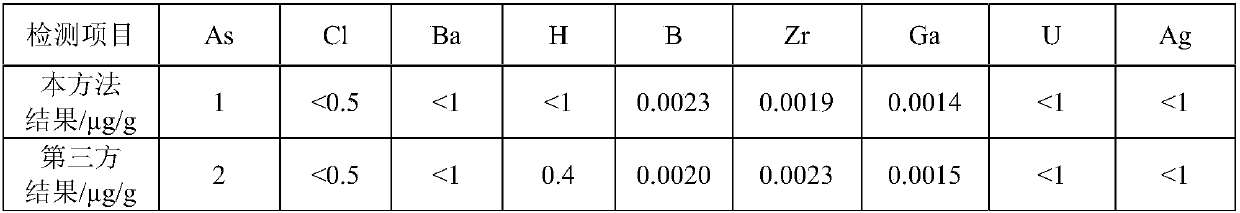

[0025] Take the detection of smelting LD-X-4 single crystal nickel-based high-temperature master alloy as an example:

[0026] (1) Sampling:

[0027] In a 2.5T vacuum induction furnace, a strong magnetic field is used to stir the single crystal nickel-based high-temperature master alloy melt to disperse the scum on the surface of the melt, and use a quartz sampling cup with an inner diameter of 30mm and a length of 50mm that is burned at a high temperature of 1100°C for more than 1h In the vacuum induction furnace, the single-crystal nickel-based high-temperature master alloy melt is taken by the secondary immersion method to ensure that there is no shrinkage cavity, porosity and cracks inside the sample, and the continuous effective length shall not be less than 25mm. After solidification, the flowing water is rapidly cooled. The sample is transported to the sample preparation room;

[0028] (2) Sample preparation:

[0029] Cut the first sample with a thickness of 10mm at t...

Embodiment 2

[0049] Take the detection of smelting Co-Al-W single crystal cobalt-based high-temperature master alloy as an example:

[0050] (1) Sampling:

[0051] Stir the single-crystal cobalt-based high-temperature master alloy melt with a strong magnetic field in a 1T vacuum induction furnace to disperse the scum on the surface of the melt. Use a brown corundum sampling cup with an inner diameter of 40mm and a length of 40mm that has been burned at 1000°C for more than 2 hours. In the vacuum induction furnace, the single crystal cobalt-based high-temperature master alloy melt is taken by the secondary immersion method to ensure that there is no shrinkage cavity, porosity and cracks inside the sample, and the continuous effective length shall not be less than 25mm. After solidification, the flowing water is rapidly cooled. The sample is transported to the sample preparation room;

[0052] (2) Sample preparation:

[0053] Cut the first sample with a thickness of 15mm at the end of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com