Device and method for preparing metal-ceramic coated powder

A technology of coated powder and ceramic powder, which is applied in the field of composite powder material preparation, can solve the problems of melting point, large quality difference, insoluble ceramics, and inability to form coated powder, etc., achieve low content of impurity elements, avoid smelting difficulties, Improve the effect of two-phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This embodiment provides a method of preparing a metal-ceramic coating powder using a plasma rotary electrode device, the specific process is as follows:

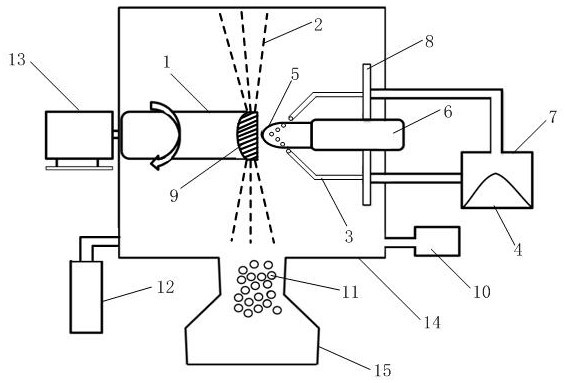

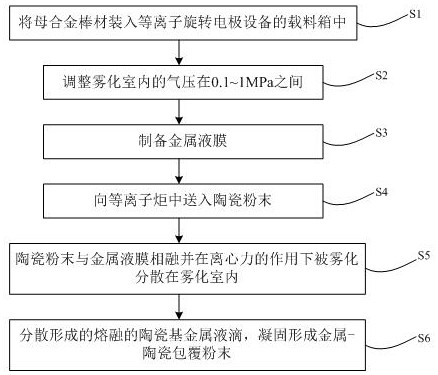

[0056] Put the machine-machined φ60 × 500mm Inconel 718 master alloy rib 1 is loaded into the carrier box of the plasma rotating electrode equipment; start the vacuum assembly 10, and the atomization chamber 14 is vacuum to 5 × 10 -3 PA, then the argon is introduced, so that the pressure of the atomization chamber 14 is 0.5 MPa; the drive motor 13 is activated by the Inconel 718 mother, and the INCONEL 718 mother-in gold ribs 1 rotational speed rises to 16000R / min and smooth rotation After the plasma gun 6, the plasma gun 6 power is 100 kW, ionizing excitation plasma torch 5, plasma torch 5 melting the INCONEL 718 master co-gold ribs 1 end surface forming a metal liquid film 9; then activates the pneumatic powder apparatus 7, the average particle size is 2μm ceramic powder Al 2 O 3 Delivered to ceramic powder nozzles 3...

Embodiment 2

[0059] In this embodiment, it provides a method of preparing a metal-ceramic coating powder using a plasma rotating electrode device, and the specific process is as follows:

[0060] The 316L master alloy rib 1-machined φ70 × 600 mm 316L parent-binding bobbin is loaded into the plasma rotary electrode equipment; start the vacuum assembly 10, and the atomization chamber 14 is vacuum to 3 × 10 -3 PA, then an inert gas argon is passed, and the atomizing chamber 14 is 0.3 MPa; the drive motor 13 is activated by the 316L mother-in-gold ribs 1 to rotate, to be 316L mother-in-gold ribs 1 speed rises to 18000R / min and smooth rotation After the plasma gun 6, the plasma gun 6 power is 120 kW, the ionizing excitation plasma torch 5, the plasma torch 5 melted 316L mother-in gold ribs 1 end surface forming a metal liquid film 9; then activates the pneumatic powder powder device 7, the average particle size is 1.5 The ceramic powder Tin of μm is sent to the ceramic powder nozzle 3 by a powder...

Embodiment 3

[0063] In this embodiment, it provides a method of preparing a metal-ceramic coating powder 11 using a plasma rotating electrode device, and the specific process is as follows:

[0064] The COCR master alloy rib 1 of the machine-machined φ80 × 700 mm is loaded into the plasma rotary electrode equipment carrier box, activate the vacuum assembly 10, and the atomization chamber 14 is vacuumed to 2 × 10 -3 PA, then pass an inert gas argon, so that the pressure of the atomizing chamber 14 is 0.2 MPa; activation drive motor 13 drives the COCR mother-in-gold ribs 1 to rotate, to be CoCr master co-gold ribs 1 speed rises to 20000R / min and smooth rotation After the plasma gun 6, the plasma gun 6 is 140 kW, the ionizing excitation plasma torch 5, the plasma torch 5 melted the COCr mother-in gold ribs 1 to form a metal liquid film 9; then activate the pneumatic powder powder device 7, the average particle size is 2.5 The ceramic powder Wc of μm was sent to the ceramic powder nozzle 3 by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com