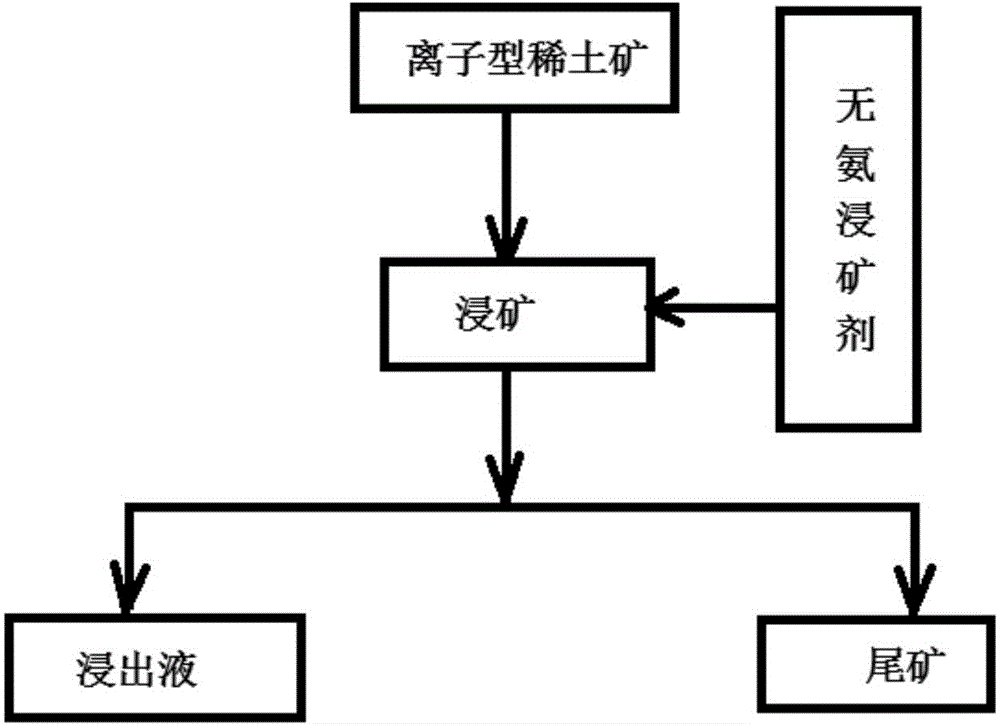

Mineral leaching method and mineral leaching system for ionic rare earth mine

An ion-type rare earth ore leaching technology, applied in the field of hydrometallurgy, can solve the problems of high NaCl concentration, damage to the environment, and long leaching cycle, etc., to achieve low content of impurity elements, high rare earth leaching rate, and good leaching effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

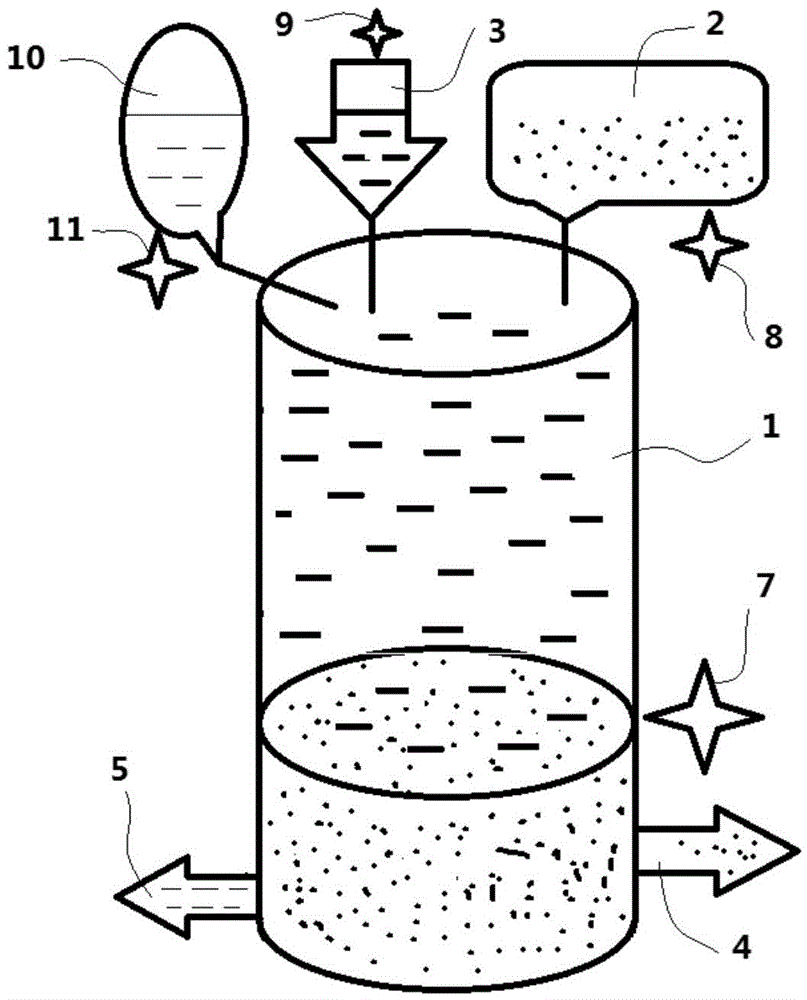

Method used

Image

Examples

example 1

[0031] Take ionic rare earth ore-1, ionic phase rare earth 0.097%, moisture 10.86%, use 2% ammonium sulfate for leaching, rare earth leaching rate is 95.05%, penetration time is 6h, leaching period is 58h, leaching solution REO1.26g / L, Fe<0.001g / L, Al0.022g / L, Si0.015g / L, Ca0.280g / L, pH4.5; using the 2% leaching agent of the present invention, the rare earth leaching rate is 95.15%, and the penetration time 7.5h, leaching cycle is 60h, leaching solution REO0.94g / L, Fe<0.001g / L, Al0.019g / L, Si0.009g / L, Ca0.240g / L, pH4.5.

example 2

[0033] Take ionic rare earth ore-1, ionic phase rare earth 0.097%, moisture 10.86%, use 2% ammonium sulfate for leaching, rare earth leaching rate is 95.05%, penetration time is 6h, leaching period is 58h, leaching solution REO1.26g / L, Fe<0.001g / L, Al0.022g / L, Si0.015g / L, Ca0.280g / L, pH4.5; using the 5% leaching agent of the present invention, the rare earth leaching rate is 95.25%, and the penetration time 6h, leaching cycle is 48h, leaching solution REO1.25g / L, Fe<0.001g / L, Al0.025g / L, Si0.011g / L, Ca0.320g / L, pH4.5.

example 3

[0035]Take ionic rare earth ore-2, ionic phase rare earth 0.062%, moisture 10.69%, use 2% ammonium sulfate for leaching, the rare earth leaching rate is 92.90%, the penetration time is 5.5h, the leaching period is 56h, and the leaching solution REO0.82g / L, Fe<0.001g / L, Al0.016g / L, Si0.009g / L, Ca0.220g / L, pH4.5; using the 2% leaching agent of the present invention, the rare earth leaching rate is 93.01%, and the penetration rate is 93.01%. The time is 7.0h, the leaching period is 58h, the leaching solution is REO0.60g / L, Fe<0.001g / L, Al0.010g / L, Si0.009g / L, Ca0.144g / L, pH4.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com