Conductive paste

A technology of conductive paste and conductive powder, which is applied in the field of conductive paste and can solve problems such as the possibility of solder leaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

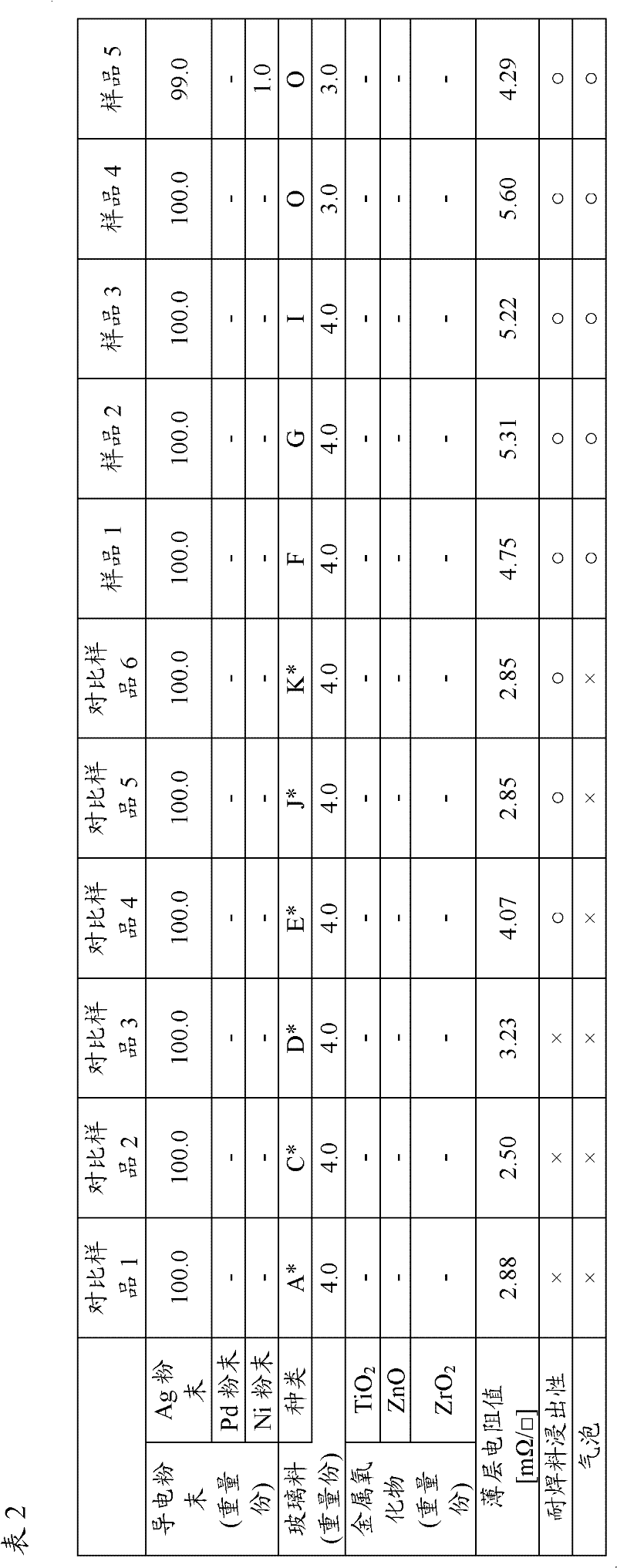

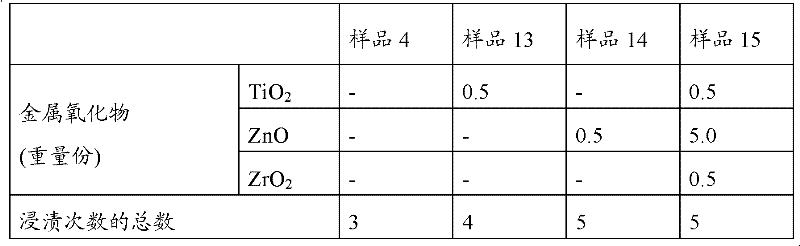

[0056] In the present embodiment, a plurality of samples having electrically conductive pastes having mutually different compositions were prepared, and properties and characteristics of each sample were evaluated.

[0057] (1) Sample preparation

[0058] (1.1) Preparation of glass frit

[0059] Glass raw materials were mixed so as to have the glass composition shown in Table 1 below, and each mixture was heated at a temperature of 1600° C. for 1 to 1.5 hours to melt, and the molten mixture was cast on graphite or flowed into a roll Quenching is carried out in a roll quench machine. The glass material obtained by quenching was ground for 48 hours using alumina balls using a ball mill to prepare glass frits "A" to "O" having an average particle diameter of about 2.5 μm. The average particle size is the 50% value (D 50 ). Here, the raw material of the glass frit B does not melt at a temperature of 1600° C., so the glass frit B cannot be produced. In the table below, * is in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com