Hafnium lead titanate-based anti-ferroelectric ceramic material and preparation method thereof

A hafnium lead titanate-based, ceramic material technology, applied in the field of electronic ceramic materials, can solve the problems of easy segregation of defective components, low electrical breakdown strength, and low energy storage density, and achieve excellent energy storage density and few defects , the effect of high energy storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

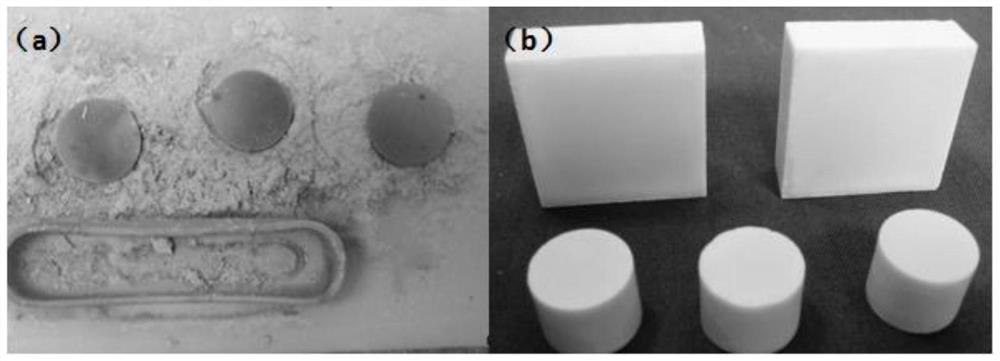

Embodiment 1

[0043] A hafnium lead titanate-based antiferroelectric ceramic material [(Pb 0.96 Ba 0.04 ) 0.94 La 0.04 ](Hf 0.96 Ti 0.04 )O 3 The preparation method is carried out as follows:

[0044] (1) One ball mill:

[0045] According to [(Pb 0.96 B 0.04 ) 0.94 La 0.04 ](Hf 0.96 Ti 0.04 )O 3 , the corresponding raw material Pb 3 o 4 , HfO 2 、TiO 2 , La 2 o 3 、BaCO 3 Insulate at 100°C for 24 hours, weigh each raw material according to the proportional relationship, and then add Pb 3 o 4 2% Pb by mass 3 o 4 , all raw materials, zirconium balls and absolute ethanol are mixed and carried out ball milling according to the mass ratio of 1:1.2:1, the rotating speed is raised to 300rpm ball milling for 3h, and finally the rotating speed is reduced to 150rpm ball milling for 2h;

[0046] (2) Pre-burning treatment:

[0047] The ball-milled slurry is dried at 70°C, with stirring during the drying process, the zirconium balls are taken out to obtain a mixed powder, and the ...

Embodiment 2

[0055] A hafnium lead titanate-based antiferroelectric ceramic material [(Pb 0.98 Sr 0.02 ) 0.94 La 0.04 ](Hf 0.96 Ti 0.04 )O 3 The preparation method is carried out as follows:

[0056] (1) One ball mill:

[0057] According to [(Pb 0.98 Sr 0.02 ) 0.94 La 0.04 ](Hf 0.96 Ti 0.04 )O 3 The corresponding raw material Pb 3 o 4 , HfO 2 、TiO 2 , La 2 o 3 , SrCO 3 Insulate at 100°C for 24 hours, weigh each raw material according to the proportional relationship, and then add Pb 3 o 4 2% Pb by mass 3 o 4 , all raw materials, zirconium balls and absolute ethanol are mixed and carried out ball milling according to the mass ratio of 1:1.4:1.2, the rotating speed is raised to 300rpm ball milling for 3h, and finally the rotating speed is reduced to 120rpm ball milling for 2h;

[0058] (2) Pre-burning treatment:

[0059] The ball-milled slurry is dried at 80°C, with stirring during the drying process, the zirconium balls are taken out to obtain a mixed powder, and th...

Embodiment 3

[0067] Hafnium lead titanate-based antiferroelectric ceramic materials [(Pb 0.96 Ba 0.04 ) 0.94 La 0.04 ]((Hf 0.8 sn 0.2 ) 0.96 Ti 0.04 )O 3 The preparation method is carried out as follows:

[0068] (1) One ball mill:

[0069] According to [(Pb 0.96 Ba 0.04 ) 0.94 La 0.04 ]((Hf 0.8 sn 0.2 ) 0.96 Ti 0.04 )O 3 will Pb 3 o 4 , HfO 2 、TiO 2 , La 2 o 3 , SnO 2 , SrCO 3 , kept at 100°C for 24 hours, weighed each raw material according to the proportional relationship, and then added Pb 3 o 4 2% Pb by mass 3 o 4 , all raw materials, zirconium balls and absolute ethanol are mixed and carried out ball milling according to the mass ratio of 1:1.2:1, the rotating speed is raised to 300rpm ball milling for 3h, and finally the rotating speed is reduced to 130rpm ball milling for 2h;

[0070] (2) Pre-burning treatment:

[0071] The ball-milled slurry is dried at 60°C, with stirring during the drying process, the zirconium balls are taken out to obtain a mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com