Preparation method for smelting copper-titanium series alloy material by adopting vacuum self-consuming electric arc

A vacuum consumable arc and alloy material technology, which is applied in the field of copper-titanium alloy preparation, can solve problems such as titanium alloy segregation, and achieve the effect of uniform structure, simple process and less inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

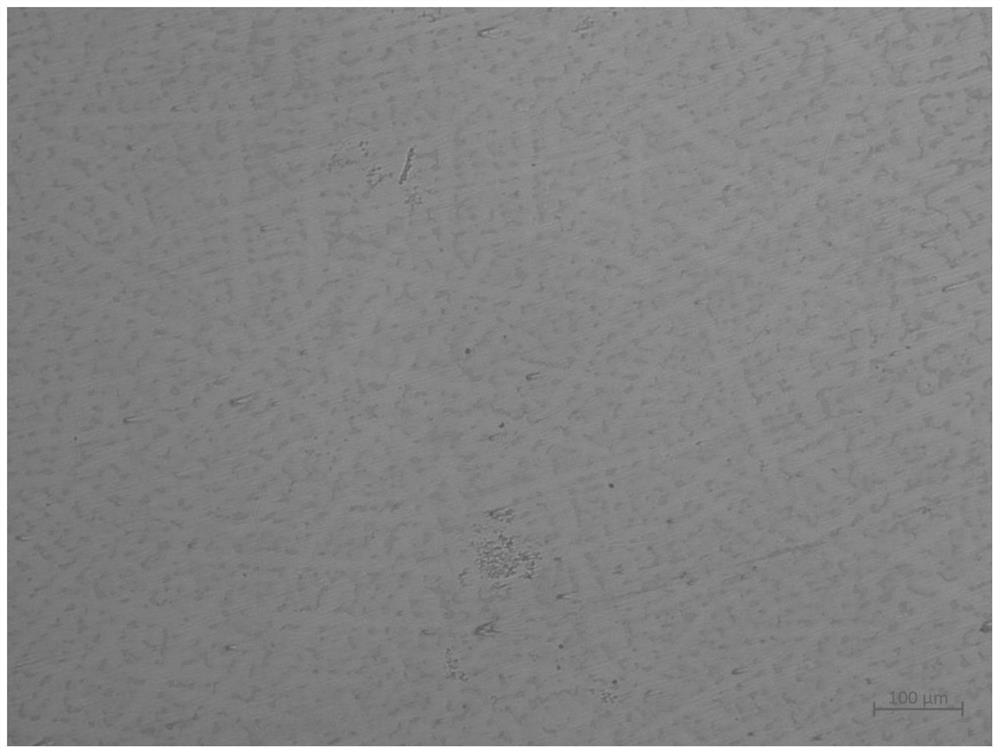

Embodiment 1

[0035] A method for preparing copper-titanium series alloy materials by vacuum consumable arc melting, comprising the following steps:

[0036] S1: Raw material ratio

[0037] The material composition and its mass percentage are: copper powder 0.5%, sponge titanium 99.5%; the copper powder is electrolytic copper powder, the copper content in the copper powder is 99.8%, the particle size is 30-40um, the sponge titanium is grade 0, and the particle size range 3-4mm;

[0038] S2: Raw material mixing

[0039] Take the required raw materials according to the mass percentage of copper powder 0.5%, and the mass percentage of titanium sponge 99.5%, and mix them in a mixer for 2 hours; the speed of the mixer is 10r / min, and the temperature of the mixer is 30°C, 30°C The ambient temperature can ensure that the mixer is dry;

[0040] S3: stereotypes

[0041] Put the mixture into the mold to pier the powder, put the puffed mold into a cold isostatic press for compaction, the compactio...

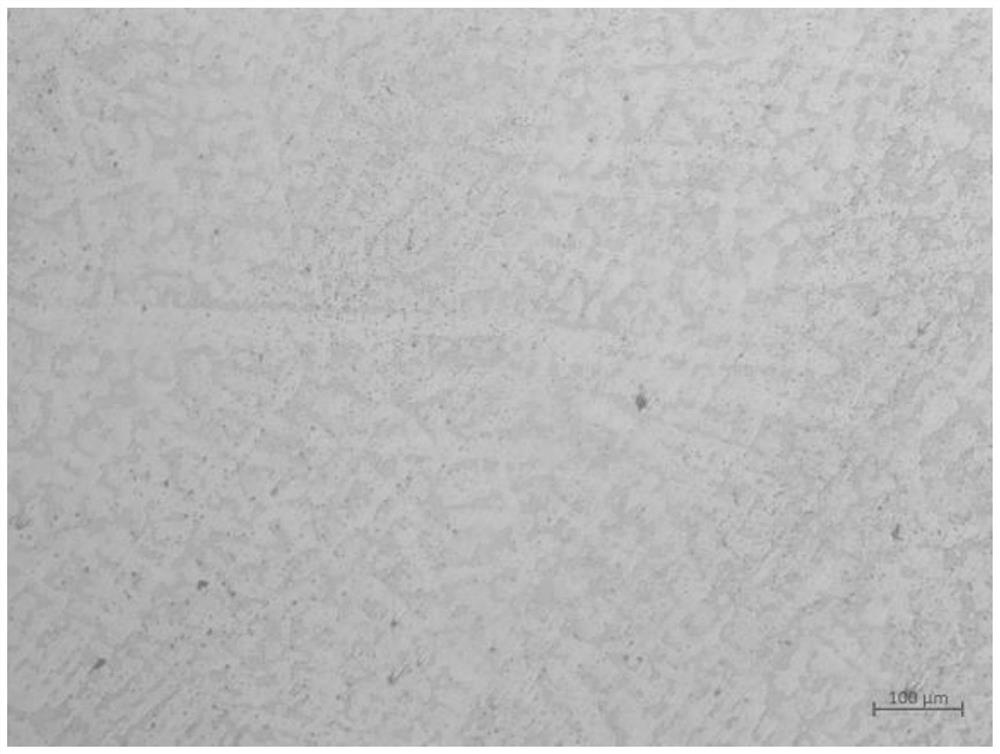

Embodiment 2

[0051] A method for preparing copper-titanium series alloy materials by vacuum consumable arc melting, comprising the following steps:

[0052] S1: Raw material ratio

[0053] The material composition and its mass percentage are: copper powder 40%, sponge titanium 60%; the copper powder is electrolytic copper powder, the copper content in the copper powder is 99.9%, the particle size is 40-50um, the sponge titanium is grade 0, and the particle size range 4-8mm;

[0054] S2: Raw material mixing

[0055] Take the required raw materials according to the mass percentage of copper powder 40%, and the mass percentage of titanium sponge 60%, and mix them in a mixer for 5 hours; the speed of the mixer is 50r / min, and the temperature of the mixer is 40°C, 40°C The ambient temperature can ensure that the mixer is dry;

[0056] S3: stereotypes

[0057] Put the mixture into the mould, and put the powdered mold into a cold isostatic press for compaction. The compaction pressure is 200Mpa...

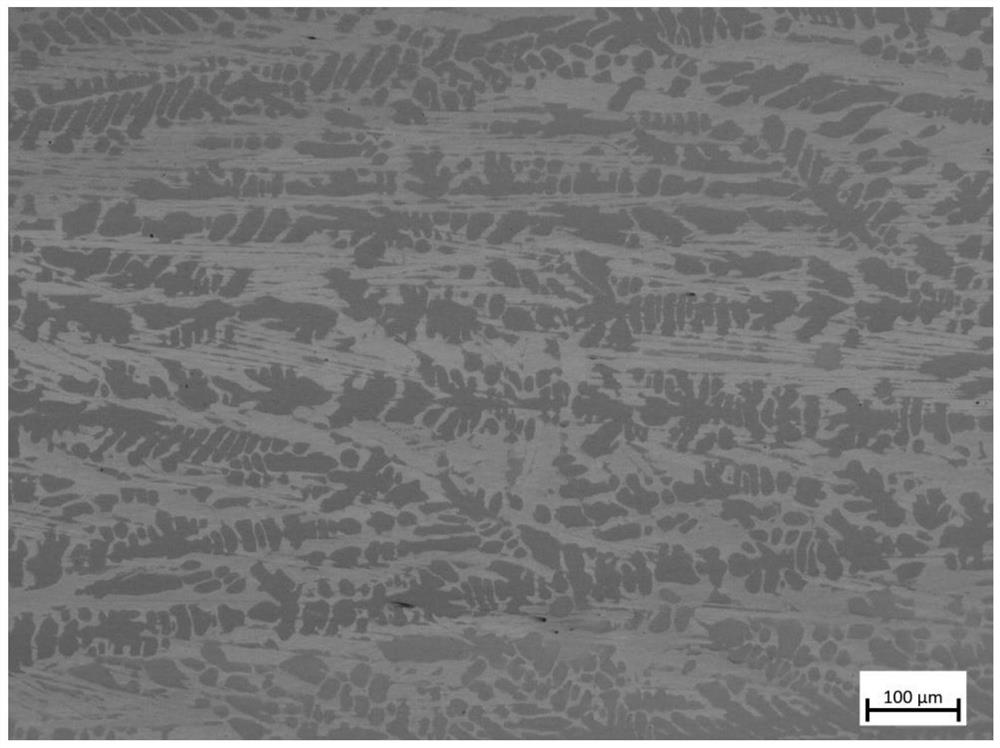

Embodiment 3

[0065] A method for preparing copper-titanium series alloy materials by vacuum consumable arc melting, comprising the following steps:

[0066] S1: Raw material ratio

[0067] The material composition and its mass percentage are: copper powder 99.5%, sponge titanium 0.5%; the copper powder is electrolytic copper powder, the copper content in the copper powder is 99.9%, the particle size is 50-74um, the sponge titanium is 0 grade, and the particle size range 8-12.7mm;

[0068] S2: Raw material mixing

[0069] Weigh the required raw materials according to the proportion, and mix them in the mixer for 7 hours; the speed of the mixer is 60r / min, the temperature of the mixer is 50°C, and the ambient temperature of 50°C can ensure the drying in the mixer;

[0070] S3: stereotypes

[0071] Put the mixture into the mold to pier the powder, put the puffed mold into the cold isostatic press for compaction, the compaction pressure is 300Mpa, and the pressure holding time is 10min; put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com