A kind of preparation method of granulated wc-co thermal spray powder

A technology for thermal spraying powder and granulation, which is applied in coating, melt spraying, metal processing equipment, etc., can solve the problems of powder collision tower wall easily broken, spray granulation powder broken, low spheroidization rate, etc. Coating substrate properties, the effect of increasing spheroidization, increasing compactness and density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Alcohol wet grinding:

[0034] Take 200kg of carburized nano-WC-6Co composite powder with Co-coated WC grain size ≤ 200nm and Co mass content of 6%, put it into a 300L tiltable rolling ball mill, add 4.8Kg of binder paraffin, 12.5L of oleic acid, alcohol 50Kg, then add ball mill rods Φ6×20mm, Φ8×20mm, Φ12×20mm, Φ16×16mm, Φ20×10mm, a total of 1000kg, ball mill for 48 hours, and obtain ball mill slurry;

[0035] The chemical composition analysis table of the carburized nano-WC-6Co composite powder used in this example is shown in Table 1. The total carbon in the powder is high, the free carbon is low, the cobalt content is normal, and the oxygen content is low.

[0036] 2) Pressure spray granulation:

[0037] Add 10Kg alcohol wet milling 10min in step 1) gained ball mill slurry, unloading passes 325 mesh sieves, heat while stirring while unloading, to prevent paraffin from separating out;

[0038]The stirred slurry is sprayed and granulated in a fully automatic press...

Embodiment 2

[0046] 1) Alcohol wet grinding:

[0047] Take 240kg of carburized nano-WC-10Co composite powder with Co-coated WC grain size ≤ 200nm and Co mass content of 10%, and put it into a 300L tiltable rolling ball mill, add 4.8Kg of binder paraffin, 15L of oleic acid, alcohol 60Kg, then add ball mill rods Φ6×20mm, Φ8×20mm, Φ12×20mm, Φ16×16mm, Φ20×10mm, a total of 1200kg, and ball mill for 48 hours to obtain ball mill slurry;

[0048] The chemical composition analysis table of the carburized nano-WC-10Co composite powder used in this example is shown in Table 1. The total carbon in the powder is high, the free carbon is low, the cobalt content is normal, and the oxygen content is low.

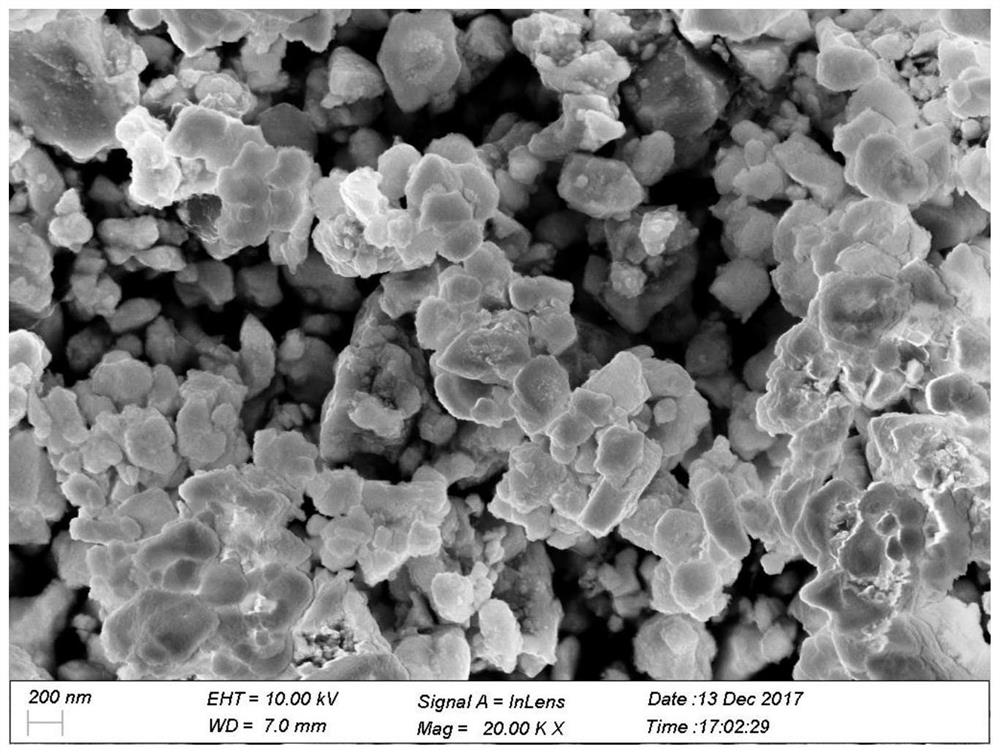

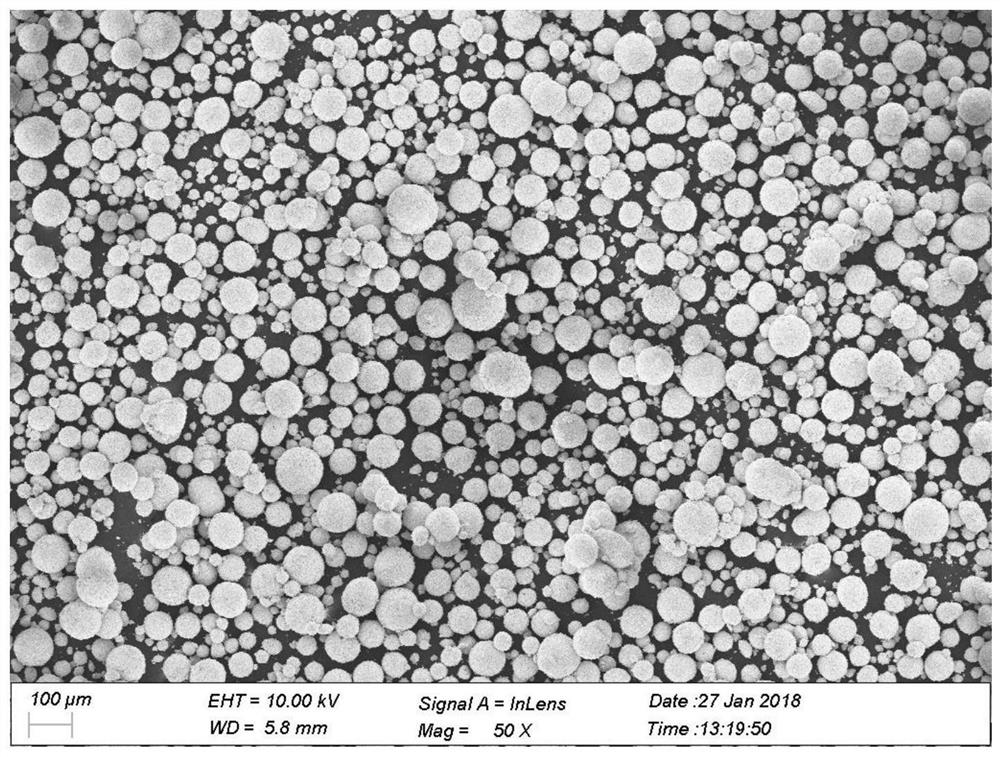

[0049] The SEM topography of the ball mill slurry obtained in this embodiment after natural drying is as follows figure 1 As shown, it can be seen that the WC grain size of the ball mill slurry obtained in this example is uniform and there is no agglomeration phenomenon. round.

[0050] 2) Pressure s...

Embodiment 3

[0062] 1) Alcohol wet grinding

[0063] Take 240kg of carburized nano-WC-12Co composite powder with Co-coated WC grain size ≤ 200nm and Co mass content of 12%, put it into a 300L tiltable rolling ball mill, add 7.2Kg of binder paraffin, 15L of oleic acid, and 60Kg of alcohol , and then add ball mill rods Φ6×20mm, Φ8×20mm, Φ12×20mm, Φ16×16mm, Φ20×10mm, a total of 1200kg, and ball mill for 72 hours to obtain ball mill slurry;

[0064] The chemical composition analysis table of the carburized nano WC-12Co composite powder used in this example is shown in Table 1. The total carbon in the powder is high, the free carbon is low, the cobalt content is normal, and the oxygen content is low.

[0065] 2) Pressure spray granulation:

[0066] Add 12Kg alcohol to wet grinding for 10min in the obtained ball mill slurry in step 1), discharge the material through a 325 mesh sieve, and heat while stirring to prevent the paraffin from separating out;

[0067] The stirred slurry is sprayed and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com