Thermal protection coating with component gradient change and preparation method

A composition gradient and thermal protection technology, applied in coating, metal material coating process, fusion spraying, etc., can solve problems such as easy phase change, large difference in thermal expansion coefficient, coating failure, etc., and achieve high hardness and strength , Excellent thermal shock resistance, and the effect of reducing the concentration of thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

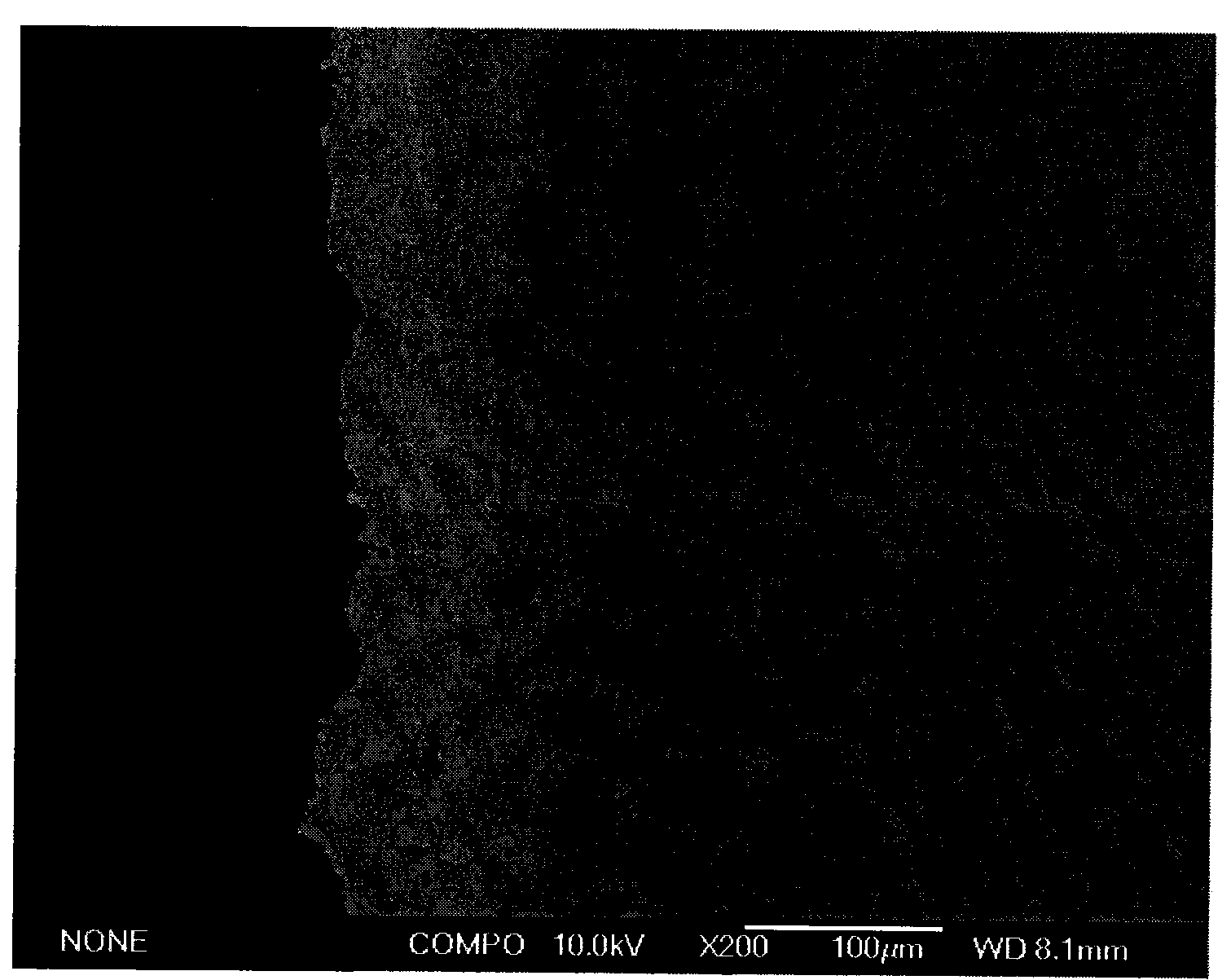

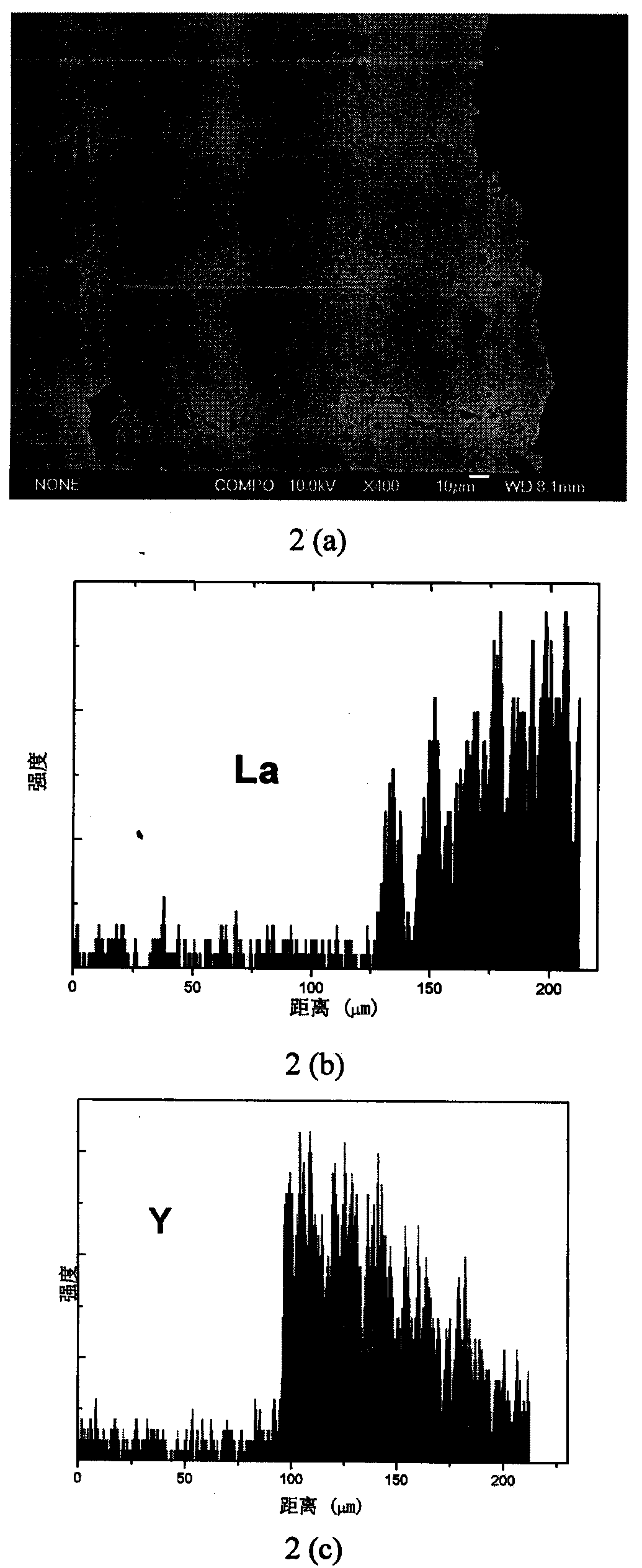

[0042] Embodiment 1: plasma spraying La on Ni-based superalloy substrate 2 Zr 2 o 7 -YSZ gradient coating, the coating consists of six layers of La 2 Zr 2 o 7 -YSZ composite material composition, from the bottom layer to the outer layer by mass percentage, the composition is as follows:

[0043] The first layer: YSZ 100%;

[0044] Second floor: YSZ 80%, La 2 Zr 2 o 7 20%;

[0045] The third floor: YSZ 60%, La 2 Zr 2 o 7 40%;

[0046] Fourth floor: YSZ 40%, La 2 Zr 2 o 7 60%;

[0047] Fifth floor: YSZ 20%, La 2 Zr 2 o 7 80%;

[0048] The sixth floor: La 2 Zr 2 o 7 100%.

[0049] Among them, the used M1 is YSZ, M2 is La 2 Zr 2 o 7 , the substrate is a Ni-based superalloy base, where the coefficient of thermal expansion of M1 (M 1 )=10.7×10-6 / °C, M 2 Coefficient of thermal expansion (M 2 )=8×10-6 / ℃, the coefficient of thermal expansion of the substrate (S)=10.1×10-6 / ℃, there is the following relationship among the three: |(M 1 )-(S)|2 )-(S)|, a...

Embodiment 2

[0058] The difference between this embodiment and the gradient coating design described in embodiment 1 is: La 2 Zr 2 o 7 -YSZ gradient coating consists of six layers of La 2 Zr 2 o 7 -YSZ composite material composition, from the bottom layer to the outer layer by mass percentage, the composition is as follows:

[0059] The first layer: YSZ 100%;

[0060] Second layer: YSZ 70%, La 2 Zr 2 o 7 30%;

[0061] Third floor: YSZ 55%, La 2 Zr 2 o 7 45%;

[0062] Fourth floor: YSZ 45%, La 2 Zr 2 o 7 55%;

[0063] Fifth floor: YSZ 30%, La 2 Zr 2 o 7 70%;

[0064] The sixth floor: La 2 Zr 2 o 7 100%.

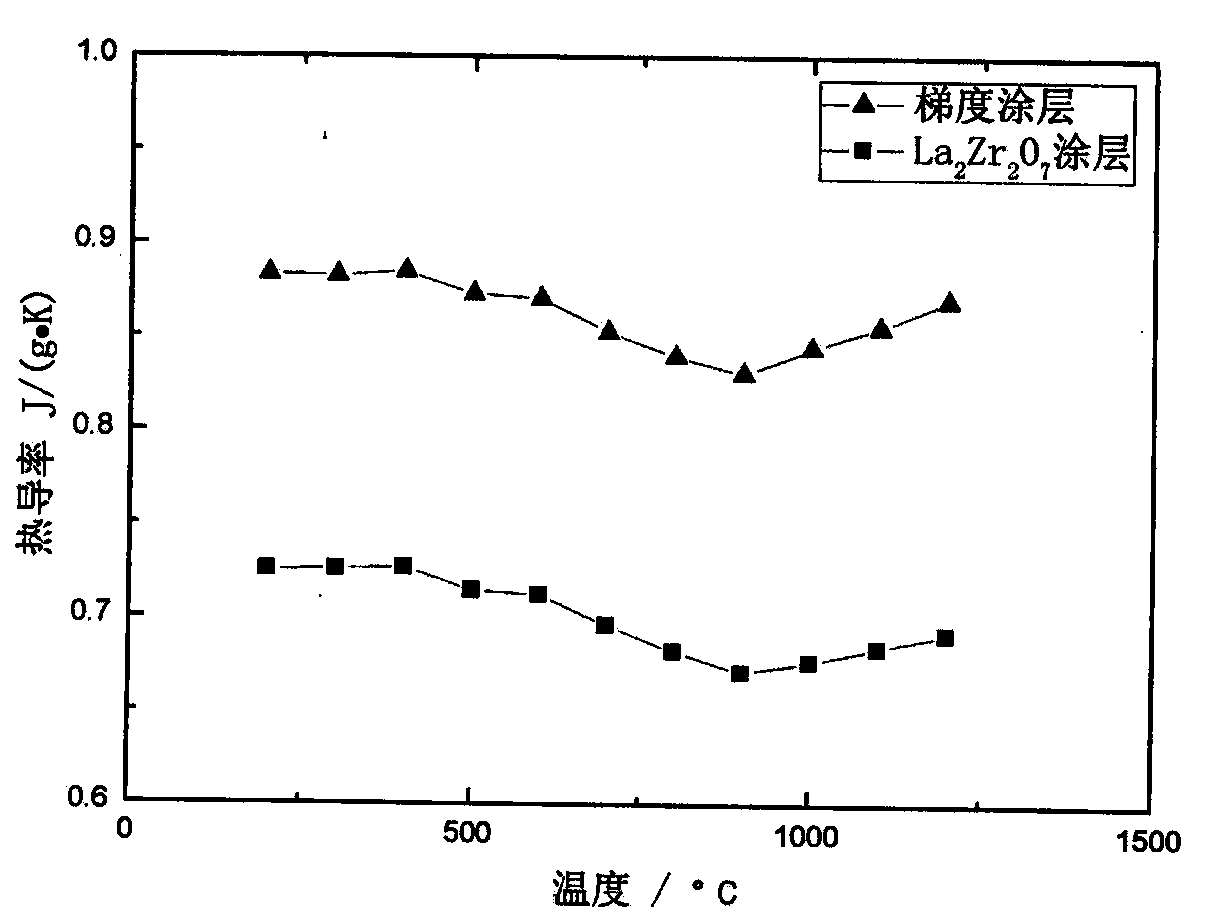

[0065] From the temperature-thermal conductivity curve, it can be calculated that the thermal conductivity of the gradient coating is 0.85J / (g·K), and after 20 thermal shock experiments (T=1200℃), the mass change of the coating is only 0.6 %, and there are only sporadic small areas peeling off on the surface, indicating that the gradient coating prepared in th...

Embodiment 3

[0067] The difference between this embodiment and the gradient coating design described in embodiment 1 is: La 2 Zr 2 o 7 -YSZ gradient coating consists of six layers of La 2 Zr 2 o 7 -YSZ composite material composition, from the bottom layer to the outer layer according to the mass percentage, its composition is respectively:

[0068] The first layer: YSZ 100%;

[0069] Second layer: YSZ 75%, La 2 Zr 2 o 7 25%;

[0070] The third layer: YSZ 65%, La 2 Zr 2 o 7 35%;

[0071] Fourth floor: YSZ 35%, La 2 Zr 2 o 7 65%;

[0072] Fifth floor: YSZ 25%, La 2 Zr 2 o 7 75%;

[0073]The sixth floor: La 2 Zr 2 o 7 100%.

[0074] From the temperature-thermal conductivity curve, it can be calculated that the thermal conductivity of the gradient coating is 0.85J / (g·K), and after 20 thermal shock experiments (T=1200℃), the mass change of the coating is only 0.5 %, and there are only sporadic small areas peeling off on the surface, indicating that the gradient coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com