Layered metal composite material manufacturing technology and equipment

A manufacturing process and composite material technology, applied in the field of metal composite material production technology, can solve the problems of inability to manufacture forged core material composite products, low cleanliness and production efficiency of outer layer materials, complex production equipment production process, etc. The effect of controlling interface quality, product quality is easy to control, and production process is easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

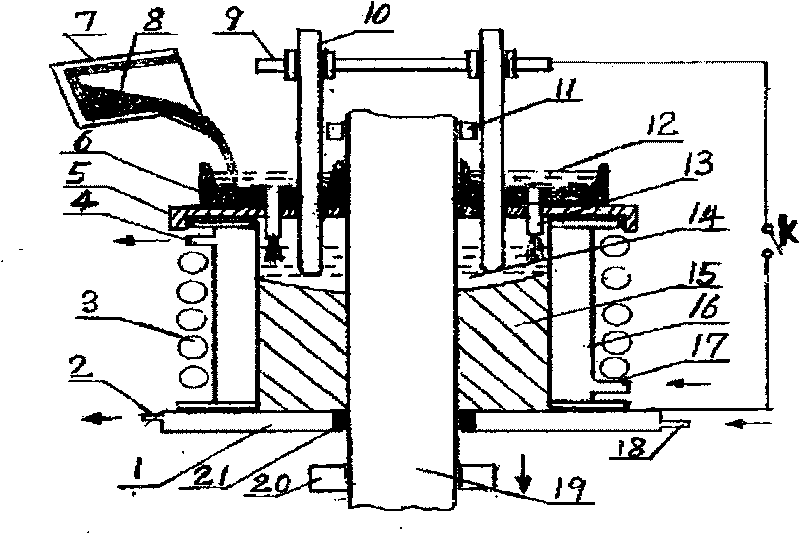

[0018] Embodiment 1: In Fig. 1, this equipment has a workbench, a hole is arranged on the workbench, a lifting device 20 is installed below the workbench, water-cooled crystallizer 16 and electrode holder 9 are installed above the workbench. The outside of the water-cooled crystallizer 16 is equipped with an induction heater 3, an insulation cover 5 and a pouring funnel 6 are installed above the water-cooled crystallizer 16, a bottom water tank 1 is installed below the water-cooled crystallizer 16, and a bottom water tank 1 is installed under the water-cooled crystallizer 16. The water inlet pipe 17 and the water outlet pipe 4 are respectively connected with the upper part, and the water inlet pipe 18 and the water outlet pipe 2 are respectively connected with the bottom and the upper part of the bottom water tank 1. The metal mandrel 19 passes through the center hole bushing 21 of the bottom tank 1 through the center of the water-cooled crystallizer 16 and is fixed on the lift...

Embodiment 2

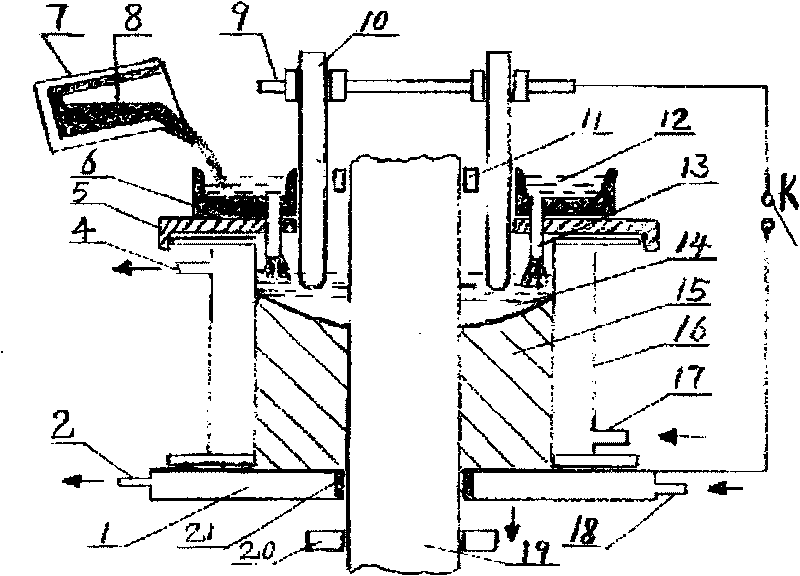

[0020]Embodiment 2: In Fig. 2, the difference from Fig. 1 is that no induction heater 3 is installed outside the crystallizer 16. After the work starts, the power supply K is directly started to melt the electroslag 14, and the metal core is passed through the liquid electroslag 14. Rod 19 is heated directly. Other processes and equipment are the same as in Embodiment 1, omitted.

Embodiment 3

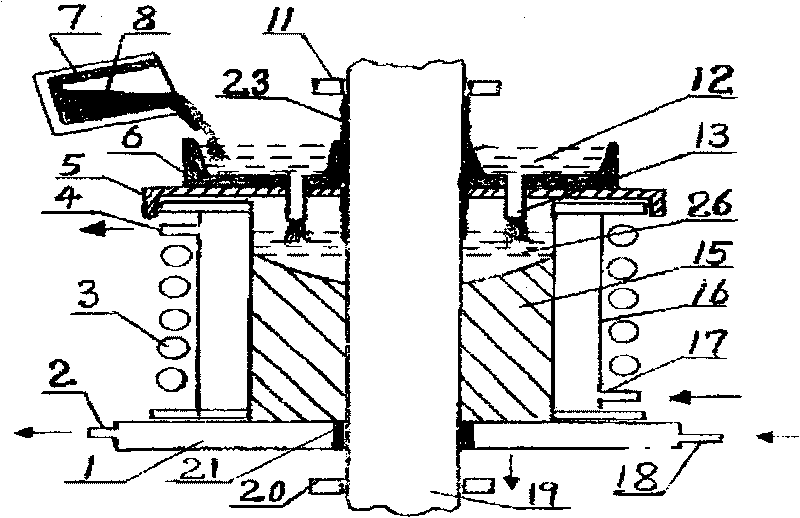

[0021] Embodiment 3: In Fig. 3, the difference from Fig. 1 is that there are no electrode holders 9, electrodes 10 and power supply K equipment on the top of the crystallizer 16. After the work starts, the metal mandrel 19 that needs to be composited will be surface treated Finally, the surface is coated with an anti-oxidation coating 23 containing a low-melting-point molten salt such as borax or an oxide, and after being dried, it is installed in the center of the water-cooled crystallizer 16 and passes through the center hole bushing 21 of the bottom water tank 1 Fixed on the lifting device 20, the ultrasonic vibrator 11 is installed on the top of the metal mandrel 19. After smelting the required composite metal, put it into the metal casting ladle 7, put the anti-oxidation slag material 26 with low melting point into the water-cooled crystallizer 16, open the inlet and outlet pipes 17 and 4 of the water-cooled crystallizer 16 and the inlet and outlet of the bottom water tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com