A kind of high-strength and high-toughness multi-element Al-cu alloy and its preparation method and application

A high-strength, high-toughness, al-cu technology, applied in the field of multi-component Al-Cu alloy materials, can solve the problems that Al-Cu alloy materials cannot meet the performance requirements of high-strength, high-toughness materials for bullet casings, and achieve microalloying efficiency, The effect of strong practicability and huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

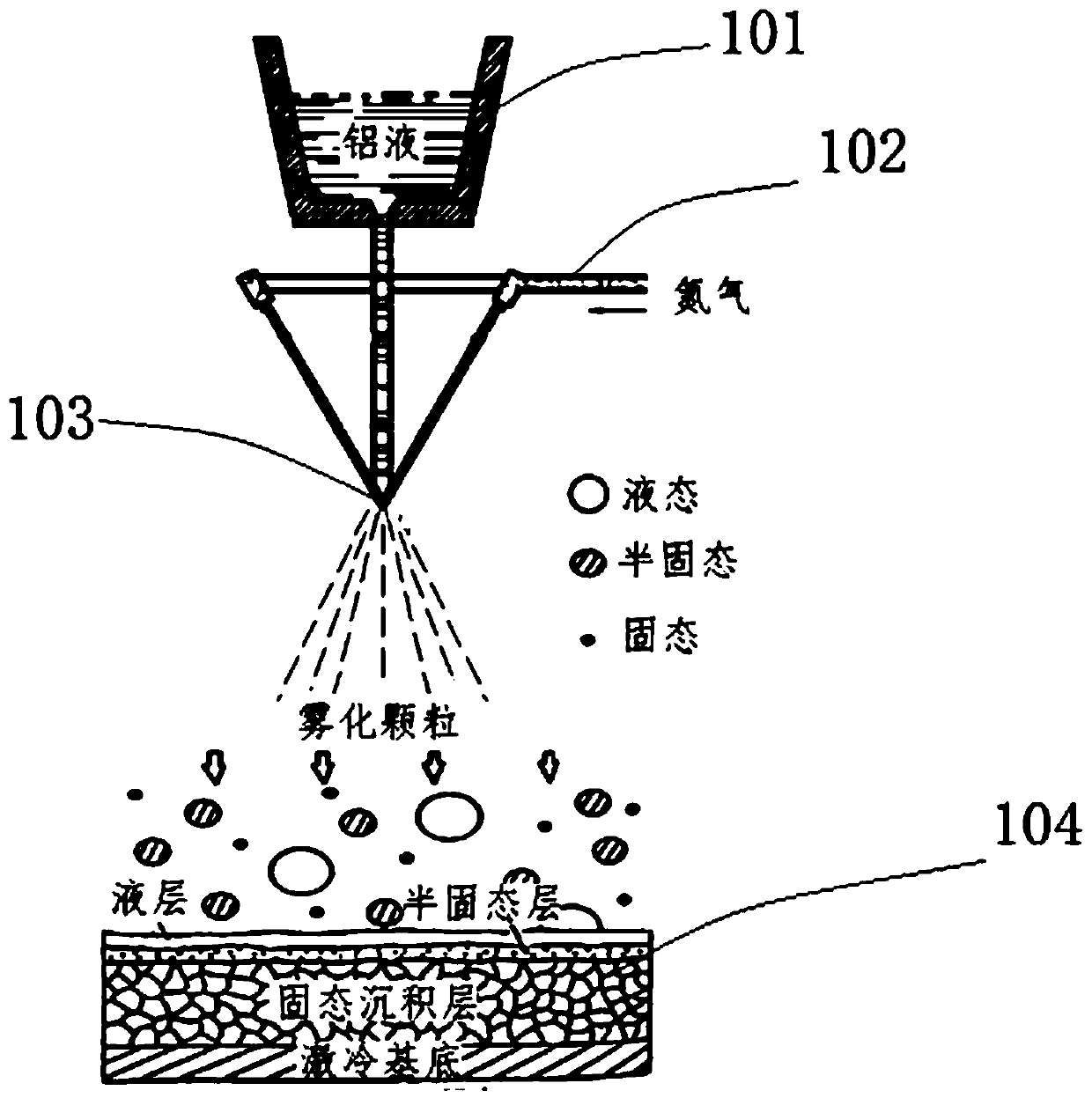

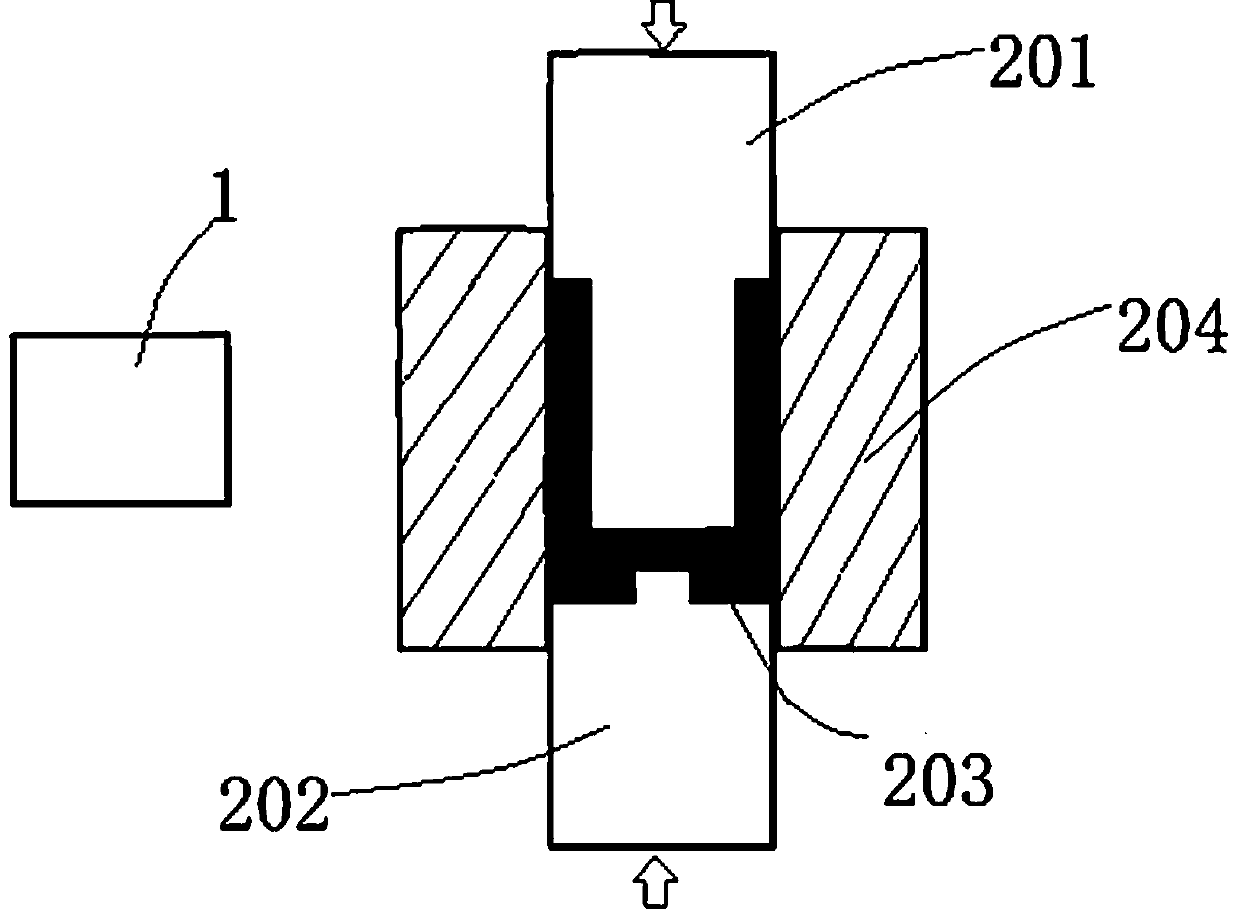

[0064] In the method for preparing a high-strength and high-toughness multi-component Al-Cu alloy provided in this example, the raw material is heated into a molten state, and then sprayed by an aluminum alloy spray forming equipment to form a multi-component Al-Cu alloy. The multi-component Al-Cu alloy is composed of Al , Cu, Mn, Ni, V, Sc and impurity Si, Fe elements. It consists of the following alloy components in mass percentage: as shown in Table 1. Pure aluminum, Al-40Cu, Al-30Mn, Al-10Ni, Al-5V and Al-5Sc master alloys are used as raw materials, and the sum of all the above alloy components is 100%.

[0065] Specifically include the following steps:

[0066] S1. Take pure aluminum with a purity of 99.98% and place it in a smelting furnace, and heat it at 800°C until all of it becomes molten;

[0067] S2. Add Al-40Cu, Al-30Mn, Al-10Ni, Al-5V and Al-5Sc master alloys in sequence, lower the temperature to 720°C, stir thoroughly, and let stand for 15-25min; The method o...

Embodiment 2

[0071] In the method for preparing a high-strength and high-toughness multi-component Al-Cu alloy provided in this example, the raw material is heated into a molten state, and then sprayed by an aluminum alloy spray forming equipment to form a multi-component Al-Cu alloy. The multi-component Al-Cu alloy is composed of Al , Cu, Mn, Ni, V, Sc and impurity Si, Fe elements. It consists of the following alloy components in mass percentage: as shown in Table 1. Pure aluminum, Al-40Cu, Al-30Mn, Al-10Ni, Al-5V and Al-5Sc master alloys are used as raw materials, and the sum of all the above alloy components is 100%.

[0072] The specific production steps are the same as in Example 1, except that the melting temperature in step S1 is 820°C, and in step S2, the temperature of the master alloy is lowered to 700°C, and then the anhydrous The method of high-purity nitrogen to remove slag, the time is 60min; the rest of the steps are the same as in Example 1. Prepare the deposition blank o...

Embodiment 3

[0074] In the method for preparing a high-strength and high-toughness multi-component Al-Cu alloy provided in this example, the raw material is heated into a molten state, and then sprayed by an aluminum alloy spray forming equipment to form a multi-component Al-Cu alloy. The multi-component Al-Cu alloy is composed of Al , Cu, Mn, Ni, V, Sc and impurity Si, Fe elements. It consists of the following alloy components in mass percentage: as shown in Table 1. Pure aluminum, Al-40Cu, Al-30Mn, Al-10Ni, Al-5V and Al-5Sc master alloys are used as raw materials, and the sum of all the above alloy components is 100%.

[0075] The specific production steps are the same as in Example 1, except that the melting temperature in step S1 is 840°C, the temperature of nitrogen in step S3 is -15°C, and the injection temperature of the alloy melt is 700°C; the remaining steps Same as Example 1. Prepare the deposition blank of spray forming multi-element Al-Cu alloy, the size of the deposition bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com