Magnesium-aluminium bimetal composite pipe/bar

A bimetallic composite pipe and magnesium alloy pipe technology, which is applied in metal extrusion, metal extrusion dies, metal processing equipment, etc., can solve the problems of poor corrosion resistance and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

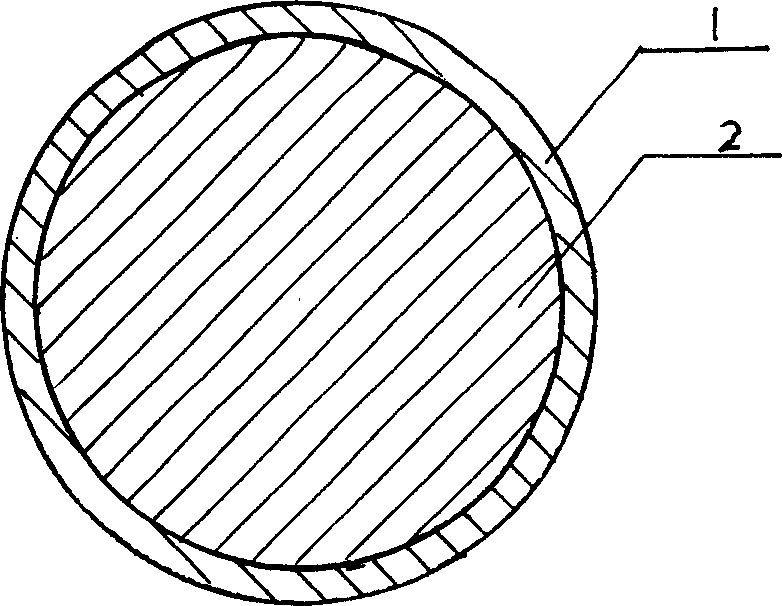

[0014] Embodiment 1: Extrusion example of magnesium-aluminum bimetal composite rod:

[0015] The mold is a cone mold with a cone angle of 150°. The 82×6 (outer diameter is 82, wall thickness is 6) 6063 aluminum alloy tube blanks are machined into 82×4 tube blanks with a length of 250 mm, and the 80 AZ31B magnesium alloy round ingots are processed into lengths It is a 74 round ingot of 250mm. The aluminum alloy tube blank is cleaned with lye, and then pickled, while the magnesium alloy round ingot is pickled. After drying, put the magnesium alloy round ingot into the aluminum alloy tube billet to become a combined ingot. Put the combined ingot into the furnace and heat it to 380°C and keep it warm for 3 hours. The heating temperature of the extrusion cylinder, mold and extrusion pad is 380°C. The extrusion speed was 0.5 m / min. Extrude 16 magnesium-aluminum composite rods. Finally, it is straightened, cut to length, packed and put into storage.

[0016] Gained magnesi...

Embodiment 2

[0017] Embodiment 2: Magnesium-aluminum bimetal composite rod extruded example:

[0018] The mold is a cone mold with a cone angle of 90°. The 82×6 (outer diameter is 82, wall thickness is 6) 6063 aluminum alloy tube blanks are machined into 82×4 tube blanks with a length of 250 mm, and the 80 AZ31B magnesium alloy round ingots are processed into lengths It is a 74 round ingot of 250mm. The aluminum alloy tube blank is cleaned with lye, and then pickled, while the magnesium alloy round ingot is pickled. After drying, put the magnesium alloy round ingot into the aluminum alloy tube billet to become a combined ingot. Put the combined ingot into the furnace and heat it to 320°C and keep it warm for 4 hours. The heating temperature of the extrusion cylinder, mold and extrusion pad is 320°C. The extrusion speed was 2.0 m / min. Extrude 16 magnesium-aluminum composite rods. Finally, it is straightened, cut to length, packed and put into storage.

Embodiment 3

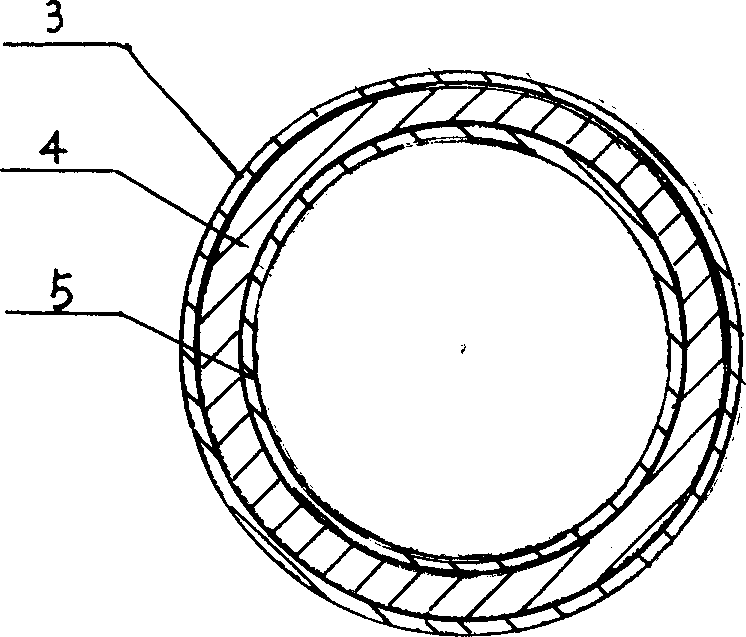

[0019] Embodiment 3: Extrusion example of magnesium-aluminum bimetallic composite pipe:

[0020] The extruder is equipped with extruding needles, and the die is a cone die with a cone angle of 120°. The aluminum alloy and magnesium alloy blanks are obtained by machining, the length is 250mm, the size of the outer aluminum alloy tube blank is 82×4 (outer diameter is 82, the wall thickness is 4), the middle layer magnesium alloy tube blank size is 74×25, The size of the inner aluminum alloy tube blank is 24×4. The aluminum alloy tube blank is cleaned with lye, and then pickled, while the magnesium alloy tube blank is pickled. After drying, assemble the combined ingot according to the order of aluminum alloy and magnesium alloy in the finished product. Put the combined ingot into the furnace and heat it to 350°C and keep it warm for 4 hours. The heating temperature of the extrusion cylinder is 350°C. Then the extrusion speed was 1 m / min. Extrude a 22×3 magnesium-aluminum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com