Poly-lactic-acid composition and formed body thereby and method for making said formed body

A manufacturing method and technology of polylactic acid, which are applied in chemical instruments and methods, cellulose plastic material layered products, layered products, etc., can solve the problem of non-conforming molding cycle, opaque heat resistance, and non-conforming productivity to industrial needs, etc. problem, to achieve the effect of shortening the forming cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

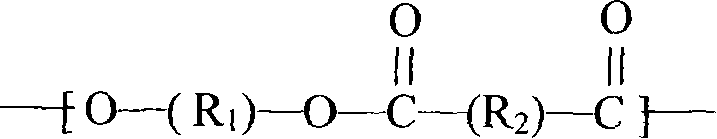

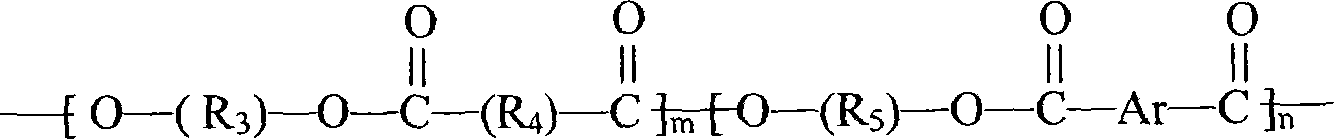

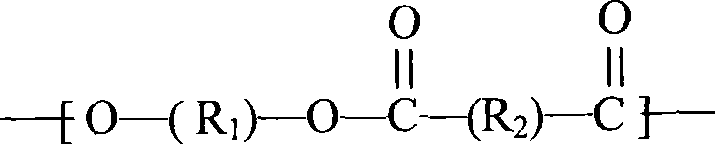

Method used

Image

Examples

Embodiment A

[0044] A total of 200 kg of polylactic acid and biodegradable polytetramethylene glycol adipate blend (the composition ratio is shown in Table 1) was supplied to a twin-screw extruder, and then extruded through melt mixing (dispersive mixing) After being bundled, it is cut into granules by a granulator. The operating conditions of the twin-screw extruder are: screw length-to-width ratio L / D=32, screw speed 200rpm, temperature distribution of the screw 190°C, 195°C, 195°C, 195°C, 190°C, die temperature 190°C.

[0045] After the pellets were dried at 70°C for 12 hours, they were supplied to a single-screw extruder and extruded from a T-shaped die to form a sheet with a thickness of 0.4 mm. At this time, the crystallinity of the sheet was 0%. Next, using a forming die with a width of 90 mm, a depth of 75 mm, and a draw ratio of 2.6, vacuum forming (vacuum degree: -70 cmHg) or pressure forming (pressure: 5 Kg) of the sheet was carried out at a mold temperature of 120° C. to obtai...

Embodiment B

[0050] The implementation steps of Example B are roughly the same as Example A, the difference is that the biodegradable polytetramethylene adipate of Example A is biodegradable polytetramethylene adipate / terephthalate "FEPOL2040 ” instead, its composition ratio is shown in Table 3, and the relevant physical property analysis is also recorded in Table 3.

Embodiment C

[0051] Example C, D, E

[0052] The implementation steps of Examples C, D, and E are roughly the same as those of Example A, except that the biodegradable polytetramethylene glycol adipate, respectively polytetramethylene glycol adipate / terephthalate "Ecoflex", polytetramethylene glycol adipate Butanediol succinate / terephthalate "Biomax", and polyethylene glycol substitution, the composition ratio is shown in Table 4, and the relevant physical property analysis is also recorded in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com