Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

139results about How to "High profile precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

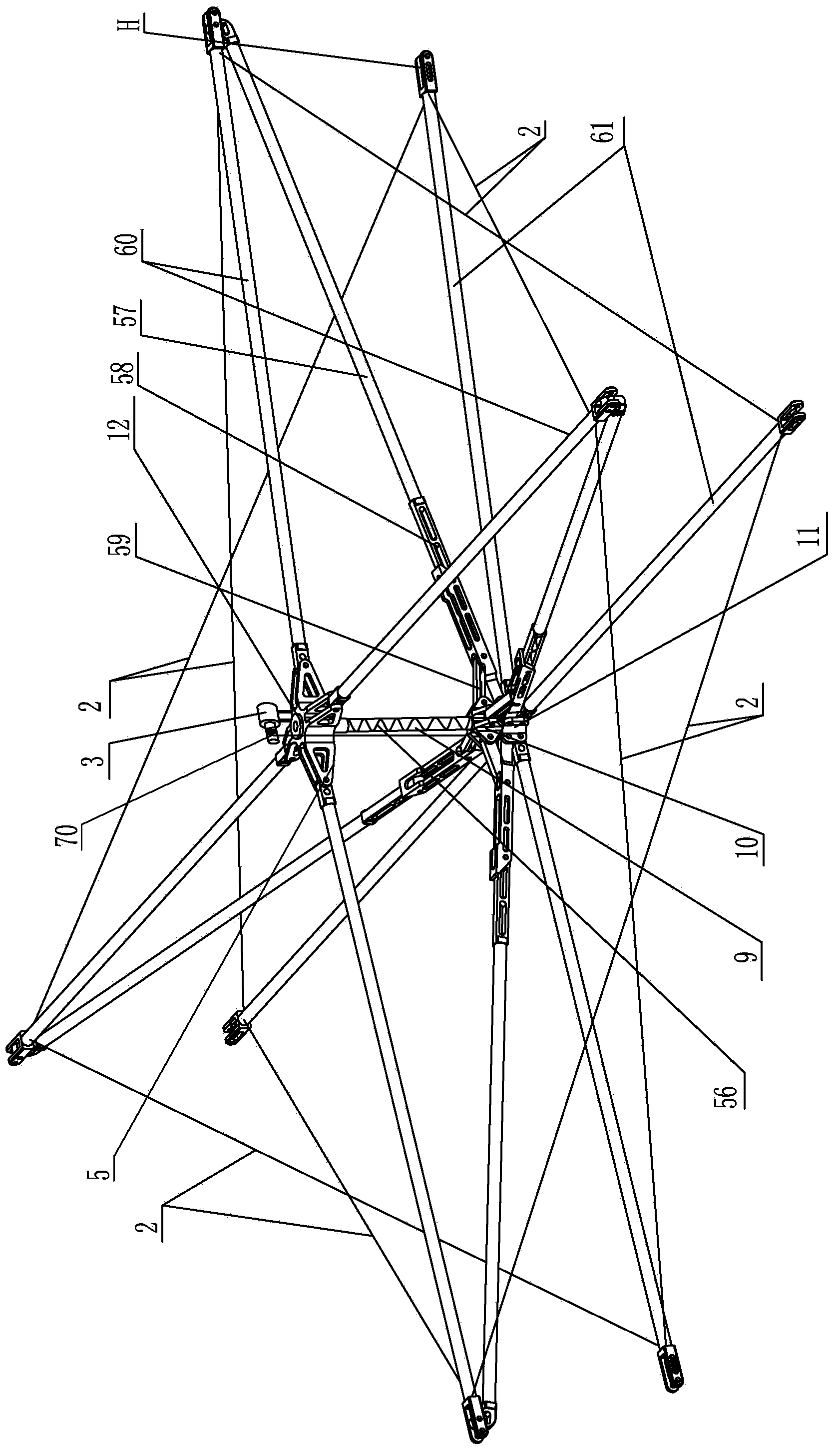

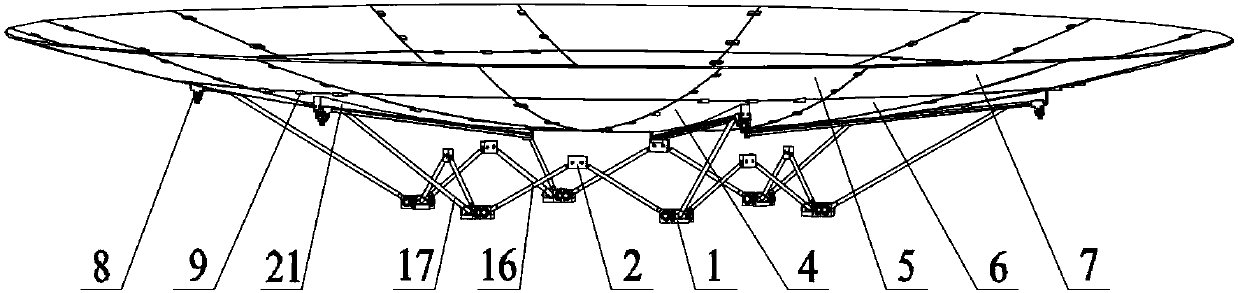

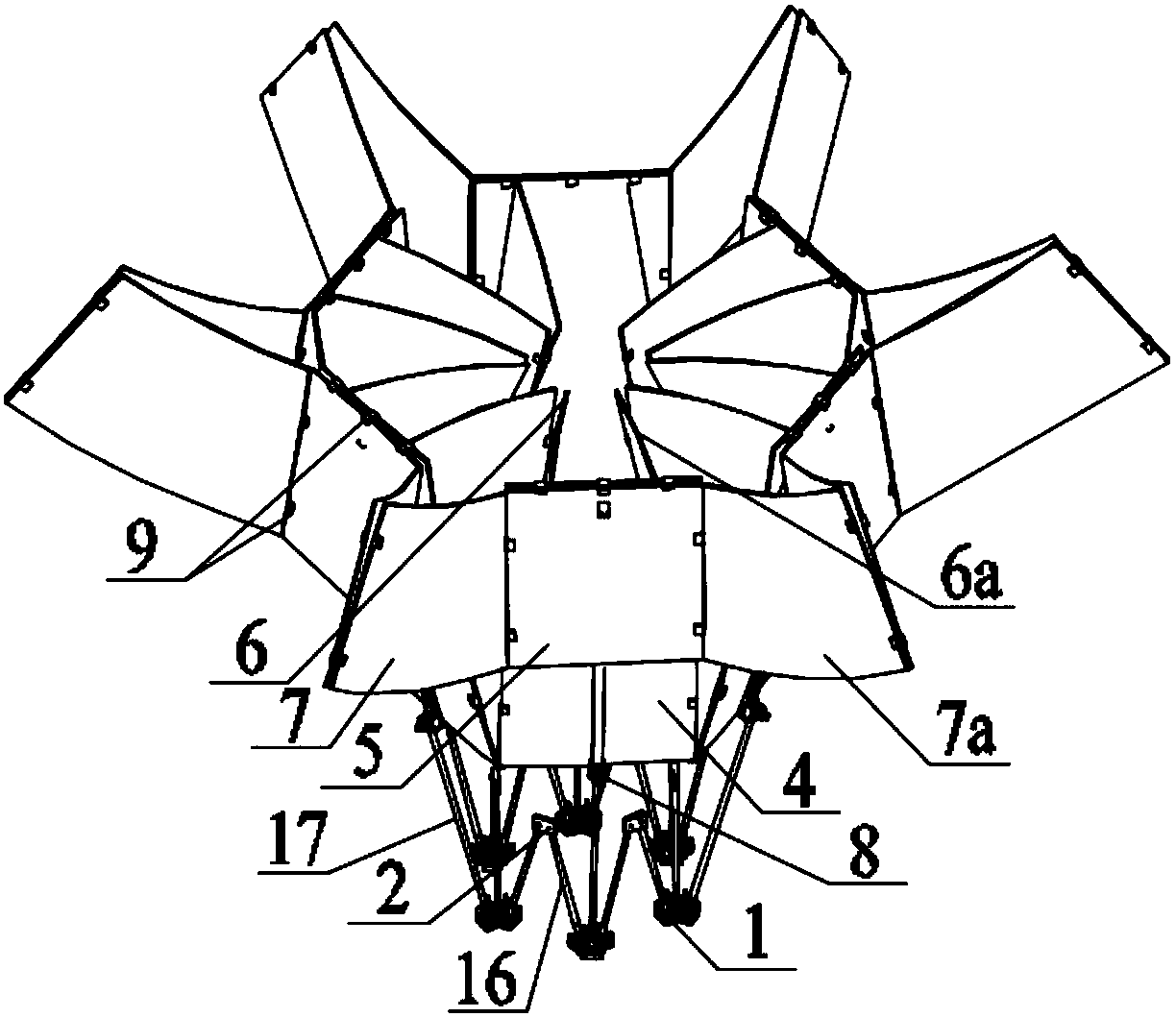

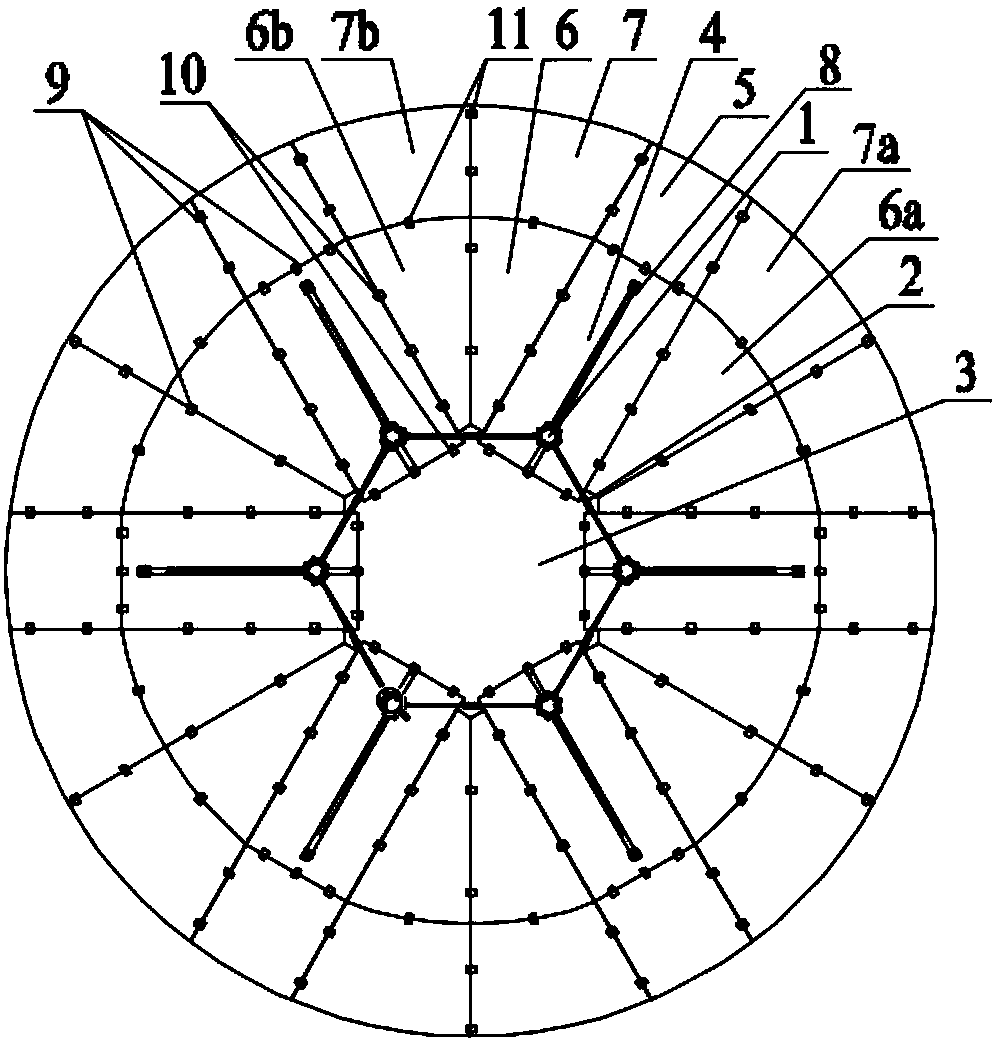

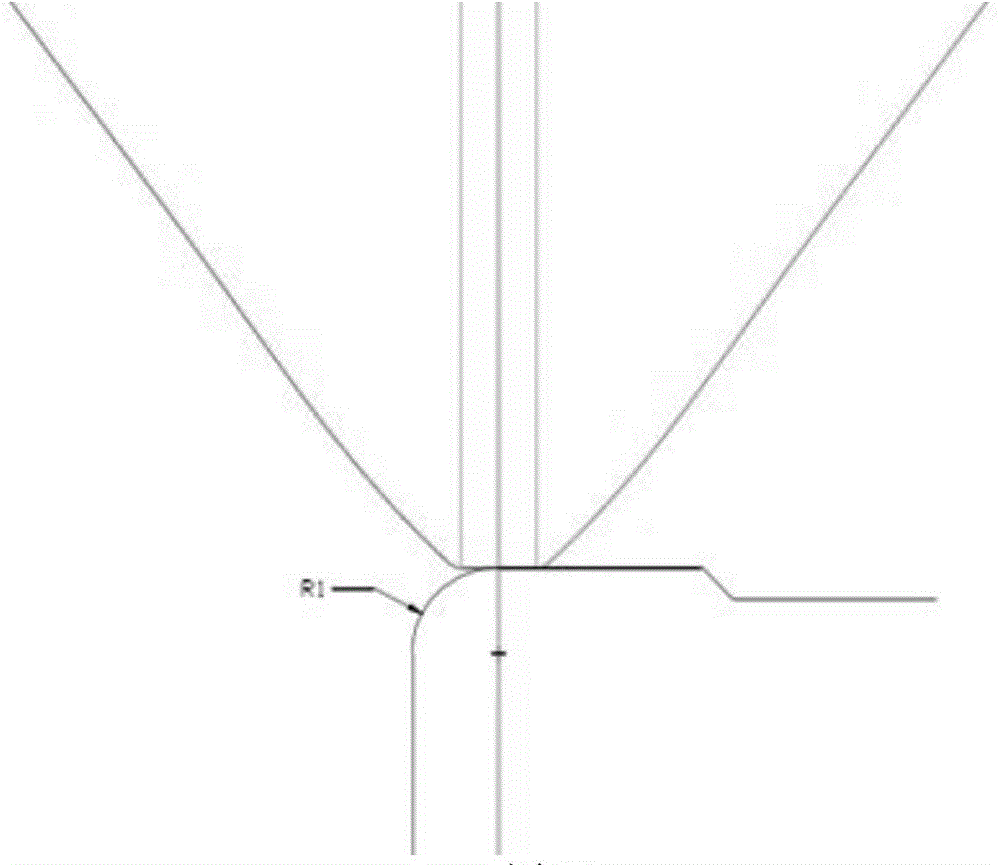

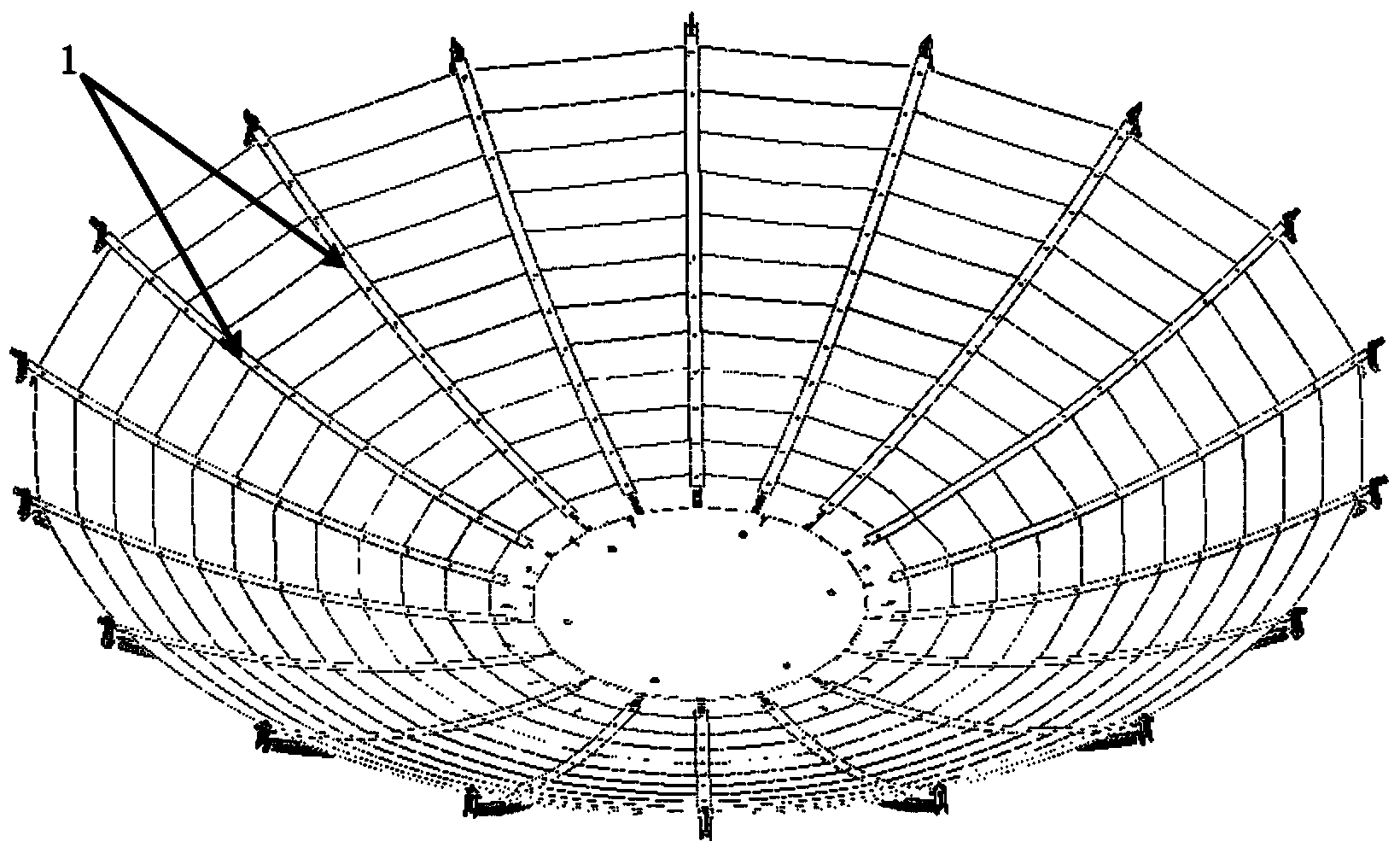

Modular spatial curved surface folding and unfolding antenna mechanism based on rib mechanisms

ActiveCN104022337ARealize modular expansionRealize modular productionCollapsable antennas meansComputer moduleSatellite

The invention relates to an antenna mechanism, in particular to a modular spatial curved surface folding and unfolding antenna mechanism based on rib mechanisms. The modular spatial curved surface folding and unfolding antenna mechanism aims to solve the problems that an existing unfolding-type parabolic cylinder antenna structure is low in molded surface precision, poor in stability and low in integral rigidity, an umbrella-shaped antenna structure is not suitable for reflecting surface stretch forming, and a truss antenna structure capable of being unfolded only can be unfolded unidirectionally but a parabolic cylinder can not be formed. The modular spatial curved surface folding and unfolding antenna mechanism comprises two speed-controlled motors, two longitudinal connection rib mechanisms, two folding and unfolding connection mechanisms, a plurality of transverse connection rib mechanisms, a plurality of single rib mechanisms, a plurality of single modular folding and unfolding mechanisms, a plurality of tensioning pull ropes and a plurality of modular connection mechanisms. Two transverse outer side supporting frames are arranged between the two longitudinal connection rib mechanisms in parallel and are respectively formed by connecting multiple transverse connection ribs in series, and the two folding and unfolding connection mechanisms, the single modular folding and unfolding mechanisms and the single rib mechanisms are arranged in the supporting frames. The modular spatial curved surface folding and unfolding antenna mechanism is applied to satellites, space stations and space probes.

Owner:HARBIN INST OF TECH

Umbrella-shaped antenna reflector

ActiveCN104269657ASuccessful implementationDoes not affect effective areaAntennasEngineeringMechanical engineering

The invention provides an umbrella-shaped antenna reflector which comprises a base, a fixing face part, a foldable part, a mesh face part and a driving assembly. The fixing face part is a fixing face reflector body. The foldable part comprises a plurality of unfolding ribs. The mesh face part comprises a front tension mesh and a rear tension mesh. The driving assembly comprises a motor and a power rope. The fixing face part is fixedly connected with the base. The foldable part is connected with the base in a hinged mode. The mesh face is arranged on the foldable part. The umbrella-shaped antenna reflector can be unfolded smoothly through the driving assembly. The umbrella-shaped antenna reflector is provided with a large diameter and high in accuracy, has the advantages of being high in molded surface accuracy, high in molded surface keeping capacity, high in stability and high in reflection efficiency and can be applied to the outer space, and the unfolding ribs are large in rigidity.

Owner:SHANGHAI YS INFORMATION TECH

Composite material satellite antenna reflection surface and manufacturing process thereof

InactiveCN101227029AHigh profile precisionImprove overall stiffnessGlass/slag layered productsNatural mineral layered productsSatelliteCarbon fiber composite

The invention relates to the technology field of communication and observation control, which provides a composite material satellite antenna reflection plane and the method for preparation. The composite material satellite antenna reflection plane adopts 3D glass fiber felt as core material, and adopts carbon fiber composite as covering sandwich type composite material satellite antenna reflection plane. Compared with the prior art, the invention has the following advantages: 1. shaped surface accuracy of the satellite antenna reflection plane is high and satellite signal gain is great, 2. quality of the reflection plane is light, and is fit for transportation, in particular to fitting for vehicle satellite antenna and portable satellite antenna, 3. integrality of the reflection plane is good, hardness is great, thereby being capable of preferably retaining the shaped surface accuracy and bearing more wind load and impact load, 4. adopting the 3D glass fiber felt as the core material, the invention inaugurates a new technology of the sandwich composite material satellite antenna reflection plane, the technology is capable of producing heavy caliber satellite antenna reflection plane, and which is simple in manufacturing technology comparatively and low in the cost.

Owner:吴豪 +1

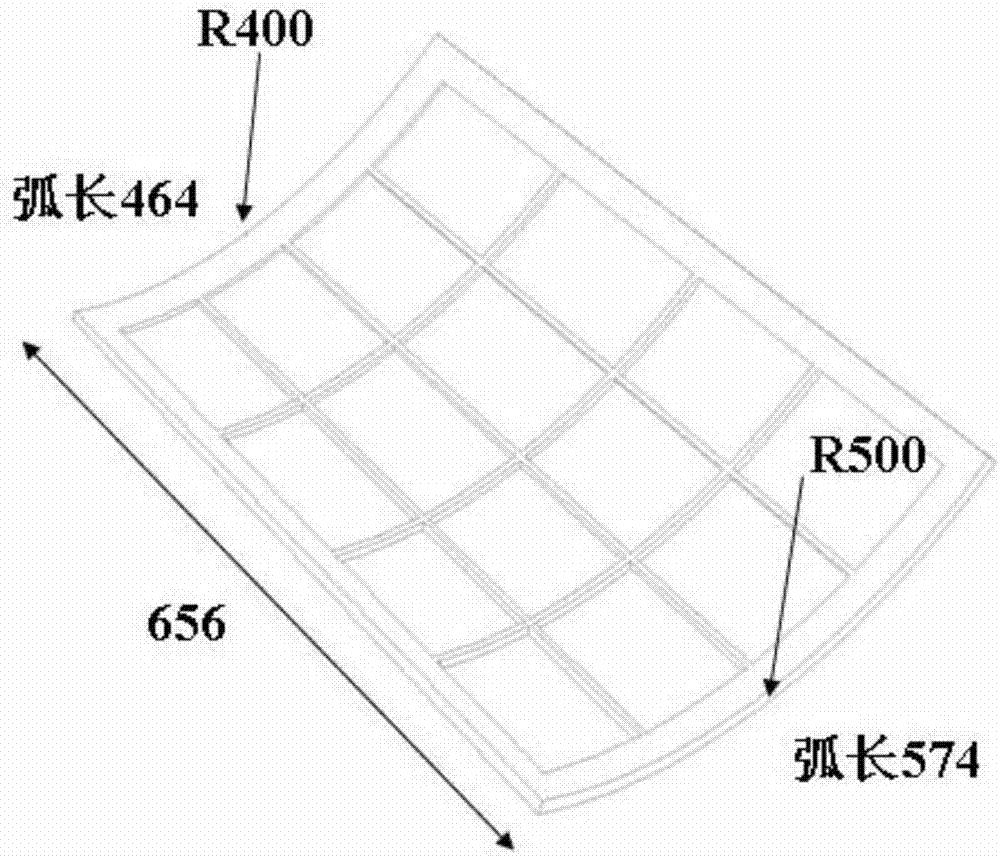

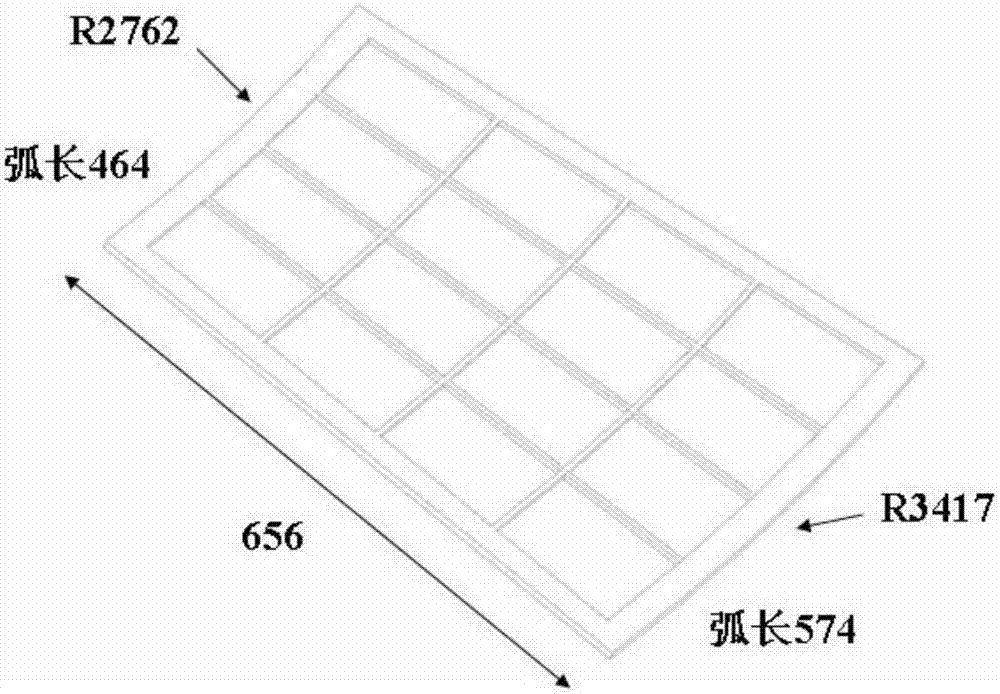

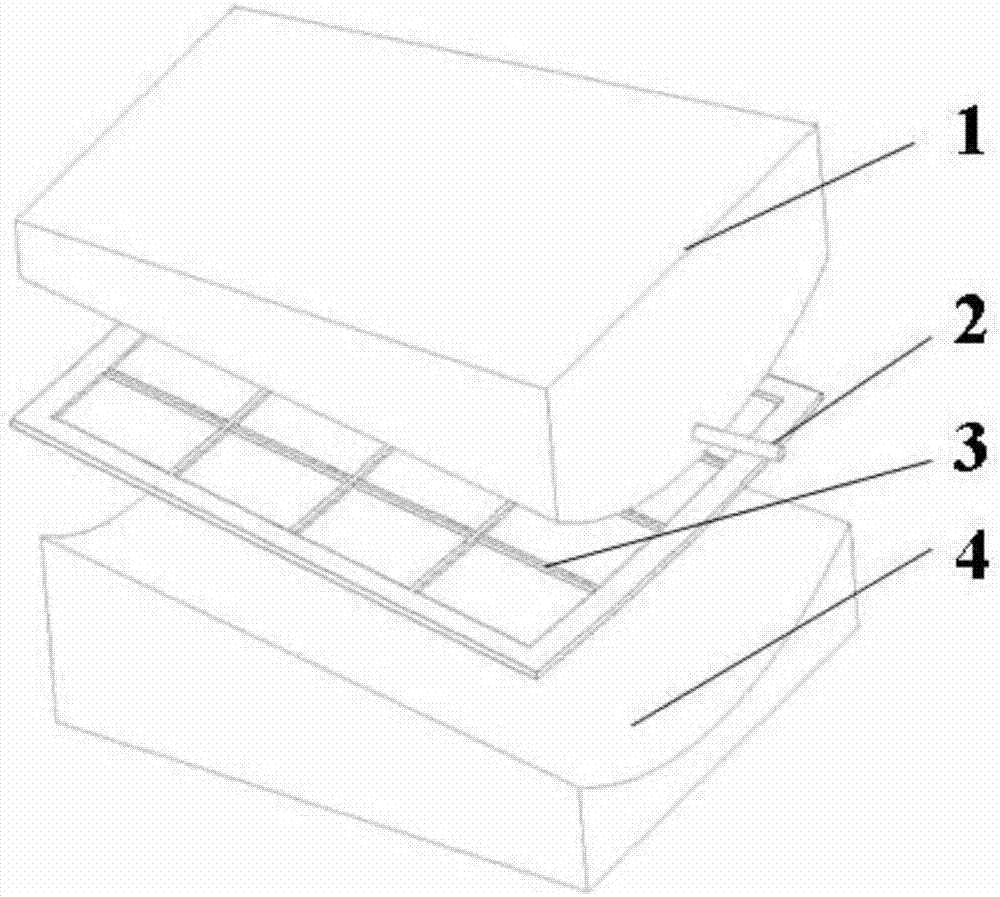

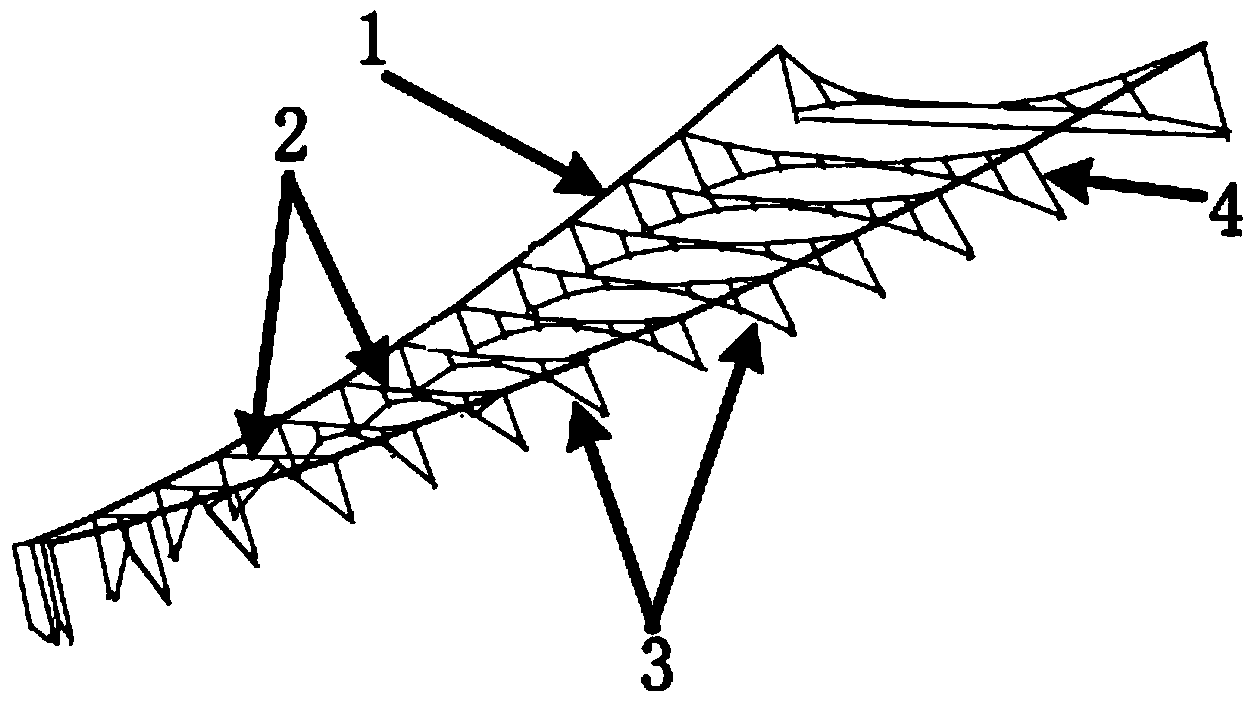

Expandable mesh parabolic cylinder antenna

InactiveCN103354303ASave spaceReduce storage volumeCollapsable antennas meansEngineeringHigh surface

The invention discloses an expandable mesh parabolic cylinder antenna, and mainly solves problems of large storage volume and low surface precision in the prior art. The expandable mesh parabolic cylinder antenna is composed of an expansion mechanism (1), a mesh surface supporting mechanism (2), flexible cables (3) and a wire mesh (4). The mesh surface supporting mechanism (2) is symmetrically installed on both sides of the expansion mechanism (1). The flexible cables (3) are interlaced on the mesh surface supporting mechanism. The wire mesh (4) is disposed on the flexible cables (3). During folding up, the expansion mechanism is retracted along a straight line; the mesh surface supporting mechanism is folded up and retracted on both sides of the expansion mechanism; and the flexible cables and the wire mesh are retracted in remaining space of the mesh surface supporting mechanism. During expansion, the expansion mechanism is expanded along a straight line; the mesh surface supporting mechanism is stretched towards both sides of the expansion mechanism (1); and the flexible cables tighten and support the wire mesh (4) so as to form a parabolic cylindrical surface. The expandable mesh parabolic cylinder antenna has the advantages of small storage volume and high surface precision, and can be used for searching targets in the air and measuring target azimuths.

Owner:XIDIAN UNIV

Forming equipment of large size composite stringer

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

Hot-pressing forming method for aluminum-alloy curved reinforcing rib plate

The invention discloses a hot-pressing forming method for an aluminum-alloy curved reinforcing rib plate. The method comprises the steps of 1, carrying out plane unfolding on the aluminum-alloy curved reinforcing rib plate; 2, preparing corresponding reinforcing ribs on the plate according to the positions of the reinforcing ribs in the plane unfolding diagram; 3, designing and processing a hot-pressing forming die of the aluminum-alloy curved reinforcing rib plate; 4, performing hot-pressing forming on the aluminum-alloy curved reinforcing rib plate; and 5, performing air inflation correction on the aluminum-alloy curved reinforcing rib plate. According to the method, the aluminum-alloy curved reinforcing rib plate is formed by adopting hot-pressing formation and air inflation correction combined technologies, the problem that the size precision and the profile precision of the parts are difficult to control in the conventional cold stamping or machining process is solved, the surface quality of the parts is improved, and the overweight problem in the casting process is avoided; firstly, hot-pressing forming is adopted so that resilience, wrinkling, cracking and other defects in the cold forming process can be effectively avoided; and then air inflation correction is adopted so that the size precision, the profile precision and the surface quality requirements of the parts can be guaranteed.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Sunflower type solid antenna capable of being spread

InactiveCN103545591AGuaranteed synchronicityReduce volumeCollapsable antennas meansDrive shaftEngineering

The invention provides a sunflower type solid antenna capable of being spread. The sunflower type solid antenna capable of being spread aims at resolving the problems that mesh type and inflatable antenna molded surfaces are not high in precision and limited in working frequency at preset. According to the sunflower type solid antenna capable of being spread, a regular dodecagon plate body serves as a base, six driving shafts and six universal shafts are arranged in a staggered mode along the edge of the base, each driving shaft is connected with a corresponding edge on the base through the corresponding driving shaft support, the two ends of each driving shaft are respectively connected with one end of an adjacent universal shaft, each driving shaft is connected with the lower end of a main spherical shell, the other side of each auxiliary spherical shell is connected with the other side of an adjacent auxiliary spherical shell through a spherical hinge mechanism, the middle of each universal shaft is connected with the lower end of a connecting rod, and the upper end of each connecting rod is connected with the corresponding spherical hinge mechanism. The sunflower type solid antenna capable of being spread is used for the field of antennas.

Owner:HARBIN INST OF TECH

Satellite-borne solid-surface deployable antenna

InactiveCN107768797ANo motion singularityHigh storage rateCollapsable antennas meansSatelliteDrive motor

The invention discloses a satellite-borne solid-surface deployable antenna which is composed of a solid-surface reflector, a deployable mechanism and a driving component. The deployable mechanism is composed of multiple synchronous three-bar deployable units and synchronous two-bar deployable units combined in an array. The solid-surface reflector is composed of a plurality of rigid sheets. The driving component includes a driving motor and an elastic energy storage element. The solid-surface reflector and the deployable mechanism are connected through a universal hinge. Under the action of the driving motor, the solid-surface reflector realizes first spatial synchronous deployment through the deployable mechanism. Under the action of the elastic energy storage element and a compression spring, the solid-surface reflector realizes second spatial synchronous deployment. After deployment, any two adjacent panels of the solid-surface reflector are hinged and locked by a locking mechanism,and the whole antenna is stabilized in a fully deployed state. The satellite-borne solid-surface deployable antenna has the characteristics of large deployment aperture, high deployment and support stiffness, and high precision of surface profile, and can be used as a reflector or a collector in space or on the ground.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Grinding wheel numerically-controlled finishing control device and control method special for face gear grinding

InactiveCN104057396ARealize real-time data communicationFirmly connectedAbrasive surface conditioning devicesNumerical controlGear grindingGear wheel

The invention discloses a grinding wheel numerically-controlled finishing control device and a control method special for face gear grinding. The device comprises a grinding wheel main shaft unit (1), a grinding wheel finishing device (2), a control device (3) and a transmission mechanism (4), wherein the control device comprises an IPC (Industrial Personal Computer), an SERCOS card, a control panel, an SERCOS optical fiber, a KE rectification power supply module, a KW main shaft control module, a KW feed control module and a PLC-IO module; the SERCOS card is mounted on the IPC through an ISA socket; the control panel is connected with the SERCOS card through a control line for sending out a control command; the SERCOS card is connected with the KE rectification power supply module, the KW main shaft control module and the KW feed control module through the SERCOS optical fiber; the KW main shaft control module is connected with a finisher main shaft motor and a grinding wheel main shaft motor; the KW feed control module is connected with each feed motor through a control line. According to the device and the method provided by the invention, the control of the numerically-controlled rectification process of the grinding wheel special for the face gear grinding is realized.

Owner:BEIHANG UNIV

Manufacturing method for large-scale thin-wall skin with inner ribs and complex mold cavities

ActiveCN105397423AAccelerate the development progressHigh profile precisionThin walledMachining process

The invention provides a manufacturing method for a large-scale thin-wall skin with inner ribs and complex mold cavities. The manufacturing method comprises the steps that 1, simulation flattening is conducted on the skin according to a skin parameter, a parameter of the flattened skin is collected, a rough machining programming and a finish machining programming are conducted, and a minimum workblank is calculated; 2, the minimum workblank is selected to be machined roughly in order to release residual stress inside the workblank in advance; 3, a roughly machined skin plate is adsorbed and fixed through a vacuum tire, finish machining is conducted on the skin plate, and the rib strips and the weight reducing cavities inside the skin are machined out through numerical control milling machining; 4, a plurality of base plates which can fill and level up each weight reducing cavity are prepared, it is ensured that the skin machined through the step 3 again becomes a slab with the flat surface after each base plate is cushioned, and then the skin is machined to be formed through a matched mould thermal forming method, and 5, annealing and stress-relieving are conducted. According to the manufacturing method for the large-scale thin-wall skin with the inner ribs and the complex mold cavities, the deformation of the thin-wall skin in the machining process is effectively controlled, and the molded surface precision of the skin is greatly improved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Automobile gearbox P-gear gear manufacturing method

The invention provides an automobile gearbox P-gear gear manufacturing method. An automobile gearbox P-gear gear is finally formed by conducting cold extruding after warm forging is conducted in a warm forging manufacturing mode. The automobile gearbox P-gear gear is characterized in that positive and negative combined extrusion is adopted for cold extruding, and outer teeth are extruded while extrusion forming of the petal portion in a product is finished. The product made through the method is high in accuracy, less in oxidation, good in internal metal organization and more refined in crystalline grain, and harmful structures of coarse crystals, mixed crystals and the like can be avoided; the required equipment is small in tonnage and less in forming force, tooth filling is easier, unit intensity of pressure born by a die is remarkably lowered, the service life of the die is very long, the process can be reduced, and the manufacturing time is greatly shortened (increased by 10 times compared with a gear hobbing machine). The product hardness ranges from HB 140 to HB 180, the tooth profile is fully filled and full, and it is guaranteed that large deformation cannot be generated in subsequent heat treatment of cold extrusion forming.

Owner:CHONGQING CHUANGJING WARM FORGING FORMING

A cable net parabolic cylindrical deployable antenna device based on a double scissors truss mechanism

ActiveCN109149119ASave storage spaceIncreased overall weight and profile accuracyAntenna adaptation in movable bodiesCable networkMetal mesh

The invention belongs to the technical field of antennas and discloses a cable net parabolic cylindrical deployable antenna device based on a double-scissor truss mechanism. The metal mesh reflector adopts soft gold-plated molybdenum wires or tungsten wires to be woven into a mesh. The supporting cable net comprises transverse flexible cables, longitudinal flexible cables and vertical adjusting cables, each longitudinal flexible cable is parabolic, and is woven with the transverse flexible cables to form a front and a rear parabolic cylindrical net surface, and the vertical adjusting cables are connected with the front and the rear net surfaces; A parabolic cylindrical support cable net formed by braiding flexible cables; A metal wire mesh is fix on that cable net to form a parabolic cylindrical reflecting surface, and the shape surface accuracy of the metal wire mesh reflecting surface is adjust by adjusting the force on the flexible cables in the supporting cable net; The deployabletruss is used to suspend the supporting cable network to deploy the antenna. The deployable truss mechanism is integrally square, and is formed by a plurality of deployable units A in series. The invention does not need to add a complex driving mechanism and an additional synchronous mechanism, has a simple and reliable structure, and reduces the complexity of antenna design.

Owner:XIDIAN UNIV

Thermal creep plastic forming method for special-shaped aluminum alloy wall plate with variable thicknesses

InactiveCN108856500AHigh dimensional accuracyHigh profile precisionShaping toolsVariable thicknessThermal creep

A thermal creep plastic forming method for special-shaped aluminum alloy wall plate with variable thicknesses and is suitable for the special-shaped aluminum alloy wall plate, high in size and moldedsurface precision requirement and good in surface quality, with the variable thicknesses. The method includes the following steps that firstly, a thermal creep plastic forming mold of the special-shaped aluminum alloy wall plate with the variable thicknesses is designed and machined; secondly, the special-shaped aluminum alloy wall plate with the variable thicknesses is subjected to plane unfolding; thirdly, according to the positions of reinforcing ribs in the plane unfolded drawing, corresponding reinforcing ribs are prepared on the plate, and positioning convex lugs are machined; fourthly,the special-shaped aluminum alloy wall plate with the variable thicknesses is bent in advance; fifthly, thermal creep plastic deforming is performed on the special-shaped aluminum alloy wall plate with the variable thicknesses; and sixthly, lineation is performed to cut off the positioning convex lugs. The wall plate formed through the method is short in machining period and low in cost, a formedpart is high in size and molded surface precision, and the surface quality is also remarkably improved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Forming method of complex structural part

ActiveCN108672705AEfficient preparationFirmly connectedAdditive manufacturing apparatusExtrusion control devicesManufacturing technologyActive agent

The invention relates to a forming method of a complex structural part, and belongs to the technical field of precision forming machining. The complex structural part is of an equal-cross-section structure with a transverse rib or a boss (except for the transverse rib or the boss, the other portion is of the equal-cross-section structure), or is of a double-side asymmetric deep cavity structure with a web plate. The composite manufacturing method of combining the arc additive and hot extrusion makes full use of the characteristics of high efficiency and low cost of the hot extrusion and arc additive manufacturing technology, so that the defect that the arc additive method and the hot extrusion method can only form a relatively simple structural part is avoided, and rapid and efficient manufacturing of the complex structural part is realized; and secondly, the mechanism based on the fact that the melting depth can be increased by an active agent is utilized to coat a region needs to undergo arc additive manufacturing on an extrusion substrate with a layer of active agent, so that the connecting performance of an interface is further improved, and the high-performance manufacturing of the complex structural part is realized.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Reflection cable net and umbrella antenna reflector with reflection cable net

InactiveCN104241805AHigh precisionMesh reflective surface lightweightCollapsable antennas meansVertical projectionUmbrella antenna

The invention provides a reflection cable net of an umbrella antenna reflector. The reflection cable net of the umbrella antenna reflector is applied to fixed net combination. The reflection cable net comprises a front tension net, a rear tension net and a tension matrix. The tension matrix is located between the front tension net and the rear tension net and connected with the front tension net and the rear tension net, and the profile of the front tension net and the profile of the rear tension net can be adjusted according to actual requirements due to the arrangement of the tension matrix. Besides, the front tension net and the rear tension net of the reflection cable net are symmetrical, the vertical projection direction is adopted for the tension matrix, and thus the reflection cable net has high profile precision and profile keeping capacity. The invention further provides the umbrella antenna reflector with the reflection cable net.

Owner:SHANGHAI YS INFORMATION TECH

Process used for machining inner gear ring with large module and deep tooth space

The invention discloses a process used for machining an inner gear ring with large module and deep tooth space, which comprises the steps of forging, normalizing, rough turning, finish turning, gear shaping and gear broaching. For forging, 20CrMnTi material is chosen, an excircle with 4mm of thickness is added, an inner diameter is decreased by 4mm, and the total height is increased by 4mm on the basis of a finished product dimension to form a forging dimension; for normalizing, a gear ring is placed at high temperature for heat preservation for a time period and then drawn from a furnace for air cooling; for rough turning, oxide scale and most of allowances are removed for the air-cooled gear ring, and 0.5mm allowance is left at each side; for finish turning, the thickness of the excircle and the total height of the gear ring after rough turning is processed to the desired dimension through finish turning, and the inner hole has 0.2mm allowance left; for gear shaping, gear shaping is carried out to the inner gear ring of the gear ring after finish turning, and an inter-rod distance dimension is shaped to be 0.4 mm less than that of a finished product; and for gear broaching, finally a tooth shape and the small diameter of the inner gear ring are broached to the finished product dimension to obtain the finished product of the inner gear ring. The process of the invention can effectively improve the gear shape precision and the consistency of gear ring dimensions, and reduce the internal stress of the gear ring.

Owner:江国辉

Large mesh antenna reflector profile high-precision test method

ActiveCN106643582AHigh precisionHigh measurement accuracyUsing optical meansImaging processingSmall data

A large mesh antenna reflector profile high-precision test method is provided. By using high-precision industrial digital photogrammetry technology, a single camera is used for separately recording the images of the same scene in a space from different locations and directions. By means of image processing and according to known camera parameters, the three-dimensional coordinates of the scene relative to a coordinate system in the space are calculated. The profile precision of the mesh antenna is obtained by fitting the coordinate values with a theoretical profile. In order to improve the profile measurement precision of a large-caliber small-datum and high-precision large flexible mesh antenna reflector, by means of a designed reference conversion device, a high-precision long reference ruler, the large mesh antenna reflector profile is subjected to high-precision testing by optimal technological parameters of the photogrammetry system.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

Method for polishing SIC optical freedom curve by Fenton-assisted rigidity-variable pneumatic grinding wheel

InactiveCN108372442AHigh profile precisionNo surfaceGrinding carriagesOptical surface grinding machinesSurface layerFenton reagent

The invention relates to a method for polishing an SIC optical freedom curve by a Fenton-assisted rigidity-variable pneumatic grinding wheel. The method comprises the following steps of firstly, sheathing the non-processing surface of an SIC workpiece with an isolation material; then, completely submerging into a reaction cell with a Fenton reagent, reacting for a period of time, uniformly forminga SiO2 surface layer with equal thickness at the surface of the SIC workpiece, fetching out the SIC workpiece, and fixing the SIC workpiece onto a worktable by a limiting device; uniformly removing the generated SiO2 surface layer after reaction by a floating connecting device; adjusting the location and gesture of a tool system corresponding to the workpiece by a mechanical arm, changing the airpressure of compressed air entering the rigidity-variable pneumatic grinding wheel to adjust the rigidity of the rigidity-variable pneumatic grinding wheel, attaching the rigidity-variable pneumaticgrinding wheel and the SIC workpiece with freedom curve, and finally polishing the SIC workpiece with the freedom curve by the rigidity-variable pneumatic grinding wheel. The method for polishing theSIC optical freedom curve by the Fenton-assisted rigidity-variable pneumatic grinding wheel has the advantages that the efficiency is high, and the cost is low.

Owner:ZHEJIANG UNIV OF TECH

Mould machining method and system

ActiveCN103769487AImproved dimensional accuracy and stabilityHigh profile precisionShaping toolsMachining processWorkload

The invention relates to the technical field of moulds and discloses a mould machining method and system. The mould machining method comprises calculating numerical control data according to the mould machining technical process; performing correction on the numerical control data according to the characteristics of changes of the profile of a mould; obtaining the mould according to the corrected numerical control data. According to the mould machining method and system, profile grinding match workloads of bench workers in the mould machining process and the error produced when the profile is manually finished can be reduced and the accuracy of the profile of the mould can be improved.

Owner:BEIQI FOTON MOTOR CO LTD

Cable section tension variance optimization-based design method for cable net structure of deployable satellite-borne antenna

InactiveCN107256288AImprove structural performanceTension variance is smallDesign optimisation/simulationSpecial data processing applicationsCable netIterative method

The invention discloses a cable section tension variance optimization-based design method for a cable net structure of a deployable satellite-borne antenna. The cable net structure of the deployable satellite-borne antenna consists of a front cable net surface, a back cable net surface and a longitudinal pull cable; when the cable net structure is designed, all cable net surface nodes fall on a paraboloid through a force density iterative method; meanwhile, boundary nodes of the front and back cable net surfaces are subjected to boundary cable section and annular truss reconnection by taking a regular hexagon in the cable net structure as an effective reflective surface, and serve as basic mesh configuration of the cable net structure of the deployable satellite-borne antenna; and then, by taking cable section tension of the front and back cable net surfaces and tension of the longitudinal pull cable as design variables, taking a cable section tension variance of the front and back cable net surfaces as a target function and taking boundary node fixation as a constraint condition, the cable net structure of the deployable satellite-borne antenna is designed. According to the method, excellent structure layout of the deployable satellite-borne antenna is realized, so that the stability and reliability of the deployable satellite-borne antenna can be remarkably improved.

Owner:XIDIAN UNIV

Technological cover plate of combined structure and production method therefor

ActiveCN104842606AQuality improvementHigh activity coordinationSynthetic resin layered productsFastening meansRubber materialForming face

The present invention belongs to the technical field of composite materials manufacturing and particularly relates to a technological cover plate of a combined structure and a production method therefor . The technological cover plate of the combined structure is compsoed of a split forming face plate, a separation area and a connection body. The split forming face plate is of a composite material structure and is formed by sub forming face plates, wherein the sub forming face plates are provided with wedge-shaped boundary structures and are overlapped through the separation area. The separation areas are formed by film structure materials with the single layer having demolding / pasting two functions. The connection body is made of rubber materials. During production, the wedge-shaped boundary structures of the sub forming face plates are produced by a prepreg gradient pasting method, the sub forming face plates are connected to form the split forming face plate through the separation area, the connection body is integrally arranged on the split forming face plate, and the split forming face plate, the seperation area and the conenction body are formed through one-step curing. The technological cover plate of the combined structure is provided with an interior structure having a high motion coordination performance, has a high-quality surface forming effect, and has an important engineering value for production of skins of irregular profile structures made of composite materials.

Owner:AVIC COMPOSITES

Heating type mold of aluminum alloy flange plate through heating pipe and extrusion molding method thereof

The invention relates to a heating type mold of an aluminum alloy flange plate through a heating pipe and an extrusion molding method thereof, belongs to the field of aluminum alloy hot processing, and is suitable for hot extrusion and forming of aluminum alloy flange plates for aerospace. The heating type mold comprises an upper mold, a lower mold, an upper push rod, a lower push rod, a lower mold base plate, a connecting bolt and hoisting suspension rings. The extrusion molding method comprises the following steps of I, according to a constant volume principle and technology allowance, determining the diameter of a blank and preparing the blank; II, after the mold is assembled, fixing the assembled mold to a press machine platform; III, assembling the heating pipe, a temperature thermocouple and a heat preservation partition board to corresponding positions on the mold; IV, respectively heating the mold and the blank to a set temperature, and performing heat preservation for some time; and V, placing the blank in a lower mold cavity, closing the upper mold and the lower mold, so as to realize the hot extrusion forming of the flange plates, and enabling the lower push rod to drivethe upper push rod to eject a formed piece, so that the forming of the flange plate is completed. The flange plate formed by the extrusion molding method disclosed by the invention is high in material utilization rate, high in forming efficiency, small in burrs, good in product consistency, high in dimension accuracy, high in profile accuracy and good in surface quality.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

High-precision reflector composite material forming die structure and forming method thereof

The invention relates to a high-precision reflector composite material forming die structure and a forming method thereof, and belongs to the technical field of composite material production. The high-precision reflector composite material forming die structure comprises a composite material shell, a first reinforcement back reinforcement, a composite material cylinder and a second reinforcement back reinforcement; the first reinforcement back reinforcement and the second reinforcement back reinforcement form a sector-shaped structure, the composite material cylinder is arranged in the central area of the sector-shaped structure, and the first reinforcement back reinforcement, the second reinforcement back reinforcement and the composite material cylinder are cemented to form one body; and the edge of the composite material shell is a two-step structure form. The invention discloses a high-precision reflector composite material forming die structure form. The structure adopts a composite material shell + composite material back reinforcement structure form, and the back reinforcements adopt the sector-shaped structure. Compared with a grid structure, the structure provided by the invention has the following advantages: 1, a composite material die has good heat stability; 2,air surrounding the die is smooth, and the die is uniformly heated; and 3, the composite material shell adopts two steps, so the self rigidity of the composite material die is increased.

Owner:JIANGXI HONGDU AVIATION IND GRP

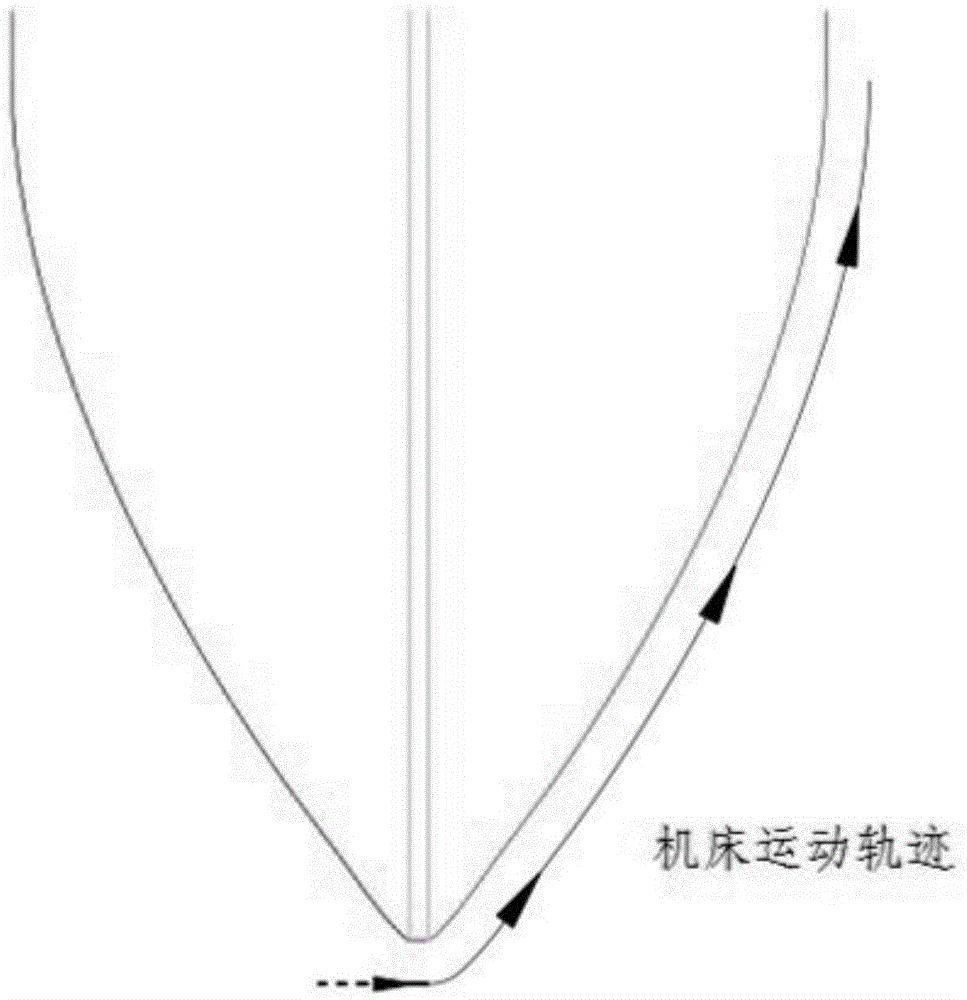

High-precision numerically-controlled rotor grinding machine

The invention discloses a high-precision numerically-controlled rotor grinding machine which comprises such components as a machine body, a workbench, a head frame, a tail frame, a grinding wheel rack, a precision grinding tool and a grinding wheel mechanism; the machine body adopts a numerically-controlled forming grinding method, a mathematical model that the motion trail of a trimming roller is conjugate with a forming surface is established, and the movement of two shafts of a grinding wheel dresser is controlled through a numerical control device to enable the arc center of a diamond roller to generate linkage in two coordinate directions, and the grinding wheel is dressed into a required forming surface. During processing, the grinding wheel is fully contacted with the outline of a workpiece, and numerically-controlled forming grinding is realized by utilizing lengthwise movement of the workbench, precision indexing movement and transverse feeding movement of the grinding wheel, so that a rotor can be ground into a required shape. The high-precision numerically-controlled rotor grinding machine has the advantages that the grinding profile accuracy reaches 0.01 mm, the tooth surface roughness can be Ra 0.2 to 0.32, the production efficiency is increased by at least two times compared with that of the traditional milling process, and the processing cost is reduced greatly compared with that of milling.

Owner:陕西汉江机床有限公司

Accurate forming method for large-curvature and high-order-difference edge sealing frame

ActiveCN106825307AAchieve precise formingHigh profile precisionMetal-working apparatusEngineeringBend radius

The invention provides an accurate forming method for a large-curvature and high-order-difference edge sealing frame. The accurate forming method is characterized by comprising the following steps that a rectangular blank is blanked, the margin of 15 mm is added to each of the two edges, in the width direction, of the blank on the basis that the part is expanded in the width direction, the length between a die to a transition section of a stretch bending equipment jaw and the length between the die and a clamping section of the stretch bending equipment jaw are added to the blank length during stretch bending forming on the basis of the length of the stretch bending forming die; trichloro ethylene vapor degreasing is conducted on the blank, the surface of a part is cleaned, burrs on the edge of the blank are removed, and an end face is sanded through abrasive paper; and a bending forming machine is used for conducting pre-forming on the blank, the order difference, the bending radius and the angle of the blank are completely the same with those of the part, the blank is pre-bent to form a ruled-surface transition part with a 45-degree Z-shaped section, the two ends of the blank are flattened to have the clamping width of the stretch bending forming machine jaw, and therefore clamping is facilitated.

Owner:HARBIN

Machining method for cycloid gear

ActiveCN105665838AExtended service lifeReduce stress deformationGear teethNumerical controlEngineering

The invention discloses a machining method for a cycloid gear. The machining method includes the following steps that a to-be-machined cycloid gear is fixed to a working table of a five-axis linkage numerical control machine tool; a flat bottom cutter is controlled by the five-axis linkage numerical control machine tool to rotate around the B axis of the five-axis linkage numerical control machine tool, so that the elevation of a cutter shaft of the flat bottom cutter is fixed to be theta, and the flat bottom cutter right faces the outline of the cycloid gear; the flat bottom cutter rotates at a high speed around the axis of the flat bottom cutter, and the cycloid gear starts to be machined and does vertical milling motion along the Z axis of the five-axis linkage numerical control machine tool along with the working table; and after walking through one track each time, the cycloid gear rotates around the C axis of the five-axis linkage numerical control machine tool along with the working table by a certain angle, and circulated machining is carried out until end milling of the overall gear is finished. According to the machining method, the gear shape accuracy and the surface quality of the cycloid gear can be effectively improved, burning generated during traditional grinding is avoided, and the problems in machining of the high-quality cycloid gear are solved.

Owner:XIAMEN UNIV OF TECH

3,350mm-level ellipsoid scalloped segment liquid-filling and forming process and die thereof

InactiveCN107175295AImprove surface quality and profile accuracyReduce labor intensityShaping toolsEllipsoidPlastic film

The invention provides a 3,350mm-level ellipsoid scalloped segment liquid-filling and forming process and a die thereof. A hydromechanical deep drawing forming mode is adopted. The hydromechanical deep drawing forming mode comprises the following specific steps: a, cleaning: removing sundries on a molded surface of the die and the surface of a blank before liquid filling; b, uniformly smearing an integral molded surface of a male die of the die with lubricating oil; c, filling of a liquid filling chamber: enabling a liquid filling chamber of a female die to be filled with hydraulic oil; d, loading: placing the blank on the female die, adjusting the front and rear positions of the blank to enable the blank to be centered, and adjusting the liquid level of the liquid filling chamber to be parallel and level to the blank; e, paving an annular plastic film on one side, which is in contact with a blank holder, of the blank, and paving a plastic film of which the shape is consistent to that of the blank on the other side, which is in contact with the liquid filling chamber, of the blank; f, hydromechanical deep drawing of a part: controlling the matching relation between the pressure of the liquid-filling chamber and a blank holder force, and carrying out hydromechanical deep drawing forming on the blank; and g, unloading. A one-time liquid-filling forming process is adopted, liquid-filling forming of a 3,350mm-level ellipsoid scalloped segment is realized, a qualified product which meets use requirements is obtained, and the quality of the surface of the part and the precision of the molded surface are improved remarkably.

Owner:TIANJIN AEROSPACE CHANGZHENG ROCKET MFGCO +1

Method for manufacturing suspension bridge tie rod

The invention provides a method for manufacturing a suspension bridge tie rod. The method comprises the following steps of: (1) arranging a blank on a machine tool and roughly cutting the tie rod by using a forming tool; (2) tempering and aligning; (3) roughly cutting tooth form of the tie rod by using the forming tool; and (4) finely extruding the tie rod tooth form to obtain the tie rod workpiece. The completely new method for manufacturing the suspension bridge tie rod of the invention has the advantages of high glossiness of the extrusion, high fineness of the tooth form and easiness of cutting of a material by threading, guarantees the quality and also improves the efficiency. The method is a preferred scheme for manufacturing the type of tie rods with diameter of more than phi 50 and long radius ratio of between 20 and 30; and the method grantees the quality, has high manufacturing capacity and high efficiency and is suitable for large-scale use and popularization.

Owner:SICHUAN TIANYUAN MECHANICAL ENG

Novel continuous molding mould for ultrathin component

The invention provides a novel continuous molding mould for an ultrathin component. The novel continuous molding mould comprises a left baffle 1, a front baffle 2, a male mould 3, a flexible mould 4, a right baffle 5, a female mould 6 and a rear baffle 7, wherein the male mould 3 has a convex curved surface; the female mould 6 has a concave curved surface at a position corresponding to the convex curved surface; the circular arc radius of the convex curved surface is equal to that of the concave curved surface; the male mould 3 is covered with the flexible mould 4; the left baffle 1, the front baffle 2, the rear baffle 7 and the right baffle 5 are respectively in screw joint to the periphery of the male mould 3 and are used for blocking the flexible mould 4. According to the novel continuous molding mould, the flexible mould and a fixing device of the flexible mould are additionally arranged, so that a composite material component for a large ultrathin non-equal-thickness complex satellite can be prepared with high accuracy; the product is excellent in surface quality, high in accuracy of the molded surface and excellent in performance; the problem of molding of the composite material component for the large ultrathin non-equal-thickness complex satellite can be solved; the problems of poor appearance quality, high porosity and poor accuracy of the molded surface caused by uneven pressure distribution of a metal mould due to the non-equal thickness of the product can be solved.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

Simple method for generating reflecting surface cable net of cable net antenna

The invention discloses a simple method for generating a reflecting surface cable net of a cable net antenna, which comprises the following steps: generating a reference spherical surface; dividing the reference spherical surface into six identical sub curved surfaces; taking one of the sub curved surfaces; equally dividing two main cables on the two sides of the sub curved surface at a uniform angle; generating an initial coordinate formula of a group of cable net nodes; according to the difference between each cable unit length and the length ls of a standard cable unit, generating a displacement matrix of free node coordinate correction, and then generating a corrected node coordinate of the free node, obtaining a corrected sub curved surface cable net and the total cable length of thesub curved surface cable net, determining the difference between the total cable length of the sub curved surface for the first time and that for the second time; enabling the difference between the total cable length of the net for the former time and that for the last time to be less than a convergence threshold through multiple iteration corrections; and rotating the obtained sub curved surfacenet by an angle of phi / 3 around the central axis of the paraboloid of revolution to generate the entire reflecting surface cable net. Compared with the common projection method and geodesic method, the length of the reflecting surface cable net unit generated through the simple method in the invention is more uniform, especially in the case that the focal length-caliber is relatively small.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com