Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Improve fit strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

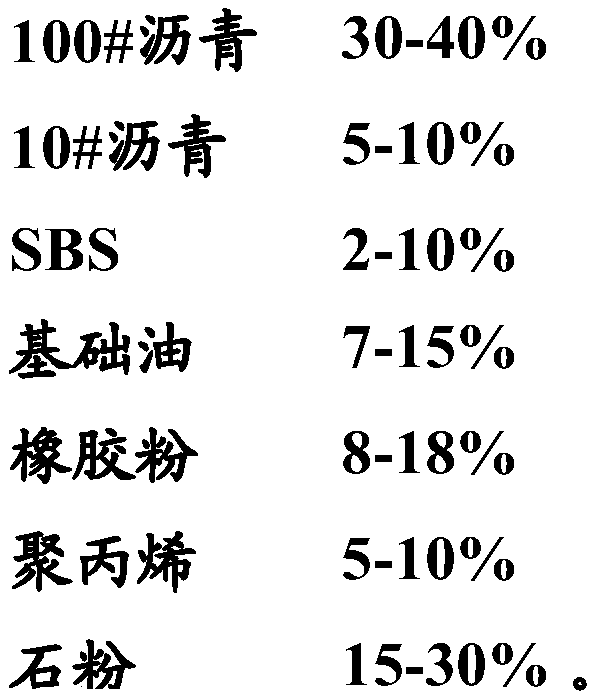

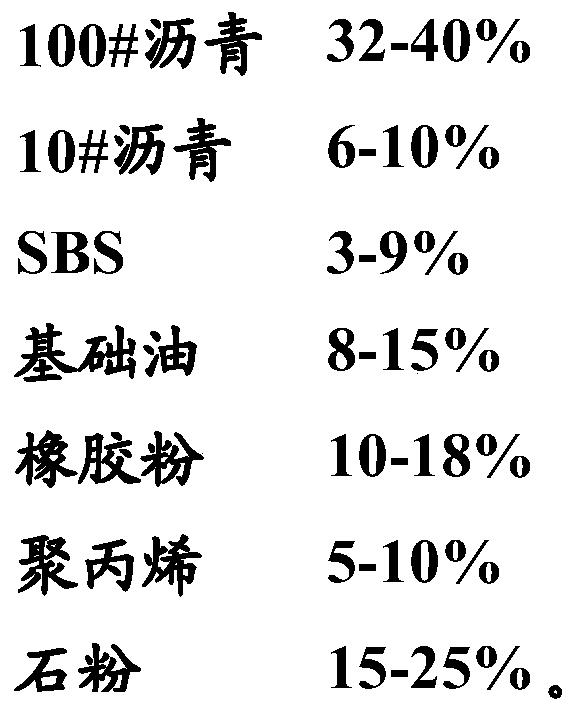

Low-temperature-resistant modified asphalt waterproof coiled material and preparation method thereof

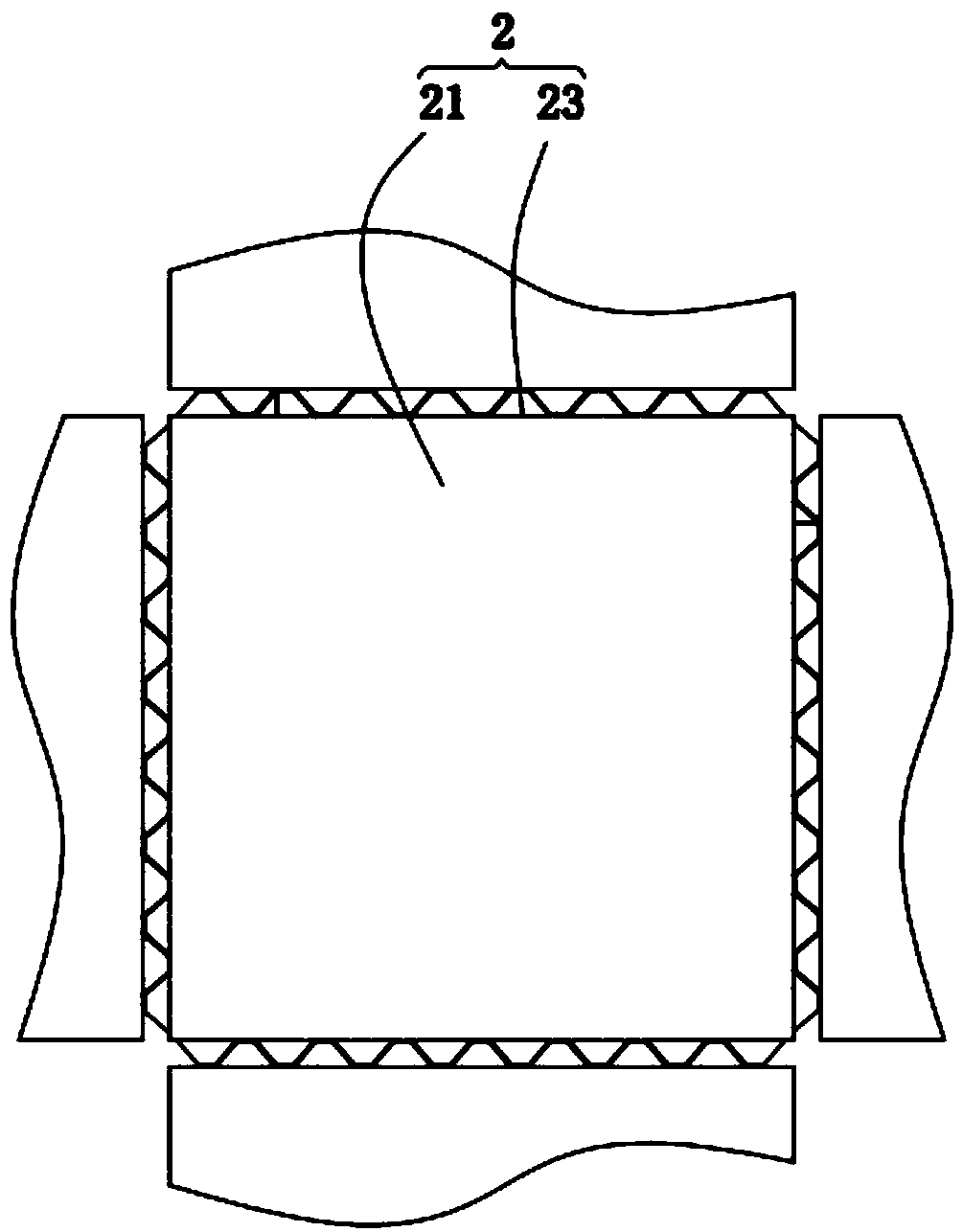

ActiveCN107901525AHigh resistance to pressure waterHigh tensile strengthSynthetic resin layered productsLaminationBituminous waterproofingIsolation layer

The invention relates to a low-temperature-resistant modified asphalt waterproof coiled material. The low-temperature-resistant modified asphalt waterproof coiled material comprises a base substrate,an upper modified asphalt layer, a lower modified asphalt layer, an isolation layer and a covering layer. The waterproof coiled material provided by the invention has the following advantages: excellent low-temperature performance is obtained through component optimization of modified asphalt under the condition of maintaining waterproofness, strength and toughness; and through close cooperation of the modified asphalt with the base substrate, the isolation layer and the covering layer, waterproofness and strength are further reinforced, and the waterproof coiled material is more long-lastingand durable.

Owner:豫王建能科技股份有限公司

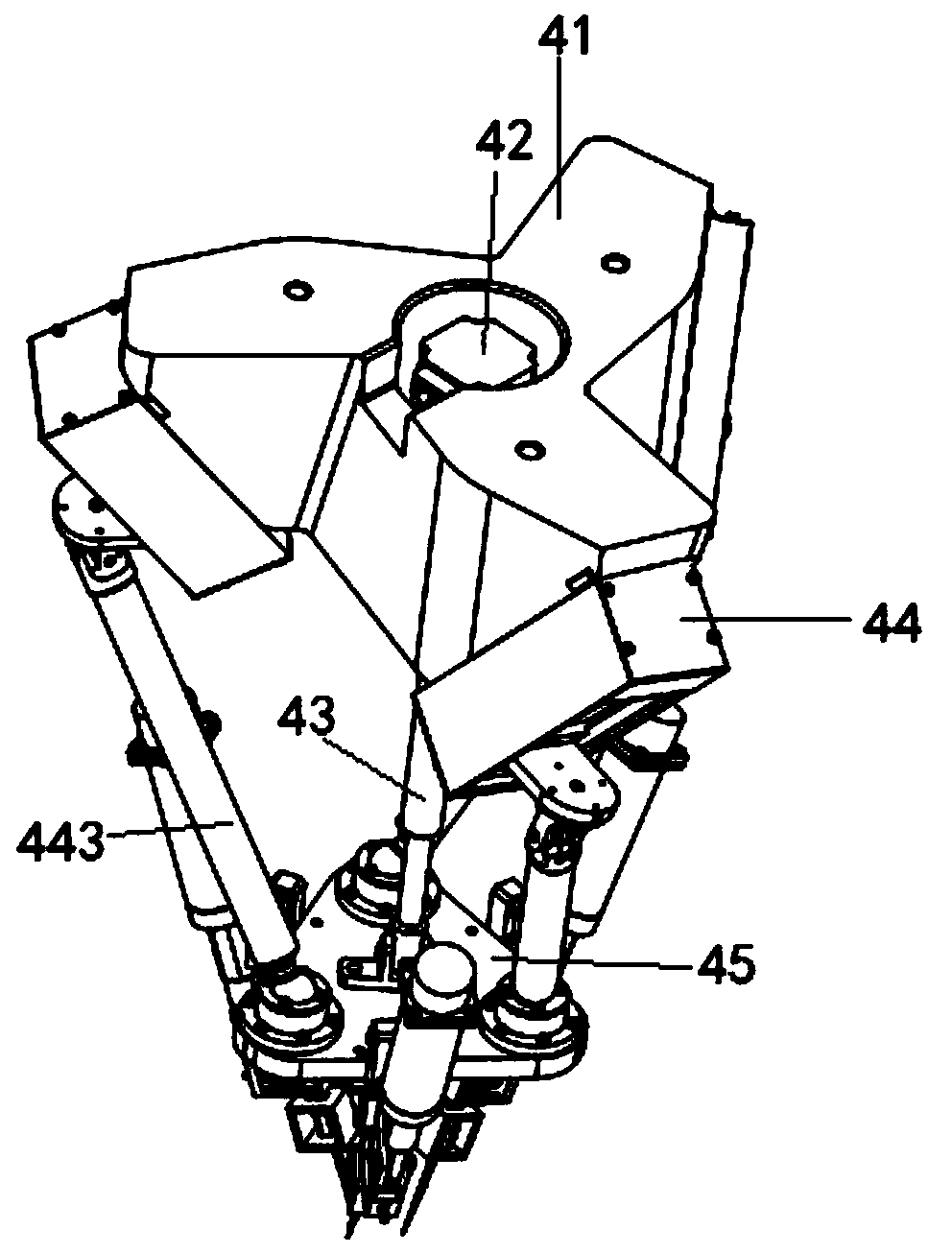

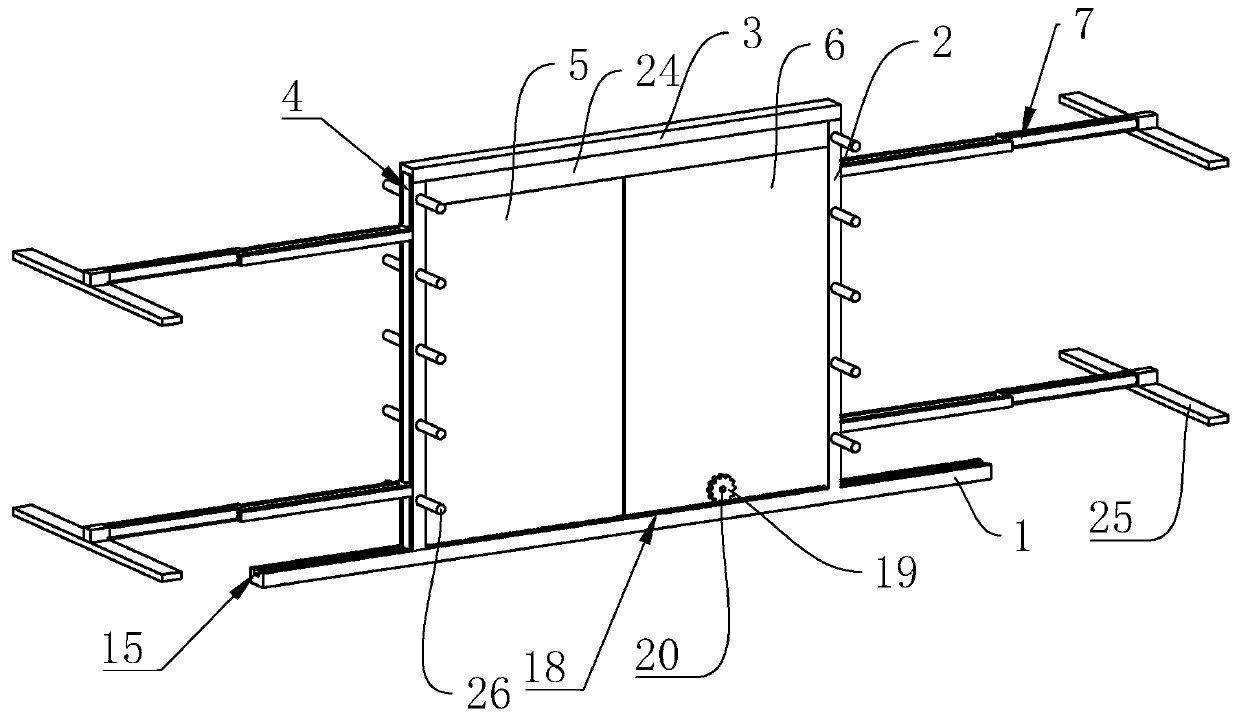

Lifting device for prefabricated concrete outer wallboard and lifting method of lifting device

ActiveCN107673185AImprove securityReduce sheddingBuilding material handlingLoad-engaging elementsClassical mechanicsStructural engineering

The invention discloses a lifting device for a prefabricated concrete outer wallboard and a lifting method of the lifting device and solves the problem of infirm lifting of outer wallboards in the prior art. According to the technical scheme, the lifting device for the prefabricated concrete outer wallboard is characterized by comprising a transverse lifting beam and first lifting chains fixed atthe lower end of the transverse lifting beam and further comprises no less than two groups of lifting assemblies matched with the first lifting chains to lift the prefabricated concrete outer wallboard; each lifting assembly comprises a metal pipe embedded in the upper end of the prefabricated concrete outer wallboard and a supporting block mounted on the inner side of the pipe wall of the metal pipe, the corresponding first lifting chain penetrates through the metal pipe, a supporting groove allowing the first lifting chain to penetrate is formed in the supporting block, and the bottom surface of the supporting groove is a downwards-bulging arc surface. By the aid of the lifting device for the prefabricated concrete outer wallboard, the prefabricated concrete outer wallboard is lifted more safely and firmly.

Owner:萧云建设股份有限公司

Heating type mold of aluminum alloy flange plate through heating pipe and extrusion molding method thereof

The invention relates to a heating type mold of an aluminum alloy flange plate through a heating pipe and an extrusion molding method thereof, belongs to the field of aluminum alloy hot processing, and is suitable for hot extrusion and forming of aluminum alloy flange plates for aerospace. The heating type mold comprises an upper mold, a lower mold, an upper push rod, a lower push rod, a lower mold base plate, a connecting bolt and hoisting suspension rings. The extrusion molding method comprises the following steps of I, according to a constant volume principle and technology allowance, determining the diameter of a blank and preparing the blank; II, after the mold is assembled, fixing the assembled mold to a press machine platform; III, assembling the heating pipe, a temperature thermocouple and a heat preservation partition board to corresponding positions on the mold; IV, respectively heating the mold and the blank to a set temperature, and performing heat preservation for some time; and V, placing the blank in a lower mold cavity, closing the upper mold and the lower mold, so as to realize the hot extrusion forming of the flange plates, and enabling the lower push rod to drivethe upper push rod to eject a formed piece, so that the forming of the flange plate is completed. The flange plate formed by the extrusion molding method disclosed by the invention is high in material utilization rate, high in forming efficiency, small in burrs, good in product consistency, high in dimension accuracy, high in profile accuracy and good in surface quality.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

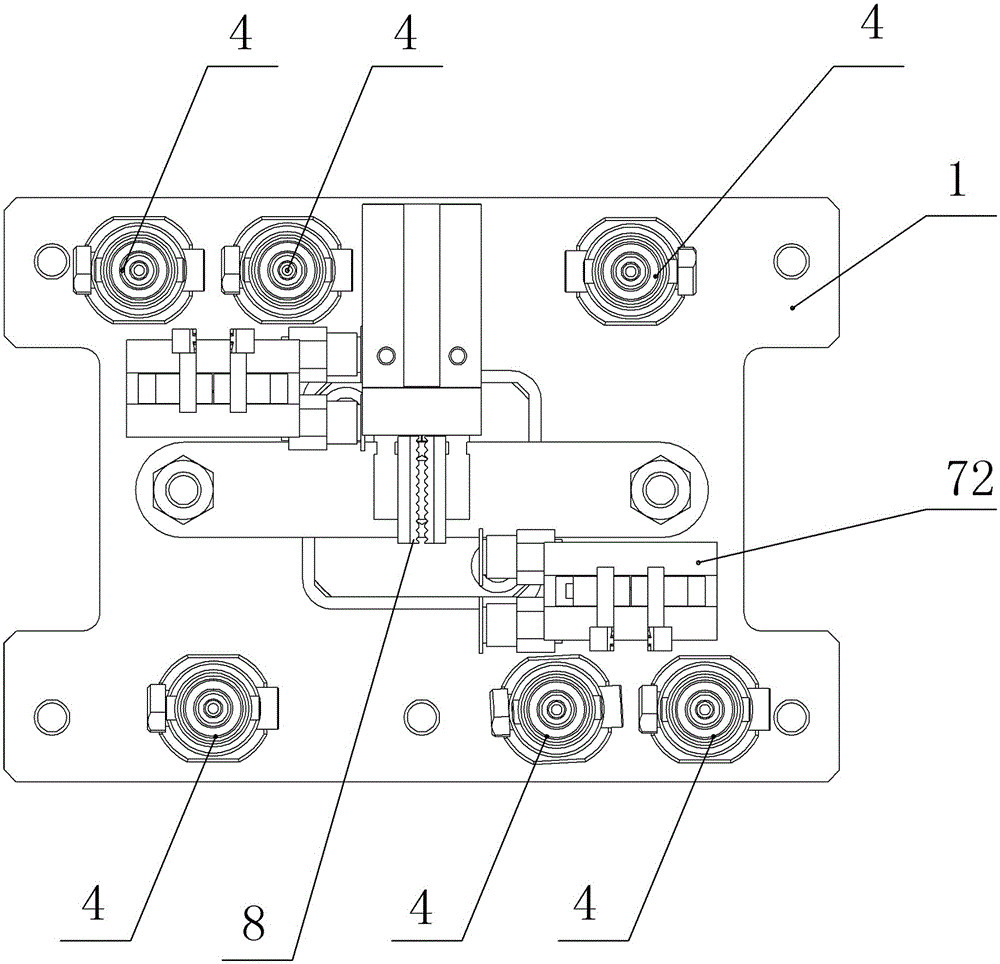

Adjustable aluminum alloy steel plate surface drilling equipment

ActiveCN111014770AImprove drilling efficiencyPrecise Drilling RequirementsBoring/drilling componentsBoring/drilling machinesPhysicsSteel plates

The invention discloses adjustable aluminum alloy steel plate surface drilling equipment. The equipment comprises a transmission positioning frame, wherein a fixed batten is slidably installed on a top end face of the transmission positioning frame, a first hydraulic cylinder is slidably installed on a surface of the fixed batten, and a synchronous drilling mechanism is installed at a power outputend of the first hydraulic cylinder. The drilling equipment is advantaged in that three hole sites can be drilled at the matching site of each steel plate at the same time, drilling efficiency is improved, and problems that in order to achieve firm connection and combination in the existing steel plate machining process, three or four hole sites are generally drilled at each matching site of thesteel plate, the matching strength between the steel plate and other plates is improved, and drilling efficiency is reduced due to the fact that drilling is generally conducted one hole site by one hole site in the existing numerical control equipment drilling process are solved.

Owner:灵璧县浩翔信息科技有限公司

Square tube connector structure and supporting mechanism

The invention relates to the technical field of fastening components, and discloses a square tube connector structure and a supporting mechanism. The square tube connector structure comprises a connecting base and adjusting bolts, the connecting base comprises a base and square connectors, the square connectors are sleeved with square tube beams to be connected, the number of the square connectors is at least two, the square connectors are arranged at the end of the base, and each square connector comprises two inserting columns arranged side by side, wherein the two inserting columns are arranged in a spaced manner, one inserting column is provided with a threaded through hole perpendicular to the inserting column, the axis of the threaded through hole penetrates through the two inserting columns, the corresponding adjusting bolt can be in threaded connection with the threaded through hole, and the corresponding adjusting bolt penetrates through one end of one insertion column and can push the other insertion column, so that the two insertion columns rotate in opposite directions. The square tube connector structure is small in fit clearance with the square tube beams, higher in fit precision and strength and convenient to disassemble and assemble, and brings convenience to replace the square tube beams.

Owner:清华大学苏州汽车研究院(吴江) +1

Production method of low-cost easily-welded steel

The invention relates to a production method of low-cost easily-welded steel and belongs to the technical field of metal rolling. According to the technical scheme, the production method is characterized in that alloy elements for improving the welding performance are not required to be added, the content of easily-welded soft-phase ferrites in the microstructure of hot rolling strip steel is controlled on line to account for 70%-95%, and the content of difficultly-welded hard-phase pearlites in the microstructure of the hot rolling strip steel is controlled on line to account for 5%-30%; and an accelerated cooling manner is adopted, the cooling rate is increased by 5-15% on the basis of the original cooling rate, after acceleration, the cooling rates of strip steel laminar cooling water-cooling sections with different thicknesses and sizes are controlled at 65-105 DEG C / s, and the cooling rate of laminar cooling in the whole stage is controlled at 12.56-19.4 DEG C / s, so that the nucleation rate of phase transformation is increased, and the grain growth slows down. According to the production method, the product with the mechanical property and the welding property which are well matched is obtained by controlling the microstructure of the hot rolling strip steel, and the welding quality of the strip steel and the labor productivity are improved; the optimization of alloy compositions is not required, the welding performance is improved by optimization of a production technology, the low-cost production is realized, and the market competitiveness of hot rolling products and cold rolling products is further increased.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

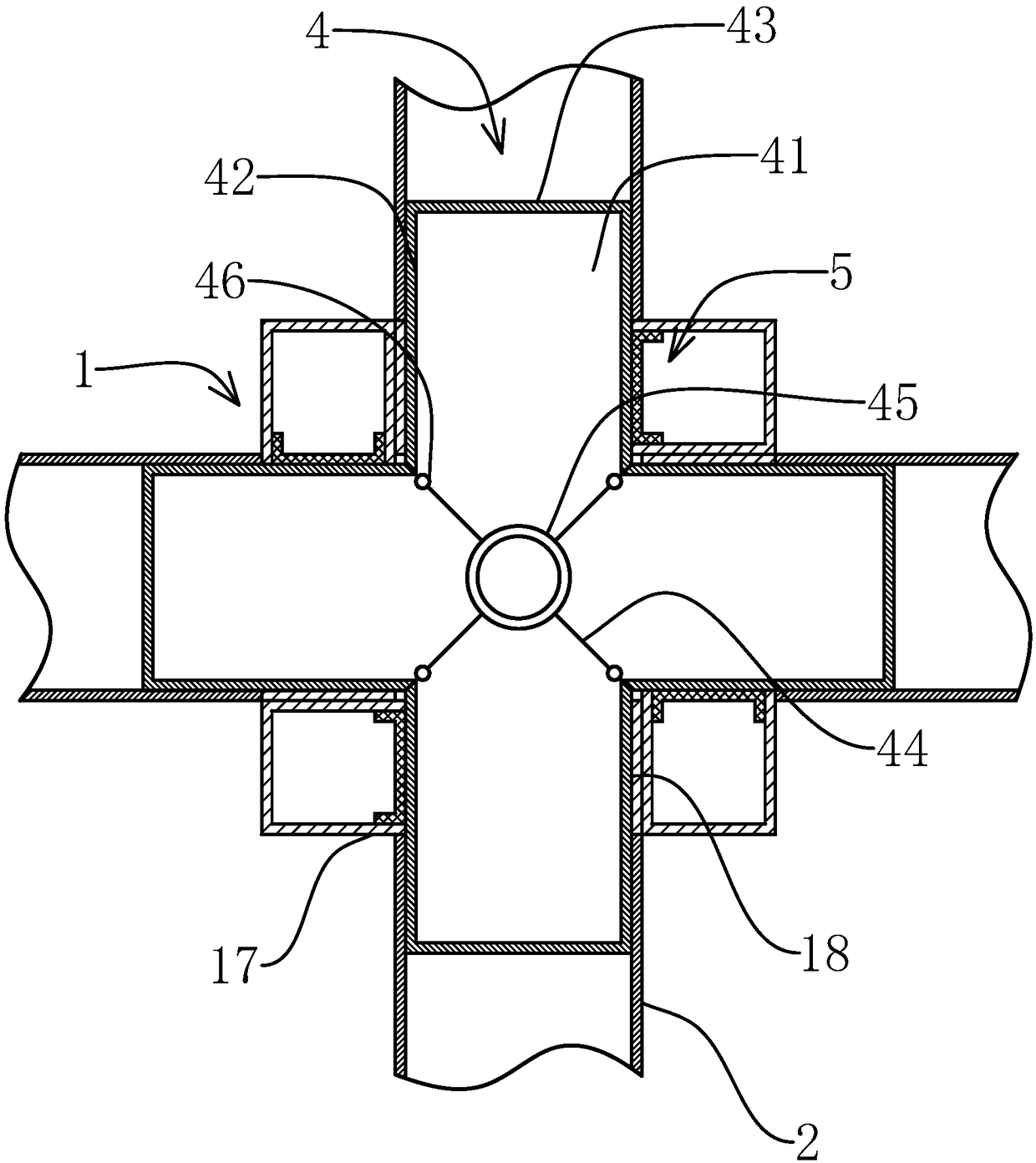

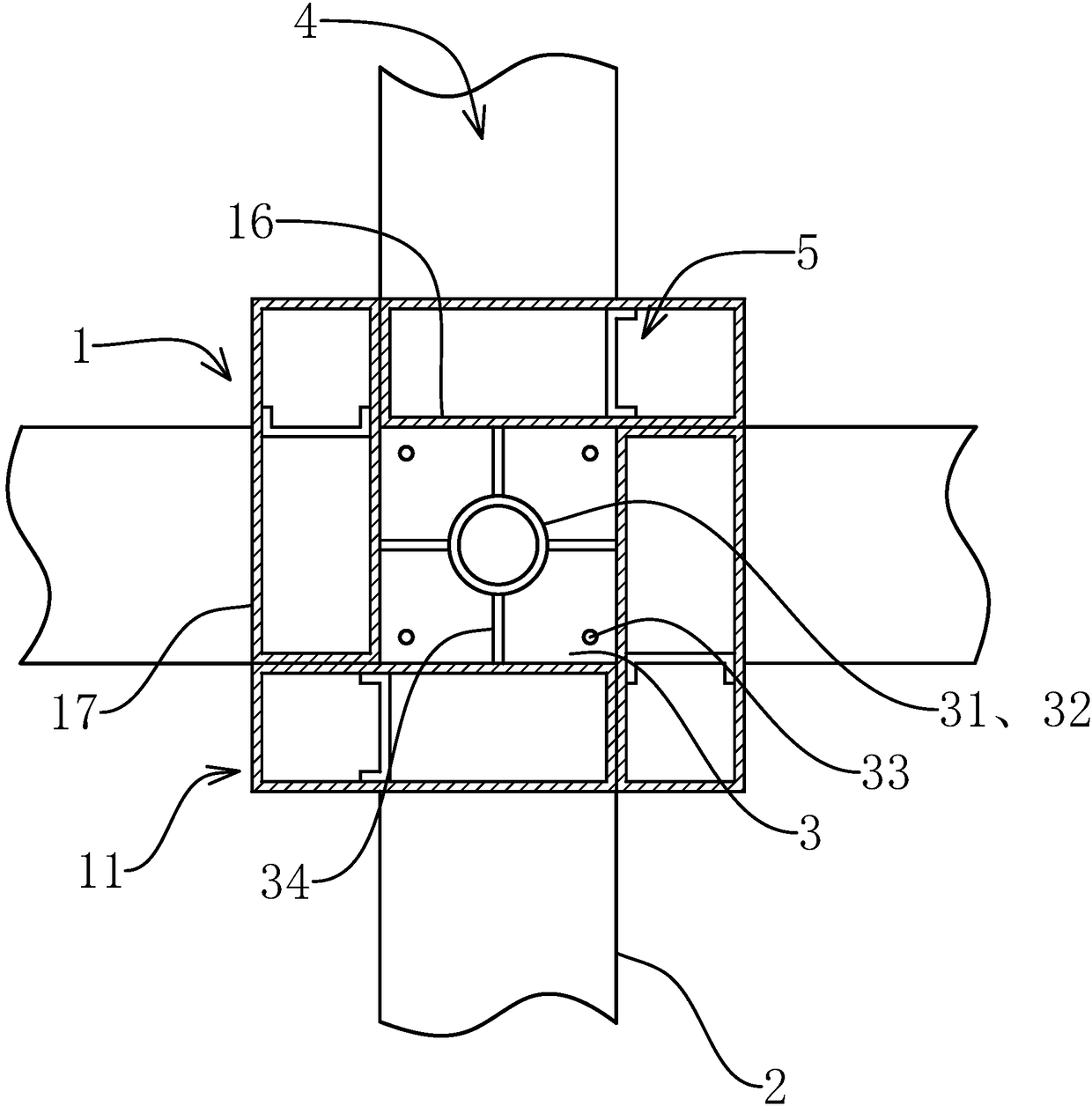

Square tube beam-column joint and construction method thereof

InactiveCN108222256APrevent leakageImprove fit strengthBuilding constructionsArchitectural engineeringUltimate tensile strength

The inventions provides a square tube beam-column joint and a construction method thereof and belongs to the field of steel structures with an aim to solve the problem that existing beam-column jointconstruction is low in efficiency and strength. The square tube beam-column joint comprises a square tube column and a beam, the column comprises four outer column plates and four inner column plates,and the inner column plates enclose to form a grouting channel; the column comprises four round tubes, each round tube comprises an inner short round plate, an outer short round plate, an inner longround plate and an outer long round plate, the outer side of the inner short round plate is adhesively fixed with the outer side of the inner long round plate of the neighboring round tube, the outerside of the outer long round plate is flushed to the outer side of the outer short round plate of the neighboring round tube to form the outer column plate, and the inner long round plate forms the inner column plate; the column further comprises an inner node plate, the periphery of the inner node plate are welded to the inner side of the inner column plate, a grouting hole is arranged in the center of the inner node plate, and each of the inner column plate and the outer column plate is provided with a running hole; the column further comprises four beam connecting tubes which penetrate therunning holes, concrete mortar is poured into the grouting channels, and ends of the beam are fixedly sleeved in the beam connecting tubes. The beam-column joint is high in strength and construction efficiency.

Owner:新昌县丽晶工业产品设计有限公司

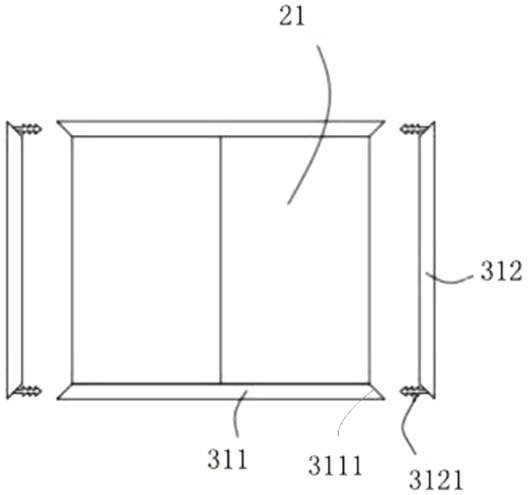

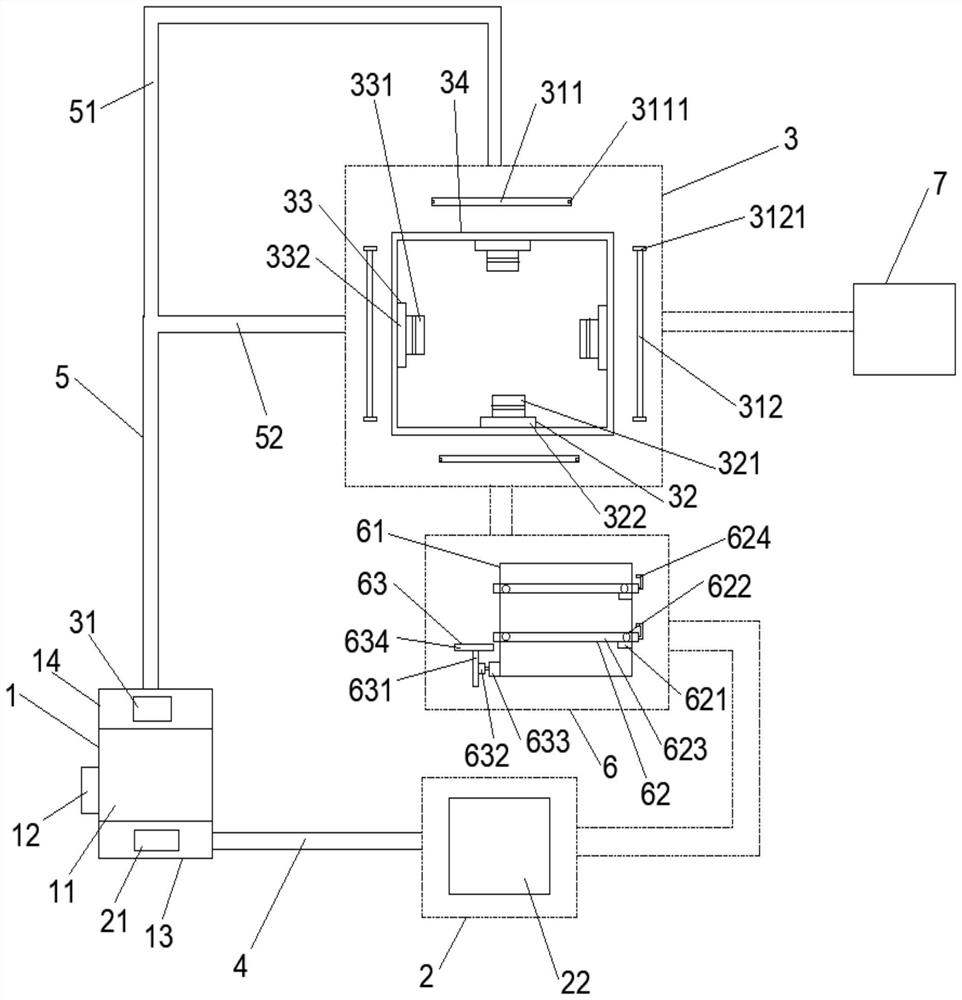

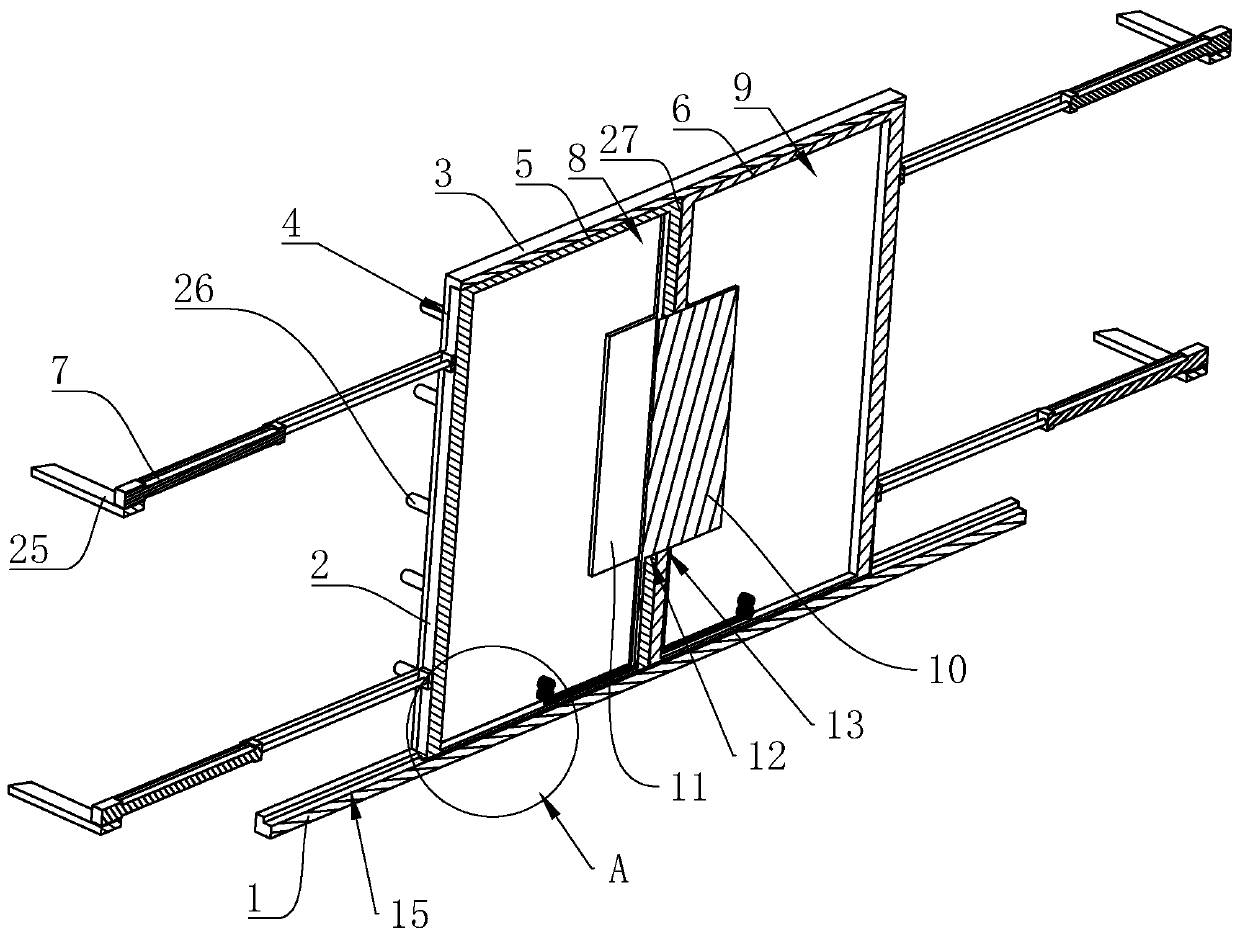

Door and window intelligent automatic production line and door and window intelligent automatic production method

ActiveCN111203762AReduce installation processReduce risk of damageMetal working apparatusNumerical controlProduction line

The invention discloses a door and window intelligent automatic production line. The production line involves a blanking mechanism, an inner-sash assembling mechanism, an outer-frame assembling mechanism, a conveying mechanism and a numerical control mechanism, wherein the blanking mechanism is used for enabling raw logs to be formed into an outer-frame sectional material and an inner-sash sectional material which can be directly assembled, the outer-frame sectional material comprises a first wall with a clamping groove and a second wall with a clamping block, and the clamping block is made ofan auxetic composite material; the inner-sash assembling mechanism is used for assembling the inner-sash sectional material and a glass block into a frame-shaped inner sash; the outer-frame assembling mechanism comprises a first clamping device and a second clamping device; the conveying mechanism comprises a first conveying device, a second conveying device and a third conveying device; and thenumerical control mechanism is connected with and controls the blanking mechanism, the inner-sash assembling mechanism, the outer-frame assembling mechanism and the conveying mechanism. Compared withthe prior art, the door and window intelligent automatic production line is small in occupied space and high in automation degree, the product structure is more stable, and installation is more convenient. A door and window intelligent automatic production method is further provided.

Owner:湖南亘晟门窗幕墙有限公司

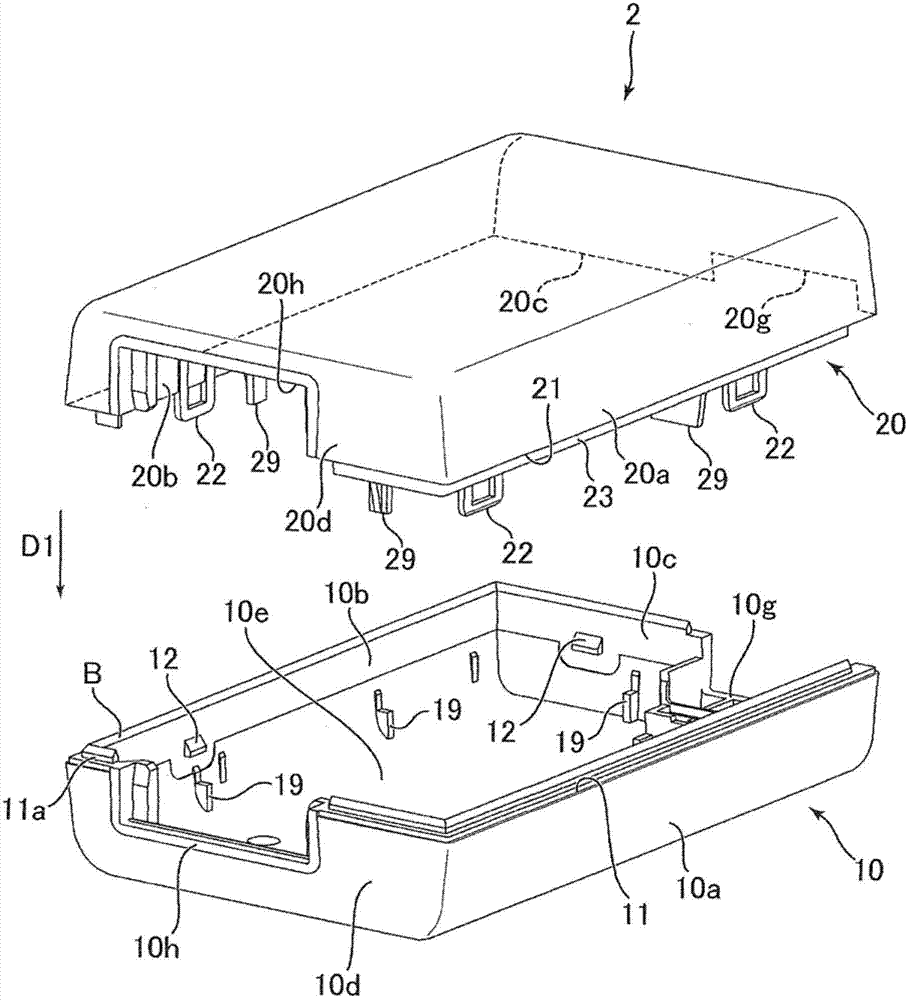

Electrical apparatus and manufacturing process of the same

Owner:SONY INTERACTIVE ENTERTAINMENT INC

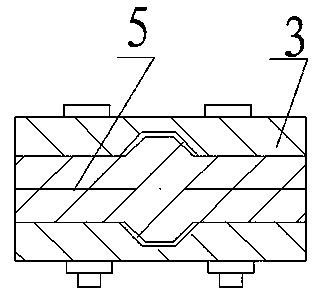

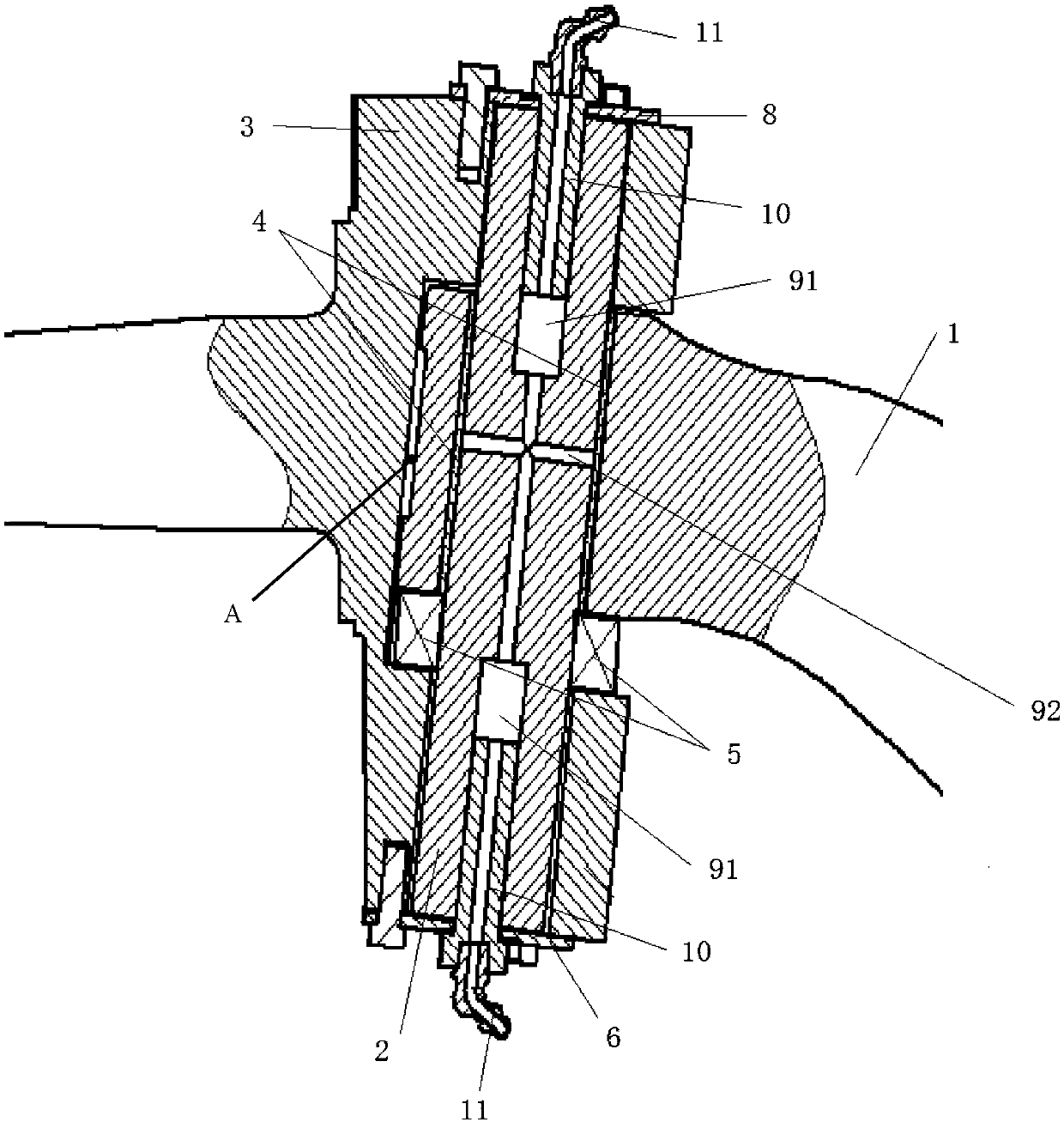

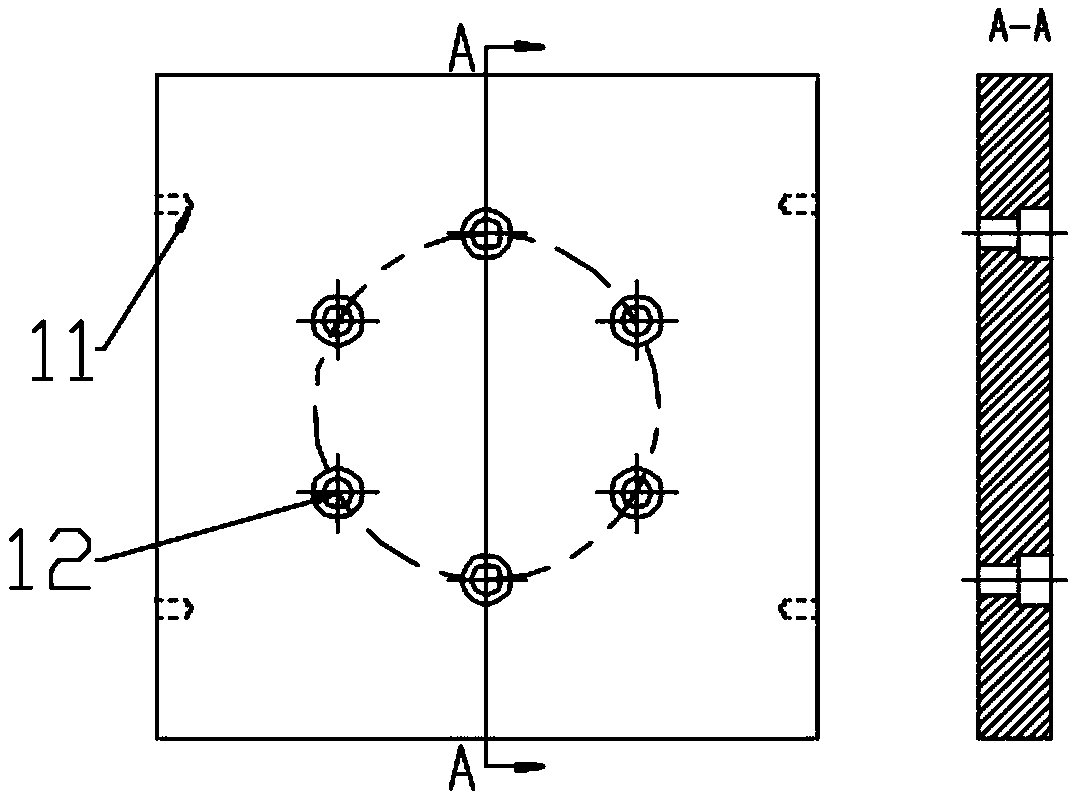

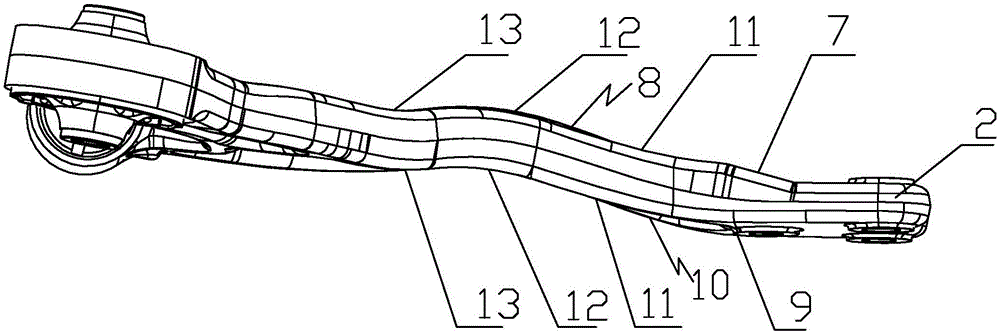

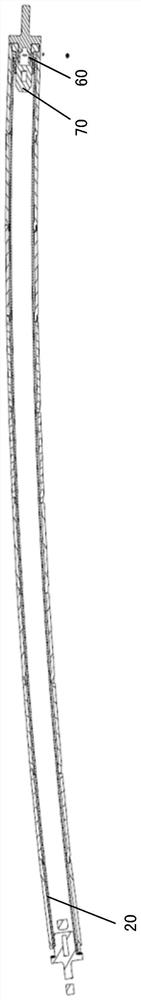

Bent shaft assembly for sunshade and bent shaft sunshade

ActiveCN107435513AImprove fit strengthHigh matching precisionWindowsPassenger spaceMechanical engineering

The invention provides a bent shaft assembly (1) for a sunshade; the shaft assembly (1) comprises a bent shaft (20); multiple sleeves (10) which sleeve on the bent shaft (20). Multiple first teeth (11) are installed on a first end of the sleeve and multiple second teeth (12) are installed on a second end of the sleeve; adjacent sleeves are mutually linked by the meshing between the multiple first teeth (11) and multiple second teeth (12); the first teeth (11) and the second teeth (12) are formed by crossing the wall of the first end and the second end of the sleeve (10). The invention also comprises a bent shaft sunshade comprising the above bent shaft assembly. By means of the bent shaft assembly, the intensity and matching precision can be increased, the friction and operation noise can be reduced; the sunshade can be used in application environment having larger stroke and curvature.

Owner:WEBASTO SHANGHAI

Improved intelligent automatic production line for doors and windows and production method thereof

ActiveCN111993046AVersatileMulti-colorGripping headsAssembly machinesNumerical controlManufacturing line

The invention discloses an improved intelligent automatic production line for doors and windows. The improved intelligent automatic production line is used for automatic production and installation ofouter frames and inner sashes of the doors and the windows. The improved intelligent automatic production line for the doors and the windows comprises a discharging mechanism, an inner sash assembling mechanism, an outer frame assembling mechanism, a conveying mechanism and a numerical control mechanism, wherein the numerical control mechanism is connected with the discharging mechanism, the inner sash assembling mechanism, the outer frame assembling mechanism and the conveying mechanism and controls the discharging mechanism, the inner sash assembling mechanism, the outer frame assembling mechanism and the conveying mechanism. According to the improved intelligent automatic production line for the doors and the windows, inner sash profiles and outer frame profiles are assembled in advance to form the doors or the windows, and subsequent installation in actual conditions is facilitated. Products produced through the improved intelligent automatic production line for the doors and thewindows are firm in structure and long in service life, the production process is stable and orderly, safety is high, the production cycle of the products can be effectively shortened, and productionefficiency is improved. The invention further discloses an improved intelligent automatic production method for the doors and the windows.

Owner:深圳市合东兴科技有限公司

Tension-resistance wire clamp

InactiveCN103427384AFacilitate contact areaGuaranteed stabilityAdjusting/maintaining mechanical tensionPower flowCarrying capacity

The invention discloses a tension-resistance wire clamp which comprises a wire clamp body, a steel anchor and a drainage tube. A U-shaped drainage plate with an internally-formed groove is arranged at the designated position of the wire clamp body, the drainage plate is provided with a forked clamping opening, a panel is arranged at one end of the drainage tube, a protrusion corresponding to the groove of the drainage plate is arranged in the panel, a hollow blind tube is arranged at one end of the panel, and a wire jumper can be arranged in the hollow blind tube. A lock hole is formed in the U-shaped drainage plate, a corresponding lock hole is formed in the segment where the drainage tube is matched with the drainage plate, when the drainage tube is inserted into the drainage plate, the drainage tube is locked by a bolt, and good locking is obtained. According to the tension-resistance wire clamp, the drainage tube for containing the wire jumper and the drainage plate have the excellent contact area, the stability of current transmission is ensured, the tension-resistance wire clamp is particularly suitable for being used for mutual connection between a wire on an iron tower and the wire jumper, the higher current-carrying capacity is met, the protrusion and the groove which are mutually matched are arranged at the position where the drainage plate is locked with the drainage tube, the matching strength of the drainage plate and the drainage tube is increased, and the tension-resistance wire clamp can bear stronger wind.

Owner:HENAN KOSEN CABLE

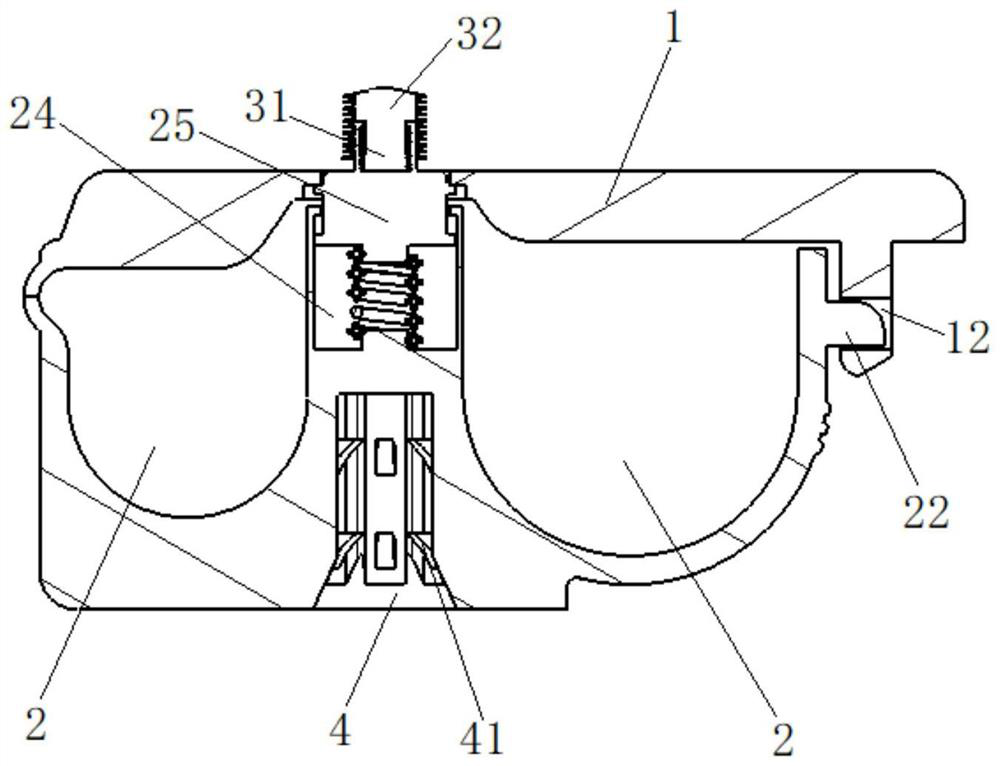

Clutch, motor device and curtain control device

PendingCN111664200AEffective output powerAchieve cooperationCurtain accessoriesDoor/window protective devicesControl engineeringElectric machinery

The invention discloses a clutch, a motor device and a curtain control device. The clutch comprises a driving force receiving part, a separation and reunion control part, and a driving force output part; the separation and reunion control part is arranged on one side of the driving force receiving part and comprises a first control piece, a separation and reunion piece and a second control piece;the first control piece is connected with the driving force receiving part; a first direction driving position and a first direction separating position in drive joint with the first direction drivingposition are arranged on the side far away from the driving force receiving part; the separation and reunion piece is positioned at the first direction driving position or the first direction separating position; the second control piece is connected with the external parts of the first control piece and the separation and reunion piece in a sleeving manner; and the driving force output part is arranged on the side, far away from the driving force receiving part, of the separation and reunion control part and is provided with a driving force transmitting piece. The clutch effectively solves the problem caused by adoption of the magnetic separating manner by the existing clutch to realize the separation and reunion function.

Owner:NINGBO SUNFREE MOTOR TECH CO LTD

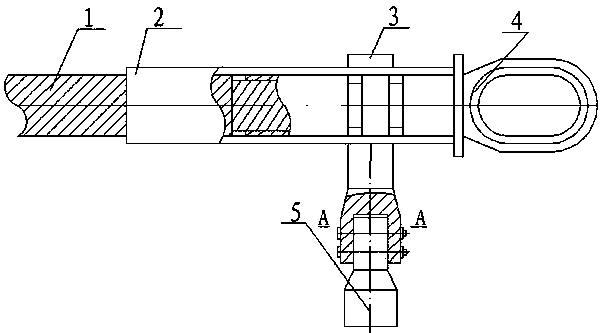

Mother linear isolated grounding combined switches

InactiveCN102201295AReduce heat lossEasy to processSwitchgear arrangementsAir-break switch detailsGround contactElectrical conductor

The invention discloses to a mother linear isolated grounding combined switch which comprises a shell body, a first conductor, a grounding contact, a second conductor and a moving contact. The shell body has two first openings set in the first direction and two second openings set in the second direction, and the first direction is vertical to the second direction. A first static contact is directly and concavely set on the first conductor. The grounding contact is connected with the shell body and arranged in the shell body. A connection seat is convexly set within the inner end of the second conductor is bent into a concave connection seat. The connection seat is provided with a second static contact, a moving channel is formed in the second static contact, is vertical to the first direction and is located between the first static contact and the grounding contact. The moving contact can be linearly connected in the moving channel in a movable way, and the moving contact moves linearly to contact the first static contact and the grounding contact selectively. In addition, the axis of the first static contact, the moving channel of the second static contact, the moving route of the moving contact and the axis of the grounding contact are coincident and paralleled to the second direction.

Owner:XIAMEN HUADIAN SWITCHGEAR

Door and window intelligent automatic production line and production method thereof

ActiveCN111203762BReduce installation processReduce risk of damageMetal working apparatusNumerical controlProduction line

The invention discloses a door and window intelligent automatic production line. The production line involves a blanking mechanism, an inner-sash assembling mechanism, an outer-frame assembling mechanism, a conveying mechanism and a numerical control mechanism, wherein the blanking mechanism is used for enabling raw logs to be formed into an outer-frame sectional material and an inner-sash sectional material which can be directly assembled, the outer-frame sectional material comprises a first wall with a clamping groove and a second wall with a clamping block, and the clamping block is made ofan auxetic composite material; the inner-sash assembling mechanism is used for assembling the inner-sash sectional material and a glass block into a frame-shaped inner sash; the outer-frame assembling mechanism comprises a first clamping device and a second clamping device; the conveying mechanism comprises a first conveying device, a second conveying device and a third conveying device; and thenumerical control mechanism is connected with and controls the blanking mechanism, the inner-sash assembling mechanism, the outer-frame assembling mechanism and the conveying mechanism. Compared withthe prior art, the door and window intelligent automatic production line is small in occupied space and high in automation degree, the product structure is more stable, and installation is more convenient. A door and window intelligent automatic production method is further provided.

Owner:湖南亘晟门窗幕墙有限公司

Anti-bending power distribution box with waterproof top cover

InactiveCN106602410ASimple structureNo problem of stagnant waterSubstation/switching arrangement casingsEngineeringMechanical engineering

Owner:QINGDAO ZHONGKE SOFTWARE

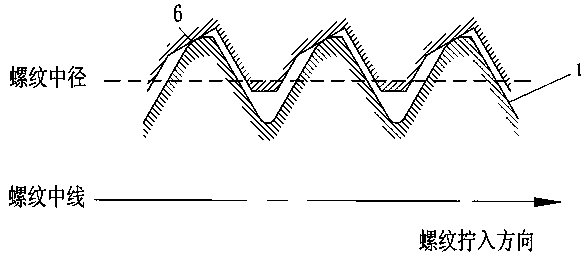

Externally-threaded structure matched with internal thread of wedge-shaped anti-loose thread

The invention discloses an externally-threaded structure matched with an internal thread of a wedge-shaped anti-loose thread. The externally-threaded structure comprises an externally-threaded body. Each external thread section of the externally-threaded body comprises a guiding side, a follower side, a top and a bottom, wherein the top and the bottom extend between the guiding side and the follower side; each top is a circular arc surface formed by extending from the guiding side to a joint of the follower side in an arc mode; and each circular arc surface can be in point contact fit with aninternal thread tip in the cooperative tightening process of the external thread and an internal thread. The structure can be freely matched with traditional internal threads of JB / T10971 30-degree wedge-shaped anti-loose threads, and the matching strength is enhanced; the structure is freely matched with standard internal threads, and the use and mechanical properties are not affected; noise caused during screwing with the internal threads can be lowered; and the screwing degree of freedom is increased, and the labor intensity during installation is relieved.

Owner:ZHEJIANG JIENENG AUTOMOBILE PARTS

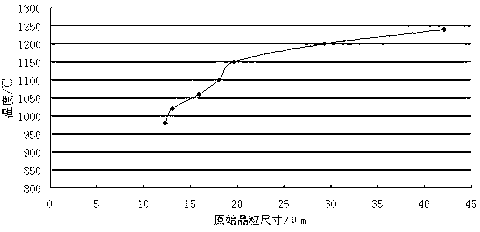

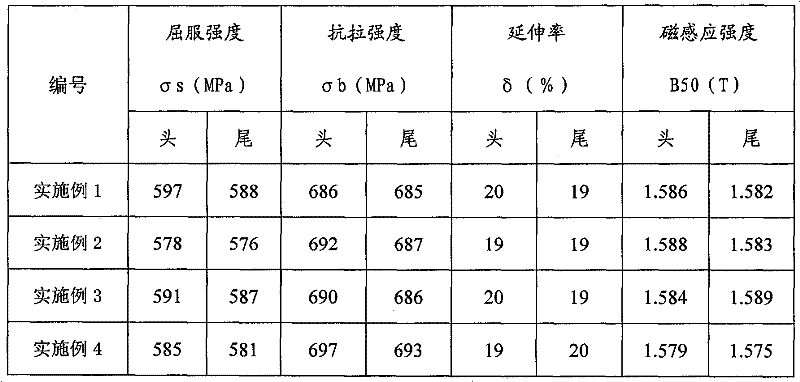

Manufacturing method of 500Mpa-grade cold-rolled magnetic steel

ActiveCN101871076BHigh yield strengthImprove mechanical propertiesTemperature control deviceFurnace typesSheet steelAcid washing

The invention discloses a manufacturing method of 500MPa-grade cold-rolled magnetic steel, which comprises the following steps that: (1) heating a slat to 1200 to 1260 DEG C, then rolling the slab into a steel sheet, the final rolling temperature is 830 to 890 DEG C, and adopting a laminar flow cooling way to cool the steel sheet to 550 to 600 DEG C to be rolled; (2) cooling the steel sheet in anair cooling way, and acid-washing the steel sheet; (3) cold rolling; (4) continuous annealing: the temperature of a uniformly-heated section of an annealing furnace is controlled within the range of 740 to 760 DEG C, the speed of the annealing process section is controlled at the range of 120 to 125 meter per minutes, and the time of the uniformly-heated section is controlled within the range of 230 to 239 s; (5) flattening. The cold-rolled magnetic steel produced with the method has high yield strength which can reach more than 570 MPa, uniform performance, small performance difference, favorable match between the magnetic sensing strength and the strength of the steel plate, favorable shape, high size precision, good surface quality and high yield.

Owner:BAOSHAN IRON & STEEL CO LTD

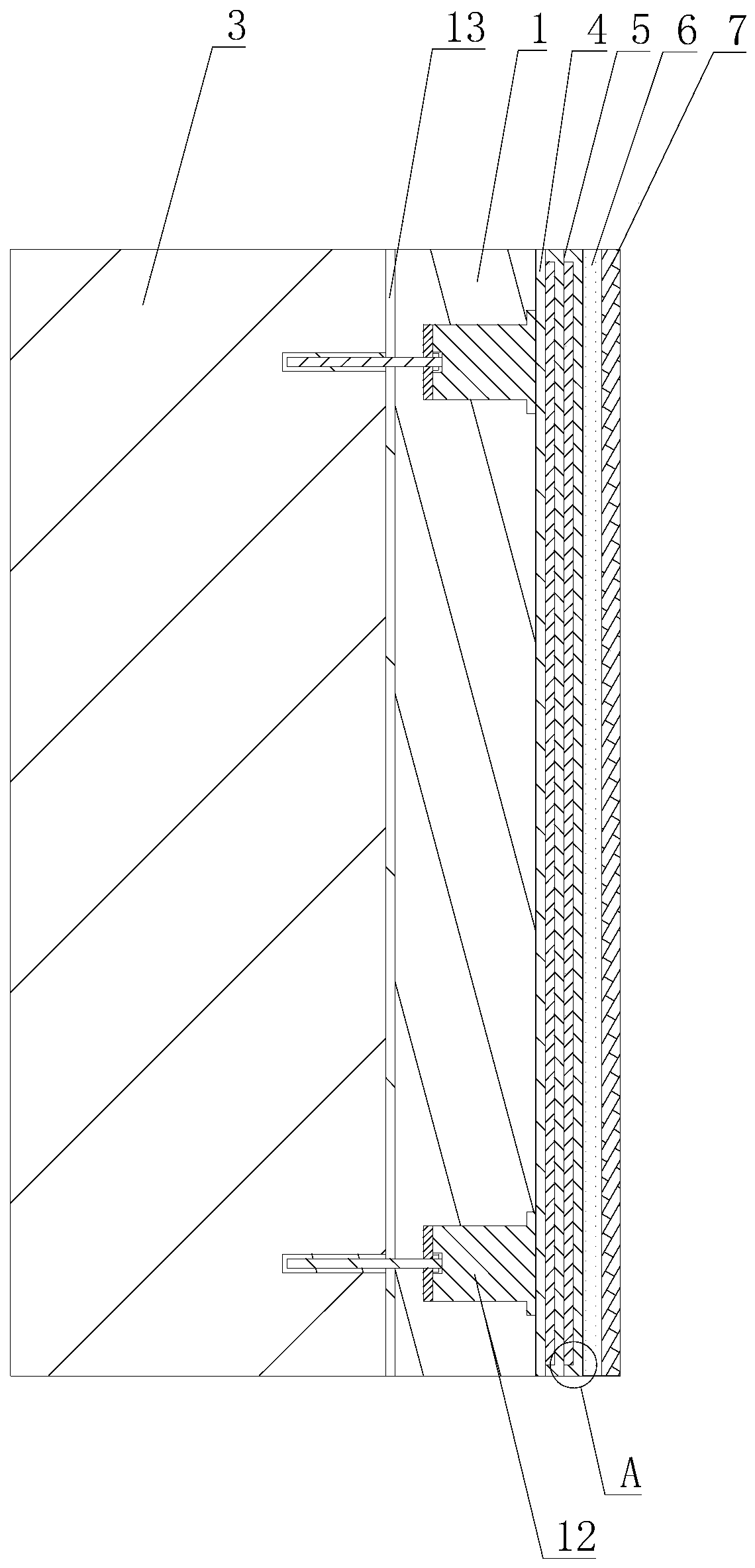

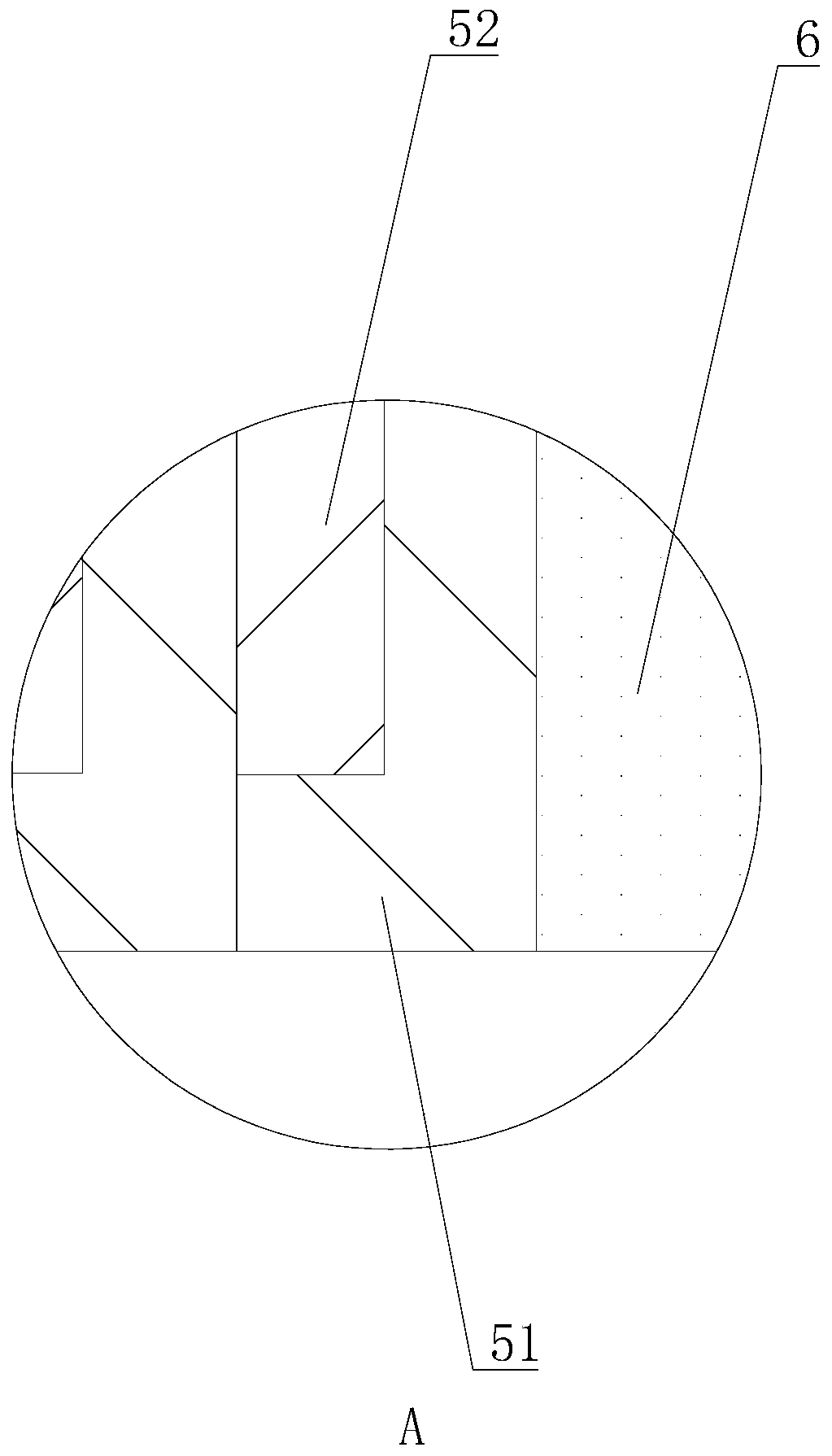

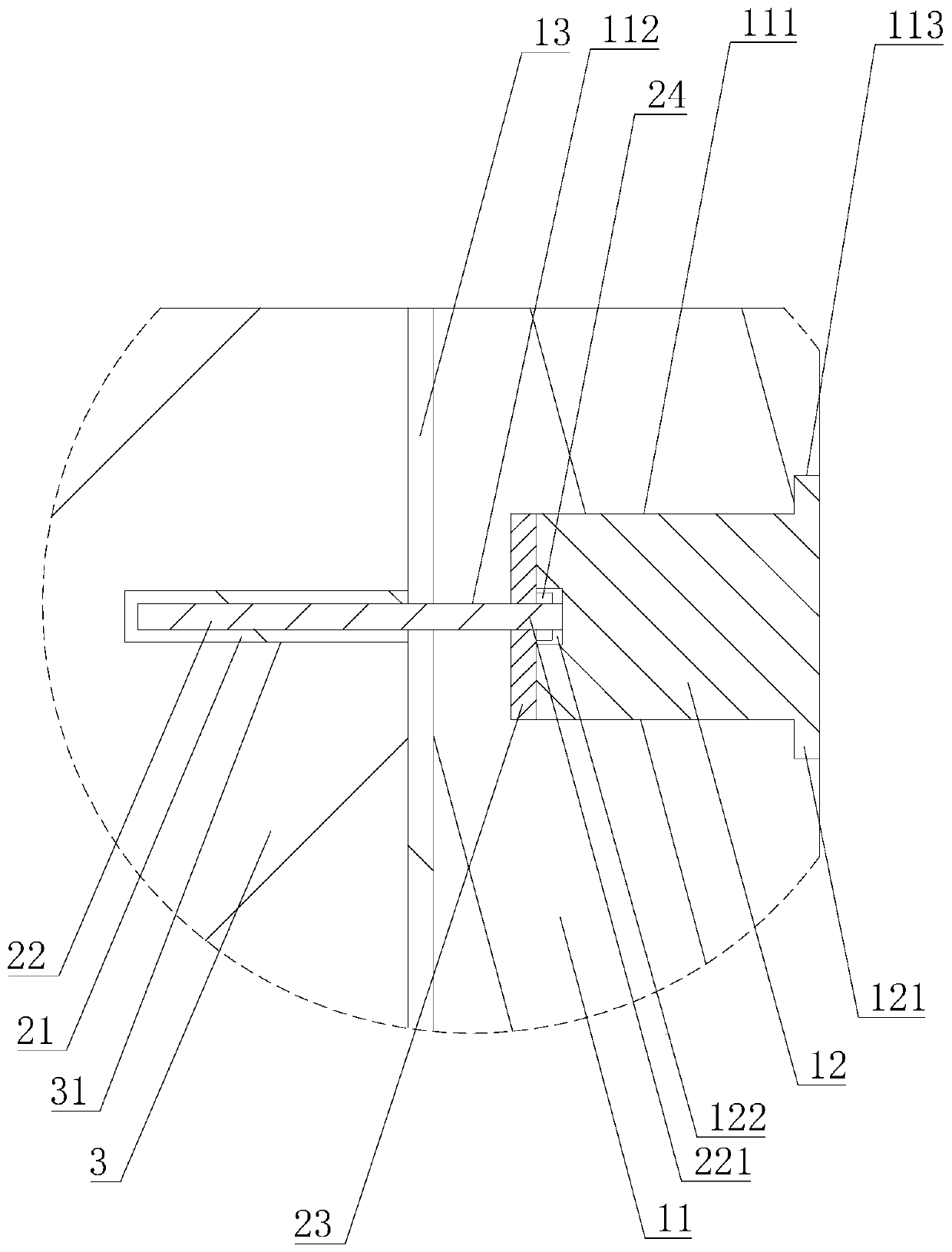

Anti-impact civil air defense door

InactiveCN111520038AImprove fit strengthStrong impact resistanceWing fastenersPower-operated mechanismHydraulic cylinderArchitectural engineering

The invention relates to an anti-impact civil air defense door. The anti-impact civil air defense door comprises a bottom plate, wherein door frames are oppositely mounted at two ends of the bottom plate. The anti-impact civil air defense door is characterized in that the door frames are provided with sliding holes in the opposite directions, a first door body and a second door body are mounted inthe sliding holes respectively in a sliding mode, driving hydraulic cylinders which drive the first door body and the second door body to move are mounted at the sides, away from each other, of the door frames respectively, the ends, away from each other, of the first door body and the second door body are fixedly connected with output ends of the driving hydraulic cylinders respectively, a firstinsertion plate and a second insertion plate are arranged at the two ends, close to each other, of the first door body and the second door body respectively, the side, close to the first door body, of the second door body is provided with a first insertion groove which is matched with the first insertion plate in an insertion mode, and the end, close to the second door body, of the first door body is provided with a second insertion groove which is matched with the second insertion plate in an insertion mode. The anti-impact civil air defense door has the effects of being convenient to open and close, good in sealing performance and high in anti-impact strength.

Owner:上海徽锋人防工程设备有限公司

Kingpin installation locking structure

InactiveCN107719468AHigh strengthGuaranteed fluencySteering linkagesMechanical engineeringEngineering

The invention discloses a kingpin installation locking structure. The structure comprises an I-beam, a kingpin and a steering knuckle. The steering knuckle comprises a top and a bottom, and steering knuckle through holes are respectively formed at the top and at the bottom. The I-beam is provided with an I-beam through hole. The I-beam is arranged between the top and the bottom of the steering knuckle. The kingpin penetrates through the steering knuckle through holes and the I-beam through hole, and the kingpin is rotatably matched with the I-beam. The kingpin is provided with a lubricating flow passage. The starting point of the lubricating flow passage is arranged at an end of the kingpin. The ending point of the lubricating flow passage is formed on the wall of the kingpin which is arranged inside the I-beam through hole. According to the kingpin installation locking structure, a groove is not provided with the I-beam, and therefore the strength of the I-beam is improved. The kingpin is provided with a lubricating flow passage therefore the smoothness of the rotation between the kingpin and the I-beam is ensured, meanwhile, the kingpin is fixed to the steering knuckle, the abrasion of the end cap and the block cap of the kingpin is prevented.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

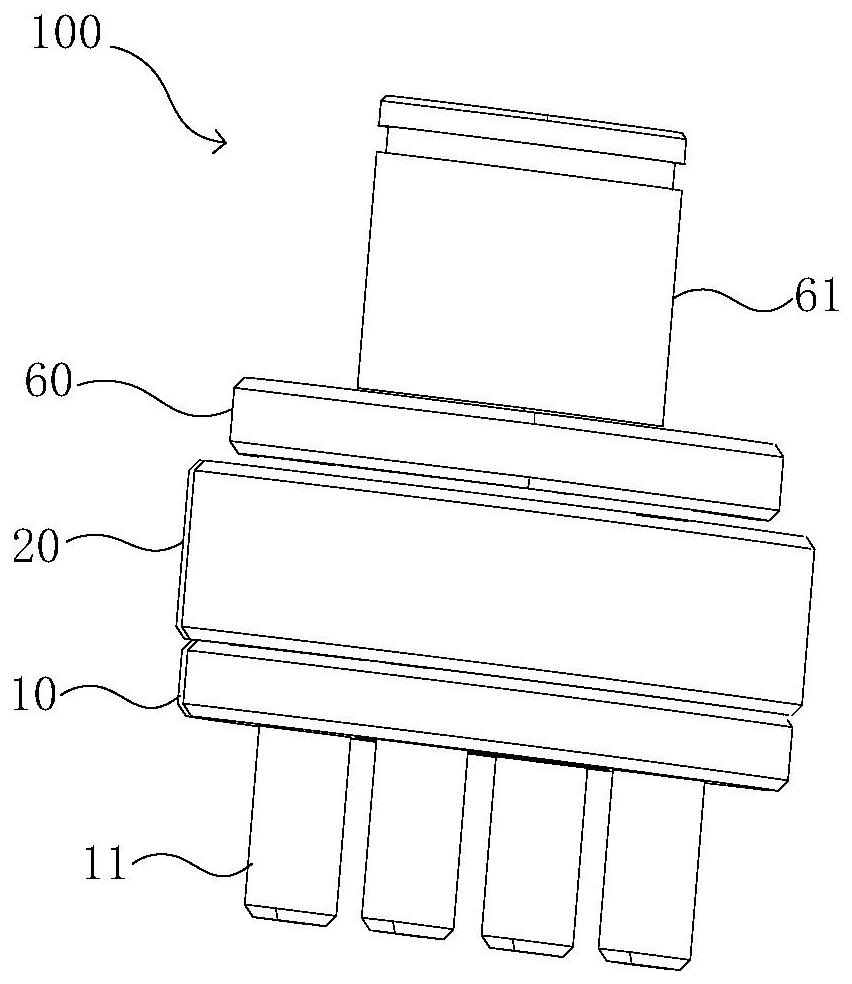

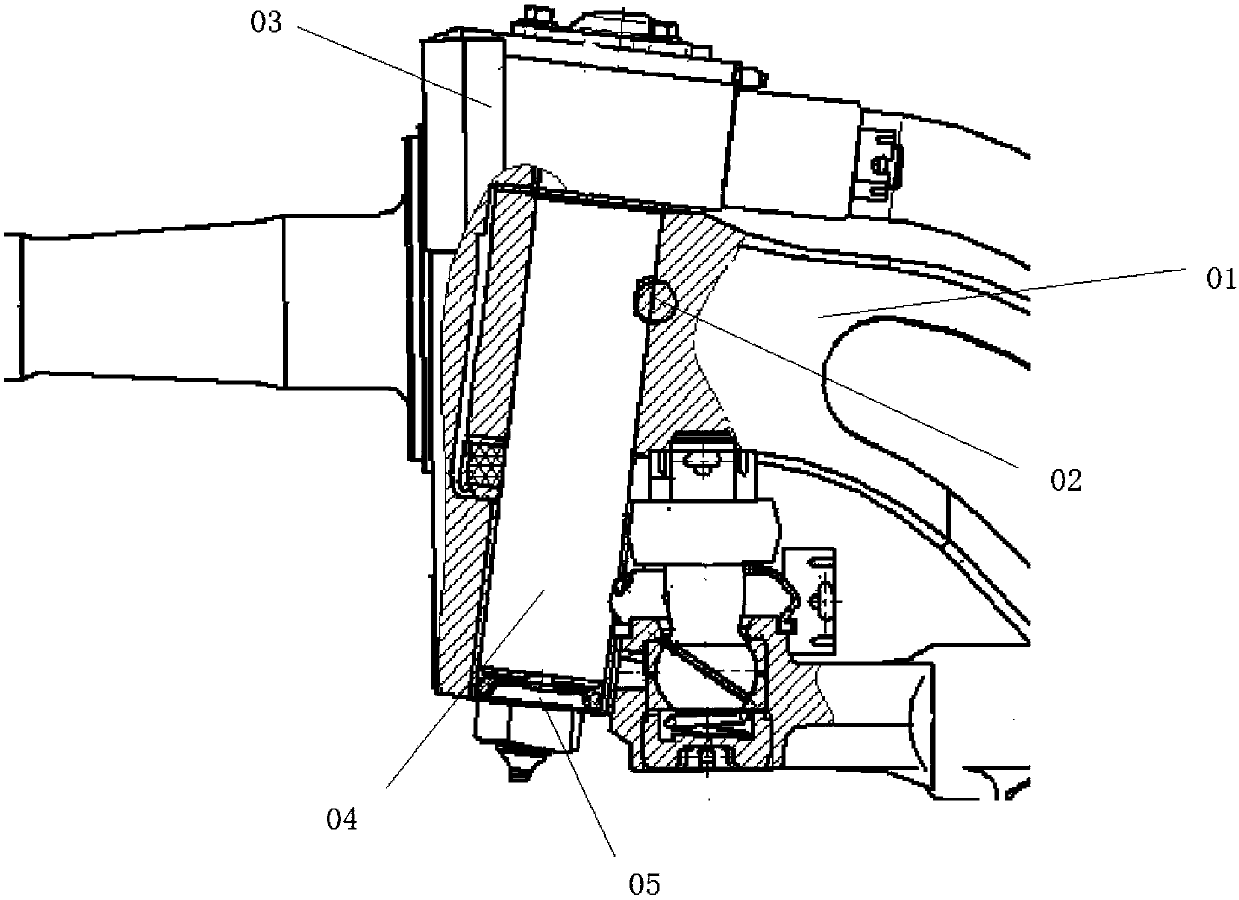

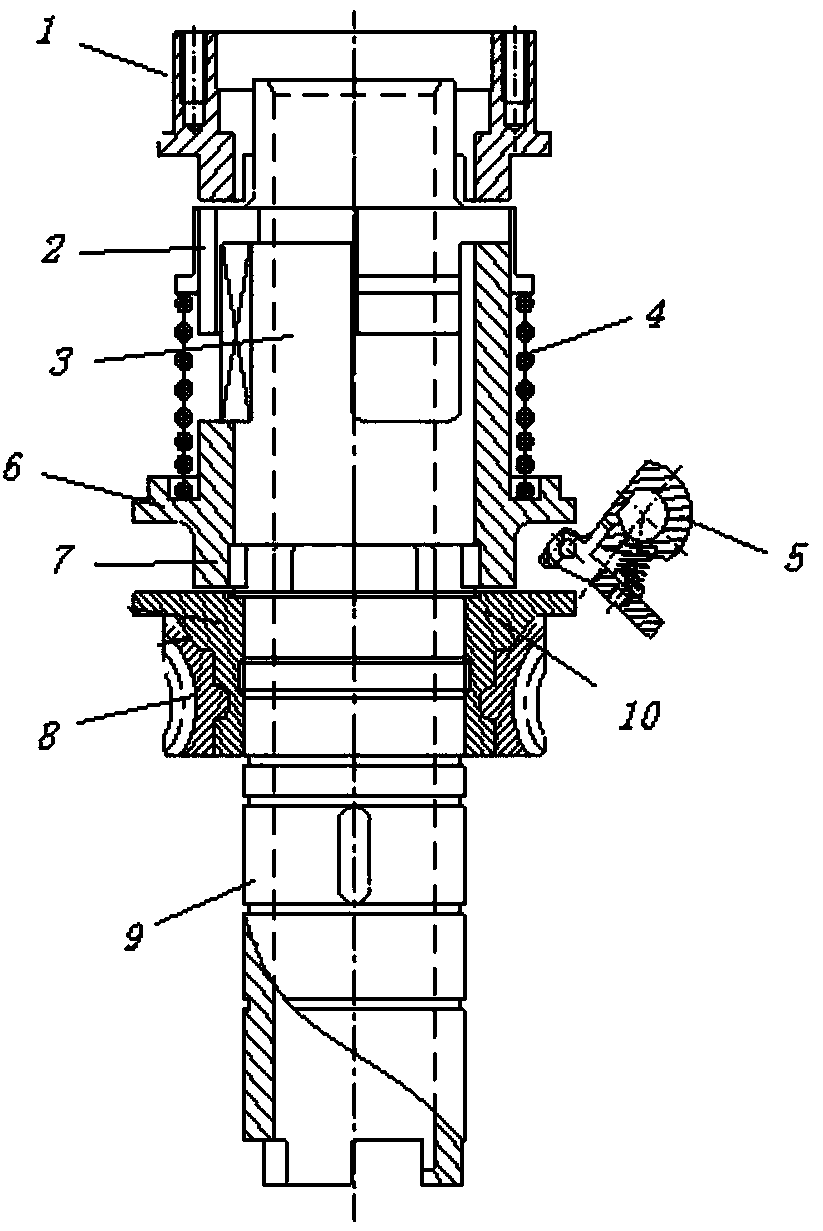

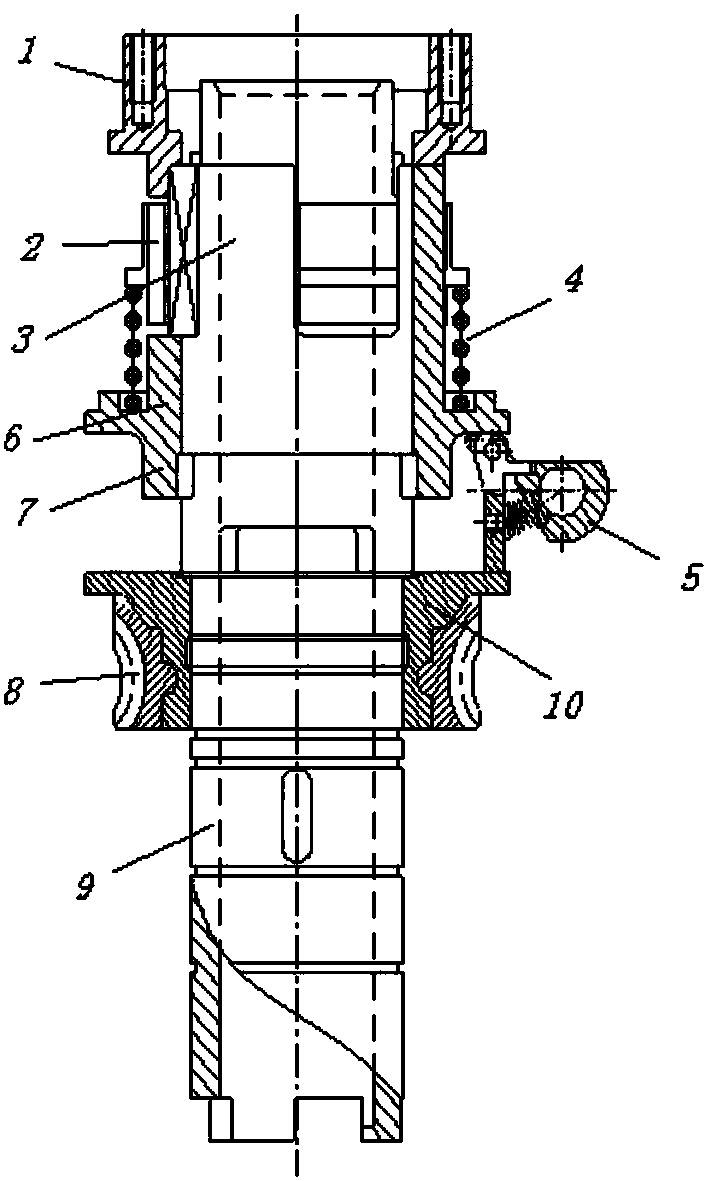

Deep cavity type hot extrusion mold for aluminum alloy joint members and preparation method thereof

A deep cavity type hot extrusion mold for aluminum alloy joint members and a preparation method thereof belong to the fields of hot process molds and designs thereof, and are applicable to hot extrusion mold design and hot extrusion formation of aerospace joint members. The mold includes an upper mold plate (1), a punch fixing plate (2), a stress ring (3), a die (4), a die plate (5), a lower moldplate (6), a top rod (7), a punch (8) and a position limiting block (9). The mold has the advantages that a guide design between the punch (8) and the die (4) ensures that the mold is intact in profile without misalignments when closed without help of a guide device such as a guide post and a guide sleeve; that two-stage transition steps of the top rod (7) and a withdrawing design can not only increase the fitting strength of the top rod with the die but also reduce edge extrusion to facilitate demolding of a member; the overall shape of the mold is a circumferential type so that a medium frequency induction heating method can be adopted with high heating efficiency and good temperature uniformity; and the aluminum alloy joint members formed by the mold have stable quality, high dimensional accuracy and profile precision.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Construction technology of rock wool board outer wall heat preservation system

ActiveCN109779053AReduce the chance of sheddingGuaranteed insulation effectClimate change adaptationHeat proofingAdhesiveEngineering

The invention discloses a construction technology of a rock wool board outer wall heat preservation system. The construction technology solves the problem that a rock wool board at the present stage is prone to disengaging from an outer wall body. According to the technical scheme, the construction technology of the rock wool board outer wall heat preservation system is characterized by comprisingthe following steps that S100, an outer wall surface is pretreated; S200, a rock wool board is pretreated; S300, the rock wool board is installed on the outer wall body, the rock wool board and the outer wall body are bonded and fixed through a heat preservation adhesive, and the fixing strength of the rock wool board and the outer wall body is further enhanced through combination of an expansionscrew sleeve, an expansion bolt, a positioning plate and an installation nut; and S400, an outer decorative surface is laid. The probability that the rock wool board falls off from the outer wall body is reduced through the construction process of the rock wool board outer wall heat preservation system.

Owner:上海艾弗森建设工程有限公司

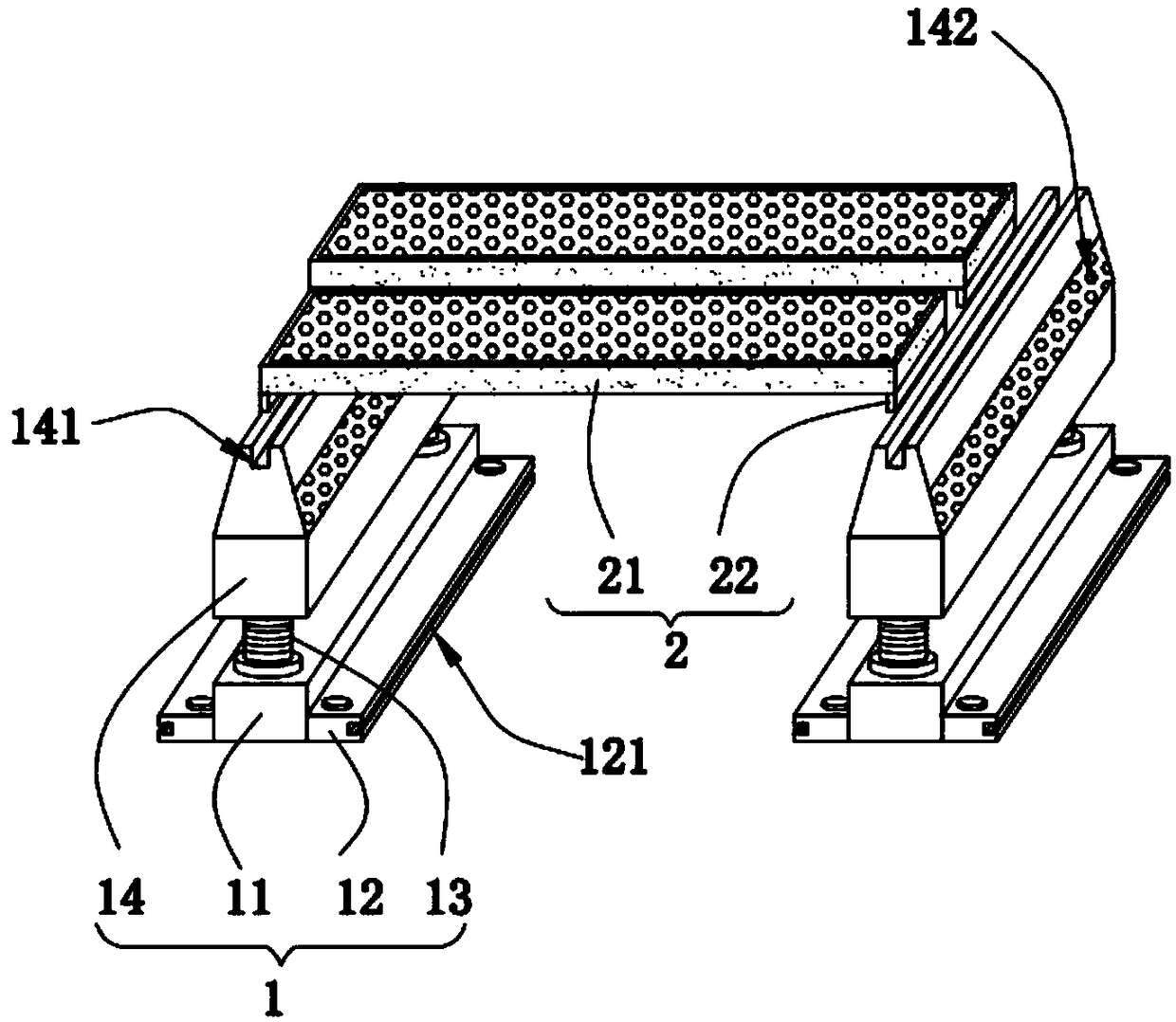

Floor anti-deformation method

PendingCN108617540AChange support heightFast installationAnimal housingGaseous substancesTerrainLiquid waste

The invention relates to the technical field of plastic floor, specifically to a floor anti-deformation method. The method uses a plastic floor, and the plastic floor comprises a support mechanism, aprotection mechanism, a sewage collection mechanism and a sterilization mechanism; support height of the support mechanism is quickly adjusted by an adjusting mechanism, so as to adapt to installationrequirements of various terrains, and during installation, only installation plates need to be buckled into an installation groove, the method is easy to operate, fast to install, and capable of effectively improving the coordination intensity through coordination teeth between the installation plates; the sewage collection mechanism is capable of collecting the waste to avoid ground pollution and facilitate unified cleaning, and solid-liquid separation is achieved through arranging filter holes and sewage tanks, so as to speed up discharge of liquid waste and reduce obstacles; the sterilization mechanism is capable of effectively performing sterilization and disinfection on a culture area to avoid bacterium breeding.

Owner:孙夏星

Field agriculture adjustable compacting device

InactiveCN111213450AReduce maintenance costsImprove the effect of repressionAgricultural rollersAgricultural engineeringCart

The present invention discloses a field agriculture adjustable compacting device. The field agriculture adjustable compacting device comprises a cart, a middle part of a lower side of the cart is provided with a combined adjustable compacting wheel device, the combined adjustable compacting wheel device comprises a positioning frame, an upper part of the positioning frame is connected with the cart, a middle part of the positioning frame is connected with a supporting plate, and an adjusting bolt is arranged in the supporting plate. The combined adjustable compacting wheel device is arranged at a lower side of the cart, can facilitate replacement of metal collars with different-shaped compacting blocks through cooperation of a hook surface of hook and loop fasteners and a loop surface of the hook and loop fasteners, so that the compacting device can carry out compacting operation on land terrain with different shapes and improves use ranges.

Owner:CHANGCHUN AGRI MACHINERY

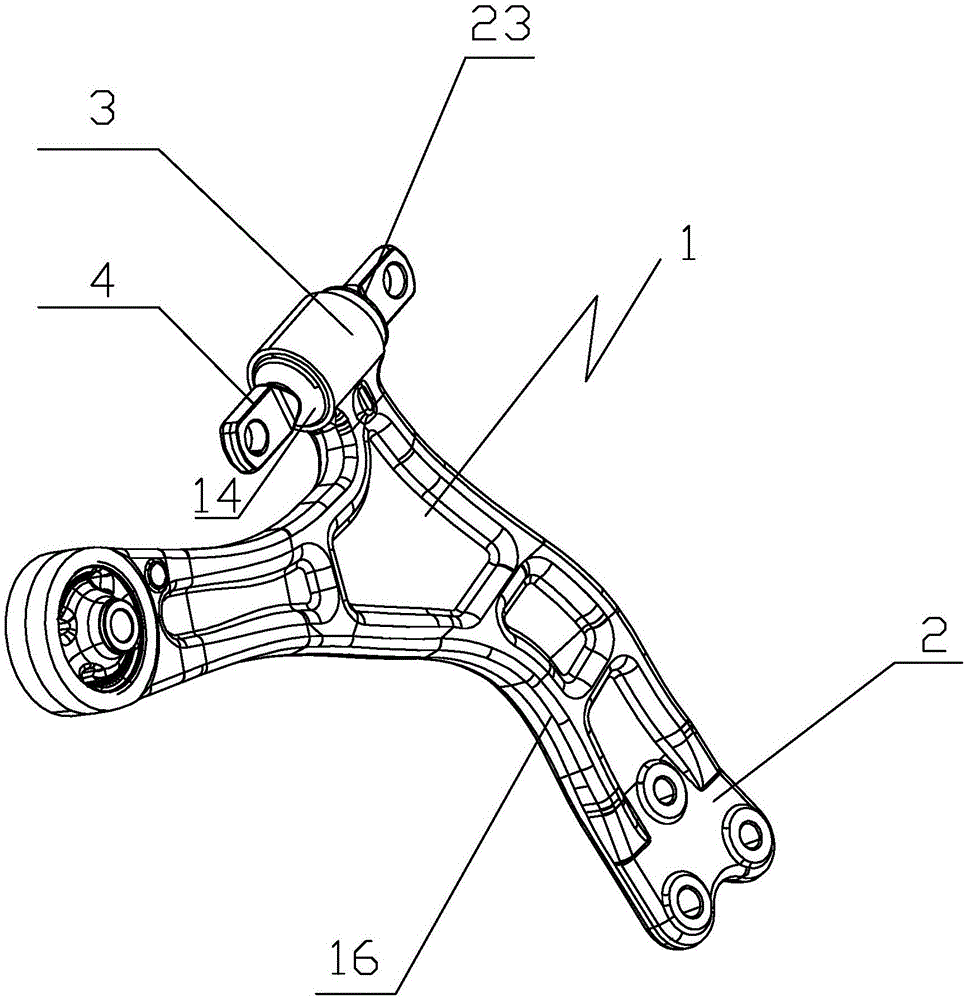

Automobile front lower swing arm assembly

The invention discloses an automobile front lower swing arm assembly which comprises a lower swing arm body assembly (1), wherein a ball head assembly (2) and a front bushing (3) are arranged on the lower swing arm body assembly (1); a swing arm (16) is arranged between the ball head assembly (2) and the front bushing (3); a front bushing connecting rod (4) is arranged inside the front bushing (3). The automobile front lower swing arm assembly is characterized in that the lower swing arm body assembly (1) is made of aluminum alloy; projection of the inner side surface of the swing arm (16) on the horizontal plane comprises a first straight line (5) parallel to the horizontal plane and an arc line (6) connected with the first straight line (5). According to the provided automobile front lower swing arm assembly, the bearing capability requirements after the material is changed can be met, and transmission mechanisms such as a transmission shaft can be avoided, so that the weight is lightest, the cost is low, the universality is good, the mounting is convenient, the reliability is good, and the rigidity adjustability of the front bushing is good.

Owner:NINGBO YONGXIN AUTO COMPONENTS MFG

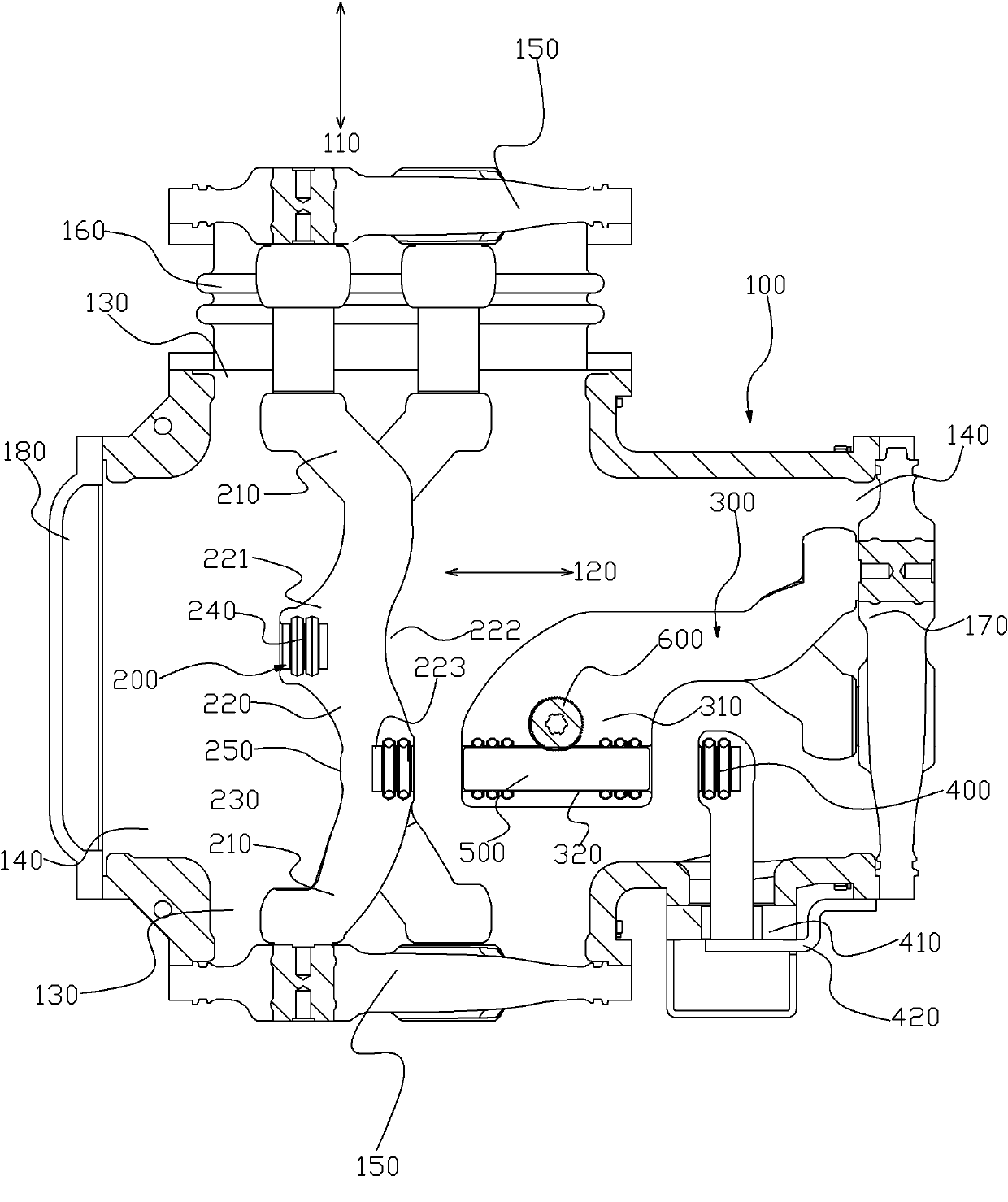

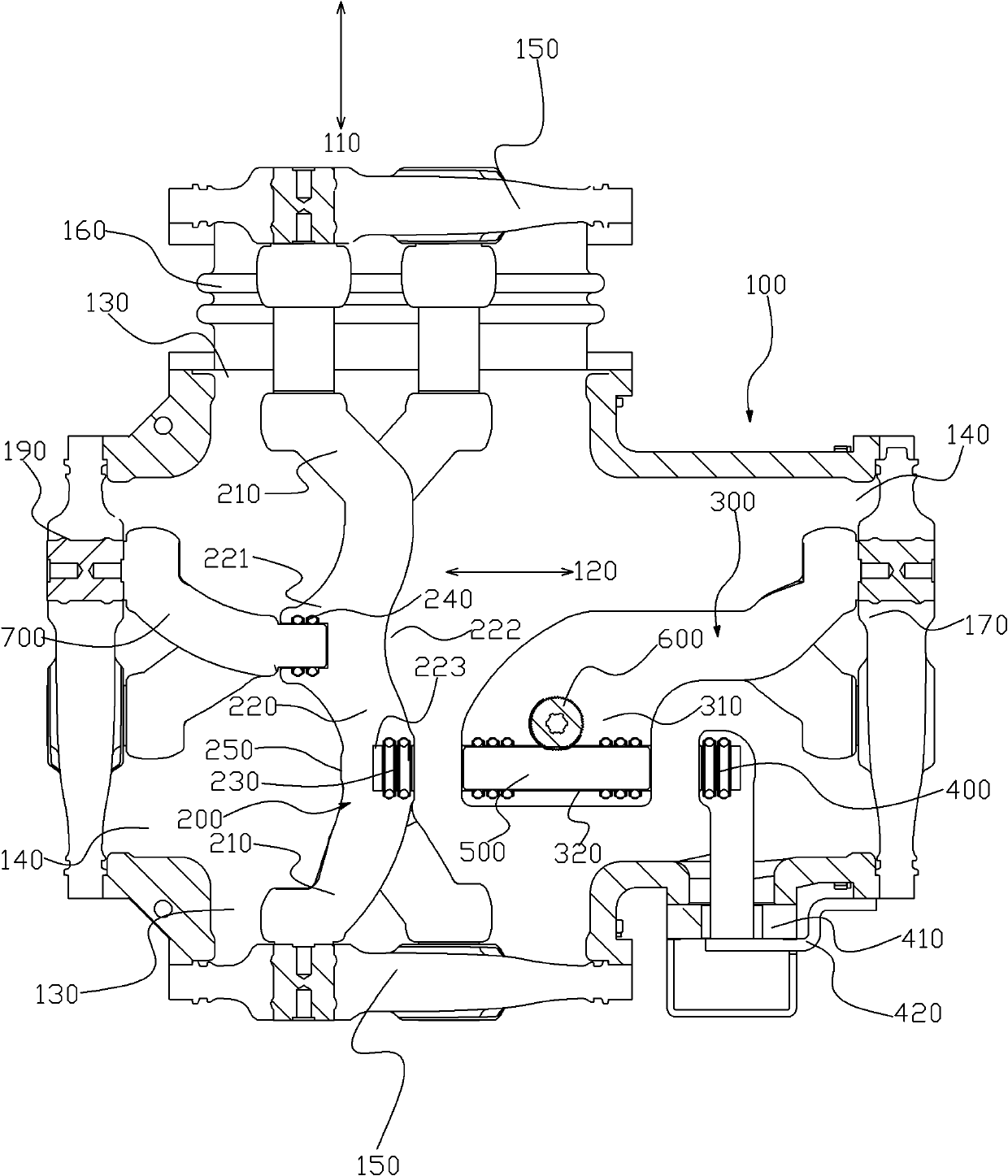

Manual operation and electric operation matching switching mechanism of electric actuator

The invention relates to a manual operation and electric operation matching switching mechanism of an electric actuator. The mechanism comprises an output shaft; the upper end of the output shaft is coated with a hand wheel base fixedly connected with a hand wheel; the upper part of the output shaft is coated with a bearing; the bearing is coated with a bearing base; the middle part of the output shaft is coated with a shaft sleeve; the shaft sleeve is coated with a worm wheel; the output shaft between the bearing base and the worm wheel is coated with a slide block; three upper bosses extend at the upper end of the slide block in the vertical direction, and two lower bosses extend at the lower end in the vertical direction; through holes matched with the upper bosses are formed in the side wall of the bearing base; grooves matched with the upper bosses are formed in the lower end of the hand wheel base; groove holes matched with the lower bosses are formed in the upper end of the shaft sleeve; and a first spring is arranged between the bearing base and the slide block. The mechanism further comprises a cam part for driving the slide block to axially move. The manual operation and electric operation matching switching mechanism of the electric actuator, provided by the invention, is simple and reasonable in structure, low in machining cost and higher in bearing capacity.

Owner:TIANJIN JINDA ACTUATOR CO LTD

Work fixture for grabbing injection parts of doll toy

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

A kind of low temperature resistant modified bitumen waterproof membrane and its preparation method

ActiveCN107901525BGood low temperatureGood adhesionSynthetic resin layered productsLaminationPolymer scienceBituminous waterproofing

The invention relates to a low-temperature-resistant modified asphalt waterproof coiled material. The low-temperature-resistant modified asphalt waterproof coiled material comprises a base substrate,an upper modified asphalt layer, a lower modified asphalt layer, an isolation layer and a covering layer. The waterproof coiled material provided by the invention has the following advantages: excellent low-temperature performance is obtained through component optimization of modified asphalt under the condition of maintaining waterproofness, strength and toughness; and through close cooperation of the modified asphalt with the base substrate, the isolation layer and the covering layer, waterproofness and strength are further reinforced, and the waterproof coiled material is more long-lastingand durable.

Owner:豫王建能科技股份有限公司

Bent Axis Assemblies for Shades and Bent Axis Shades

ActiveCN107435513BImprove fit strengthHigh matching precisionWindowsPassenger spaceClassical mechanicsStructural engineering

The invention provides a bent shaft assembly (1) for a sunshade, the bent shaft assembly (1) comprising: a bent shaft (20); a plurality of sleeves (10), the plurality of sleeves (10 ) is set on the bent shaft (20), and a plurality of first teeth (11) are provided at the first end, and a plurality of second teeth (12) are provided at the second end, wherein adjacent sleeves pass through A plurality of said first teeth (11) and a plurality of said second teeth (12) are mutually meshed and coupled to each other; wherein, said first teeth (11) and said second teeth (12) are respectively horizontal formed across the wall thickness of said first end and said second end of said sleeve (10). The present invention also relates to a bent axis sunshade comprising the above bent axis assembly. Utilizing the bent shaft assembly of the present invention can improve the strength and fit precision, reduce friction and running noise, and can adapt to the application environment with larger stroke and larger curvature.

Owner:WEBASTO SHANGHAI

Sheet metal part fixing pipe clamp

InactiveCN113374941AFirmly connectedAchieve separationPipe supportsElectrical apparatusEngineeringPipe

The invention discloses a sheet metal part fixing pipe clamp. The sheet metal part fixing pipe clamp comprises a clamping arm and a pipe groove, wherein one end of the clamping arm is rotationally connected to the pipe groove, the other end of the clamping arm is connected to the pipe groove in a clamped mode, a connecting column is arranged on the end face, away from the pipe groove, of the clamping arm, a base is arranged on the side face, away from the clamping arm, of the pipe groove, a fixing groove is formed in the base, when adjacent fixing pipe clamps are connected, the fixing groove matches with the connecting column, and the connecting column and the fixing groove can further be used for being fixedly connected to an external structure. According to the sheet metal part fixing pipe clamp, the connecting column with the adjustable length is designed, the length of the connecting column can be adjusted according to the actual situation, therefore the connecting column can be fixedly connected to other structures conveniently, the sheet metal part fixing pipe clamp is easy to disassemble, the clamping groove and a boss can be separated by extruding a pressing part, a spring and an ejector block are designed and used for automatically separating and enhancing the combining force of the clamping groove and the boss, the fixing groove is designed in the bottom, a clamping jaw is arranged inside the fixing groove, the matching strength of self-expansion application is improved, and the sheet metal part fixing pipe clamp is used for long bolt fixing.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com