Manufacturing method of 500Mpa-grade cold-rolled magnetic steel

A manufacturing method and technology of magnetic pole steel, which are applied in the direction of manufacturing tools, temperature control, furnace type, etc., can solve the problem of inability to meet the safety requirements of hydraulic generators, improper selection of raw material slab components, and insufficient yield strength of cold-rolled magnetic pole steel. Advanced problems, to achieve uniform product performance, solve the effect of magnetic performance and strength, and small difference between head and tail performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

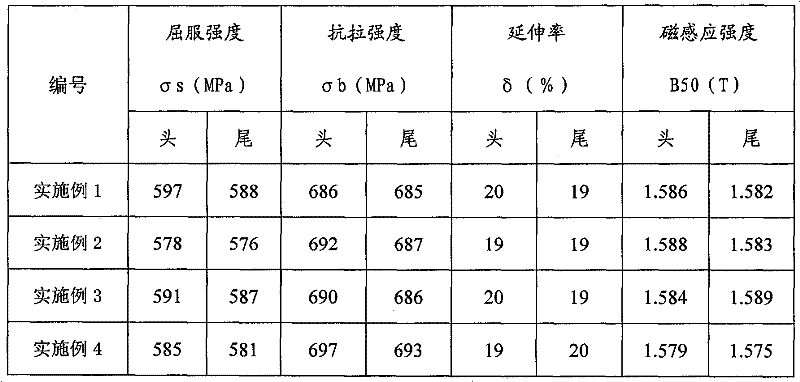

Examples

Embodiment 1

[0043] (1) The slab corresponding to Table 1 is heated to 1260°C, and the heated slab is rough-rolled and finish-rolled by a 7-stand continuous rolling mill, and the slab is rolled into a thin steel plate of 2mm gauge. The final rolling temperature The temperature is 890℃, and then it is cooled to 600℃ by laminar cooling for coiling;

[0044] (2) Cooling by air cooling, and pickling when cooled to 80°C;

[0045] (3) Cold rolling, in which the cold rolling reduction rate is 45%;

[0046] (4) Continuous annealing step: the temperature of the soaking section of the annealing furnace is controlled at 740℃, the speed of the annealing process section is controlled at 120 m / min, and the soaking section time is controlled at 239s.

[0047] (5) Use 0.2% flattening elongation for flattening to produce 500MPa grade cold-rolled magnetic pole steel according to Example 1 of the present invention.

Embodiment 2

[0049] (1) The slab corresponding to Table 1 is heated to 1200°C, and the heated slab is rough-rolled and finish-rolled by a 7-stand tandem mill, and the slab is rolled into a 4mm thin steel plate. The final rolling temperature It is 830℃, and then it is cooled to 550℃ by laminar cooling method for coiling;

[0050] (2) Air cooling is adopted, and pickling is carried out when cooled to 60°C;

[0051] (3) Cold rolling, in which the cold rolling reduction rate is 55%;

[0052] (4) Continuous annealing step: the temperature of the soaking section of the annealing furnace is controlled at 760℃, the speed of the annealing process section is controlled at 125 m / min, and the soaking section time is controlled at 230s.

[0053] (5) Flattening is carried out with a flattening elongation of 0.8%, and the 500MPa grade cold-rolled magnetic pole steel of Example 2 of the present invention is made.

Embodiment 3

[0055] (1) The slab corresponding to Table 1 is heated to 1230°C, the heated slab is rough-rolled and finish-rolled by a 7-stand continuous rolling mill, and the slab is rolled into a 3mm thin steel plate. The final rolling temperature It is 860℃, and then it is cooled to 570℃ by laminar cooling method for coiling;

[0056] (2) Cooling by air cooling, and pickling when cooled to 70°C;

[0057] (3) Cold rolling, in which the cold rolling reduction rate is 52%;

[0058] (4) Continuous annealing step: the temperature of the soaking section of the annealing furnace is controlled at 755°C, the speed of the annealing process section is controlled at 122 m / min, and the soaking section time is controlled at 234s.

[0059] (5) Use 0.5% flattening elongation for flattening to produce 500MPa grade cold-rolled magnetic pole steel according to Example 3 of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com