Low-temperature-resistant modified asphalt waterproof coiled material and preparation method thereof

A technology for modifying asphalt and waterproofing membranes, applied in building thermal insulation materials, asphalt layered products, chemical instruments and methods, etc., can solve the problems of surface asphalt cracking, affecting the waterproof effect, etc., to achieve resistance to sunlight and excellent dimensional stability. , the effect of large elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation of embodiment 1 modified asphalt

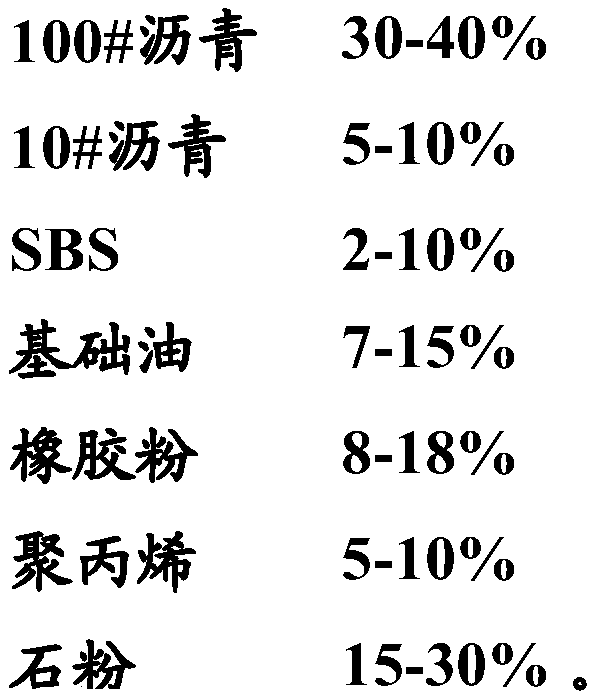

[0033] Weigh 37% of modified asphalt raw materials 100# asphalt, 8% of 10# asphalt, 7% of SBS, 10% of naphthenic oil, 12% of rubber powder, 6% of polypropylene and 20% of stone powder according to the following weight percentages.

[0034] Mix 100# asphalt and 10# asphalt and heat to 170°C;

[0035] Under the condition of stirring, add naphthenic oil, SBS, rubber powder, and polypropylene in sequence, stir evenly, raise the temperature to 190°C, keep stirring, and keep warm for 30 minutes.

[0036] Add stone powder and continue to stir for 1 hour at 180°C to obtain low-temperature-resistant modified asphalt.

Embodiment 2

[0037] The preparation of embodiment 2 waterproof coiled material

[0038] Heat the filament polyester felt to 160°C until fully dried.

[0039] Immerse the dry filament polyester felt with naphthenic oil at a temperature of 190°C; squeeze out excess naphthenic oil on the surface after fully soaking in oil.

[0040] Put the pretreated filament polyester felt base into the coating pool, and evenly coat the modified asphalt prepared in Example 1 on both sides of the filament polyester felt base, and control the coating temperature to 180°C .

[0041] After the tire base is coated, cool down to a lower surface temperature of 120°C and press the release film with a film pressing machine.

[0042] Control the temperature of the modified asphalt on the upper surface of the waterproof membrane to 120°C, and use a sand covering device to evenly cover the upper surface of the membrane with ceramic sintered sand. The mold plate outside the sand covering device controls the flow of sa...

Embodiment 3-40

[0044] Example 3-40°C low temperature resistant modified bitumen waterproof membrane

[0045]Refer to Example 1-2 to prepare -40°C low-temperature-resistant modified bitumen waterproofing membrane. Except for the ratio of raw materials, other steps are the same as those in Example 1-2.

[0046] Raw material ratio of -40°C low temperature resistant modified asphalt waterproofing membrane, by weight: 100# asphalt 38%, 10# asphalt 7%, SBS 6%, naphthenic oil 14%, rubber powder 10%, polypropylene 7%, stone powder 18%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| force | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com