Production method of low-cost easily-welded steel

A production method and easy welding technology, applied in the field of metal rolling, can solve the problems of poor plasticity, deterioration of the structure, affecting the compactness of the weld, and achieve the effects of increasing the welding speed, optimizing the production process, and improving the welding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

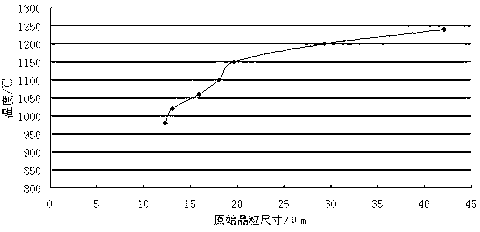

Image

Examples

Embodiment 1

[0043] Example 1: Purified molten steel is obtained through smelting, and then cast into slabs through a continuous casting machine. The composition weight percentages are: C: 0.183%, Si: ≤0.112%, Mn: 0.234%, P: ≤0.016% , S: ≤0.009%, Als: 0.0097%.

[0044] Heat the slab to 1181°C, keep it warm for 30 minutes, then turn on all the high-pressure water for descaling, and the pressure is 17.3Mpa; the slab after descaling is subjected to rough rolling for 3+3 times, and the temperature setting at the entrance of the finish rolling is 998°C , Open 3 groups of cooling water between racks. The temperature setting value of the finish rolling outlet is 862°C, the thickness range is 3.5-3.15mm, the laminar flow cooling method adopts the accelerated cooling mode, the strip cooling rate is increased by 5-7.9%, and the laminar flow cooling "water cooling section" cooling rate reaches 65- 78°C / s, laminar flow cooling "full stage" cooling rate is controlled at 12.65-15.65°C / s, coiling temper...

Embodiment 2

[0045] Example 2: Purified molten steel is obtained through smelting, and then cast into slabs through a continuous casting machine. The composition weight percentages are: C: 0.189%, Si: ≤0.104%, Mn: 0.241%, P: ≤0.012% , S: ≤0.008%, Als: 0.0010%.

[0046] Heat the slab to 1189°C, keep it warm for 25 minutes, then turn on all the high-pressure water for descaling, and the pressure is 17.6Mpa; the slab after descaling is subjected to rough rolling for 3+3 times, and the temperature setting at the entrance of the finish rolling is 992°C , Open 3 groups of cooling water between racks. The temperature setting value of the finish rolling exit is 867°C, the thickness range is 3.14-2.75mm, the laminar flow cooling method adopts the accelerated cooling mode, the strip cooling rate is increased by 5.8-8.3%, and the laminar flow cooling "water cooling section" cooling rate reaches 73- 87°C / s, the laminar flow cooling "full stage" cooling rate is controlled at 14.65-17.25°C / s, and the c...

Embodiment 3

[0047] Example 3: Purified molten steel is obtained by smelting, and then continuously cast into a slab through a continuous casting machine. The composition weight percentages are: C: 0.196%, Si: ≤0.092%, Mn: 0.256%, P: ≤0.010% , S: ≤0.0089%, Als: 0.011%.

[0048] Heat the slab to 1190°C, keep it warm for 22 minutes, then turn on all the high-pressure water for descaling, and the pressure is 18Mpa; the slab after descaling is subjected to rough rolling for 3+5 times, and the temperature at the entrance of the finish rolling is set at 985°C. The cooling water between the racks is opened to 4 groups. The temperature setting value of the finish rolling exit is 870°C, the thickness range is 2.75-2.25mm, the laminar flow cooling method adopts the accelerated cooling mode, the strip cooling rate is increased by 7-12.9%, and the laminar flow cooling "water cooling section" cooling rate reaches 81- 102°C / s, laminar flow cooling "full stage" cooling rate is controlled at 15.3-18.4°C / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com