Heat insulating mold, mold component, molding machine, and method for manufacturing the heat insulating mold

A mold and thermal insulation technology, applied in the field of thermal insulation molds, can solve the problems of abrasion of the thermal insulation layer, expansion or contraction of the die, and reduced bonding stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be described in detail below with reference to the drawings. In this case, an injection molding machine as a molding machine will be described.

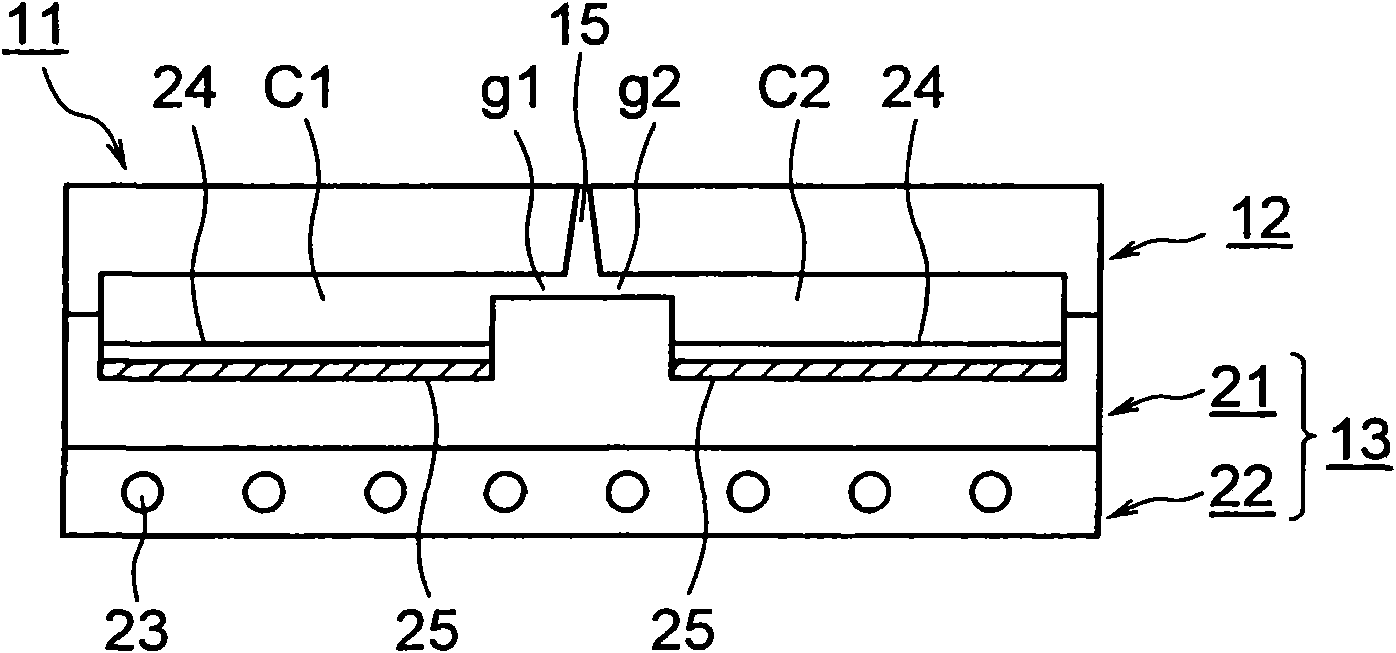

[0034] figure 1 It is a cross-sectional view of the heat insulating mold according to the first embodiment of the present invention.

[0035] In the figure, 11 is a mold device as a heat-insulating mold for forming molded products such as light guide plates and disk substrates, 12 is a fixed mold as a first mold, and 13 is a first mold that is freely arranged on the fixed mold 12 to advance and retreat. 2 Movable molds of the mold, C1 and C2 are cavity spaces formed between the fixed mold 12 and the movable mold 13 accompanying mold closing.

[0036] And, the above-mentioned movable mold 13 is provided with the upper plate 21 as a template and as the first mold part, and the lower plate 22 as the carrier plate for carrying the upper plate 21 and as the second mold part; On the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com