Micronano transfer device

A micro-nano, mold technology, applied in the direction of optics, opto-mechanical equipment, instruments, etc., can solve the problems that affect the forming quality of forming materials, the complexity of light source design mechanism, and the small transfer area, so as to improve the industrial utilization value and design more Effects of flexibility and equipment cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

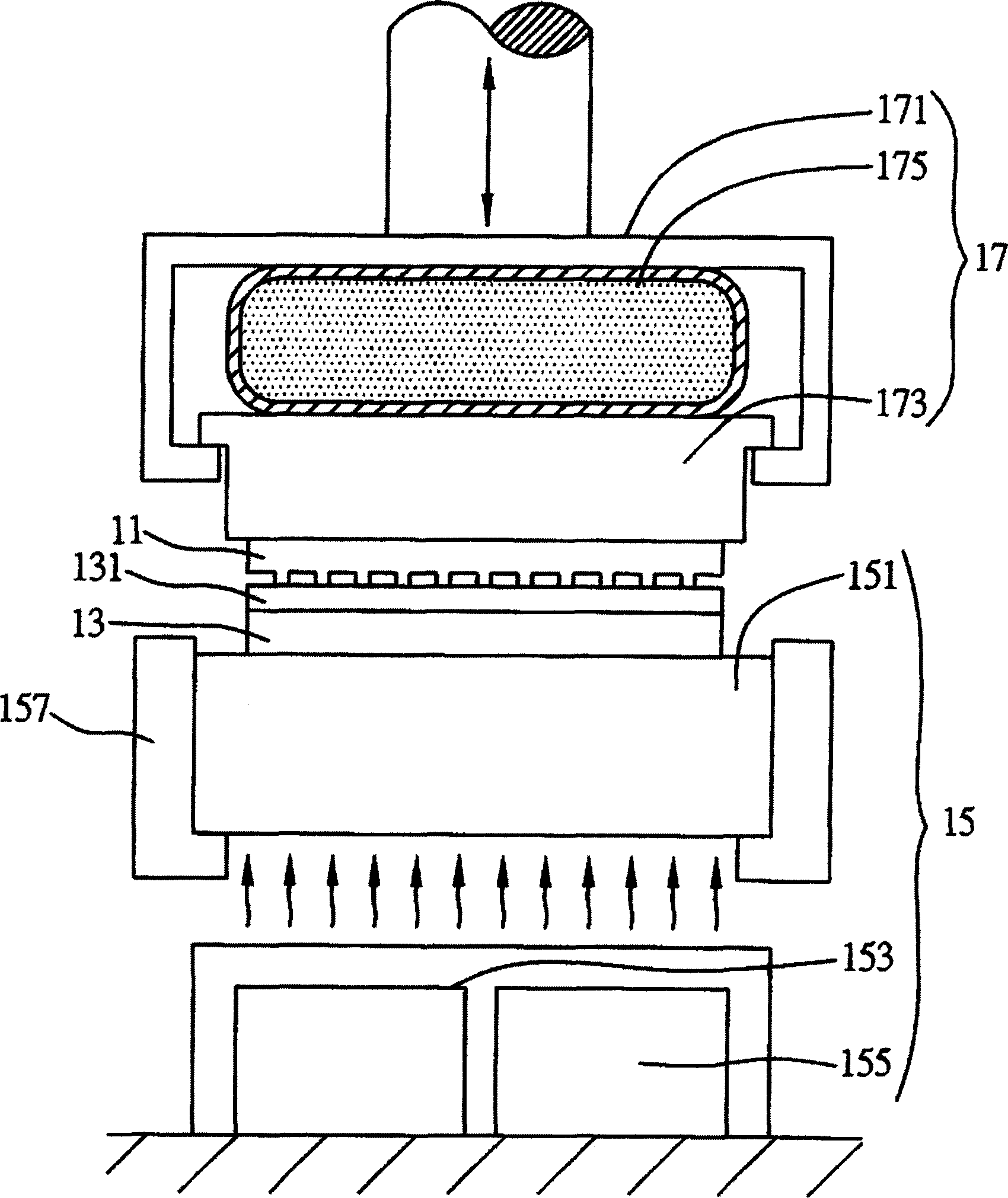

[0033] figure 1It is drawn according to Embodiment 1 of the micro-nano transfer device of the present invention. It should be noted that the micro-nano transfer printing device of the present invention is used to transfer nano-scale structures. The following examples use a micro-nano transfer printing device that can manufacture nanostructures with a characteristic structure size below 100 microns as an example for illustration, but Not limited to this. Since the existing nanostructures are all applicable objects, their structures have not changed, so for the sake of simplification, the features and structures of the present invention are clearer and easier to understand. In the accompanying drawings, only the structures directly related to the present invention are shown, and the rest Omit.

[0034] Such as figure 1 As shown, the micro / nano transfer device of this embodiment at least includes: a mold 11 , a substrate 13 and an energy transfer module 15 .

[0035] The di...

Embodiment 2

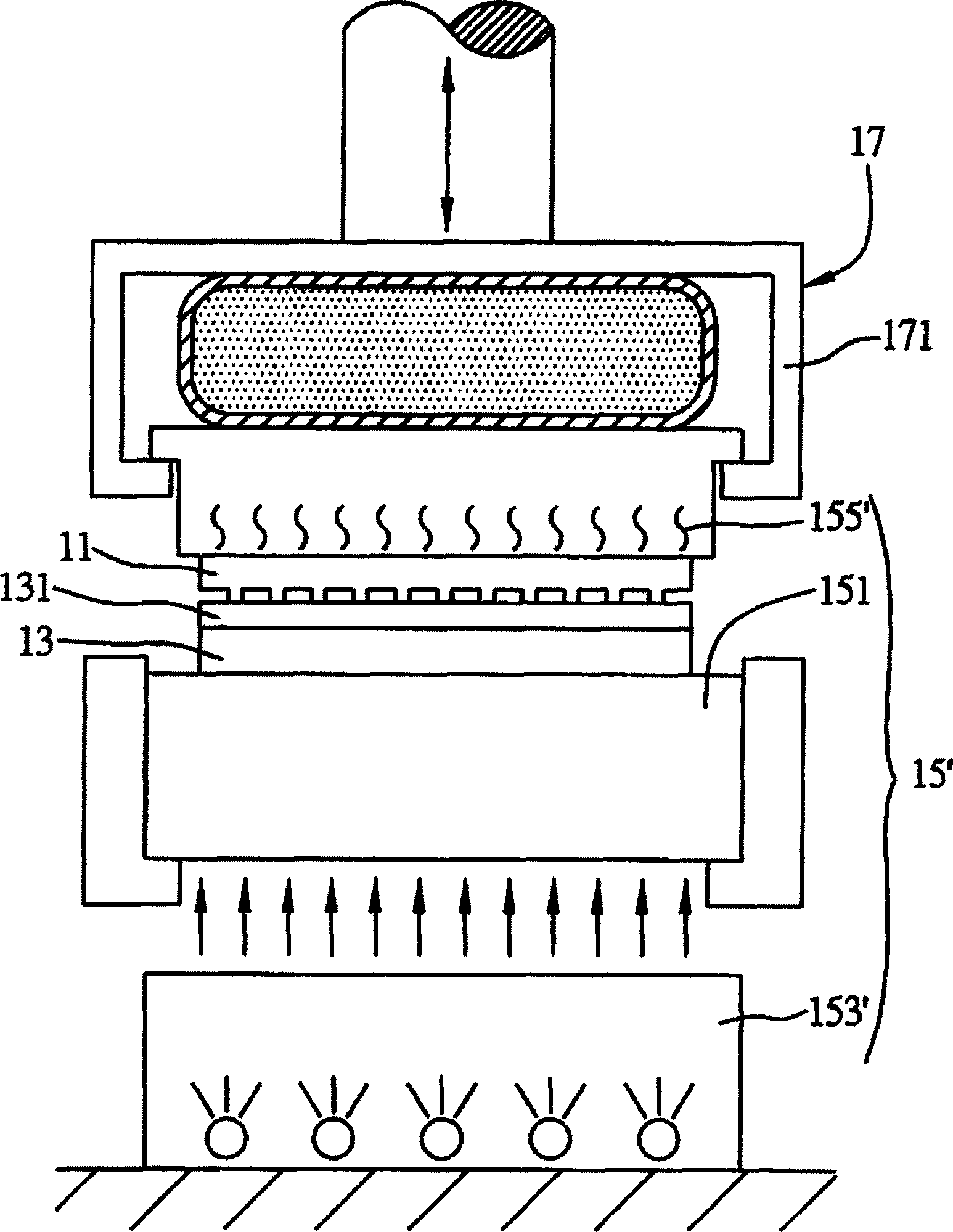

[0047] figure 2 It is drawn according to Embodiment 2 of the micro-nano transfer device of the present invention. Wherein, the same or similar components as in Embodiment 1 are represented by the same or similar component symbols.

[0048] The biggest difference between Embodiment 2 and Embodiment 1 is that Embodiment 1 uses an energy transfer module with two energy sources on the same side, while Embodiment 2 can form an energy transfer module with two energy sources on different sides.

[0049] Such as figure 2 As shown, the micro / nano transfer device of this embodiment at least includes: a mold 11, a substrate 13, and an energy transfer module 15'. The energy transfer module 15' includes the energy transfer member 151, an energy source 153', and an energy source 155'. The energy source 153' can be, for example, an ultraviolet light source, and the energy source 155' can be a heating element that can hold the mold 11. source, and the energy source 155' can be set on the...

Embodiment 3

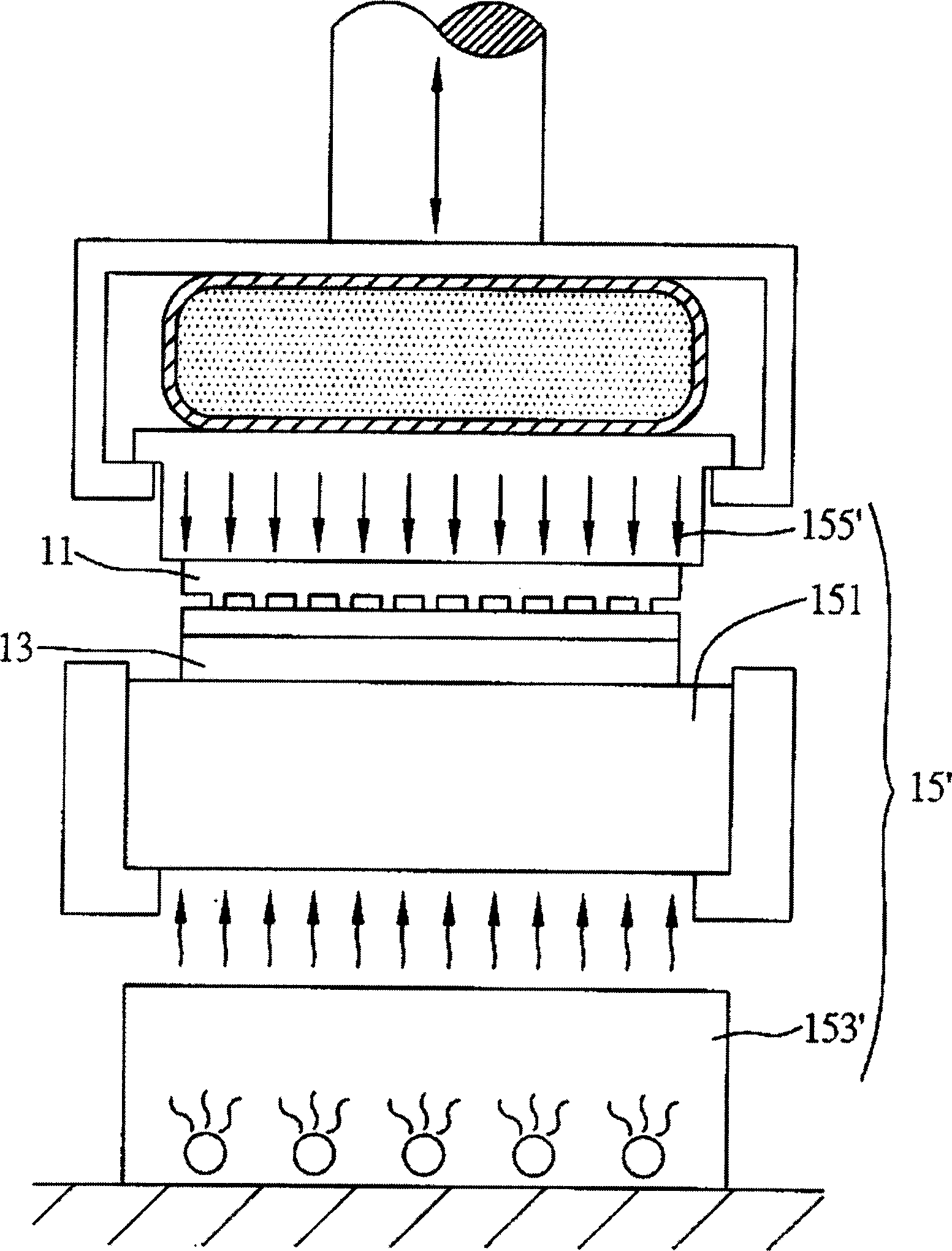

[0052] image 3 It is drawn according to Embodiment 3 of the micro-nano transfer device of the present invention. Wherein, the same or similar components as those in the above-mentioned embodiments are represented by the same or similar component symbols.

[0053] The biggest difference between embodiment 3 and embodiment 2 is that in embodiment 2, the energy source 153 ′ such as an ultraviolet light source is arranged below the energy transfer member 151 , and the energy source 155 ′ such as a heating source is arranged above the mold 11 In the third embodiment, the positions of the energy source 153' and the energy source 155' in the second embodiment are exchanged.

[0054] Such as image 3 As shown, in this embodiment, the energy transfer module 15 ′, such as the energy source 155 ′ of the heating source, is arranged below the energy transfer member 151 , and the energy source 153 ′, such as an ultraviolet light source, is arranged above the mold 11 . At this time, a mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com