Shoe-heel regenerated leather

A technology for regenerated leather and shoe heel, applied in the field of regenerated leather, can solve the problems of loss of high-quality collagen and tannin available resources, ordinary families cannot afford it, and the price of natural leather is expensive, so as to achieve a soft, plump and smooth hand feel, low price, and organization. tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Regenerated shoe heel leather The composition includes the following components by weight percentage: 17% natural latex, 5% fish oil, 13% latex white rubber, the rest is 50% crushed leather, and 4% tannin extract.

Embodiment 2

[0018] Example 2: Regenerated shoe heel leather The composition includes the following components by weight percentage: 22% natural latex, 8% fish oil, 12% latex white rubber, the rest is 45% crushed leather, and 3% tannin extract.

Embodiment 3

[0019] Example 3: Heel regenerated leather The composition includes the following components by weight percentage: 27% of natural latex, 10% of fish oil, 10% of latex white rubber, the rest is 40% of broken leather, and 2% of tannin extract.

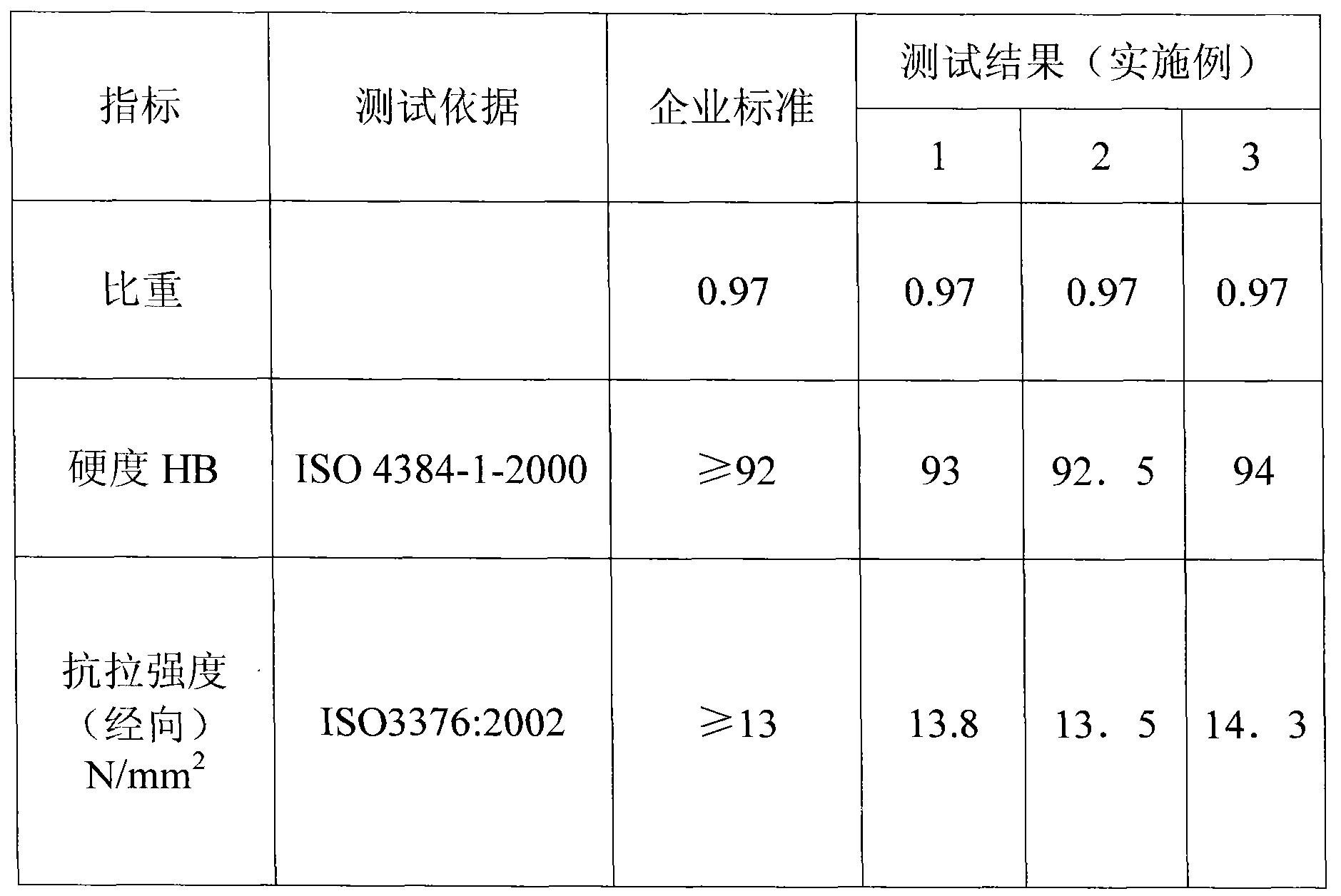

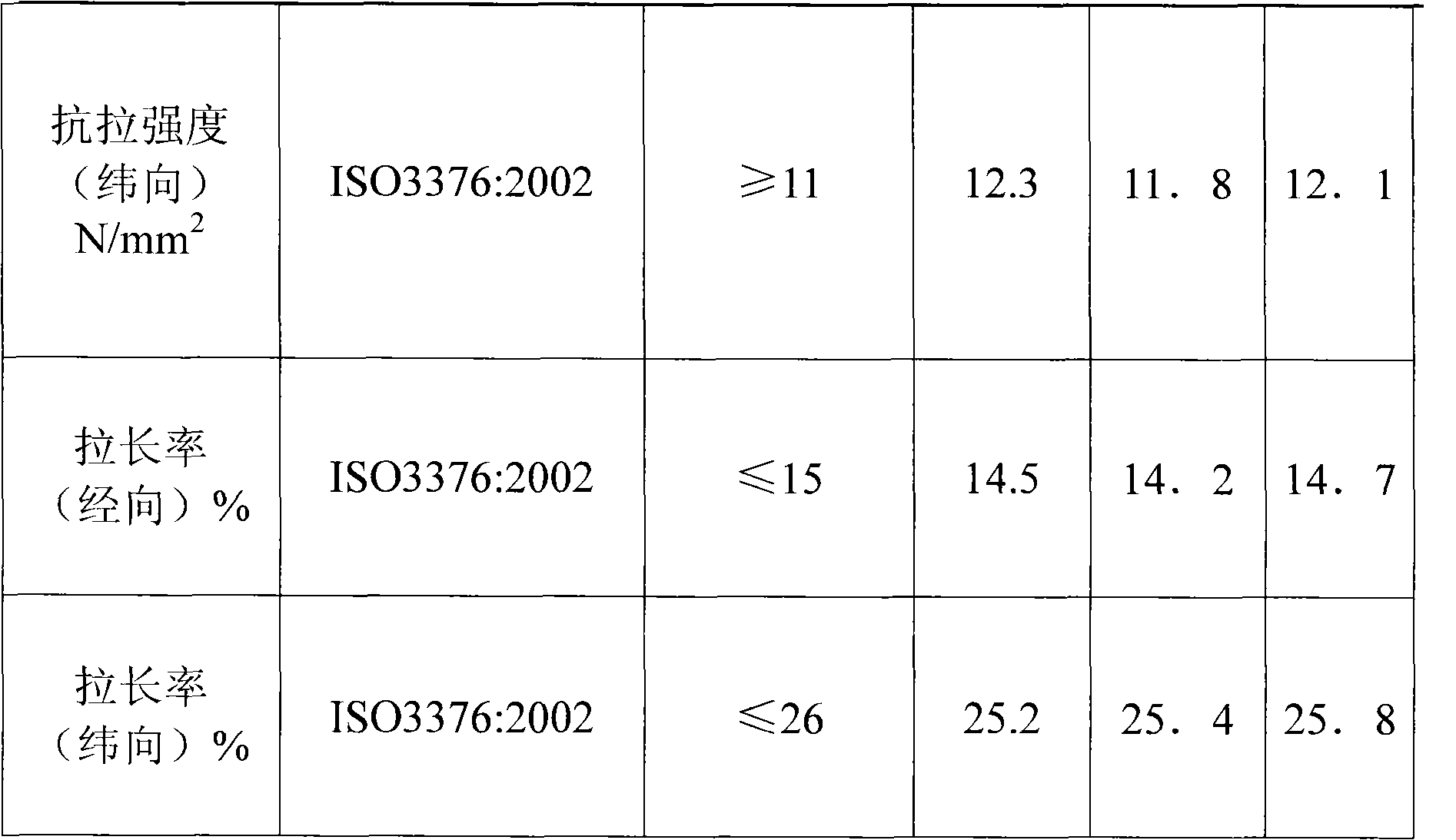

[0020] Performance Results Test Form

[0021]

[0022]

[0023] The performance test shows that the tensile strength (warp direction) is greater than 13N / mm 2 , the tensile strength (latitude) is greater than 11N / mm 2 , The warp elongation rate is less than 15%, the weft elongation rate is less than 26%, and the hardness is greater than 92HB, which meets the standard requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com