Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about How to "Does not affect softness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Making method of single-face-super-hydrophobic and single-face-hydrophilic Janus-type fabric

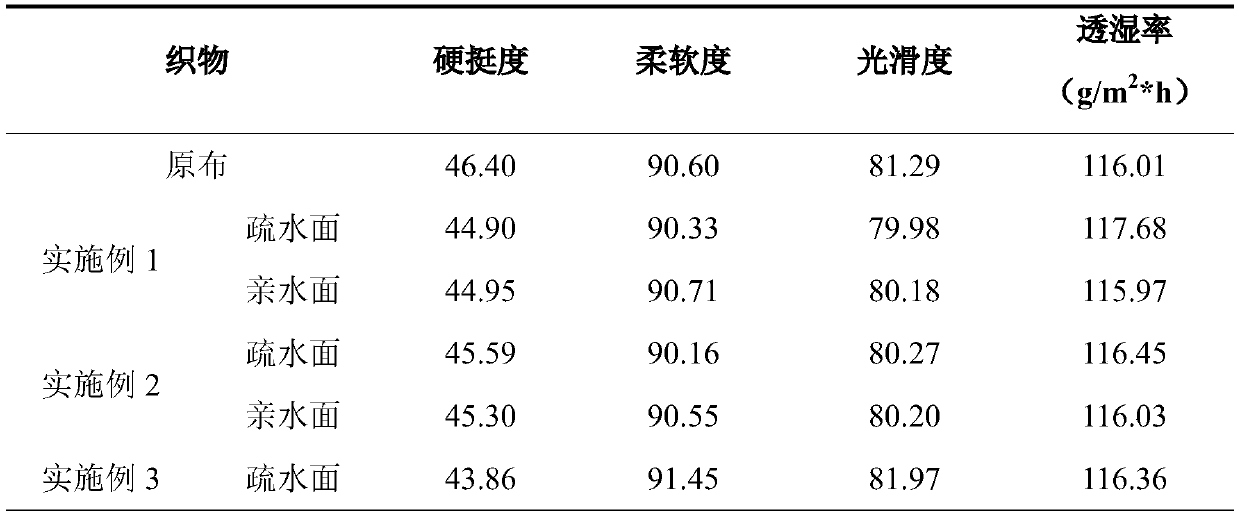

InactiveCN109706735AGood softnessGood performanceUltrasonic/sonic fibre treatmentVegetal fibresGlow dischargeWoven fabric

The invention relates to a making method of a fabric, in particular to a making method of a single-face-super-hydrophobic and single-face-hydrophilic Janus-type fabric and belongs to the field of textile function arrangement. The method comprises the following steps that 1, the fabric is cleaned and then dried for use; 2, the single face of the fabric is protected, under the condition of constantoxygen pressure intensity, plasma glow discharge treatment is conducted on the single face of the fabric, after oxygen is switched off, under the condition of constant steam pressure intensity of a grafting monomer, plasma glow discharge treatment is conducted again, and the single-face-super-hydrophobic and single-face-hydrophilic Janus-type fabric is obtained. According to plasma glow dischargetreatment, a cold plasma treatment instrument is used for generating plasma glow, the plasma treatment power is within 30-120 W, and the time is within 1-10 min. According to the method, the technology is simple and easy to control, the method is suitable for single-face treatment of various cotton fabrics and acetate fiber non-woven fabrics, the functionality demand is met, and the method also has good wearing performance.

Owner:ZHEJIANG SCI-TECH UNIV

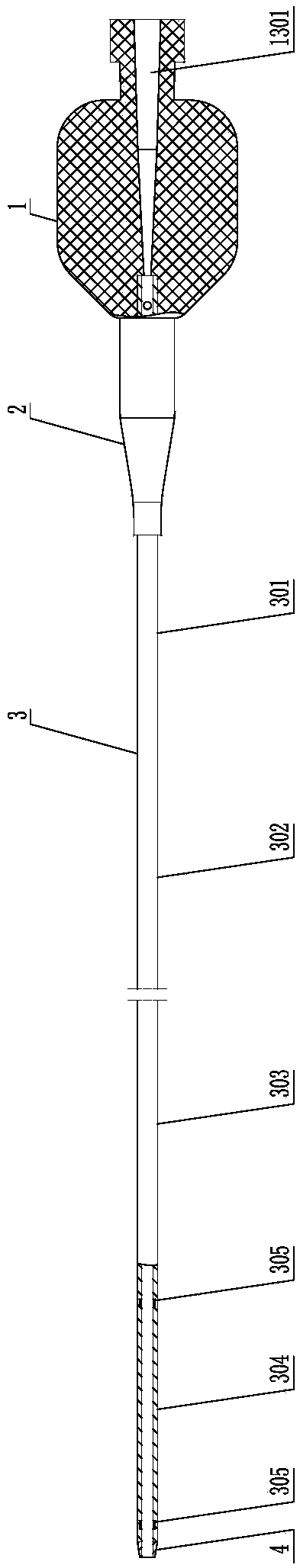

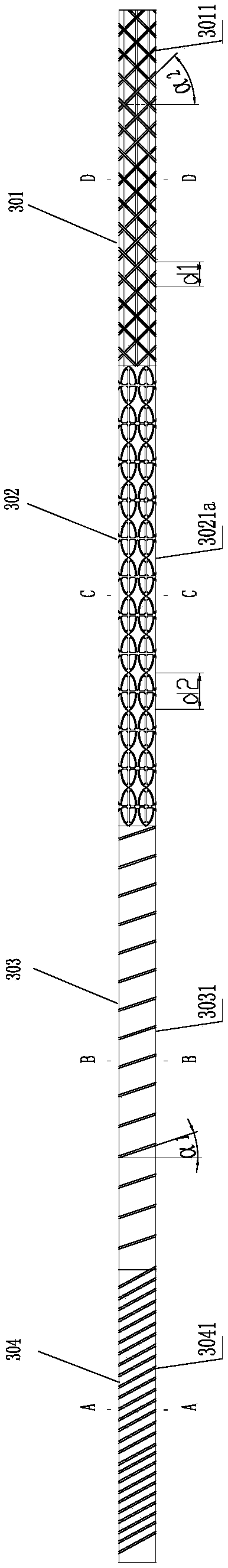

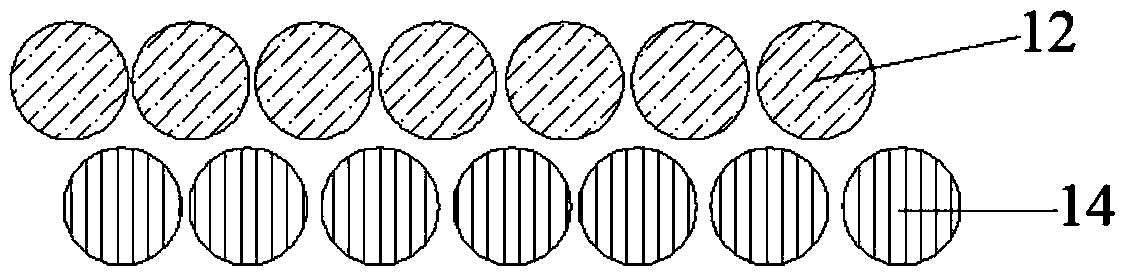

Blood vessel thrombus-taking device with spine-shaped structures and thrombus therapeutic instrument thereof

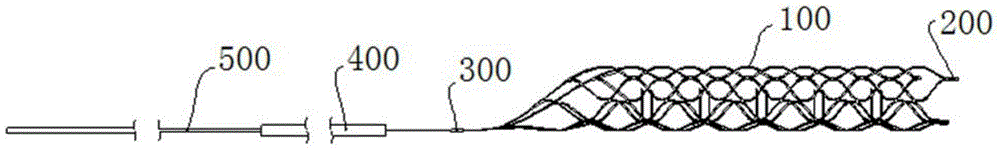

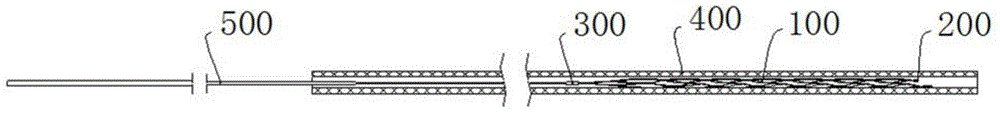

ActiveCN105662534ADoes not affect softnessAvoid damageBalloon catheterSurgeryThrombusHemostasis valve

The invention relates to a blood vessel thrombus-taking device with spine-shaped structures and a thrombus therapeutic instrument thereof. The blood vessel thrombus-taking device comprises a thrombus-taking instrument, a development ring located at the near-end of the thrombus-taking instrument and a development coil located at the far-end of the thrombus-taking instrument. The thrombus-taking instrument comprises a mesh tubular or cage-shaped structure composed of a plurality of mutually connected unit grids, and each unit grid is formed by embracement of mutually connected ribs. The ribs of the unit grids are provided with the spine-shaped structures respectively, and each spine-shaped structure extends into an outer cavity. The thrombus therapeutic instrument comprises the blood vessel thrombus-taking device with the spine-shaped structures, a protective sheath tube, a conveying wire, a micro catheter, a guide catheter and a rotary hemostasis valve. The micro catheter is pushed to the thrombus position in the guide catheter along the guide catheter, the protective sheath tube is communicated with the micro catheter through the rotary hemostasis valve, and the thrombus-taking instrument is placed in the protective sheath tube and pushed into the micro catheter through the conveying wire. The blood vessel thrombus-taking device is good in flexibility, and the thrombus-taking instrument can make the damage to the blood vessel wall smallest by bending a blood vessel or reaching a thin blood vessel at the far-end.

Owner:ZHUHAI TON-BRIDGE MEDICAL TECH CO LTD

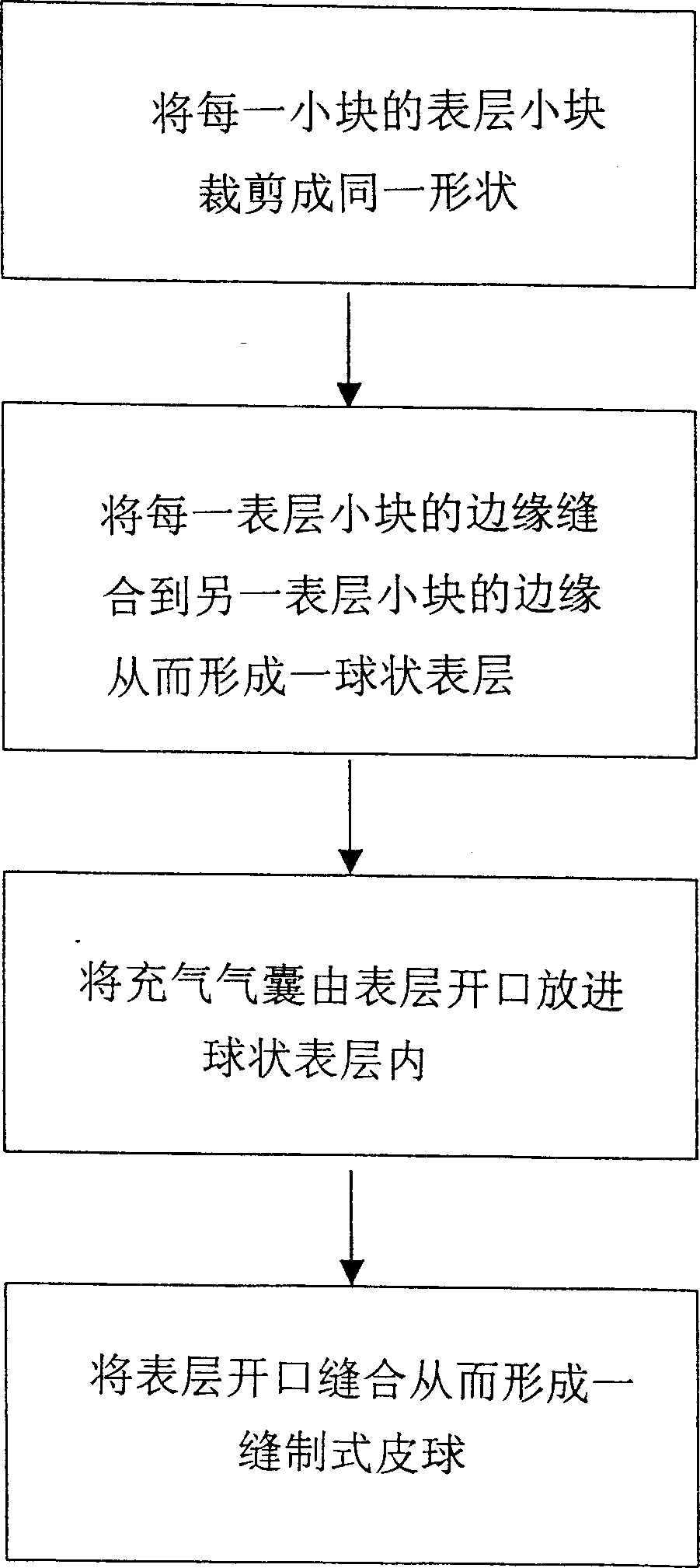

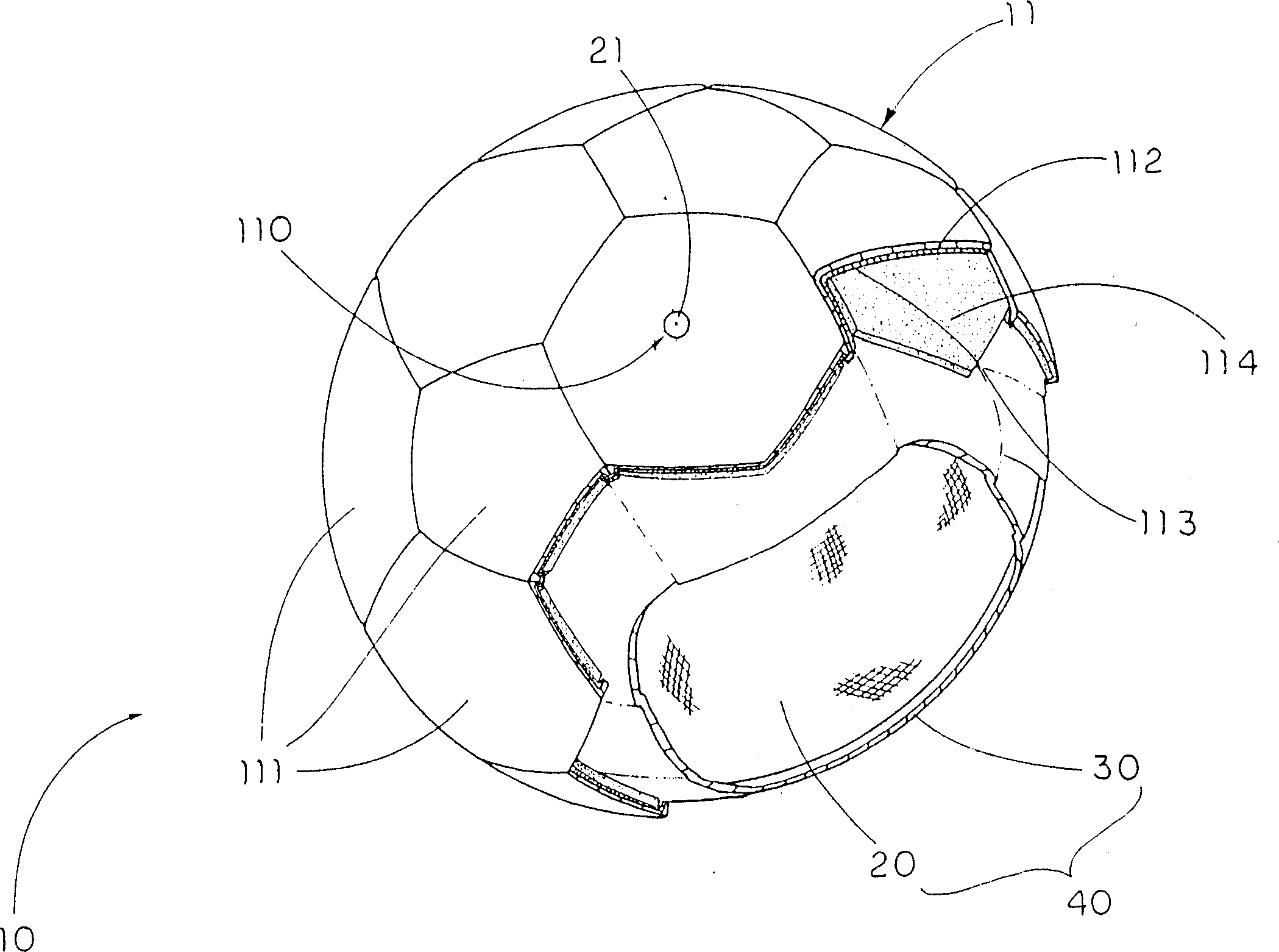

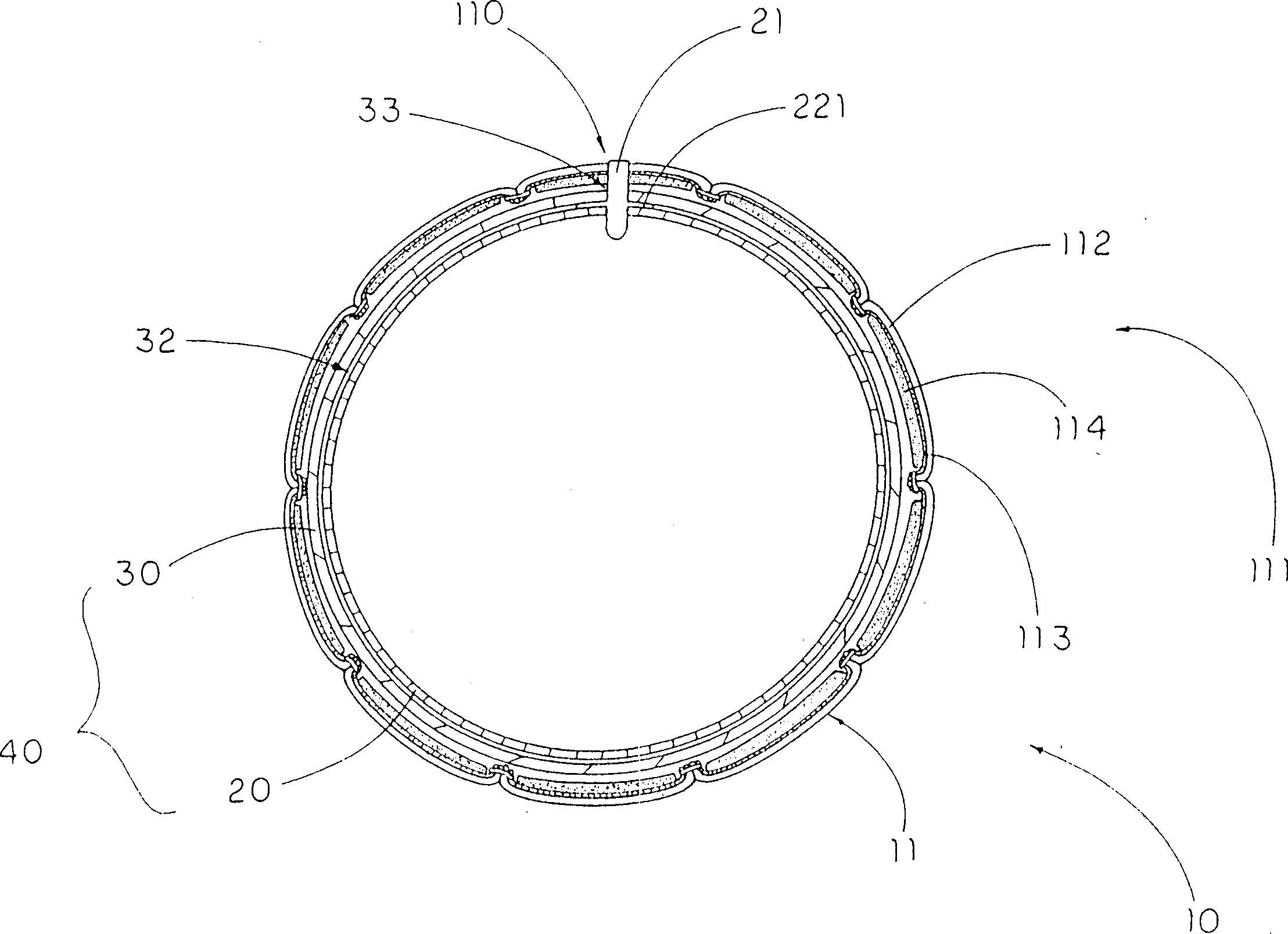

Ball bag built-in sewn ball

The present invention relates to a sewed ball with built-in ball bag. Said ball is formed from a ball surface layer and a ball bag internal bladder placed in the interior of ball surface layer. Said ball bag internal bladder includes an inflatable air bag with an inflatable hole, a built-in ball bag which has a receiving space for receiving said inflatable air bag and a movable air hole from which the inflatable hole can be passed through and extended outward. Said ball surface layer can be used for receiving said ball bag internal bladder, after said ball bag internal bladder is inflated, said ball surface layer can be expanded and formed into a ball with a certain radian and flexibility. Said invention also provides its sewing method.

Owner:欧陈丽卿

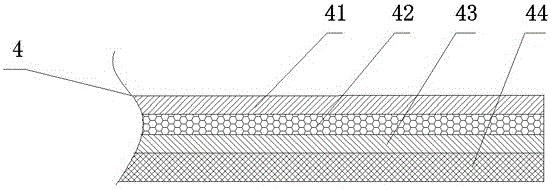

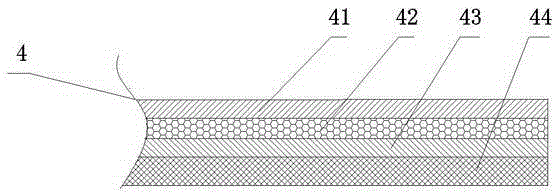

Intermediate catheter

The invention provides an intermediate catheter comprising a seat, a stress relief tube and a catheter arranged from a proximal end to a distal end in sequence; the main improvement is that the catheter has a proximal push segment, a middle support segment, a distal torsional control segment and an ultra-distal tracking segment along the axial direction from proximal to distal. The catheter tip iscoaxially connected with the ultra-distal tracking segment; the bore of the seat is coaxially connected with the inner lumen of the catheter to form a guide lumen; an inn liner layer, an intermediatereinforcement layer and an outer cladding layer are radially distributed from the inner to the outer of the conduit, and the intermediate reinforcement layer is respectively connected with the innerliner layer and the outer cladding layer. The present invention is capable of providing superior proximal pushability, good midsection vascular support, high distal torque response torque control, andultra-distal complex tortuous vessel passage, facilitating catheter passage through distal intracranial vessels or delivery of other instruments to distal vessels.

Owner:MINITECH MEDICAL JIANGSU LTD

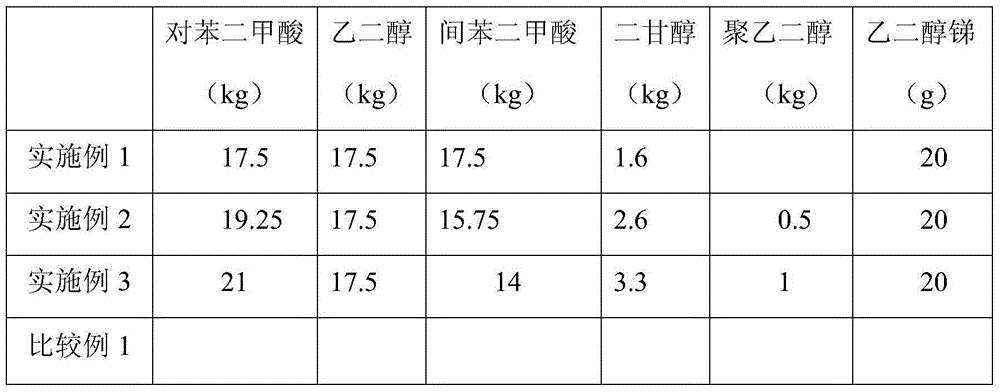

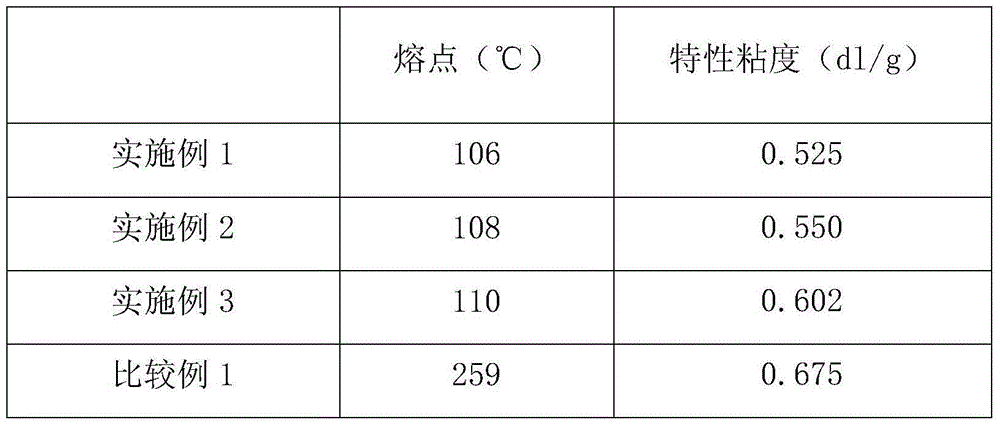

A preparing method of low-melting point polyester used for manufacturing terylene sewing threads

InactiveCN104558560ALow intrinsic viscosityReduced crystallization performanceAdhesivesSolventPolymerization catalysts

The invention relates to a preparing method of low-melting point polyester used for manufacturing terylene sewing threads. The method includes: 1) performing esterification by adopting terephthalic acid, ethylene glycol, isophthalic acid, and a straight-chain monomer having double hydroxyl reaction functional groups except the ethylene glycol; and 2) under the existence of a condensation polymerization catalyst, performing further esterification and pre-condensation polymerization, and performing condensation polymerization under a vacuum condition of 0.1-2 KPa. The melting point and the intrinsic viscosity of a polyester product prepared by the method are lower than that of conventional polyester. Compared with present low-melting point polyester, the intrinsic viscosity and the crystallization property of the product prepared by the method are low, and dissolution performance when the product is used for producing an adhesive used for solvent type bonded threads is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

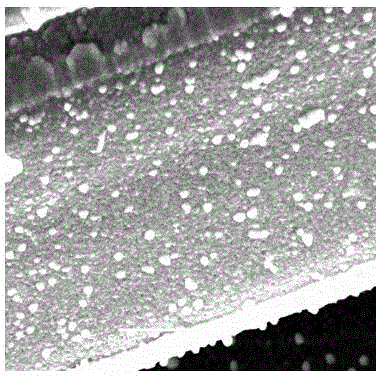

Preparation method of copper-zinc-iron ternary alloy chemical plating layer on surface of aramid fiber

InactiveCN104088138AHigh surface energyImprove wetting performancePhysical treatmentFibre typesChemical platingSurface modification

The invention discloses a preparation method of a copper-zinc-iron ternary alloy chemical plating layer on the surface of aramid fiber. The preparation method comprises the following steps: carrying out surface modification on aramid fiber; carrying out low-concentration colloid palladium treatment; and carrying out a copper-zinc-iron ternary alloy chemical plating process. The preparation method has the beneficial effects that an environment-friendly glyoxylic acid chemical plating process is used to realize co-deposition of a copper-zinc-iron ternary alloy; the plating layer is composed of following components in percentage by mass: 85%-90.5% of copper, 1.0%-3.0% of iron, 0.5%-1.5% of zinc and the balance of carbon and oxygen; through detection, the surface resistance of the plating layer keeps below 50m(omega) / sq; an adhesive tape method is used for determining the binding force between the plating layer and fabric fibers and the weight loss ratio is less than 0.1%; the plating layer is bright and a microstructure is uniform; the plating layer can resist atmosphere corrosion and meets the requirements of electric conduction, electromagnetic shielding, static electricity prevention and the like.

Owner:SHANDONG JIANZHU UNIV

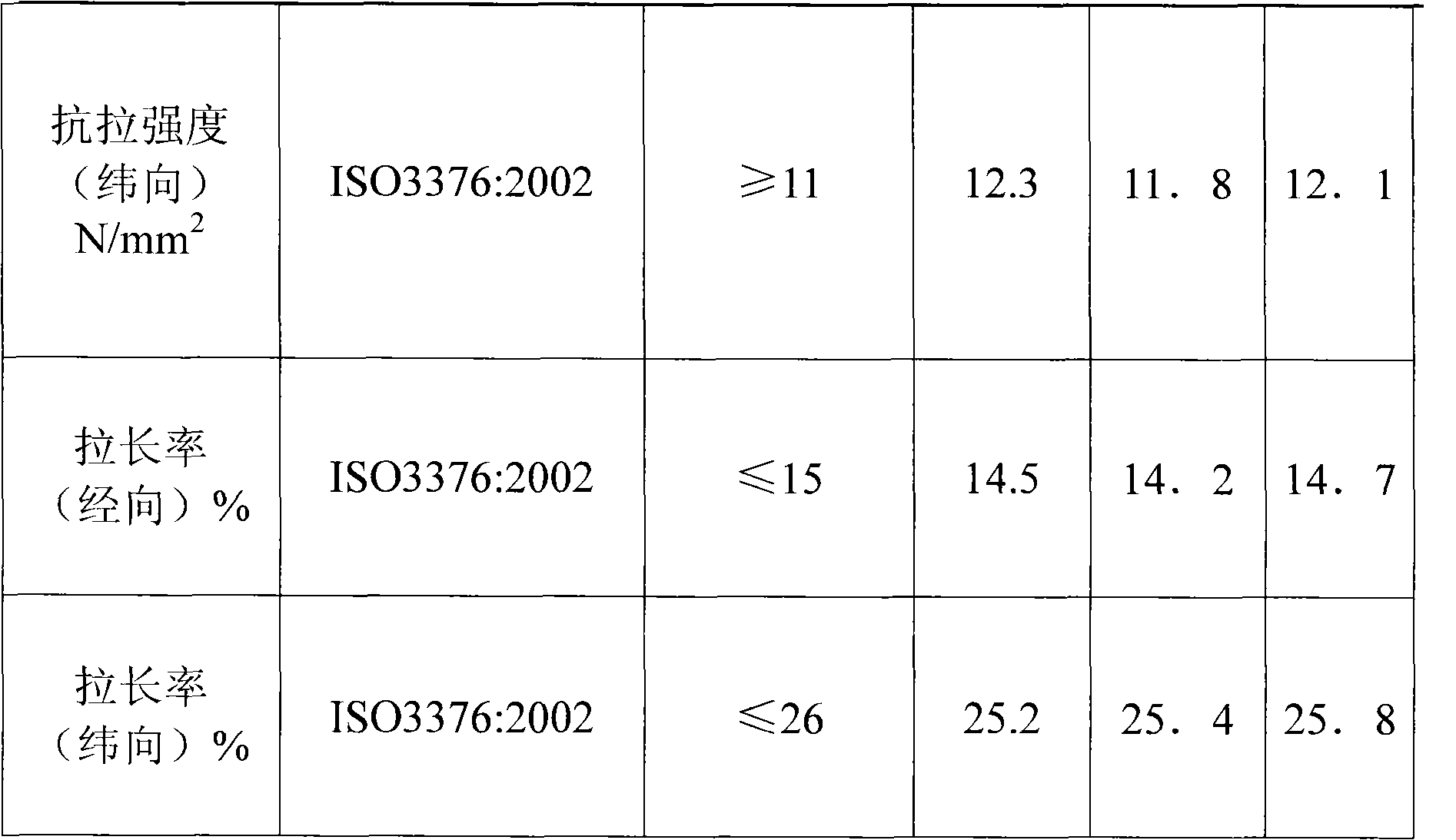

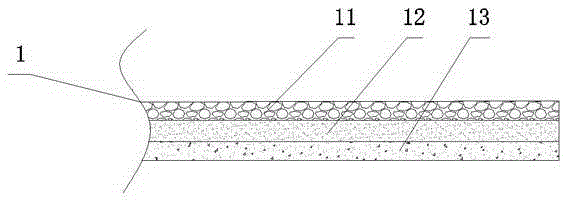

Far-infrared carbon fiber composite heating film

The invention relates to a far-infrared carbon fiber composite heating film, which comprises an upper base layer, a lower base layer, a carbon fiber composite heating layer, an upper insulated flame-retardant and heat-resistant waterproof layer and a lower insulated flame-retardant and heat-resistant waterproof layer, wherein the carbon fiber composite heating layer is located between the upper base layer and the lower base layer; and the upper insulated flame-retardant and heat-resistant waterproof layer and the lower insulated flame-retardant and heat-resistant waterproof layer coat the outer sides of the upper base layer and the lower base layer, wherein the far-infrared carbon fiber composite heating film is preferably carbon fiber cloth or carbon fiber composite paper. The far-infrared carbon fiber composite heating film is simple in structure, has good flexibility and can be freely cut and folded; the flexibility is not affected in a low-temperature condition; the load resistance deviation does not exceed 8% after a single side is folded for 1,000 times at a speed of 30times / min; the security and the stability are significantly improved; the service life is long; and furthermore, the far-infrared carbon fiber composite heating film has high external insulativity, high-temperature resistance, open fire resistance and waterproofness, the internal conductivity and the heating property are good and the security is high.

Owner:石家庄邦迪高分子材料有限公司

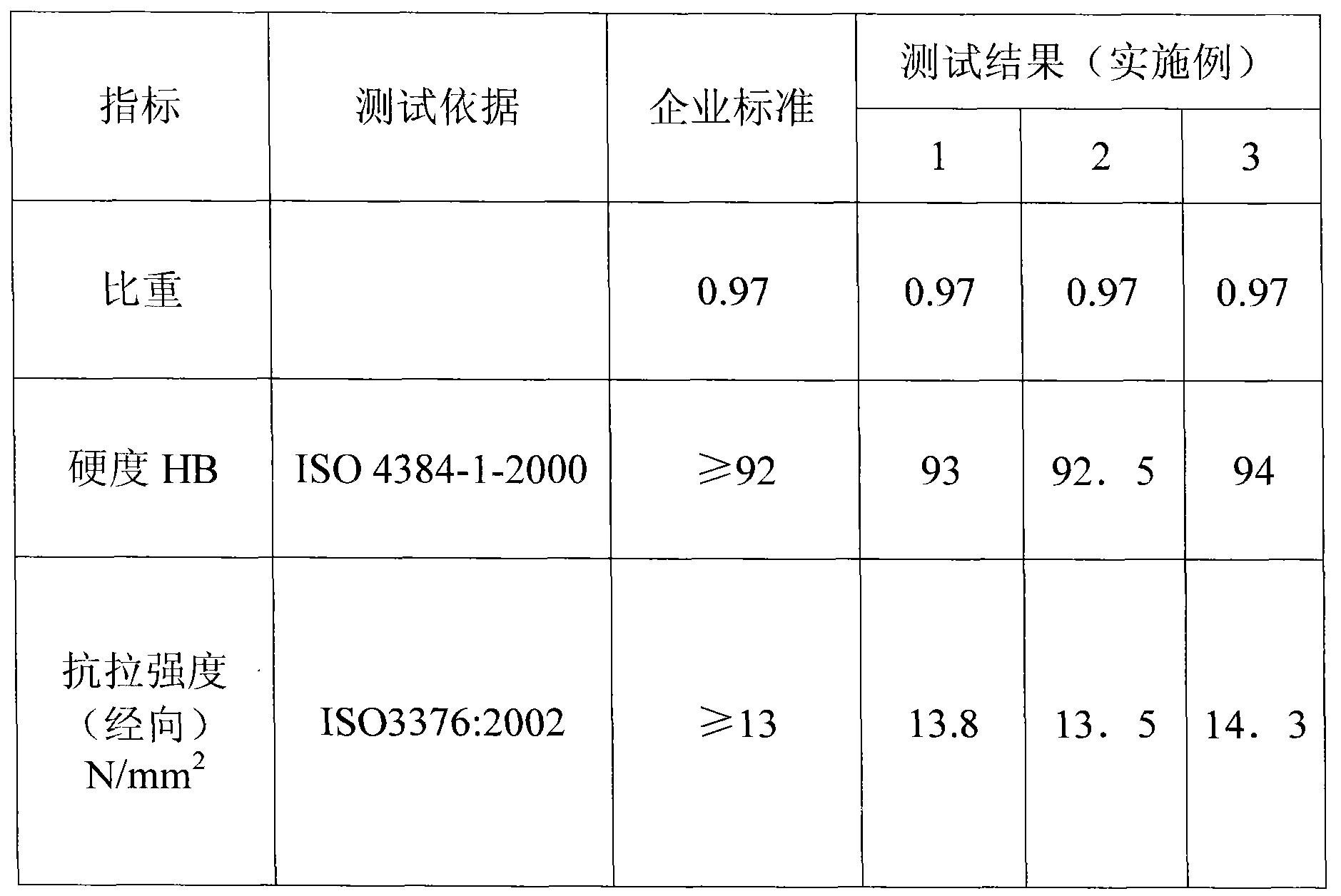

Shoe-heel regenerated leather

The invention relates to shoe-heel regenerated leather which is characterized in that the composition comprises the following components in percentage by weight: 17-27 natural latex, 5-10 fish oil, 10-13 white glue, 40-50 crushed leather and 2-4 tannin extract. A manufacturing method of the shoe-heel regenerated leather comprises the following steps of: primarily crushing and intermediately crushing the crushed leather to manufacture pulp after the two steps of fine crushing, then refining through a refiner to separate impurities with large grain diameters, tanning the pulp through the tannin extract, carrying out leather auxiliary-agent processing , such as greasing by adding the fish oil, hardness increasing by using the white glue, dye toning and the like, simultaneously combining the processed pulp together with the natural latex and aluminum sulfate (used for drying and controlling a pH value) to be manufactured into a regular shape through dewatering and drying, and finally dewatering and drying. The product has the advantages of low price, high production efficiency, high drying speed and energy saving.

Owner:ZHEJIANG SUNNYESINA REGENERATED LEATHER

Non-woven composite gauze sheet for surgery

ActiveCN106671504AReduces hair lossWill not cause lossNon-adhesive dressingsLayered productsSocial benefitsHair falling

A non-woven composite gauze sheet for surgery comprises a non-woven gauze sheet and a gauze sheet, and is characterized in that the non-woven gauze sheet and the gauze sheet are composited, a bamboo fiber gauze layer and a dressing layer are composited on the gauze sheet, and the dressing layer is formed by compositing an antibacterial layer, a healing-promoting layer and a bleeding-stopping layer. The non-woven composite gauze sheet for surgery has the effects of being strong in water-absorbing power, free of loose thread and hair falling, capable of blending with advanced surgical sensors, strong medical function and the like, and has extremely high social benefit and economic benefit.

Owner:湖北唯美医疗用品有限公司

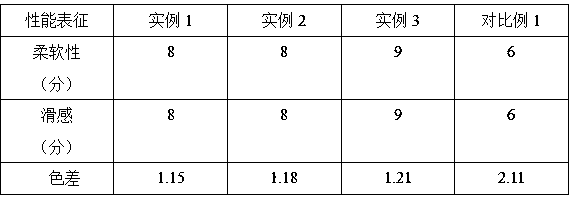

Method for darkening finishing of wool fabric

InactiveCN103643528AIncreased apparent color depthDoes not affect the feelAnimal fibresChemistryWool

The invention provides a method for darkening finishing of a wool fabric, and the method at least comprises the following steps: (1) preparation of fluoroalkyl modified amino silicone oil; (2) emulsifying of the fluoroalkyl modified amino silicone oil; (3) padding; (4) preliminary drying; and (5) baking. Compared with the prior art, the method for darkening finishing uses the fluoroalkyl modified amino silicone oil as a finishing agent, the apparent color depth (K / S) of the wool fabric after the finishing can be increased by more than 20%, and the hand feeling, the flexibility and the serviceability of the fabric may not be affected.

Owner:TONGXIANG PUYUAN WOOLEN KNITTING TECH SERVICE CENT

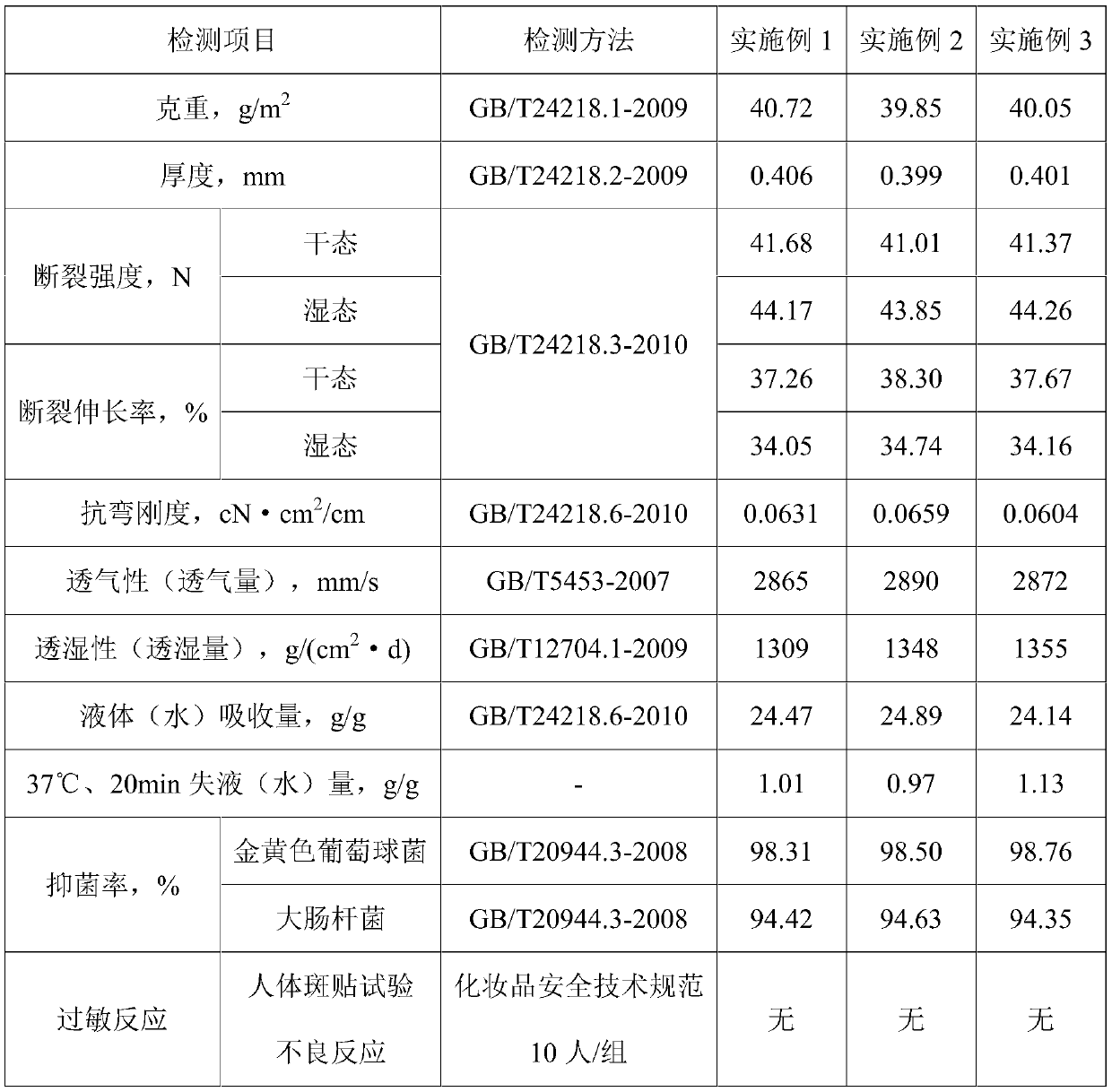

Bacteriostatic and water-absorbing functional wet tissue

ActiveCN108286125AEfficient use ofImprove performancePhysical treatmentConjugated synthetic polymer artificial filamentsWater useNonwoven fabric

The invention discloses a bacteriostatic and water-absorbing functional wet tissue. The functional wet tissue is composed of a carding fiber layer, a modified hot-melt fiber net layer, a hot-rolled fiber net layer and a water absorbing fiber net layer through spunlace reinforcement. The bacteriostatic and water-absorbing functional wet tissue comprises chitosan fibers, bamboo pulp fibers and othermaterials good in bacteriostatic property and water absorption, and is soft in texture, capable of absorbing water and inhibiting bacteria, comfortable to use, high in wet strength, capable of caringskin, capable of being circularly used and recycled, capable of saving energy, good in biodegradability and biological regulation, and free of pollution to the environment; a non-woven fabric has anantibacterial function, functional finishing is carried out, and a bacteriostatic agent and a preservative do not need to be added in soaking liquid, so that the wet tissue is safe to use and free ofirritation; the processing process is simple, water used in the preparation process can be recycled, and energy and the cost are saved.

Owner:联丰纤维制品(始兴)有限公司

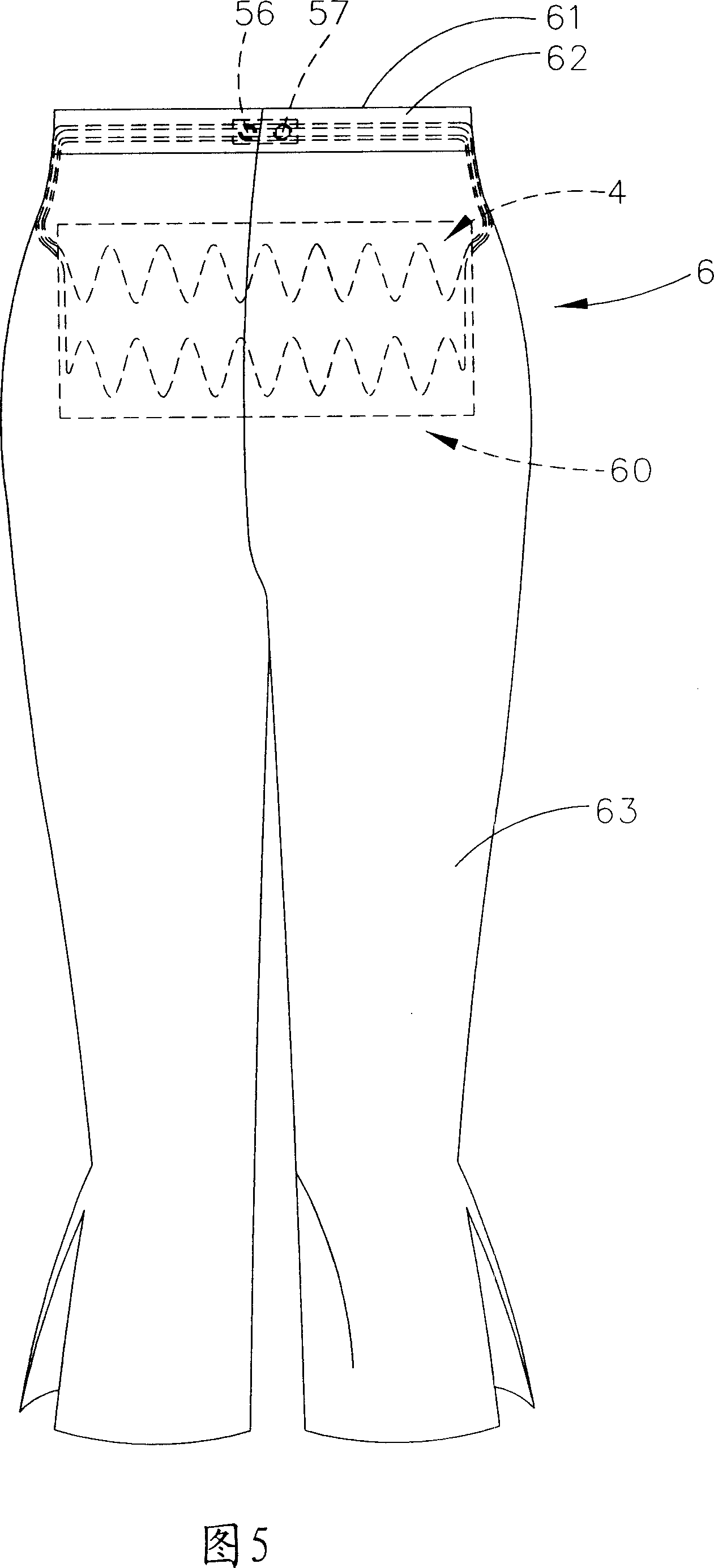

Method for preparing underwear with antibacterial effect by utilizing electrostatic spinning method

InactiveCN111251693ADoes not affect softnessHigh porositySynthetic resin layered productsCellulosic plastic layered productsFiberSpinning

The invention provides a method for preparing underwear with an antibacterial effect by utilizing an electrostatic spinning method. The method comprises the following steps: preparing hydrophobicallymodified chitosan by adopting chitosan; dissolving a natural antibacterial agent into the chitosan solution, and crosslinking glutaraldehyde to obtain a hydrophobically modified chitosan coated natural antibacterial agent; adding carboxymethyl chitosan and hydrazine hydrate into silver nitrate, and obtaining a nano-silver antibacterial solution; dispersing the hydrophobic modified chitosan coatednatural antibacterial agent and the nano-silver antibacterial solution into a high-molecular polymer solution, and defoaming to obtain a nano-antibacterial spinning solution; adding the nano-antibacterial spinning solution into electrostatic spinning, and electrospinning a composite nano-antibacterial fiber layer on the surface of the base cloth layer; obtaining the underwear fabric with the antibacterial effect through a hot pressing process; and preparing the underwear with the antibacterial effect. The silver and a natural antibacterial agent are processed into nanofibers and rapidly embedded into the fabric, multiple antibacterial materials are compounded into the nano antibacterial fibers at a time, and the nano antibacterial fibers have high porosity and high specific surface area and bring air and moisture permeability and antibacterial effects.

Owner:FOSHAN QINGZI PRECISION MEASUREMENT & CONTROL TECH

Sound-insulating environment-friendly material used for decoration and production method of sound-insulating environment-friendly material used for decoration

ActiveCN110435259APrevent directional reflectionReduce resonanceMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesResonanceMedium frequency

The invention discloses a sound-insulating environment-friendly material used for decoration and a production method of the sound-insulating environment-friendly material used for decoration. The sound-insulating environment-friendly material comprises a hard sound-insulating layer, a sound-absorbing layer and a protective layer, wherein the sound-absorbing layer is arranged between the hard sound-insulating layer and the protective layer, the hard sound-insulating layer is arranged on the face opposite to an internal space, the protective layer is arranged on the face close to the internal space, and lamination bulges are arranged on the hard sound-insulating layer, so that effects on an external space are reduced, and the lamination bulges can reduce resonance between a wall and the hardsound-insulating layer; and the sound-absorbing layer comprises two layers of foamed polypropylene thin layers and a lamination fiber layer arranged between the two layers of foamed polypropylene thin layers, the protective layer is a foamed polypropylene sheet, and the lamination fiber layer is provided with winding small holes which communicate, thus a good effect of attenuating high-frequencynoise can be achieved, and closed hole structures of the foamed polypropylene sheet can insulate noise from low and medium frequency to medium and high frequency, so that broad-band noise is insulatedand absorbed.

Owner:深圳市集洁号环保科技有限公司

Textile fabric dye

InactiveCN106988132AUniform and firm dyeingReduce manufacturing costDyeing processPyrophosphateEthyl acetate

The invention relates to a textile fabric dye, comprising, by weight, 30-40 parts of attapulgite clay, 2-4 parts of polypropylene glycol, 3-5 parts of tetracarboxydiphthalic ether dianhydride, 1-2 parts of zinc stearate, 10-13 parts of blocked isocyanate, 8-9 parts of calcium sulfate, 9-10 parts of magnesium sulfate, 2-3 parts of aluminum oxide powder, 20-30 parts of waterborne nano color paste, 7-9 parts of a surfactant, 6-8 parts of ethyl acetate, 10-12 parts of an initiator, 15-25 parts of plant extract, 12-15 parts of chitosan, 2-3 parts of mica powder, 1-1.6 pars of tetramethyl ammonium bromide, 1-3 parts of a water softener, 3-4 parts of sodium carbonate, 2-3 parts of sodium pyrophosphate, 5-8 parts of iron blue, and 20-30 parts of water. The textile fabric dye is low in cost, natural and healthy, nontoxic and harmless to human body, and resistant to fading; the preparation method is simple, has low equipment requirements and is easy to popularize.

Owner:合肥云都棉花有限公司

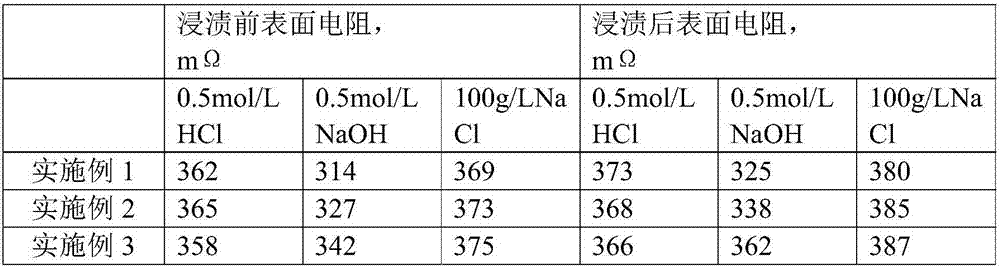

Novel fiber or textile cold piling chemical silvering method

InactiveCN104805685ADoes not affect softnessImprove comfortLiquid/solution decomposition chemical coatingVegetal fibresElectrical resistance and conductanceRoom temperature

The invention provides a novel fiber or textile cold piling chemical silvering method. According to the method, natural fiber, chemical fiber or textiles are subjected to fiber surface treatment through room temperature piling; then, chemical silvering is adopted, so that the natural fiber, the chemical fiber or the textiles obtain good electrical conductivity and electromagnetic shielding function. The fiber or textiles prepared by the method provided by the invention have the advantages that the excellent and durable electrical conductivity and the electromagnetic shielding function are realized, the surface resistance is below than 4 omega / cm, the softness of the fiber fabric is not influenced, in addition, the comfort degree of the coating fiber fabric is greatly improved, the environment is protected, the economy is realized, the discharged pollution is little, and higher practical values are realized.

Owner:张利荣

Compound non-woven fabric gauze swab for surgical operation

InactiveCN105311671AStrong water absorptionStrong medical functionNon-adhesive dressingsSynthetic resin layered productsWoven fabricBiomedical engineering

A compound non-woven fabric gauze swab for surgical operation comprises a non-woven fabric piece and a gauze piece and is characterized in that the non-woven fabric piece and the gauze piece are compounded, the gauze piece is compounded with a bamboo fiber gauze layer and a dressing layer, and the dressing layer is formed by compounding a bacteriostatic layer, a healing promoting layer and a hemostatic layer. The compound non-woven fabric gauze swab has the advantages that the gauze swab has strong water-absorbing capacity, threads do not loose, no lint falls, and the gauze swab can be integrated with an advanced operation sensor, has a good medical functionality and the like and has very high social benefits and economic benefits.

Owner:周坤友

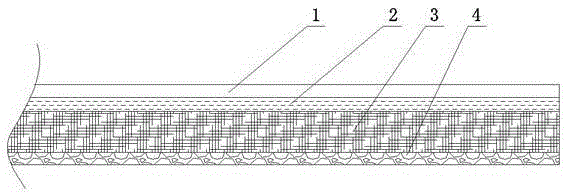

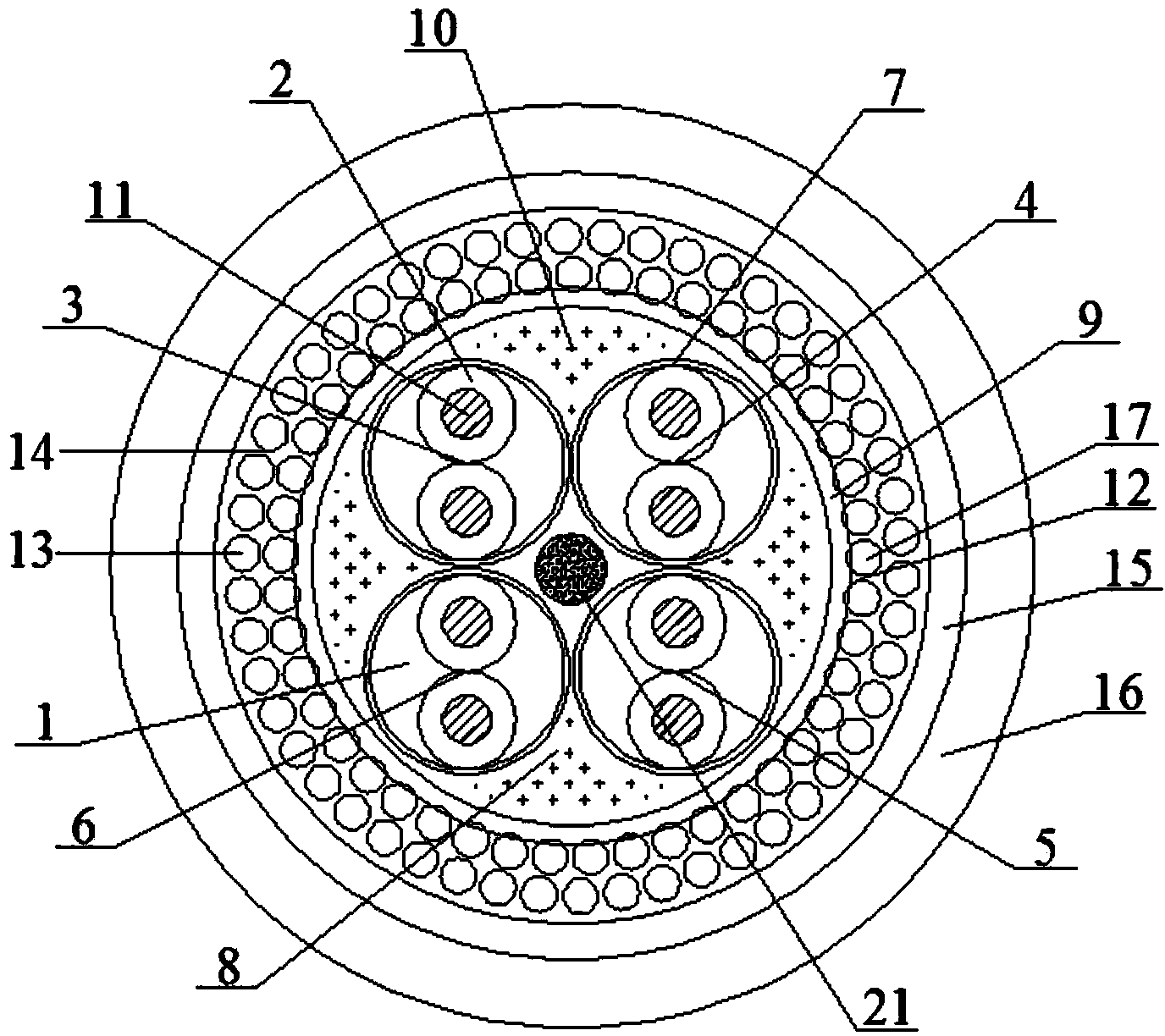

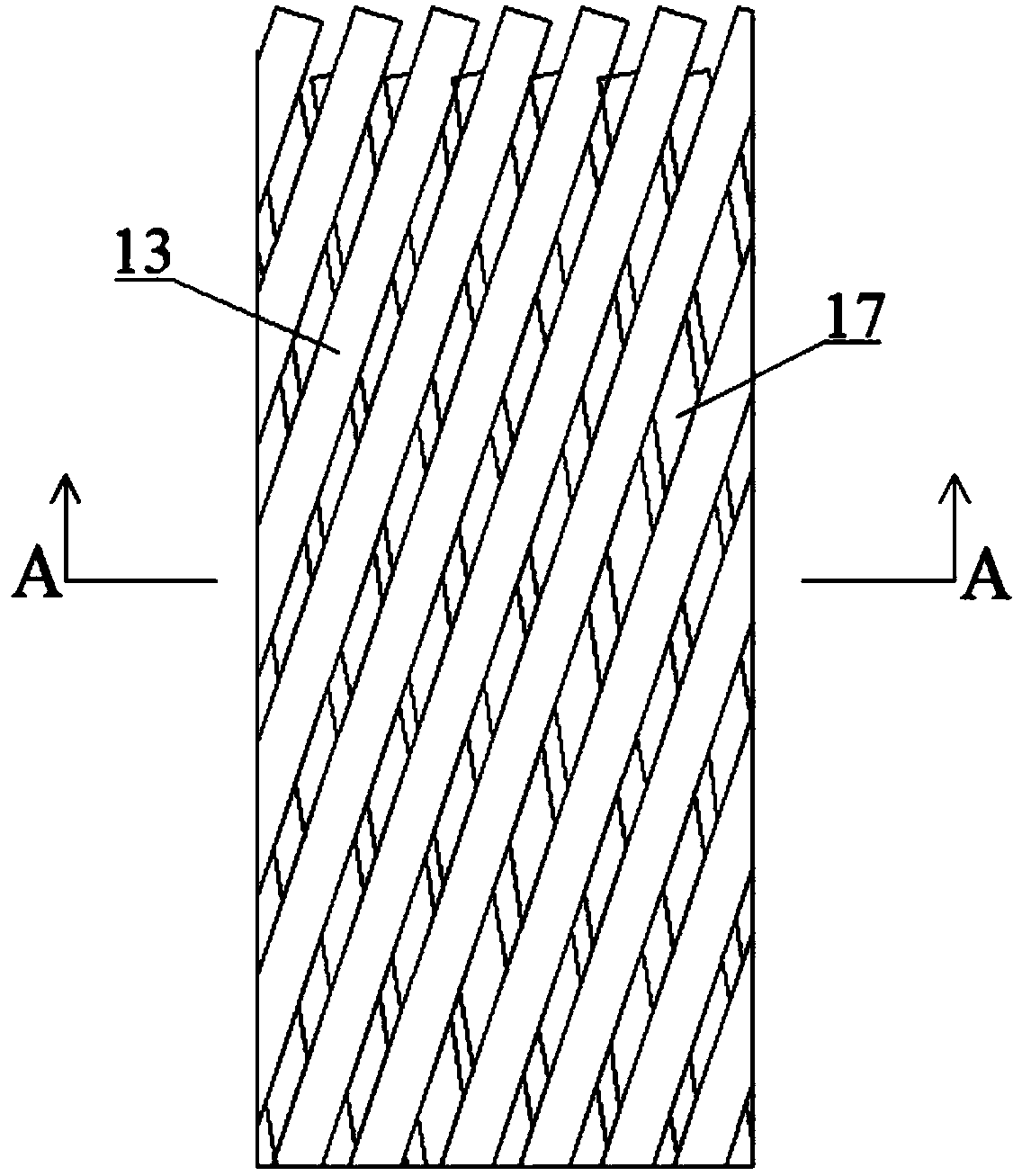

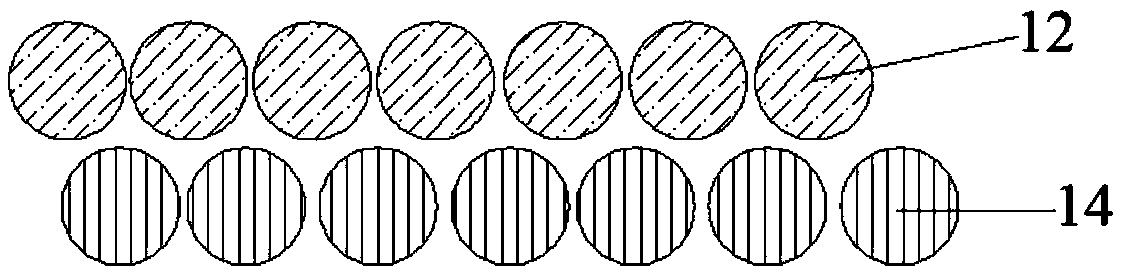

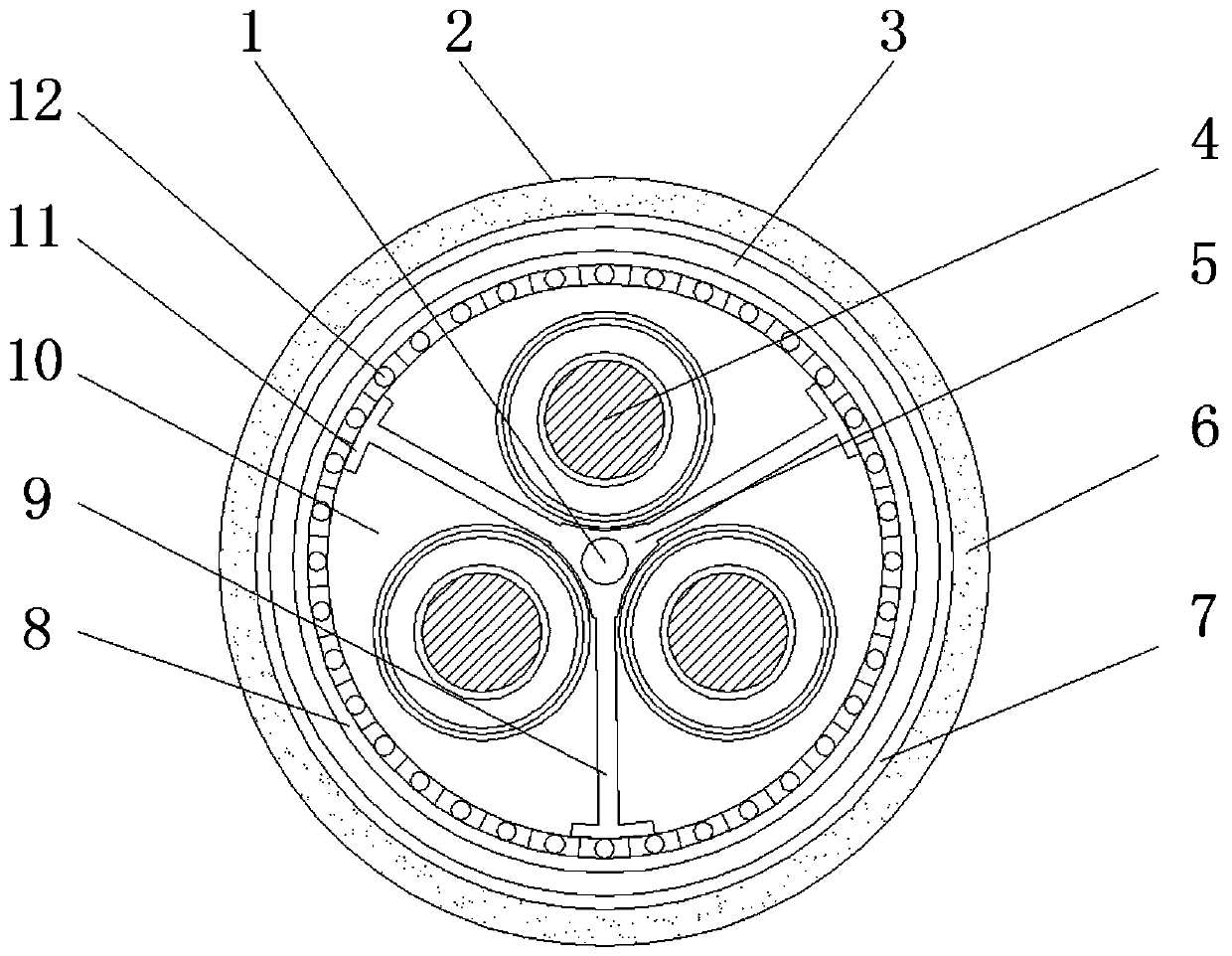

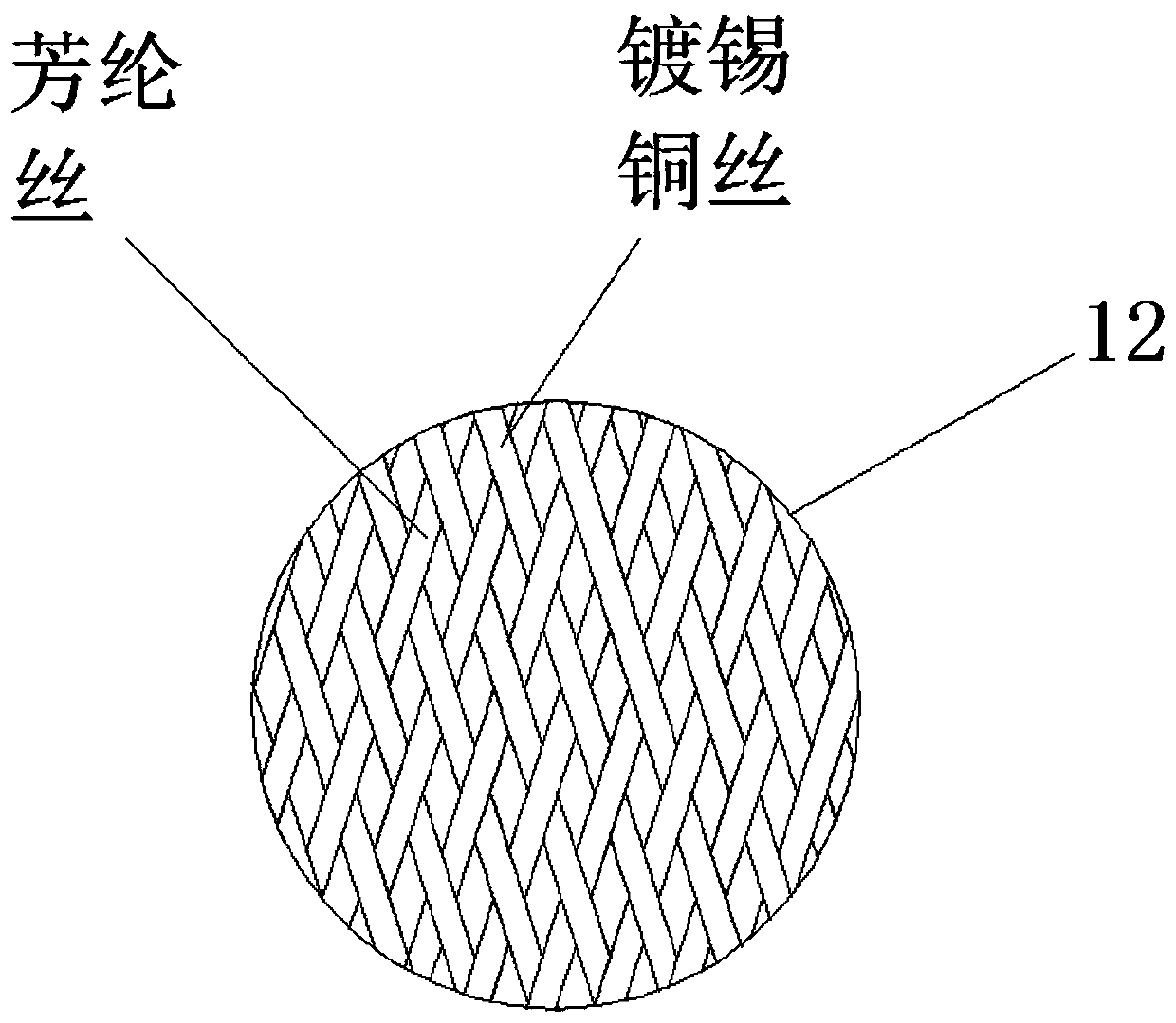

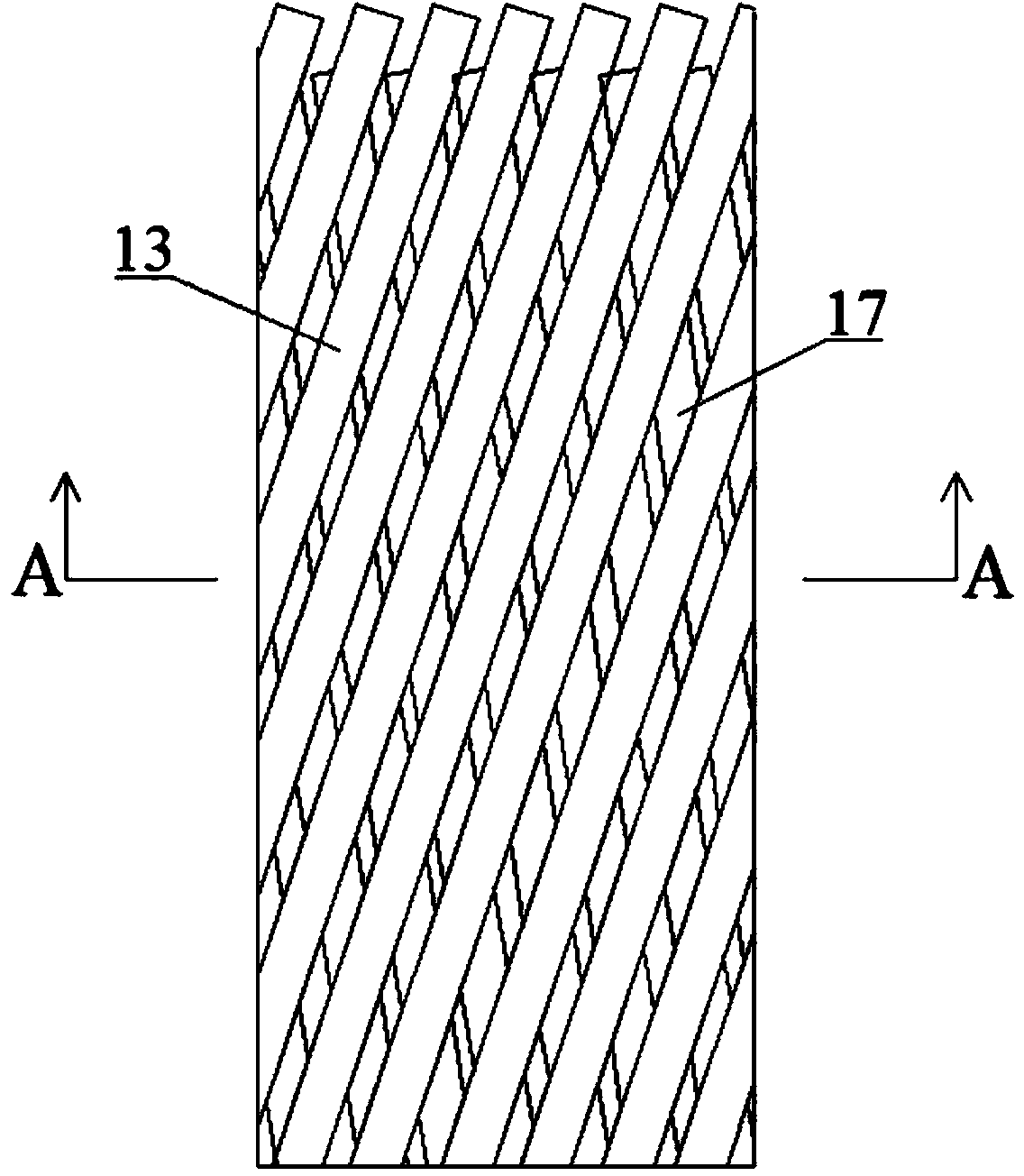

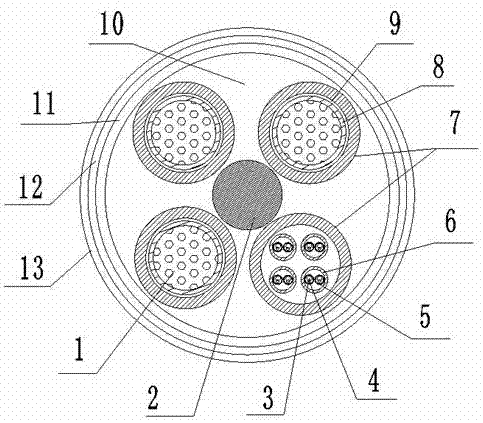

Stretch- and fatigue-resistant shielding soft data cable

ActiveCN104036869AReduce coefficient of frictionIncrease coefficient of frictionInsulated cablesInsulated conductorsYarnElectrical conductor

The invention discloses a stretch- and fatigue-resistant shielding soft data cable which comprises eight metal conductor units and an aramid reinforcement element, wherein the metal conductor units comprise aramid fiber arranged at the centers, inner conducting layers and outer conductor layers; four symmetric insulated wire pairs are twisted around the outer surface of the aramid reinforcement element to form a cable core; a second polytetrafluoroethylene layer longitudinally wraps the outer surface of the cable core, gaps between the second polytetrafluoroethylene layer and the four symmetric insulated wire pairs are filled with a plurality of cotton yarns, a cotton fiber thread is wound around the outer surface of the second polytetrafluoroethylene layer to form a buffer sliding layer, the winding direction of the cotton fiber thread is opposite to the twisting direction of the four symmetric insulated wire pairs, a plurality of metal wires are wound around the outer surface of the buffer sliding layer in parallel to form a metal shielding layer, the winding direction of the metal wires in the metal shielding layer is opposite to that of the cotton fiber thread, and a third polytetrafluoroethylene layer wraps the outer surface of the metal shielding layer. The stretch- and fatigue-resistant shielding soft data cable has the advantages of low friction coefficient, softness, stretch resistance and no friction static generation, and stable structural and electrical performance after frequent moving still can be guaranteed.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Nano-antibacterial fiber compounded underpants fabric and preparation method thereof

InactiveCN111329135AAvoid breakingNot easy to fall offLamination ancillary operationsLaminationFiberMolecular sieve

The invention provides a nano-antibacterial fiber compounded underpants fabric and a preparation method thereof. The preparation method comprises the specific steps of: adding a molecular sieve into asilver nitrate solution, performing standing adsorption after even mixing, and obtaining a nano-silver loaded molecular sieve after filtering, drying and roasting are conducted; dispersing the nano-silver loaded molecular sieve in a high-molecular polymer solution, and performing defoaming to obtain a nano antibacterial spinning solution; adding the nano-antibacterial spinning solution into a liquid storage mechanism of electrostatic spinning equipment, taking the base cloth layer as a spinning collection mechanism for electrostatic spinning, and directly electrospinning a composite nano-antibacterial fiber layer on the surface of the base cloth layer by using the electrostatic spinning equipment; compounding the fabric layer on the outer surface of the nano-antibacterial fiber layer by adopting a hot pressing process to obtain the underpants fabric compounded with the nano-antibacterial fibers. Silver and graphene are processed into nanofibers and quickly embedded into the fabric, multiple antibacterial materials are compounded into the nano antibacterial fibers at a time, and the nano antibacterial fibers have high porosity and high specific surface area and bring air and moisture permeability and antibacterial effects.

Owner:FOSHAN QINGZI PRECISION MEASUREMENT & CONTROL TECH

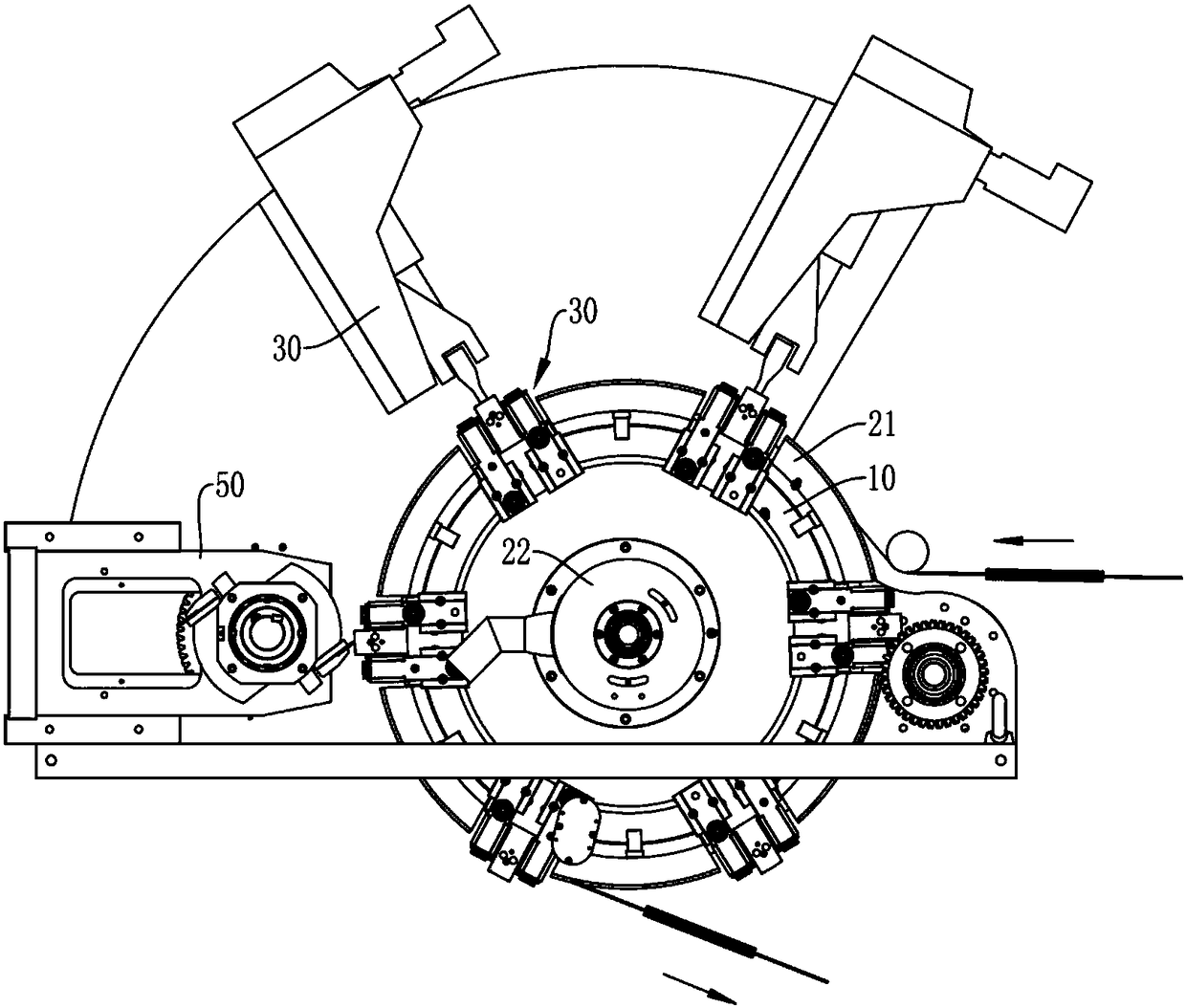

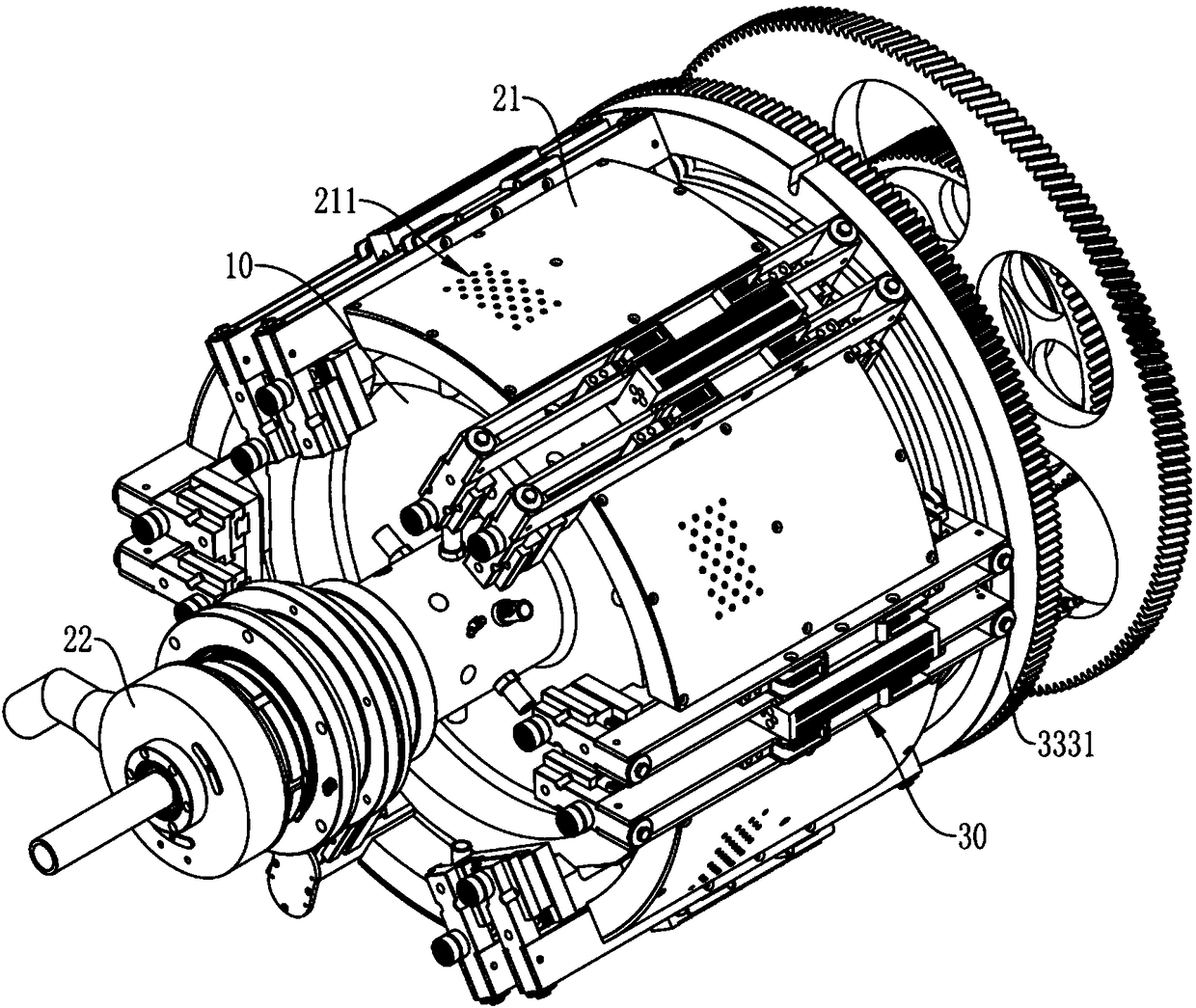

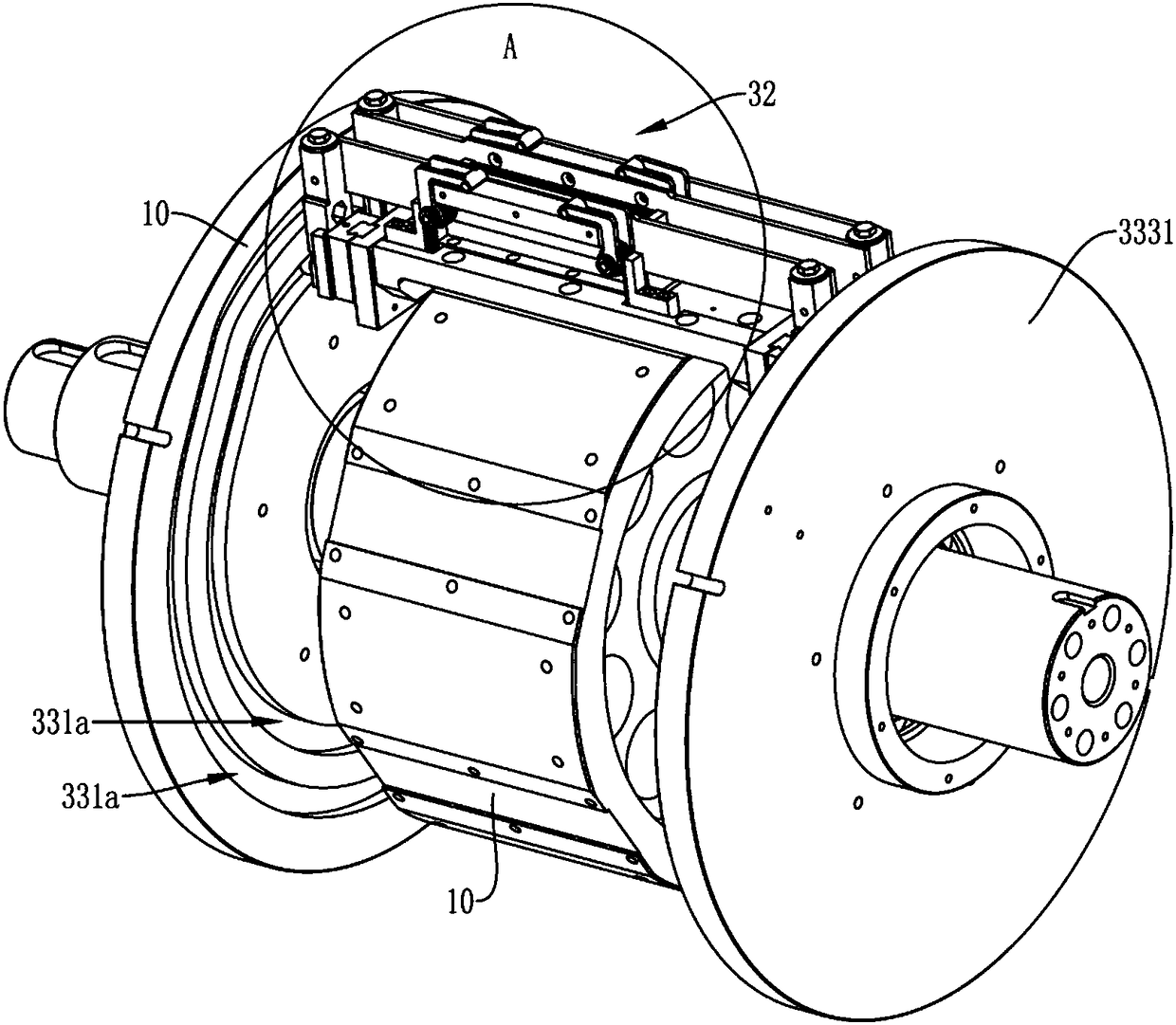

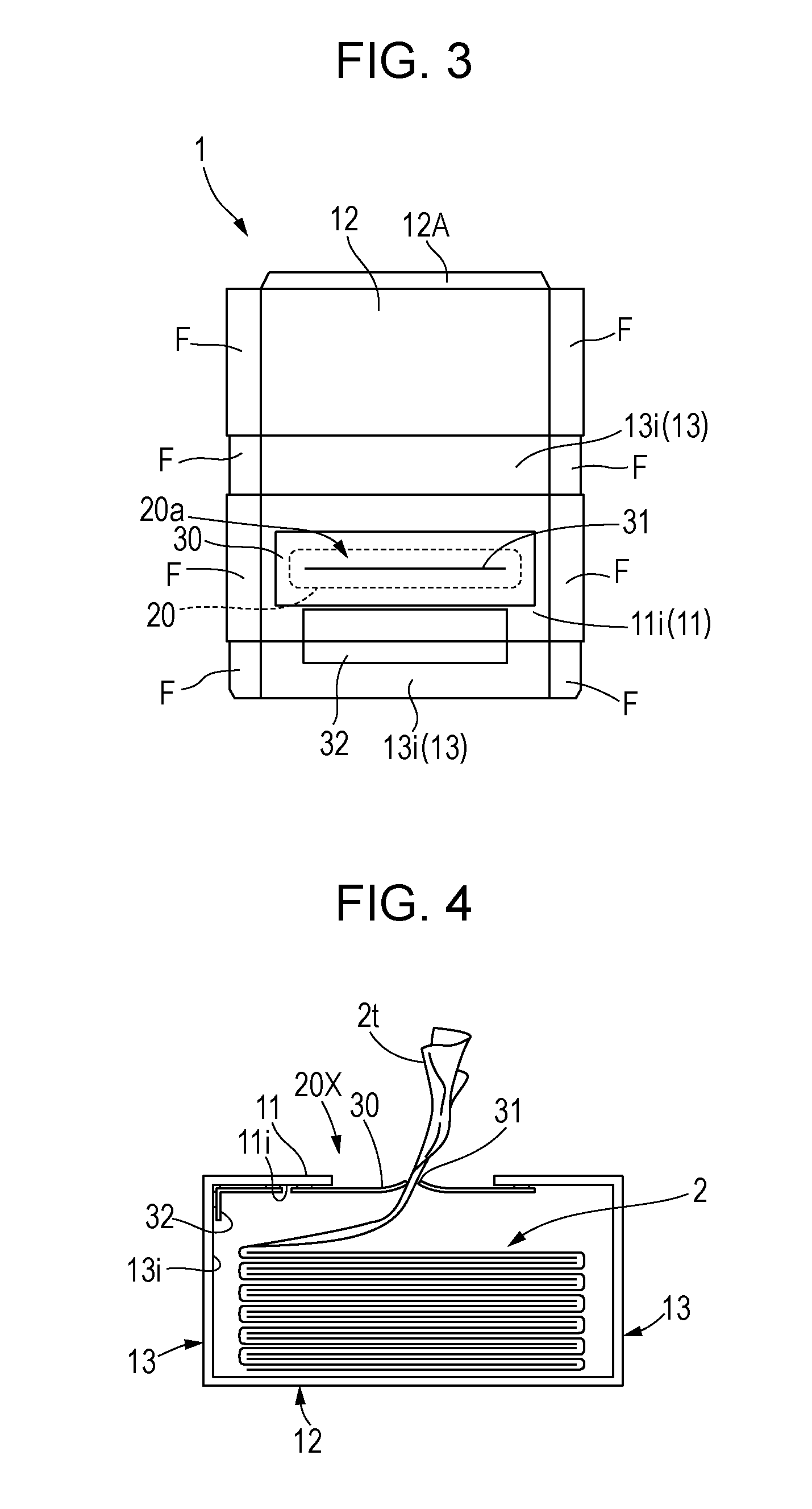

Ultrasonic sealing and pressing equipment and process

PendingCN108186203AGuaranteed accuracyStable sealing pressureAbsorbent padsBaby linensMechanical engineering

The invention relates to the technical field of mechanical sealing and pressing, and discloses ultrasonic sealing and pressing equipment and process. The ultrasonic sealing and pressing equipment comprises a rotating roll, fixing assembly, a clamping mechanism, an ultrasonic sealing and pressing assembly and a cutter assembly, wherein the fixing assembly is used for fixing a product to be sealed and pressed on the surface of the rotating roll; the clamping mechanism is used for clamping the waistline of the product to be sealed and pressed; the ultrasonic sealing and pressing assembly is fixedly mounted on the outer side of the rotating roll in a radial direction; the fixing assembly and the clamping mechanism are connected to the rotating roll, and are arranged along the peripheral direction of the rotating roll at intervals; a feeding opening is formed in front of the ultrasonic sealing and pressing assembly; and a discharging opening is formed in the rear of the cutter assembly. Inthe sealing and pressing process of the ultrasonic sealing and pressing equipment, the product to be sealed and pressed can be clamped, a sealing and pressing position and the position of a cutter arecontrolled accurately, and the flexibility of the sealing and pressing opening is good.

Owner:GUANGZHOU XINGSHI EQUIPS

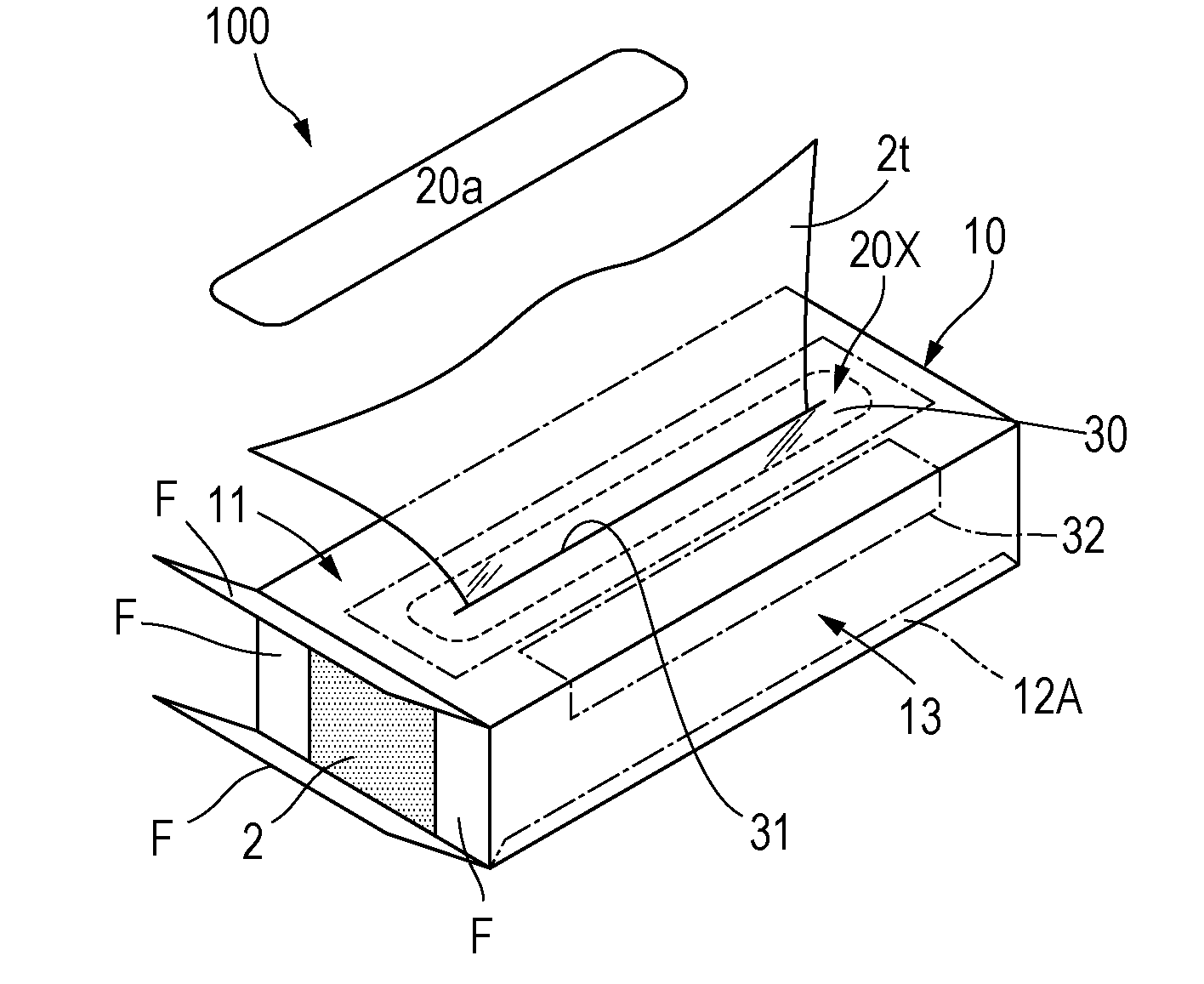

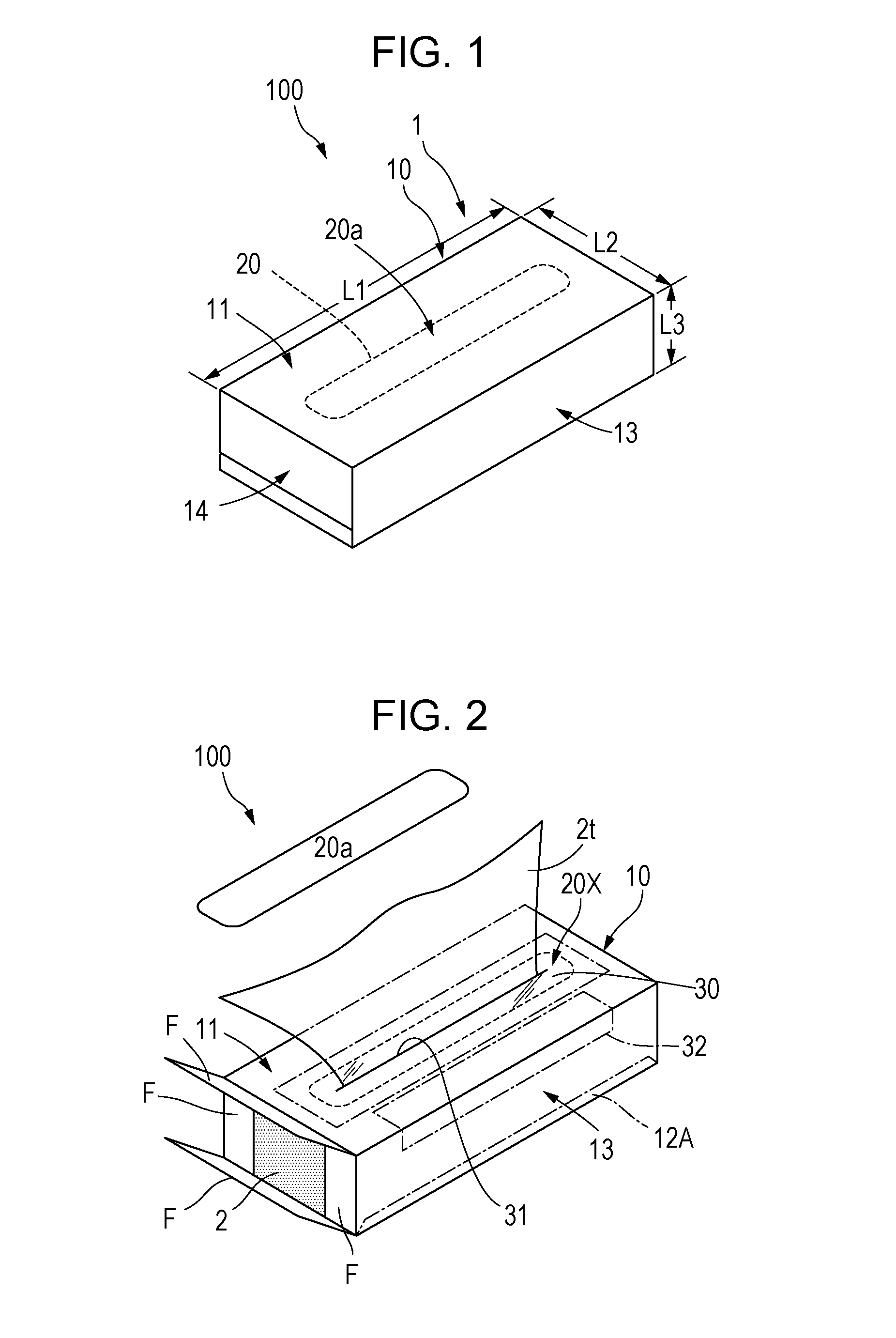

Scented-tissue-paper storage body

ActiveUS20160244241A1Does not affect softnessAffect textureContainer decorationsLevel indicationsEngineeringMechanical engineering

A scented sheet member, in which a gelatin gel including at least one of a perfume and a perfume-containing microcapsule is enclosed in a space between film sheets in at least one of which a perfume-permeating hole is formed, is affixed to an inner surface of an upper surface of the containing box so that the at least one of the film sheets having the micropore faces a stack of paper tissues. This can provide a scented paper tissue container that can strengthen a scent when necessary.

Owner:DAIO PAPER CORP

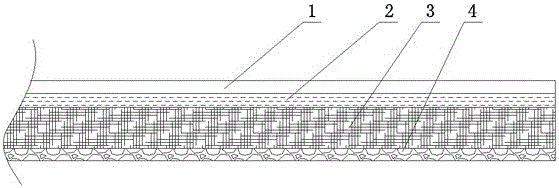

Multilayer viscose fiber composite spunlace mask base cloth and viscose fiber composite mask

InactiveCN110685070AReduce thicknessLose weightCosmetic preparationsToilet preparationsPolymer scienceMoisture permeability

The invention relates to a multilayer viscose fiber composite spunlace mask base fabric and a viscose fiber composite mask. The multilayer viscose fiber composite spunlace mask base fabric is preparedby 1) cutting raw ramie into small sections, and soaking with water to obtain a softened material; 2) carrying out steam explosion on the softened material to obtain an exploded mixture; 3) ultrasonically rinsing the exploded mixture in water, and performing impregnation modification to obtain modified ramie fibers; 4) opening and carding the modified ramie fibers to obtain a ramie fiber web; and5) opening and carding viscose fibers to obtain a viscose fiber web, cross-lapping a layer of the modified ramie fiber web between two or more layers of viscose fiber web, and performing water jet process, dewatering and drying to obtain the base fabric. The base fabric has good dry-wet strength and toughness, and the spunlace composite structure can bear the three-dimensional large-cut-number cutting and subsequent rinsing and lifting processes without damage, tearing or deformation; the base fabric has good air and moisture permeability, is soft and comfortable to touch, has good fitting property, is strong in liquid-retaining capacity and is suitable for producing a three-dimensional cut mask.

Owner:魏路平

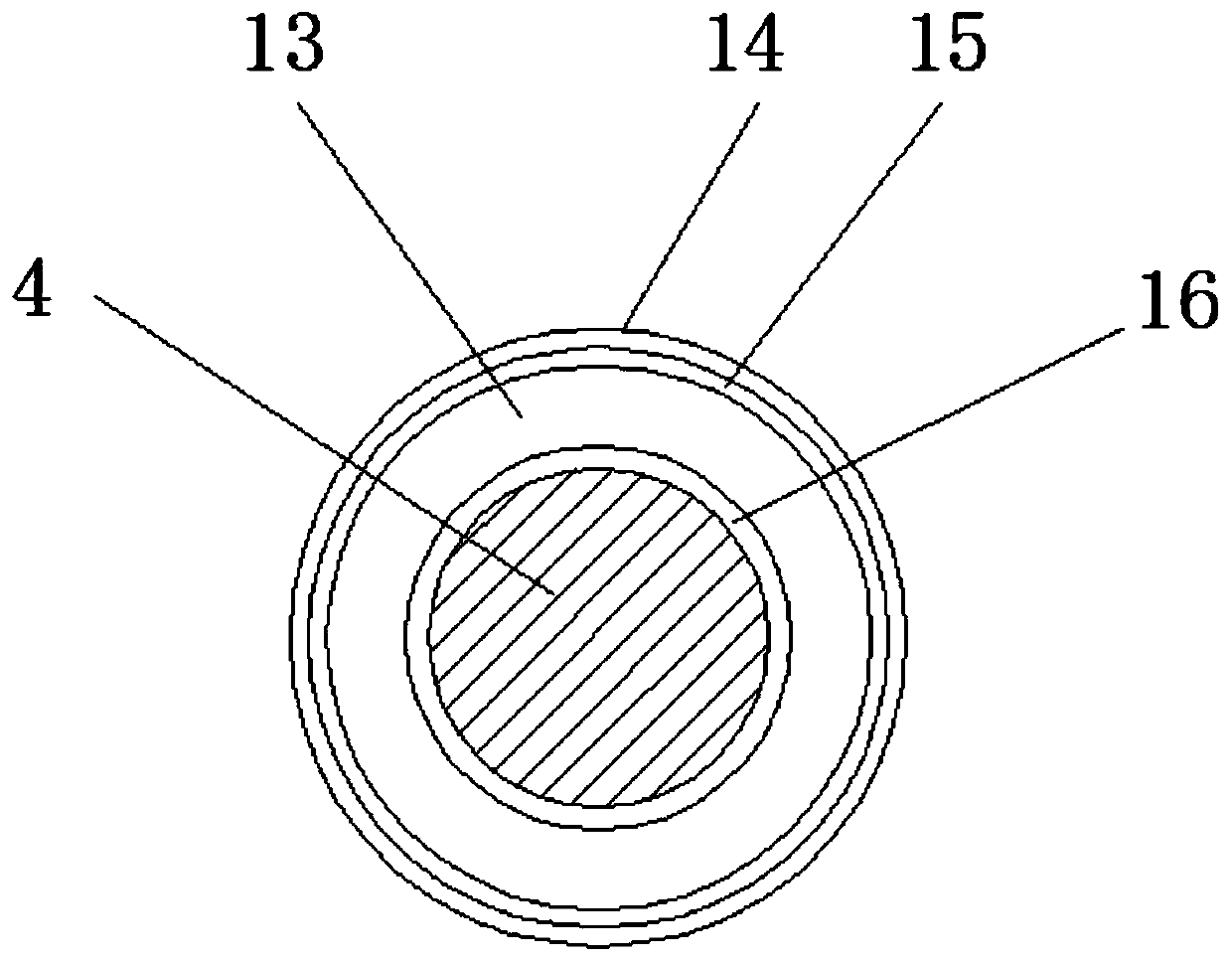

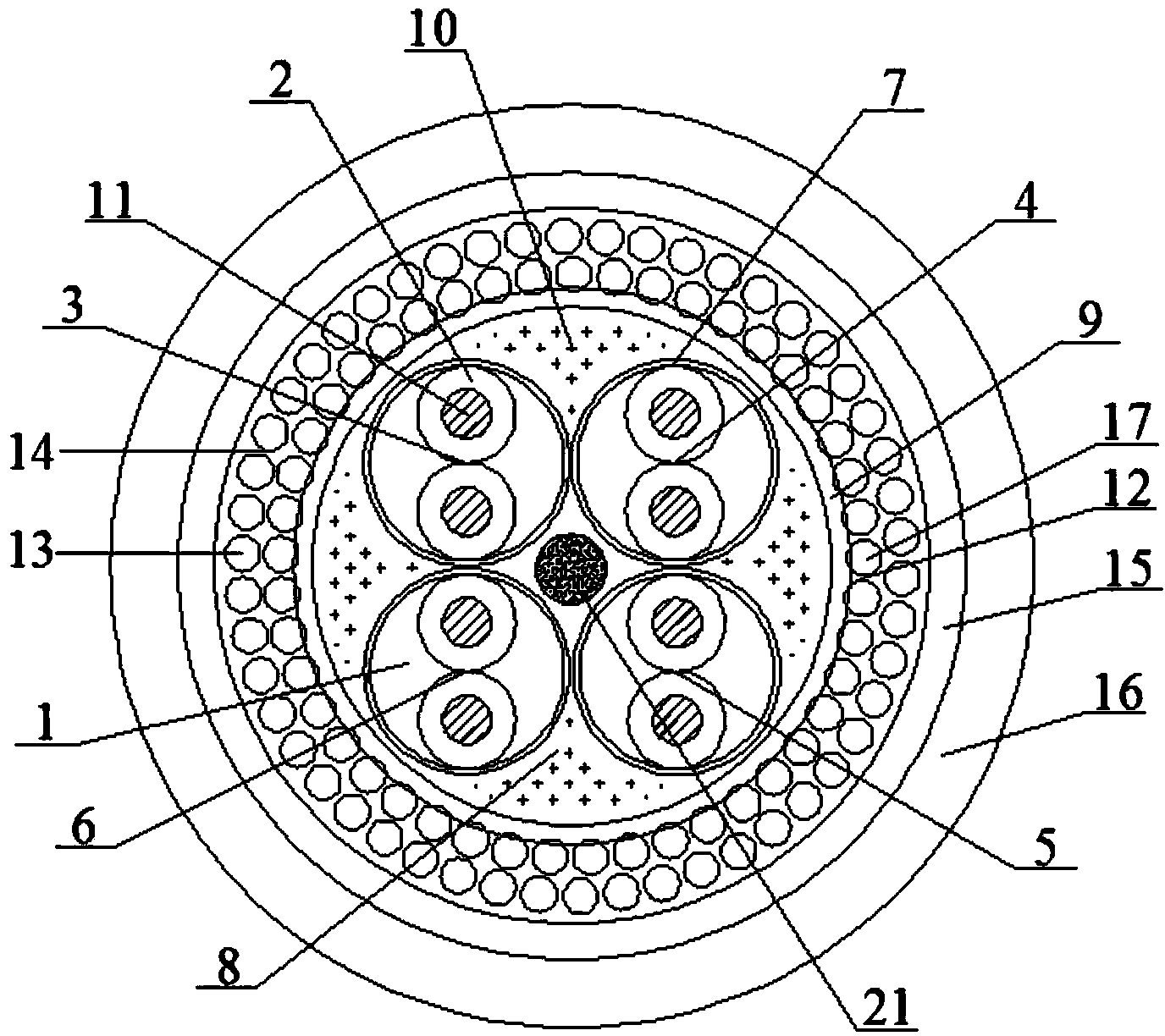

Ultraviolet-proof and corrosion-resistant medium-pressure rubber flexible cable for ships

InactiveCN110060813AImprove water resistanceImprove heat resistanceRubber insulatorsNon-insulated conductorsCorrosion resistantEngineering

The invention discloses an ultraviolet-proof and corrosion-resistant medium-pressure rubber flexible cable for ships; the cable comprises a cable body, cable cores, a connecting seat and an outer sheath layer, wherein metal connecting blocks are uniformly arranged at the middle position of the inner part of the cable body at equal intervals. The metal connecting blocks are uniformly arranged in the cable bodies on the inner sides of the three cable cores at equal intervals, the metal connecting blocks are connected through a connecting ball, and a supporting rod is arranged on the metal connecting blocks; the interior of the cable cores can also generate heat during use, and the cable cores are not easy to dissipate heat; one sides, close to each other, of the cable cores are connected byusing the connecting blocks, so that the heat conduction of the metal connecting blocks is utilized, the heat is conveniently transferred, and the inside of the cable is uniformly heated, the flexibility of the cable cannot be influenced by the hinged connecting blocks; in addition, the bearing capacity of the cable is improved by the supporting rod, and damage caused by extrusion deformation of the cable is avoided; and moreover, the two adjacent cable cores also can be blocked, so that leakage between the cable cores caused by mutual abrasion is avoided, and the service life of the cable isprolonged.

Owner:ANHUI LINGYU CABLE TECH

Mercerized wool smoothing finishing agent and preparation method thereof

InactiveCN108442119AReduce coefficient of frictionGood flexibilityGrip property fibresAnimal fibresFiberProtein structure

The invention relates to a mercerized wool smoothing finishing agent and a preparation method thereof, and belongs to the technical field of detergents. An amino-modified silicone smoothing agent canbe synthesized from octamethylcyclotetrasiloxane, aminoethylaminopropyl polydimethyl siloxane, silane coupling agent HD-109 and silane coupling agent HD-110 as raw materials through bulk polymerization under the action of a catalyst, and excellent soft and smoothing effects can be obtained. The method adopts multi-amino coupling agents for bulk polymerization, the synthesis and emulsification process is simple, easy to operate and suitable for industrial production, and a silicone oil molecular chain contains more secondary amino groups and tertiary amino groups, can effectively reduce the amount of active hydrogen and greatly reduces the yellowing of a fabric. The protein structure contained in the mercerized wool smoothing finishing agent has a good affinity with a wool scale layer structure, can promote fiber swelling, reduces the dynamic friction coefficient and the static friction coefficient of wool, thereby playing the role of smoothing and elasticity, and the mercerized wool smoothing finishing agent does not affect the softness of the fabric, has good hand feeling, and has broad application prospects.

Owner:汪逸凡

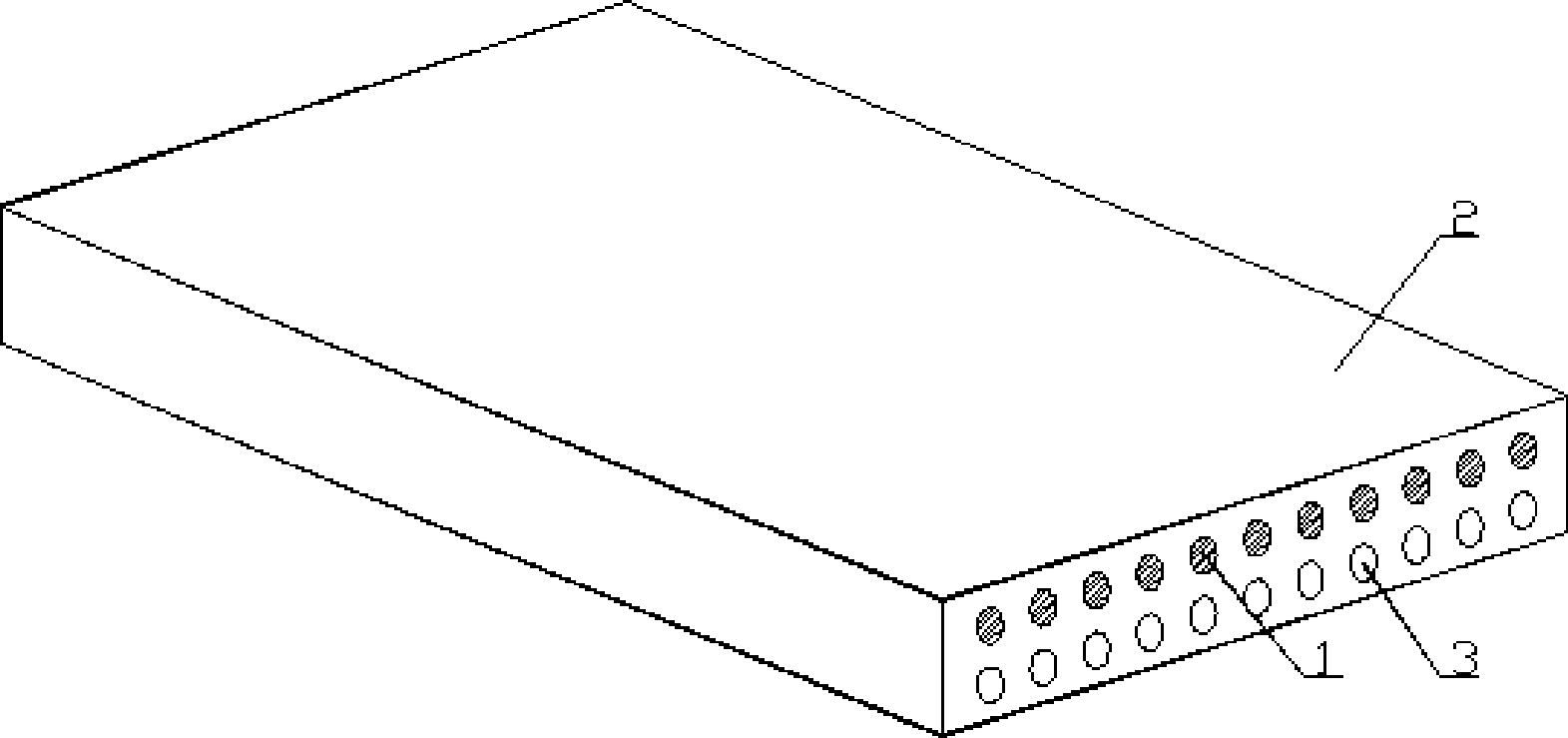

Bamboo charcoal stick fiber mattress and production method

ActiveCN101371739AElasticity does not affectStay flexibleStuffed mattressesSpring mattressesArenga engleriNatural fiber

The invention discloses a bamboo carbon rod fiber mattress and a preparation method; the bamboo carbon grains are prepared as bamboo carbon rods; round holes are prepared in the middle of the fiber mattress; the prepared bamboo carbon rod is arranged into the round holes of the fiber mattress; the mattress uses solid bamboo carbon rods or cylindrical bamboo carbon rods made of purely natural bamboo carbon and uses special technology for processing so as to be prepared; the mattress is provided with a certain elasticity; when being arranged in the round holes of the mattress, the elasticity and softness of the mattress are not affected; on the basis of keeping the comfortableness of the original fiber mattress, the bamboo carbon is added, thus leading the mattress to have the functions of anti-moisture, anti-mildew, deodorization and air purification and keeping the dryness and cleanness of the mattress. The mattress has the advantages that the bamboo carbon inside the mattress can be replaced, the efficacy of the bamboo carbon can be sufficiently exerted, dryness and cleanness of the mattress can be kept, and the like, and is applicable to the mattress prepared by various natural fiber mattress such as arenga engleri fiber, oil palm fiber, coconut fiber, linen fiber, bamboo fiber, etc.

Owner:GUIZHOU DAZIRAN TECH

Anti-fatigue high speed data cable for mechanical arm

ActiveCN104036852AReduce coefficient of frictionHigh strengthClimate change adaptationInsulated cablesPolytetrafluoroethyleneYarn

The invention discloses an anti-fatigue high speed data cable for a mechanical arm. The cable comprises eight metal conductor units and an aramid reinforcer, wherein the metal conductor units comprise aramid fibers, and first stannum-copper alloy conductors and first oxygen-free copper conductors which are twisted on the external surfaces of the aramid fibers; second stannum-copper alloy conductors and second oxygen-free copper conductors are twisted on the external surfaces of internal conductive layers; a second polytetrafluoroethylene layer longitudinally wraps the external surface of a cable core; a plurality of cotton yarns are filled in gaps between the second polytetrafluoroethylene layer and four symmetric insulated wire pairs; a cotton fiber wire is wound on the external surface of the second polytetrafluoroethylene layer to form a buffer sliding layer; a winding direction of the cotton fiber wire is opposite to twisting directions of the four symmetric insulated wire pairs; a plurality of metal wires are wound on the external surface of the buffer sliding layer side by side to form a metal shielding layer; winding of the metal wires in the metal shielding layer is opposite to that of the cotton fiber wire; and a third polytetrafluoroethylene layer wraps the external surface of the metal shielding layer. The cable is small in friction coefficient, soft and anti-tensile, does not generate friction static, and can still ensure stable structure and electrical performance after frequent movement.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

A kind of medical silicone adhesive tape and preparation method thereof

ActiveCN104491911BWill not affect secondary useImprove fitAbsorbent padsBandagesThermoplastic polyurethaneEngineering

The invention discloses a medical silica gel adhesive tape. The medical silica gel adhesive tape comprises a gelatinous layer and a cloth base material, wherein the cloth base material comprises one of a PE (polyethylene) film, a TPU (thermoplastic polyurethane) film and foam and a non-woven fabric material, and the adhesive tape comprises one of the PET film, the TPU film and the foam, the non-woven fabric material and the gelatinous layer sequentially from outside to inside. The adhesive tape provided by the invention is good in air permeability, good in effect of jointing with skin and less prone to degumming during the use, and can be used repeatedly.

Owner:NANJING 3H MEDICAL PROD CO LTD

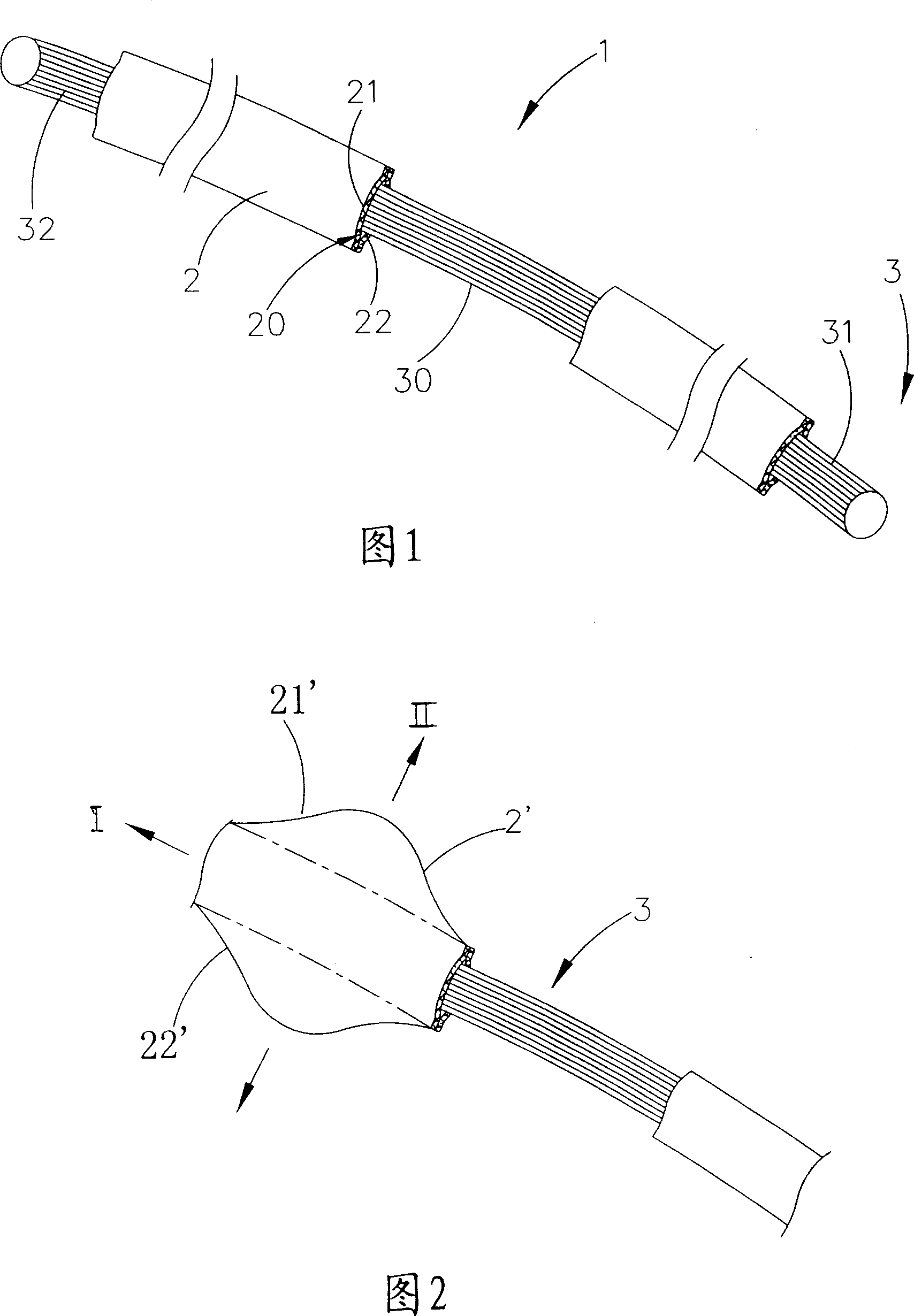

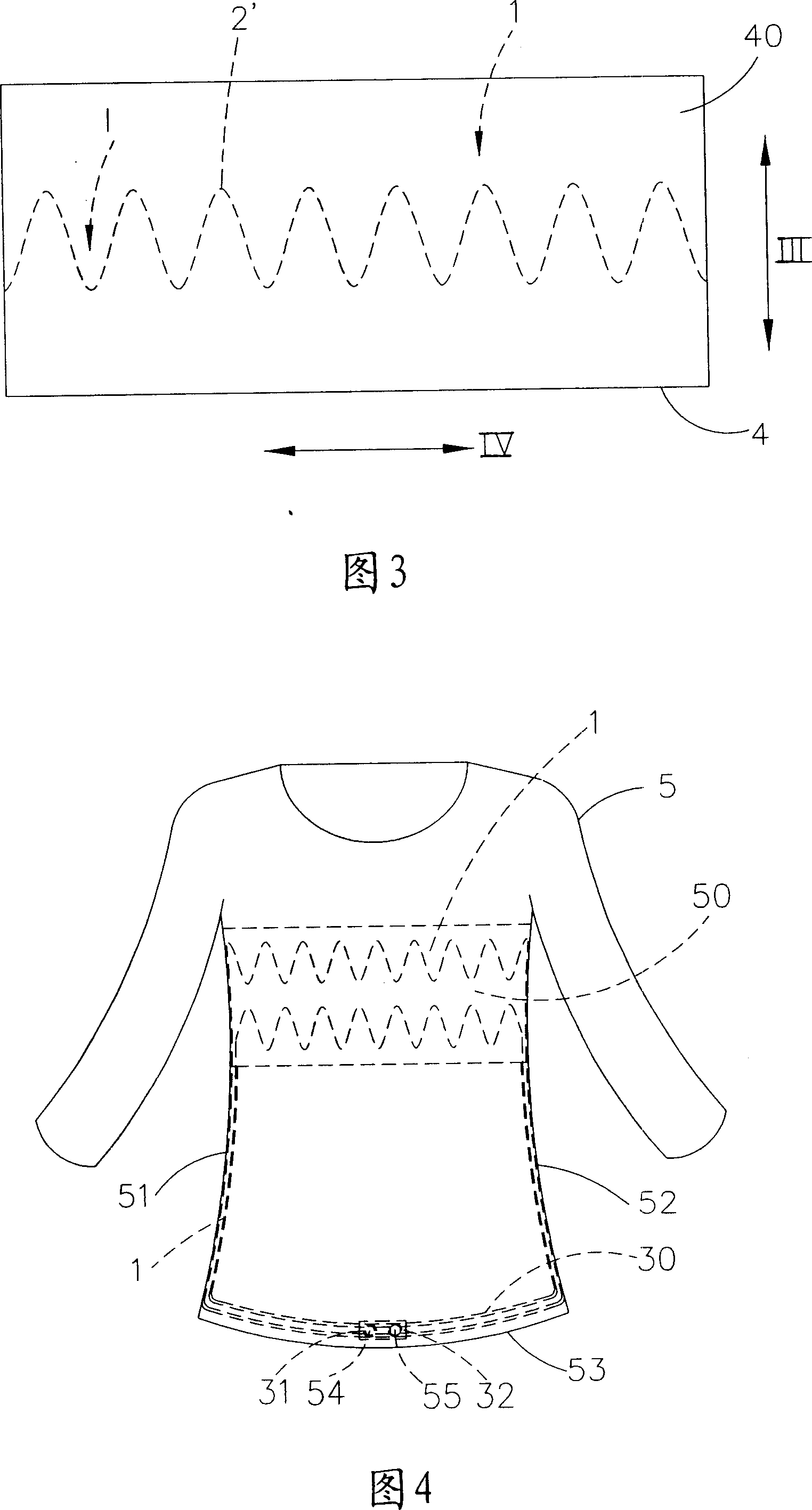

Warm element in dress

InactiveCN101001487AIt has the function of keeping warm and preventing coldDoes not affect softnessOhmic-resistance heatingProtective garmentEngineeringElectrical and Electronics engineering

Owner:喻孟华

Composite type control cable for coal cutter

InactiveCN107359011AImprove anti-interference abilityExtended service lifePower cables including communication wiresPower cables with screens/conductive layersInsulation layerHeat resistance

The invention discloses a composite type control cable for a coal cutter. The cable comprises a cable core composed of three power wire cores, a ground wire core and eight signal wire cores; each signal wire core is wrapped with a signal insulation layer; every two signal wire cores form one group of signal wire cores; each group of signal wire cores is wrapped with a signal shielding layer; the four groups of signal wire cores are arranged to form a rectangle; the signal shielding layers are jointly wrapped with a wrapping tape layer; the ground wire core is located at the center of the cable core; the power wire cores and the signal wire cores surround the ground wire core; a power insulation layer, a power shielding layer and a wrapping tape layer which are sequentially wrapped with one another from inside to the outside are located in each power wire core; gaps between the wrapping tape layer and the ground wire core are filled with a filling layer made of an explosion-proof material; and the wrapping tape layer and the filling layer are jointly wrapped with an inner sheath layer, a reinforcing layer and an outer sheath layer sequentially. The composite type control cable of the present invention has the advantages of excellent heat resistance, excellent physical and mechanical properties, high electrical insulation performance, good product usability and long service life.

Owner:贵州遵义铭东商贸有限公司

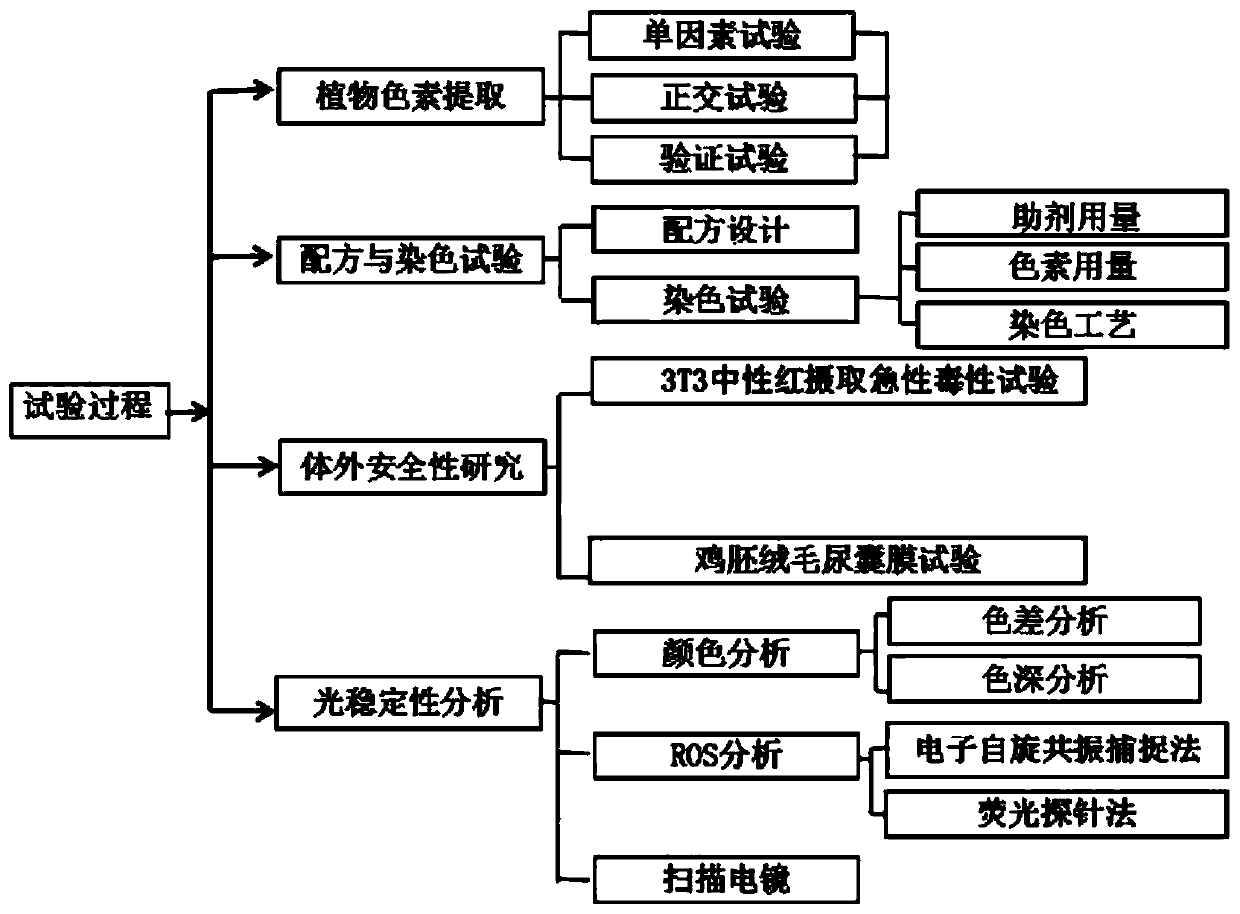

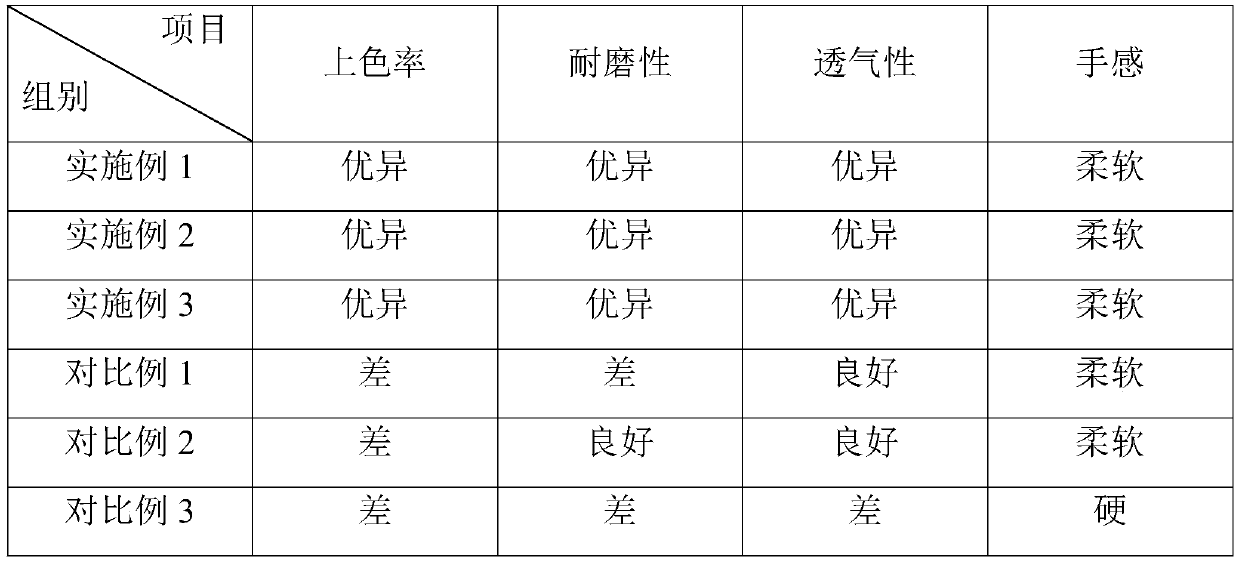

Environmentally-friendly textile dye and method for preparing textile fabric by using textile dye

InactiveCN111118923AHigh extraction rateGood quality pigmentNatural dyesDyeing processAcetic acidPolymer science

The present invention discloses environmentally-friendly textile dye and a method for preparing textile fabric by using the textile dye. The environmentally-friendly textile dye contains a natural pigment prepared from discarded dragon peels through condensation and reflux extraction, and the natural pigment is compounded with acrylic emulsion and additives containing cationic polymers to form theenvironmentally-friendly textile dye that can be applied to the textile fabric; by extracting the pigment from discarded dragon peels, not only waste resources can be reused, but also a pigment of good quality can be obtained; the pigment is compounded with acrylic emulsion, acetic acid and cationic polymers to achieve high compound stability, and the negative charge on the textile fabric synergistically forms a stable combination; and through the Coulomb gravitational effect, the adhesion strength and wear resistance of natural pigments on the textile fabric can be effectively enhanced, thecoloring rate of dyeing can be improved, and then high-quality uniform coloring effect can be obtained to ensure production quality.

Owner:BIEM L FDLKK GARMENT CO LTD

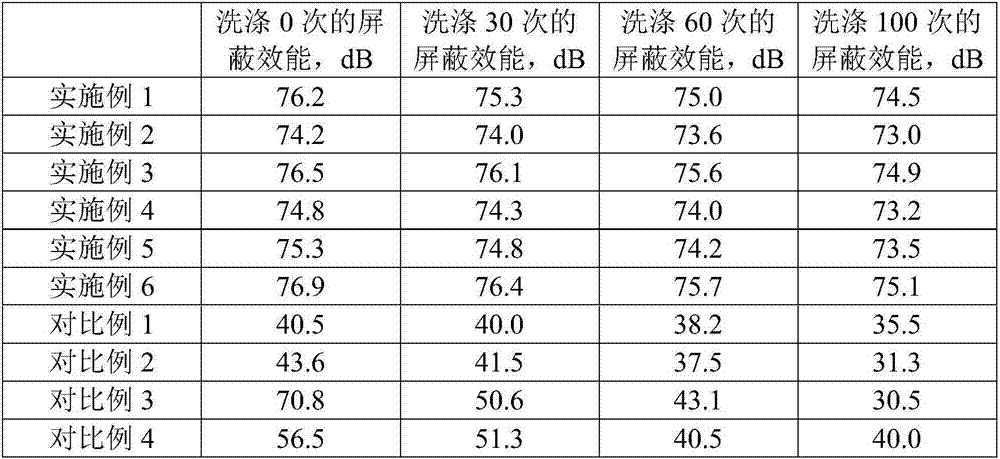

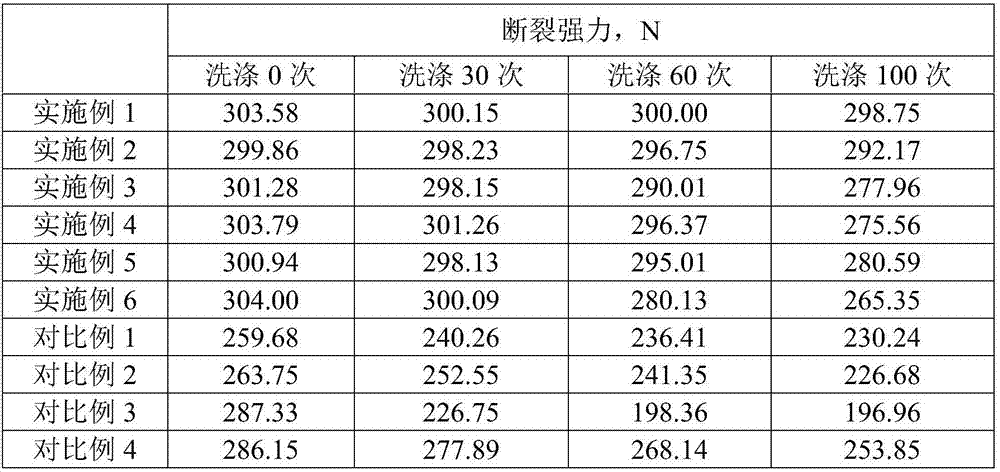

Preparation method of corrosion-resistant anti-electromagnetic radiation fabric

ActiveCN107083675AGood electromagnetic shieldingHigh electromagnetic shieldingWeft knittingGrip property fibresFiberPolyester

The invention discloses a preparation method of a corrosion-resistant anti-electromagnetic radiation fabric. The method comprises the steps of firstly preparing a copper powder-doped polyaniline electromagnetic shielding material; mixing the copper powder-doped polyaniline electromagnetic shielding material with water, a polyvinyl acetate emulsion, carboxymethylcellulose, polyethylene glycol and amino silicon oil to prepare mixed slurry, and coating a polylactic acid fiber surface treated by a camphor sulfonic acid solution with the mixed slurry; and finally mixing the polylactic acid fiber with spandex to form a second weft, and with a blended yarn formed by a bamboo fiber and a polyester fiber as a first weft, weaving by adopting a weft plain stitch structure to prepare the corrosion-resistant anti-electromagnetic radiation fabric. The prepared fabric is good in softening property, high in strength, good in irradiation resistance and excellent in decay resistance.

Owner:廷镁创智(浙江)服饰股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com